ASTM F1446-05

(Test Method)Standard Test Methods for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear

Standard Test Methods for Equipment and Procedures Used in Evaluating the Performance Characteristics of Protective Headgear

SCOPE

1.1 These test methods describe laboratory equipment, procedures, and basic requirements pertinent to testing protective headgear. Deviations or additions, or both, to these test methods will be specified, as required, in individual performance standard specifications.

1.2 Requirements—The protective headgear is to be tested under specified environmental conditions for the following:

1.2.1 Impact attenuation (the limiting of head acceleration) of the protective headgear.

1.2.2 Strength of the retention system and its attachment.

1.2.3 Special tests for particular protective headgear uses will be specified in the individual standard specifications to be used in conjunction with these test methods.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1446 – 05

Standard Test Methods for

Equipment and Procedures Used in Evaluating the

1

Performance Characteristics of Protective Headgear

This standard is issued under the fixed designation F 1446; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

These test methods specify equipment and procedures used for testing protective headgear.

Individual ASTM performance standards (standard specifications) will use these procedures and

equipment. Test conditions, pass-fail criteria, and other performance requirements will be specified in

the individual performance standards, tailored to the needs of a particular activity (for example,

bicycling, skateboarding, skiing, etc.).

These test methods were developed using resources in medical, scientific, mechanical engineering,

human factors, and biomechanical fields. However, it is recognized that it is not possible to write a

protective headgear performance standard that will result in headgear that can protect against injury

or death in all accidents. It is also recognized that serious injury or death can result from both low-

and high-energy impacts, even when protective headgear is worn.

These test methods incorporate aspects of other recognized headgear performance standards. They

draw from work done by others where appropriate for these test methods. These standards are

referenced within this standard test method. It should be noted that these test methods specify

laboratory tests of completed headgear to measure its ability to reduce head acceleration during use

and other selected parameters.

1. Scope priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

1.1 These test methods cover laboratory equipment, proce-

dures, and basic requirements pertinent to testing protective

2. Referenced Documents

headgear. Deviations or additions, or both, to these test

2

2.1 ASTM Standard:

methods will be specified, as required, in individual ASTM

F 2220 Specification for Headforms

performance standards.

3

2.2 Federal Motor Vehicle Safety Standard:

1.2 Requirements—The protective headgear is to be tested

218 S7.1.8 Motorcycle Helmets

under specified environmental conditions for the following:

4

2.3 SAE Standard:

1.2.1 Impact attenuation (the limiting of head acceleration)

SAE J211 Recommended Practice for Instrumentation for

of the protective headgear, and

Impact Tests—Requirements for Channel Class 1000

1.2.2 Strength and stability of the retention system and its

attachment to the protective headgear.

3. Reference Table

1.2.3 Special tests for particular protective headgear uses

3.1 For references to these test methods, the standard terms

will be specified in the individual performance standards to be

for reference are listed in bold type inTable 1 with the items to

used in conjunction with these test methods.

consider for each method. For conditions and anvils, use the

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contactASTM Customer Service at service@astm.org. ForAnnual Book ofASTM

Standards volume information, refer to the standard’s Document Summary page on

1

These test methods are under the jurisdiction of ASTM Committee F08 on the ASTM website.

3

Sports Equipment and Facilities and are the direct responsibility of Subcommittee Available from National HighwayTraffic SafetyAdministration (NHTSA), 400

F08.53 on Headgear and Helmets. 7th St., NW, Washington, DC 20590.

4

Current edition approved Dec. 1, 2005. Published December 2005. Originally Available from Society of Automotive Engineers (SAE), 400 Commonwealth

approved in 1993. Last previous edition approved in 2004 as F 1446 – 04. Dr., Warrendale, PA 15096-0001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1446–05

TABLE 1 Table for Reference

Terms for Reference Section Items to Consider for Each Method

Chin Bar Rigidity 12.9 Types defined: impact velocity, nominal drop height

Conditioning Environments 10 Types defined: ambient, low temperature, high temperature, water

immersion

Configuration 12.2 Standard requirement defined

Dynamic Retention Test 12.7.1 Types defined: mass of drop weight, drop height, extension pass/fail

criteria

Headforms 7.1 Headforms to be used in all tests in T

...

Questions, Comments and Discussion

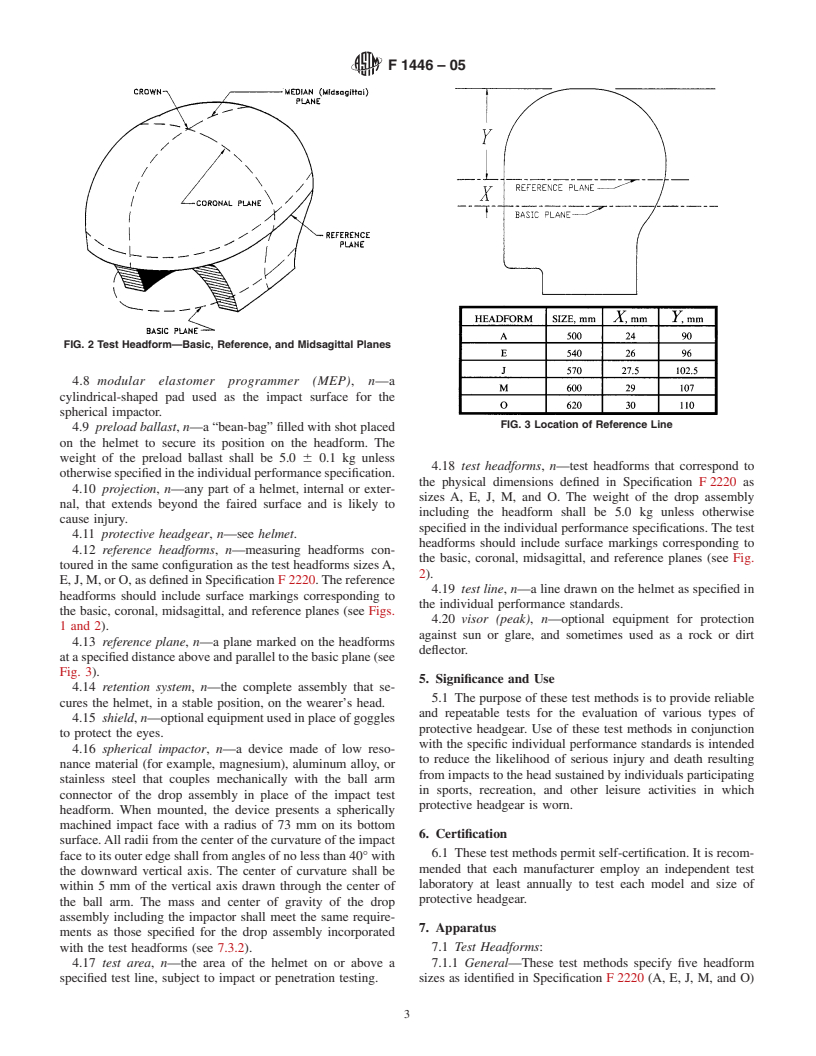

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.