ASTM F1698-02(2008)

(Practice)Standard Practice for Installation of Poly(Vinyl Chloride)(PVC) Profile Strip Liner and Cementitious Grout for Rehabilitation of Existing Man-Entry Sewers and Conduits

Standard Practice for Installation of Poly(Vinyl Chloride)(PVC) Profile Strip Liner and Cementitious Grout for Rehabilitation of Existing Man-Entry Sewers and Conduits

SIGNIFICANCE AND USE

This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations involved in the rehabilitation of non-pressure sewers and conduits. As for any practice, modifications may be required for specific job conditions.

SCOPE

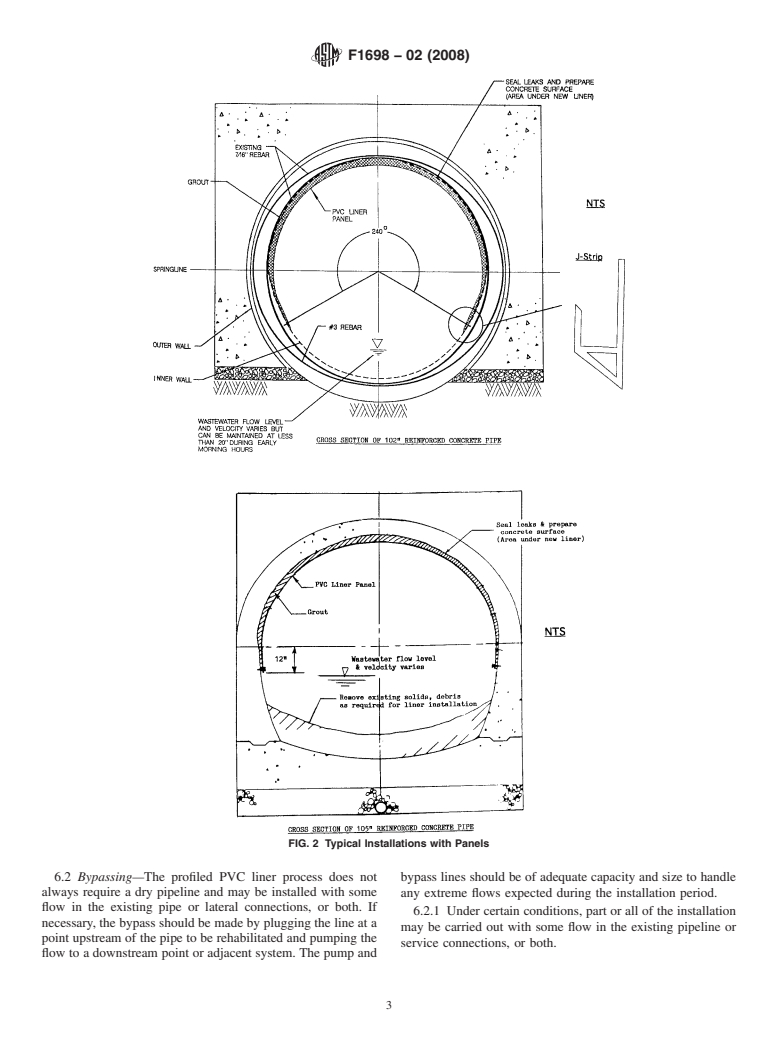

1.1 This practice describes the procedures for the rehabilitation of sewer lines and conduits by the installation of a field-fabricated PVC liner. After installation of the liner, cementitious grout is injected into the annular space between the liner and the existing sewer or conduit. The rehabilitation of the host structure by this installation practice results in a rigid composite structure (PVC/grout/existing pipe). This rehabilitation process may be used in a variety of gravity applications, such as sanitary sewers, storm sewers and process piping of man-entry sizes (36 to 144 in. in vertical dimension). The profile strips used for field fabrication of PVC liners are supplied in coils for spiral winding of the liner or in custom-cut flat panels for circumferential lining of all or any portion of the circumference of the host conduit (see Figs. 1 and 2).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Particular attention is drawn to those safety regulations and requirements involving entering into and working in confined spaces.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1698 −02(Reapproved 2008)

