ASTM D6804-02(2015)

(Guide)Standard Guide for Hand Hole Design in Corrugated Boxes

Standard Guide for Hand Hole Design in Corrugated Boxes

SIGNIFICANCE AND USE

4.1 It may be desirable at times to provide hand holes in corrugated boxes. Package designers use hand holes to solve ergonomic and handling problems associated with large or awkward containers. This guide provides an aid for proper hand hole design and use.

4.2 Ergonomics:

4.2.1 In studying and applying ergonomic principles, of primary concern is the need to provide a safe work environment for material handlers who may be required to lift or transport packages. A safe work environment is difficult to define and varies with the package in question. Several ergonomic safety issues involve repetitive motions and spine loading in the lifting process. Other issues involve finger and foot protection.

4.2.2 In distribution centers or warehouses, low back disorders have been identified as areas of elevated risk. Low back problems continue to represent the most common and costly musculoskeletal disorders in the work place.4

4.2.3 One method used to reduce the concern of distance of lift (spinal loading) is to bring the reach of the material handler's hands closer to the body. With large or awkward boxes, placing hand holes in a more advantageous position can solve this problem.

4.3 NIOSH:

4.3.1 The National Institute for Occupational Safety and Health (NIOSH) has published Work Practices Guide for Manual Lifting.5 This document may be of assistance in developing proper hand holes and their placement for a specific package.

4.4 Improper Use of Hand Holes:

4.4.1 Because of past lawsuits involving the use and misuse of hand holes, the corrugated box industry prefers the term access hole instead of hand hole on specifications. This terminology may have to be agreed upon between supplier and user.Fig. 1

4.4.2 Since all end use conditions and requirements cannot be foreseen and since designing for worst case scenario for all applications is prohibitively expensive, designers should follow best practices. The prudent designer will consider product an...

SCOPE

1.1 This standard provides guidelines for designing pre-cut apertures intended for use as hand holes in corrugated boxes during manual handling of boxed cargo.

1.2 Limitations—This standard offers guidance for package development and for subsequent testing of boxes to measure performance. It is not intended to provide specific information on the design of hand holes.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6804 − 02 (Reapproved 2015)

Standard Guide for

Hand Hole Design in Corrugated Boxes

This standard is issued under the fixed designation D6804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Specified Precision, the Average for a Characteristic of a

Lot or Process

1.1 This standard provides guidelines for designing pre-cut

apertures intended for use as hand holes in corrugated boxes

3. Terminology

during manual handling of boxed cargo.

3.1 Definitions—General definitions for packaging and dis-

1.2 Limitations—This standard offers guidance for package

tribution environments are found in Terminology D996.

development and for subsequent testing of boxes to measure

3.2 Definitions of Terms Specific to This Standard:

performance. It is not intended to provide specific information

3.2.1 hand holes—apertures, pre-cut in corrugated boxes by

on the design of hand holes.

box manufacturers, as requested by box purchasers. These

1.3 The values stated in inch-pound units are to be regarded

apertures facilitate manual handling during distribution and

as the standard. The SI units are for information only.

improve grip during handling.

1.4 This standard does not purport to address all of the

4. Significance and Use

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

4.1 It may be desirable at times to provide hand holes in

priate safety and health practices and determine the applica-

corrugated boxes. Package designers use hand holes to solve

bility of regulatory requirements prior to use.

ergonomic and handling problems associated with large or

awkward containers. This guide provides an aid for proper

2. Referenced Documents

hand hole design and use.

2.1 ASTM Standards:

4.2 Ergonomics:

D585Practice for Sampling and Accepting a Single Lot of

4.2.1 In studying and applying ergonomic principles, of

Paper, Paperboard, Fiberboard, and Related Product

primary concern is the need to provide a safe work environ-

(Withdrawn 2010)

ment for material handlers who may be required to lift or

D996Terminology of Packaging and Distribution Environ-

transport packages. A safe work environment is difficult to

ments

define and varies with the package in question. Several

D1974Practice for Methods of Closing, Sealing, and Rein-

ergonomic safety issues involve repetitive motions and spine

forcing Fiberboard Boxes

loading in the lifting process. Other issues involve finger and

D4332Practice for Conditioning Containers, Packages, or

foot protection.

Packaging Components for Testing

4.2.2 In distribution centers or warehouses, low back disor-

D5276Test Method for Drop Test of Loaded Containers by

ders have been identified as areas of elevated risk. Low back

Free Fall

problems continue to represent the most common and costly

E4Practices for Force Verification of Testing Machines

musculoskeletal disorders in the work place.

