ASTM F2439-17(2023)

(Specification)Standard Specification for Headgear Used in Soccer

Standard Specification for Headgear Used in Soccer

ABSTRACT

This specification covers performance requirements for headgear used in soccer which are intended to reduce the forces reaching the impact area of the head. However, this specification does not address any injury that may rise from any type of impact that may occur during the play of soccer as the tests covered by this specification are laboratory simulation tests only and do not attempt in any way to recreate actual situations. Materials covered by this specification are test headforms consisting of Hybrid III adult male head and neck assembly and three types of anvils: steel post, headform, and molecular elastomer programmer (MEP). The headgear shall be conditioned in ambient, low temperature, high temperature, and water immersion conditions prior to shock attenuation impact and multiple impact tests. The tests shall involve three types of impact: head to forehead, head to goal post, and head to MEP impacts, and shall conform to the requirements specified.

SCOPE

1.1 This specification defines performance requirements for headgear used for participation in the sport of soccer. The technical requirements in this specification do not address the administrative requirements of soccer governing bodies, so it should not be assumed that any headgear satisfying this specification will be acceptable for use in sanctioned soccer events.

1.2 This specification is intended to reduce the forces from external physical sources reaching the defined impact area of the head in impacts that may occur in the sport of soccer. No headgear can provide protection against all impacts, foreseeable or not. This specification does not address the potential for injury from any type of impact. The tests specified in this specification are laboratory simulation tests only, and do not purport to create situations identical to the impacts that may occur during the playing of soccer.

1.3 All testing and requirements of this specification shall be in accordance with Test Methods F1446, except where noted herein. In the event of a discrepancy between the requirements of this specification and those of Test Methods F1446, this specification shall prevail.

1.4 Partial utilization of this specification is prohibited. Any statement of compliance with this specification shall be a certification that the headgear meets all of the requirements of this specification in its entirety. Headgear that fails to meet any one of the requirements of this specification is considered to have failed the specification and should not be sold with any indication that it meets parts of the specification.

1.5 The values stated in SI units are to be regarded as the standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2439 − 17 (Reapproved 2023) An American National Standard

Standard Specification for

Headgear Used in Soccer

This standard is issued under the fixed designation F2439; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Soccer is a sport with inherent risks. Participation in the sport implies acceptance of risk of injury.

This specification was developed to address forces of some of the incidental (non-ball) head impacts

that may occur while engaging in soccer. Although headgear satisfying this specification may provide

limited protection against heading impacts which are generally sub-concussive, heading impacts are

not addressed by this specification. In addition, the issue of multiple sub-concussive impacts is not

addressed here. Note–Protection provided by headgear satisfying this specification is not equivalent to

the protection provided by rigid “helmets” used in many other sports activities. Headgear that meets

these standard specifications may not provide significant protection in some head impact situations.

This specification is intended to be used with other standards and documents listed in the

Referenced Documents.

1. Scope certification that the headgear meets all of the requirements of

this specification in its entirety. Headgear that fails to meet any

1.1 This specification defines performance requirements for

one of the requirements of this specification is considered to

headgear used for participation in the sport of soccer. The

have failed the specification and should not be sold with any

technical requirements in this specification do not address the

indication that it meets parts of the specification.

administrative requirements of soccer governing bodies, so it

should not be assumed that any headgear satisfying this

1.5 The values stated in SI units are to be regarded as the

specification will be acceptable for use in sanctioned soccer

standard.

events.

1.6 This standard does not purport to address all of the

1.2 This specification is intended to reduce the forces from

safety concerns, if any, associated with its use. It is the

external physical sources reaching the defined impact area of

responsibility of the user of this standard to establish appro-

the head in impacts that may occur in the sport of soccer. No

priate safety, health, and environmental practices and deter-

headgear can provide protection against all impacts, foresee-

mine the applicability of regulatory limitations prior to use.

able or not. This specification does not address the potential for

1.7 This international standard was developed in accor-

injury from any type of impact. The tests specified in this

dance with internationally recognized principles on standard-

specification are laboratory simulation tests only, and do not

ization established in the Decision on Principles for the

purport to create situations identical to the impacts that may

Development of International Standards, Guides and Recom-

occur during the playing of soccer.

mendations issued by the World Trade Organization Technical

1.3 All testing and requirements of this specification shall

Barriers to Trade (TBT) Committee.

be in accordance with Test Methods F1446, except where noted

herein. In the event of a discrepancy between the requirements

2. Referenced Documents

of this specification and those of Test Methods F1446, this

2.1 ASTM Standards:

specification shall prevail.