Standard Practice for

Installation of Poly(Vinyl Chloride)(PVC) Profile Strip Liner

and Cementitious Grout for Rehabilitation of Existing Man-

Entry Sewers and Conduits

This standard is issued under the fixed designation F1698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope C942Test Method for Compressive Strength of Grouts for

Preplaced-Aggregate Concrete in the Laboratory

1.1 This practice describes the procedures for the rehabili-

C969Practice for Infiltration and Exfiltration Acceptance

tation of sewer lines and conduits by the installation of a

Testing of Installed Precast Concrete Pipe Sewer Lines

field-fabricated PVC liner. After installation of the liner,

D883Terminology Relating to Plastics

cementitious grout is injected into the annular space between

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

thelinerandtheexistingsewerorconduit.Therehabilitationof

tics

the host structure by this installation practice results in a rigid

D1735Practice for Testing Water Resistance of Coatings

compositestructure(PVC/grout/existingpipe).Thisrehabilita-

Using Water Fog Apparatus

tion process may be used in a variety of gravity applications,

F412Terminology Relating to Plastic Piping Systems

such as sanitary sewers, storm sewers and process piping of

2.2 NASSCO Standard:

man-entry sizes (36 to 144 in. in vertical dimension). The

SpecificationGuidelinesforSewerCollectionSystemMain-

profile strips used for field fabrication of PVC liners are

tenance and Rehabilitation

suppliedincoilsforspiralwindingofthelinerorincustom-cut

flatpanelsforcircumferentialliningofalloranyportionofthe

3. Terminology

circumference of the host conduit (see Figs. 1 and 2).

3.1 General—Definitions are in accordance with Termi-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

nologiesD883andF412.Abbreviationsareinaccordancewith

as standard. The values given in parentheses are mathematical

Terminology D1600, unless otherwise indicated.

conversions to SI units that are provided for information only

3.2 Definitions of Terms Specific to This Standard:

and are not considered standard.

3.2.1 extruded PVC joiner strip—a companion product to

1.3 This standard does not purport to address all of the

the profile former strip of such configuration as to provide the

safety concerns, if any, associated with its use. It is the

locking mechanism at the edges of the former strips; the joiner

responsibility of the user of this standard to establish appro-

strip contains within it a coextruded flexible PVC seal which

priate safety and health practices and determine the applica-

forms a compression seal when mated with the edges of the

bility of regulatory limitations prior to use.Particular attention

former strips.

isdrawntothosesafetyregulationsandrequirementsinvolving

3.2.2 extruded PVC profile former strip—a product, avail-

entering into and working in confined spaces.

able in various sizes, consisting of a smooth inner surface and

a ribbed outer surface (profile) with edge configurations to

2. Referenced Documents

allow mechanical locking of adjacent strips.

2.1 ASTM Standards:

3.2.3 PVC liner—a product field fabricated from extruded

PVC profile strip into a shape substantially conforming to the

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

shape of the existing pipe or conduit, for example, circular,

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

oval, ovoid, and so forth (see Fig. 1).

Trenchless Plastic Pipeline Technology.

Current edition approved March 1, 2008. Published November 2008. Originally

3.2.4 production run—a continuous extrusion of a given

approved in 2002. Last previous edition approved in 2002 as F1698–02. DOI:

profile type.

10.1520/F1698-02R08.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Availablefrom,NASSCO,Inc.,11521CronridgeDrive,SuiteJ,OwingsMills,

the ASTM website. MD 21117.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1698−02 (2008)

FIG. 1 Example of Profile PVC Strip

4. Significance and Use vapors or lack of oxygen shall be undertaken in accordance

with local, state, or federal safety and confined space entry

4.1 This practice is for use by designers and specifiers,

regulations.

regulatory agencies, owners, and inspection organizations in-

6.1.2 Cleaning of Pipeline—Internal debris should be re-

volved in the rehabilitation of non-pressure sewers and con-

moved from the existing pipeline. Gravity pipes should be

duits. As for any practice, modifications may be required for

cleaned with hydraulically powered equipment, high-velocity

specific job conditions.

jet cleaners, or a combination of these methods and manually

5. Materials directed high-pressure (2500-psi minimum) water blasting to

ensure that the exposed pipe wall is free of contamination of

5.1 The extruded PVC profile strip (former and joiner) used

foreign materials and corrosion products and the surface is

for the field fabrication of PVC liner should be made as

hard, competent original pipe material.

specified in Specifcation D1735.

6.1.3 Inspection of Pipeline—Inspection of pipeline should

5.2 The profile strip should be coiled in a continuous length

be performed by experienced personnel trained in locating

as long as practical, or cut in custom length panels for storage

breaks, obstacles, and service connections, either by direct

and shipping to the job site. Handling and storage should be in

visual observation or by closed-circuit television. The interior

accordance with the manufacturer’s published recommenda-

of the pipeline should be carefully inspected to determine the

tions.

location of any conditions that may prevent or adversely

5.3 The adhesive/sealant, used should be compatible with

impact proper installation of the profile liner, such as protrud-

thePVCcompoundandthelinerprocess,soasnottoeffectthe ing service taps, collapsed or crushed pipe, significant line

propertiesofthefinishedliner.(Apolyurethane-baseproductis sags, and deflected joints. These conditions should be noted,

suggested.) and as appropriate, corrected prior to installation.

6.1.4 Line Obstructions—The existing pipeline should be

6. Installation Recommendations

clear of obstructions that will prevent the proper placement of

6.1 Cleaning and Inspection: the PVC liner. If inspection reveals an obstruction that cannot

6.1.1 Prior to entering access areas such as manholes, and be removed by conventional equipment, then a point repair

performing inspection or cleaning operations, an evaluation of excavationshouldbemadetouncoverandremoveorrepairthe

theatmospheretodeterminethepresenceoftoxicorflammable obstruction.

F1698−02 (2008)

FIG. 2 Typical Installations with Panels

6.2 Bypassing—The profiled PVC liner process does not bypass lines should be of adequate capacity and size to handle

always require a dry pipeline and may be installed with some

any extreme flows expected during the installation period.

flow in the existing pipe or lateral connections, or both. If

6.2.1 Under certain conditions, part or all of the installation

necessary, the bypass should be made by plugging the line at a

may be carried out with some flow in the existing pipeline or

point upstream of the pipe to be rehabilitated and pumping the

service connections, or both.

flow to a downstream point or adjacent system. The pump and

F1698−02 (2008)

6.3 PVC Liner Installation: integrity of the renovated sewer and should be designed and

executed with great care. The grouting plan should be as

6.3.1 Liner Installation (Panels)—If the job requires the

recommended by the liner material supplier and be reviewed

profiled PVC strips be provided in the form of panels or if the

and approved by the owner’s representative in advance of the

jobentailstheliningofonlyaportionofthecircumference,the

work.

panels should be cut and trimmed to fit as near as practical to

6.4.1 Although the goal of grouting is to fill 100% of the

the internal circumference of the structure to be lined or to

annulus, hydrostatic buckling strength required by the job

produce the required annulus (space between the liner and the

specifications determines the required minimum grout fill of

pipe wall). The panels should be placed square with the pipe

the annulus. If no specification for the job exists, it is

wall, that is, circumferentially (see Fig. 2). The adjacent panel

recommendedthattherequiredgroutfilloftheannulusbesuch

edges should be locked together using the manufacturer-

that there be no voids greater in circumferential extent than

supplied joiner strip by means recommended by the manufac-

5%oftheinsidecircumferenceoftheliner.Voidsfoundlarger

turer. End joints or supports should be made with a

than specified shall be filled by drilling a hole in the void,

manufacturer-supplied connector section or support (for

pumping grout into the void, and then plugging the grouting

example, “J” strips) and sealed with a bead of an approved

hole with a PVC plug as above. For purposes of this practice,

sealant/adhesive. If necessary, the panels may be shimmed off

adjacent voids separated circumferentially less than 4 in.