F1446 Test Methods for Equipment and Procedures Used in

1.4 Partial utilization of this specification is prohibited. Any

Evaluating the Performance Characteristics of Protective

statement of compliance with this specification shall be a

Headgear

This specification is under the jurisdiction of ASTM Committee F08 on Sports

Equipment, Playing Surfaces, and Facilities and is the direct responsibility of

Subcommittee F08.53 on Headgear and Helmets. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Nov. 1, 2023. Published December 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 2006. Last previous edition approved in 2017 as F2439 – 17 . DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F2439-17R23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2439 − 17 (2023)

2.2 Other Documents: mounted to a rigid structure. The headform anvil shall be

49 CFR Part 572, Subpart E Anthropometric Test Dummies positioned such that the only impact between the drop head-

Procedures for Assembly, Disassembly, and Inspection form and the impact anvil is at the selected impact location,

(PADI) of the Hybrid III 50th Percentile Dummy’s Nine with no other parts of the headform and anvil coming into

Accelerometer Array Head (NAAH) with Redundant contact with each other during the initial impact. The headform

Head C. G. Accelerometers anvil need not be instrumented.

5.5 MEP Anvil—The MEP anvil shall be as defined in the

3. Terminology

section on Modular Elastomer Programmer (MEP) of Test

3.1 Definitions:

Methods F1446. The MEP anvil shall be positioned with its

3.1.1 impact area—the region of the headform within which

upper surface horizontal, such that the only impact between the

the center of each impact footprint must fall. F1446

drop headform and the impact anvil is at the selected impact

location, with no other parts of the headform and anvil coming

4. Significance and Use

into contact with each other during the initial impact.

4.1 The purpose of this specification is to provide reliable

and repeatable test methods for the evaluation of headgear for

6. Equipment Calibration and System Checks

soccer. Headgear satisfying this specification is intended to

6.1 Instrumentation used in testing shall be calibrated ac-

reduce forces reaching the head in some of the impacts that

cording to the requirements of Test Methods F1446 and 49

may occur in soccer.

CFR Part 572, Subpart E.

5. Apparatus 6.2 The 50th percentile Hybrid III adult male test headform

used with this specification shall pass a system check according

5.1 Apparatus used for this testing shall be in accordance

to the procedures described in Appendix X2. Duration of the

with Test Methods F1446 except as noted herein.

system check cycle shall be no more than 12 months.

5.2 Test Headforms—Test headforms used with this speci-

6.3 Instrumentation System Check—The system instrumen-

fication shall be the 50th percentile Hybrid III adult male head

tation shall be checked before and after each series of tests by

and neck assembly, including the upper and lower neck

dropping the Hybrid III head and neck assembly (see 5.2) onto

adjusting brackets and all associated hardware. The equipment

the MEP pad (see section on Modular Elastomer Programmer

shall be as defined in the United States of America Code of

(MEP) of Test Methods F1446 ) at an impact velocity of

Federal Regulations (49 CFR Part 572, Subpart E). A complete

2.8 m ⁄s 6 2 %. The head and neck assembly shall be oriented

listing of all parts and components which make up the head and

such that the neck of the Hybrid III headform is at a 24° 6 1°

neck assembly is found in Appendix X1; see also Procedures

downward angle relative to the horizontal and the forehead

for Assembly, Disassembly, and Inspection (PADI) of the

shall contact the center of the MEP pad. The peak acceleration

Hybrid III 50th Percentile Dummy’s Nine Accelerometer Array

obtained during this impact shall be 112 g 6 8 g. Three such

Head (NAAH) with Redundant Head C.G. Accelerometers.

impacts at intervals of 75 s 6 15 s shall be performed before

5.2.1 The test headform shall be mounted to a standard

and after each series of tests. If the average peak acceleration

monorail or twin-wire system or similar system, as shown in

obtained in the pretest impacts differs by more than 5 % from

Test Methods F1446. Mass of the entire drop system shall be

the average peak acceleration obtained in the post test impacts,

8.8 kg 6 5 % (19.4 lb 6 5 %). Accelerometer instrumentation

recalibration of the instruments and transducers must be carried

shall be installed into the test headform to measure resultant

out, and all data obtained during that series of impact tests shall

linear accelerations of the test headform as specified in the

be discarded.

section on Accelerometer of Test Methods F1446.