the wall to avoid discontinuities on the surface or to ensure a

should be considered one void.Also, the total void circumfer-

minimum annulus required by the specified design. These

ential extent in any one-foot section of the pipe should not

shims should be of such a configuration as to not significantly

exceed10%ofthecircumferenceoftheliner,regardlessofthe

impede the flow of grout into the annulus.

sizes of the individual voids.As both the compressive strength

6.3.2 Liner Installation (Coils)—If the job requires the

and the gro

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

An American National Standard

Designation:F 1698–96 Designation: F 1698 – 02 (Reapproved 2008)

Standard Practice for

Installation of Poly(Vinyl Chloride)(PVC) Profile Strip Liner

and Cementitious Grout for Rehabilitation of Existing Man-

Entry Sewers and Conduits

This standard is issued under the fixed designation F 1698; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes the procedures for the rehabilitation of sewer lines and conduits by the installation of a

field-fabricatedPVCliner.Afterinstallationoftheliner,cementitiousgroutisinjectedintotheannularspacebetweenthelinerand

the existing sewer or conduit. The rehabilitation of the host structure by this installation practice results in a rigid composite

structure (PVC/grout/existing pipe). This rehabilitation process may be used in a variety of gravity applications, such as sanitary

sewers, storm sewers and process piping of man-entry sizes (36 to 144 in. in vertical dimension). The profile strips used for field

fabrication of PVC liners are supplied in coils for spiral winding of the liner or in custom-cut flat panels for circumferential lining

of all or any portion of the circumference of the host conduit (see Figs. 1 and 2).

1.2The values in parentheses are provided for information purposes only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. Particular attention is drawn to those safety regulations and requirements involving entering into and

working in confined spaces.

2. Referenced Documents

2.1 ASTM Standards:

C39Test Method for Compressive Strength of Cylindrical Concrete Specimens 942 Test Method for Compressive Strength of

Grouts for Preplaced-Aggregate Concrete in the Laboratory

C969 Practice for Infiltration and Exfiltration Acceptance Testing of Installed Precast Concrete Pipe Sewer Lines

D790Test Method for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials

D883 Terminology Relating to Plastics

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1784Specification for Rigid Poly(Vinyl Chloride) (PVC) Compounds and Chlorinated Poly(Vinyl Chloride) (CPVC)

Compounds 1735 Practice for Testing Water Resistance of Coatings Using Water Fog Apparatus

F412 Terminology Relating to Plastic Piping Systems

2.2 NASSCO Standard:

Specification Guidelines for Sewer Collection System Maintenance and Rehabilitation

3. Terminology

3.1 General—Definitions are in accordance with Terminologies D883 and F412 and F412. Abbreviations are in accordance

with Terminology D1600, unless otherwise indicated.

3.2 Definitions of Terms Specific to This Standard:

ThispracticeisunderthejurisdictionofASTMCommitteeF-17onPlasticPipingSystemsandisthedirectresponsibilityofSubcommitteeF17.67onTrenchlessPlastic

Pipeline Technology.

Current edition approved March 10, 1996. Published May 1996.

This practice is under the jurisdiction ofASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 onTrenchless Plastic

Pipeline Technology.

Current edition approved March 1, 2008. Published November 2008. Originally approved in 2002. Last previous edition approved in 2002 as F1698–02.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

, Vol 04.02.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 04.05.

Available from, NASSCO, Inc., 11521 Cronridge Drive, Suite J, Owings Mills, MD 21117.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1698 – 02 (2008)

FIG. 1 Example of Profile PVC Strip

3.2.1 extruded PVC joiner strip—acompanionproducttotheprofileformerstripofsuchconfigurationastoprovidethelocking

mechanism at the edges of the former strips; the joiner strip contains within it a coextruded flexible PVC seal which forms a

compression seal when mated with the edges of the former strips.

3.2.2 extruded PVC profile former strip—aproduct,availableinvarioussizes,consistingofasmoothinnersurfaceandaribbed

outer surface (profile) with edge configurations to allow mechanical locking of adjacent strips.

3.2.3 PVC liner—a product field fabricated from extruded PVC profile strip into a shape substantially conforming to the shape

of the existing pipe or conduit, for example, circular, oval, ovoid, and so forth (see Fig. 1).

3.2.4 production run—a continuous extrusion of a given profile type.

4. Significance and Use

4.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations involved in

the rehabilitation of non-pressure sewers and conduits. As for any practice, modifications may be required for specific job

conditions.

5. Materials

5.1The extruded PVC profile strip (former and joiner) used for the field fabrication of PVC liner should be made from PVC

compound meeting all requirements for Cell Classification12344-C or higher, as defined in Specification D1784. The coextruded

flexible PVC seal in the joiner strip should be made from extrusion grade PVC with Shore A durometer of between 60 and 80

(when measured in accordance with Test Method D2240).

NOTE1—An ASTM specification for PVC profile strip materials is under preparation and will be referenced in this practice when approved.

5.1 The extruded PVC profile strip (former and joiner) used for the field fabrication of PVC liner should be made as specified

in Specifcation F1735.

5.2 The profile strip should be coiled in a continuous length as long as practical, or cut in custom length panels for storage and

shipping to the job site. Handling and storage should be in accordance with the manufacturer’s published recommendations.

5.3 Theadhesiveorsealant,orboth,adhesive/sealant,usedshouldbecompatiblewiththePVCcompoundandthelinerprocess,

so as not to effect the properties of the finished liner. (A1-component, moisture-cured, polyurethane-base product is suggested.)

6. Installation Recommendations

6.1 Cleaning and Inspection:

F 1698 – 02 (2008)