5.2.2 The headform center of gravity shall fall within 5° of

7. Samples for Testing

the vertical axis through the point of impact when the test

headform assembly is in the impact position, as described in 7.1 Conditions and Attachments—Headgear shall be tested

the Appendix of Test Methods F1446.

complete, in the condition as offered for sale. They must satisfy

all requirements of this specification with or without any

5.3 Steel Post Anvil—The steel post anvil used in this

included attachments.

specification is to represent a nominal 7.62 cm (3 in.) diameter

steel post. The anvil shall consist of a 7.62 cm (3 in.) diameter 7.2 Number of Samples—A test series requires 12 samples

steel bar (65 %) that is welded (or securely attached to

of each size headgear and shall be tested according to the

similarly minimize vibration between the bar and the plate) in following schedule (see Table 1).

a horizontal position to a steel plate.

8. Conditioning Requirements

5.4 Headform Anvil—The headform anvil is a 50th percen-

tile Hybrid III headform and neck assembly as defined in 5.2.

8.1 Ambient Condition—Four samples of each size headgear

The headform anvil shall be oriented such that the forehead is

shall be conditioned at the ambient condition defined in ASTM

in an upright target position. The lower neck bracket shall be

Test Methods F1446.

8.2 Low Temperature—Three samples of each size headgear

shall be conditioned at the low temperature conditions as

Available from National Highway Traffic Safety Administration (NHTSA), 400

7th St., NW, Washington, DC 20590. defined in Test Methods F1446.

F2439 − 17 (2023)

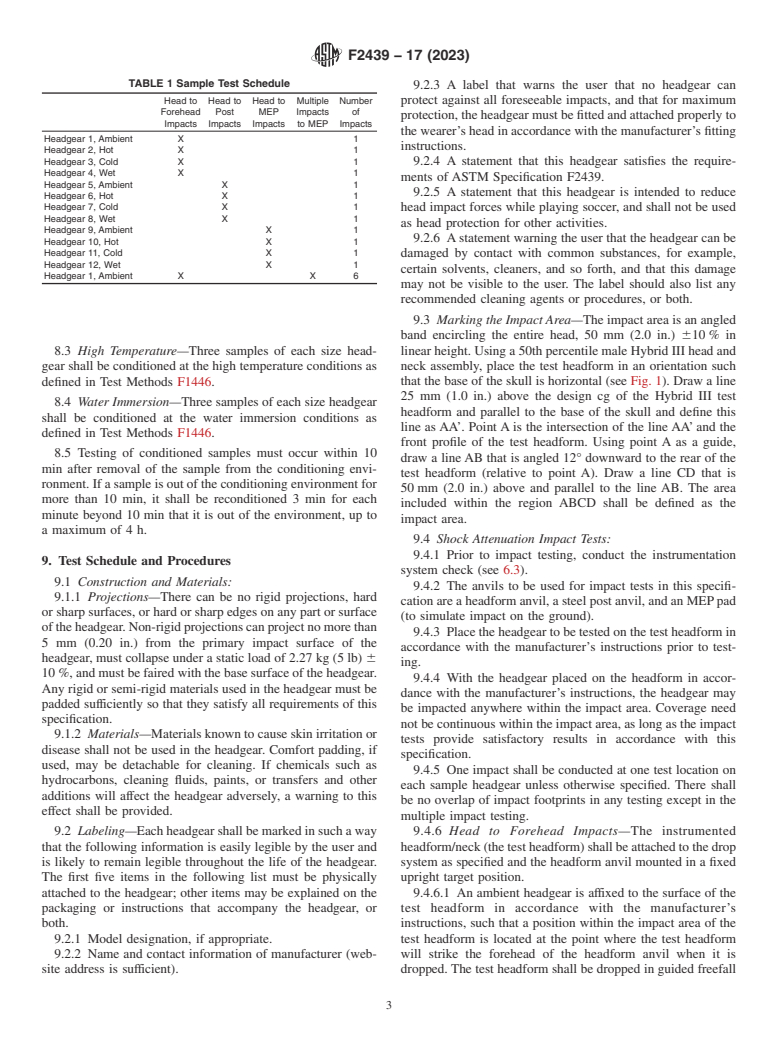

TABLE 1 Sample Test Schedule

9.2.3 A label that warns the user that no headgear can

Head to Head to Head to Multiple Number protect against all foreseeable impacts, and that for maximum

Forehead Post MEP Impacts of

protection, the headgear must be fitted and attached properly to

Impacts Impacts Impacts to MEP Impacts

the wearer’s head in accordance with the manufacturer’s fitting

Headgear 1, Ambient X 1

instructions.