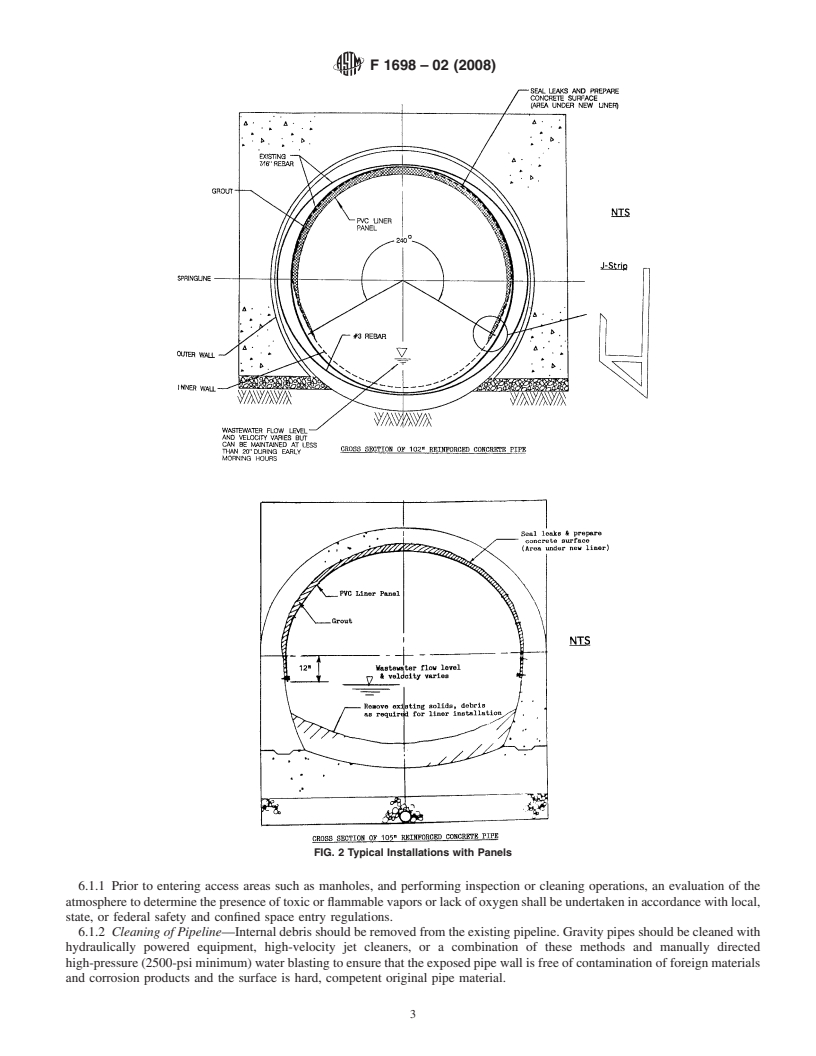

FIG. 2 Typical Installations with Panels

6.1.1 Prior to entering access areas such as manholes, and performing inspection or cleaning operations, an evaluation of the

atmospheretodeterminethepresenceoftoxicorflammablevaporsorlackofoxygenshallbeundertakeninaccordancewithlocal,

state, or federal safety and confined space entry regulations.

6.1.2 Cleaning of Pipeline—Internaldebrisshouldberemovedfromtheexistingpipeline.Gravitypipesshouldbecleanedwith

hydraulically powered equipment, high-velocity jet cleaners, or a combination of these methods and manually directed

high-pressure(2500-psiminimum)waterblastingtoensurethattheexposedpipewallisfreeofcontaminationofforeignmaterials

and corrosion products and the surface is hard, competent original pipe material.

F 1698 – 02 (2008)

6.1.3 Inspection of Pipeline—Inspection of pipeline should be performed by experienced personnel trained in locating breaks,

obstacles, and service connections, either by direct visual observation or by closed-circuit television. The interior of the pipeline

should be carefully inspected to determine the location of any conditions that may prevent or adversely impact proper installation

of the profile liner, such as protruding service taps, collapsed or crushed pipe, significant line sags, and deflected joints. These

conditions should be noted, and as appropriate, corrected prior to installation.

6.1.4 Line Obstructions—The existing pipeline should be clear of obstructions that will prevent the proper placement of the

PVC liner. If inspection reveals an obstruction that cannot be removed by conventional equipment, then a point repair excavation

should be made to uncover and remove or repair the obstruction.

6.2 Bypassing—The profiled PVC liner process does not always require a dry pipeline and may be installed with some flow in

the existing pipe or lateral connections, or both. If necessary, the bypass should be made by plugging the line at a point upstream

of the pipe to be rehabilitated and pumping the flow to a downstream point or adjacent system.The pump and bypass lines should

be of adequate capacity and size to handle any extreme flows expected during the installation period.

6.2.1 Undercertainconditions,partoralloftheinstallationmaybecarriedoutwithsomeflowintheexistingpipelineorservice

connections, or both.

6.3 PVC Liner Installation:

6.3.1 Liner Installation (Panels)—If the job requires the profiled PVC strips be provided in the form of panels or if the job

entails the lining of only a portion of the circumference, the panels should be cut and trimmed to fit as near as practical to the

internal circumference of the structure to be lined or to produce the required annulus (space between the liner and the pipe wall).

The panels should be placed square with the pipe wall, that is, circumferentially (see Fig. 2). The adjacent panel edges should be

locked together using the manufacturer-supplied joiner strip by means recommended by the manufacturer. End joints or supports

should be made with a manufacturer-supplied connector section or support (for example, “J” strips) and sealed with a bead of an

approvedsealant/adhesive.Ifnecessary,thepanelsmaybeshimmedoffthewalltoavoiddiscontinuitiesonthesurfaceortoensure

a minimum annulus required by the specified design.These shims should be of such a configuration as to not significantly impede

the flow of grout into the annulus.