Headgear 2, Hot X 1

Headgear 3, Cold X 1

9.2.4 A statement that this headgear satisfies the require-

Headgear 4, Wet X 1

ments of ASTM Specification F2439.

Headgear 5, Ambient X 1

9.2.5 A statement that this headgear is intended to reduce

Headgear 6, Hot X 1

Headgear 7, Cold X 1 head impact forces while playing soccer, and shall not be used

Headgear 8, Wet X 1

as head protection for other activities.

Headgear 9, Ambient X 1

9.2.6 A statement warning the user that the headgear can be

Headgear 10, Hot X 1

Headgear 11, Cold X 1

damaged by contact with common substances, for example,

Headgear 12, Wet X 1

certain solvents, cleaners, and so forth, and that this damage

Headgear 1, Ambient X X 6

may not be visible to the user. The label should also list any

recommended cleaning agents or procedures, or both.

9.3 Marking the Impact Area—The impact area is an angled

band encircling the entire head, 50 mm (2.0 in.) 610 % in

8.3 High Temperature—Three samples of each size head- linear height. Using a 50th percentile male Hybrid III head and

neck assembly, place the test headform in an orientation such

gear shall be conditioned at the high temperature conditions as

defined in Test Methods F1446. that the base of the skull is horizontal (see Fig. 1). Draw a line

25 mm (1.0 in.) above the design cg of the Hybrid III test

8.4 Water Immersion—Three samples of each size headgear

headform and parallel to the base of the skull and define this

shall be conditioned at the water immersion conditions as

line as AA’. Point A is the intersection of the line AA’ and the

defined in Test Methods F1446.

front profile of the test headform. Using point A as a guide,

8.5 Testing of conditioned samples must occur within 10

draw a line AB that is angled 12° downward to the rear of the

min after removal of the sample from the conditioning envi-

test headform (relative to point A). Draw a line CD that is

ronment. If a sample is out of the conditioning environment for

50 mm (2.0 in.) above and parallel to the line AB. The area

more than 10 min, it shall be reconditioned 3 min for each

included within the region ABCD shall be defined as the

minute beyond 10 min that it is out of the environment, up to

impact area.

a maximum of 4 h.

9.4 Shock Attenuation Impact Tests:

9.4.1 Prior to impact testing, conduct the instrumentation

9. Test Schedule and Procedures

system check (see 6.3).

9.1 Construction and Materials:

9.4.2 The anvils to be used for impact tests in this specifi-

9.1.1 Projections—There can be no rigid projections, hard

cation are a headform anvil, a steel post anvil, and an MEP pad

or sharp surfaces, or hard or sharp edges on any part or surface

(to simulate impact on the ground).

of the headgear. Non-rigid projections can project no more than

9.4.3 Place the headgear to be tested on the test headform in

5 mm (0.20 in.) from the primary impact surface of the

accordance with the manufacturer’s instructions prior to test-

headgear, must collapse under a static load of 2.27 kg (5 lb) 6

ing.

10 %, and must be faired with the base surface of the headgear.

9.4.4 With the headgear placed on the headform in accor-

Any rigid or semi-rigid materials used in the headgear must be

dance with the manufacturer’s instructions, the headgear may

padded sufficiently so that they satisfy all requirements of this

be impacted anywhere within the impact area. Coverage need

specification.

not be continuous within the impact area, as long as the impact

9.1.2 Materials—Materials known to cause skin irritation or

tests provide satisfactory results in accordance with this

disease shall not be used in the headgear. Comfort padding, if

specification.

used, may be detachable for cleaning. If chemicals such as

9.4.5 One impact shall be conducted at one test location on

hydrocarbons, cleaning fluids, paints, or transfers and other

each

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.