6.3.2 Liner Installation (Coils)—IfthejobrequirestheprofiledPVCbeprovidedintheformofcoils,thecoilshouldbeplaced

over the open access manhole and the strip pulled down into the pipe through the manhole from the center of the coil. The liner

shouldbespirallywoundwiththeribbedprofileofthestripasnearaspracticaltothewalloftheexistingstructure,orasspecified

by the owner. If necessary, the strip may be shimmed off the wall to avoid discontinuities of the wall surface or to maintain the

specifiedannulus.Suchshimsshouldbeofaconfigurationthattheywillnotsignificantlyimpedetheflowofgroutintotheannulus.

The adjacent profile strip edges should be locked together using the manufacturer-supplied joiner strip by means approved by the

material supplier. Additional coils of PVC strip may be introduced by joining the ends of the strip by means of a

manufacturer-suppliedPVCsplicingprofile(forexample,“H”connectorsection).Thespliceshouldbesealedonbothsidesofthe

splice with an approved sealant/adhesive.

6.4 Grouting—Once the PVC liner is in place, the ends of the pipe at the manhole are sealed by dry packing with rapid-setting

mortar. Through this mortar and around the liner are placed a series of tubes which act as grout injection tubes or breather tubes,

orboth.Alternatively,orinaddition,groutholesmaybedrilledinthePVCliningatappropriatepointsandflowablegroutinjected

into them until satisfactory fill is obtained. Grout holes in the liner should be sealed with PVC plugs which, in turn, should be

sealedbyabeadofapprovedsealant/adhesive(a1-component,moisture-cured,polyurethane-baseproductissuggested).Grouting

shouldproceedinliftsorstages;generallytheriseofthefirstliftislimitedbytheallowablefloatingofthelineroffthepipeinvert

and avoiding contact of the liner with the crown of the existing pipe, while the succeeding lifts are limited in vertical rise by liner

wall deflection. There should be no leakage of the grout at the joints/seams of the liner. Due to the presence of the breather

holes/tubes,thelinerwillbesubjectedonlytothehydraulicheadpressureoftheliquidgrout,thatis,willnotsensethegroutpump

pressure. Thus, pressure monitoring at the grouting hose is generally not required. The grouting of the annular space is very

importanttothestructuralintegrityoftherenovatedsewerandshouldbedesignedandexecutedwithgreatcare.Thegroutingplan

should be as recommended by the liner material supplier and be reviewed and approved by the owner’s representative in advance

of the work.

6.4.1 Although the goal of grouting is to fill 100% of the annulus, hydrostatic buckling strength required by the job

specifications determines the required minimum grout fill of the annulus. If no specification for the job exists, it is recommended

that the required grout fill of the annulus be such that there be no voids greater in circumferential extent than 5% of the inside

circumference of the liner. Voids found larger than specified shall be filled by drilling a hole in the void, pumping grout into the

void, and then plugging the grouting hole with a PVC plug as above. For purposes of this practice, adjacent voids separated

circumferentially less than 4 in. should be considered one void.Also, the total void circumferential extent in any one-foot section

of the pipe should not exceed 10% of the circumference of the liner, regardless of the sizes of the individual voids.As both the

compressive strength and the grout thickness (size of annulus) are design variables and, therefore, job specific, no general

specification can be given here.

6.4.2 Thegroutshouldconsistofthefollowing:Portlandcement,Cement,water,flyashorlime,admixtures,andBentoniteclay

(less than 5% by weight of solids).admixtures. The grout mix design, including viscosity and minimum compressive strength to

be used for the project application, should be as recommended by the manufacturer (of the PVC strips) and approved by the

F 1698 – 02 (2008)

owner’s representative prior to commencement of work. Grout components should be clean, fresh, and stored in a suitably dry

condition. Premixed grouts and grout admixtures should be used in accordance with their manufacturer’s specifications.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.