E122PracticeforCalculatingSampleSizetoEstimate,With

4.2.3 One method used to reduce the concern of distance of

lift (spinal loading) is to bring the reach of the material

handler’s hands closer to the body. With large or awkward

ThisguideisunderthejurisdictionofASTMCommitteeD10onPackagingand

boxes,placinghandholesinamoreadvantageouspositioncan

is the direct responsibility of Subcommittee D10.27 on Paper and Paperboard

solve this problem.

Products.

Current edition approved Oct. 1, 2015. Published October 2015. Originally

4.3 NIOSH:

approved in 2002. Last previous edition approved in 2011 as D6804–02 (2011).

4.3.1 The National Institute for Occupational Safety and

DOI: 10.1520/D6804-02R15.

2 Health (NIOSH) has published Work Practices Guide for

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. “EffectsofBoxFeaturesonSpineLoadingduringWarehouseOrderSelecting,”

The last approved version of this historical standard is referenced on Marras, Granata, Davis,Allread, and Jorgensen,The Institute for Ergonomics, Ohio

www.astm.org. State University.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6804 − 02 (2015)

Manual Lifting. This document may be of assistance in 4.4.2 Since all end use conditions and requirements cannot

developingproperhandholesandtheirplacementforaspecific be foreseen and since designing for worst case scenario for all

package. applications is prohibitively expensive, designers should fol-

low best practices. The prudent designer will consider product

4.4 Improper Use of Hand Holes:

and package weight when deciding the proper use of a hand

4.4.1 Because of past lawsuits involving the use and misuse

hole.

of hand holes, the corrugated box industry prefers the term

access hole instead of hand hole on specifications. This

5. General Design Considerations

terminology may have to be agreed upon between supplier and

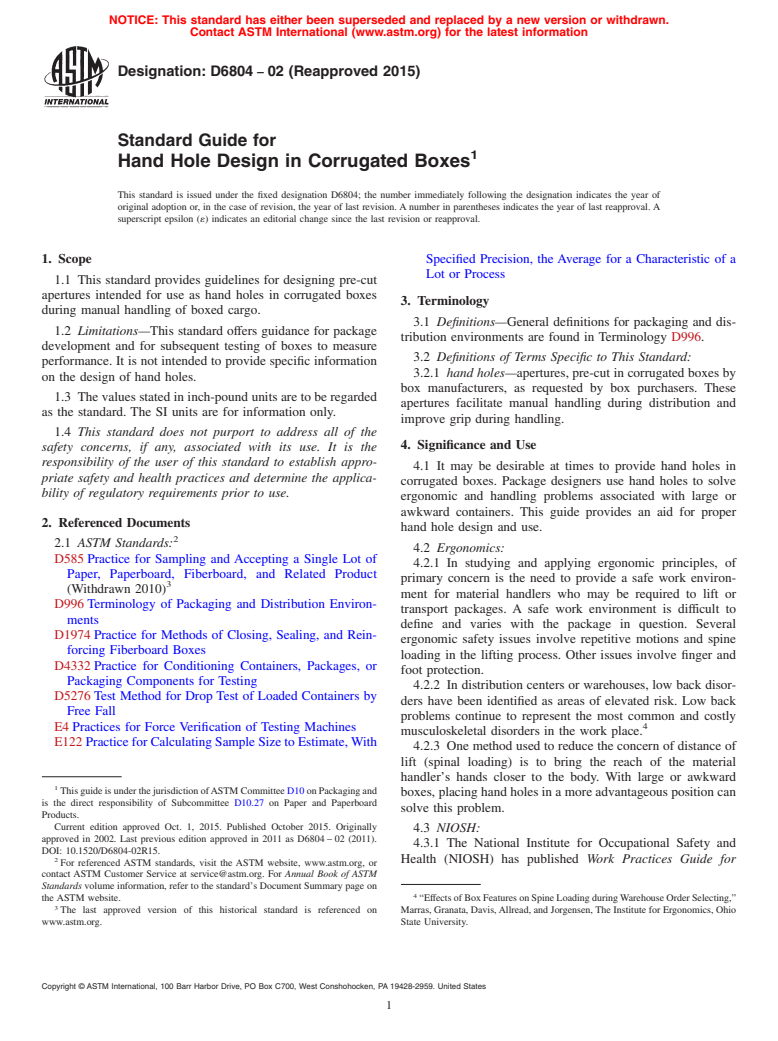

user.Fig. 1

5.1 Hand holes can take many forms (see Fig. 1).They can:

5.1.1 Be a simple hole in a box,

5.1.2 Be a complex molded handle with a reinforcement

mounted at the attaching point,

5.1.3 Incorporate rope handles, and

NIOSH Technical Report No. 81-122 from the US Department of Health and

Human Sevices.

FIG. 1 Common Hand Hole Types

D6804 − 02 (2015)

5.1.4 Be reinforced by the box maker with reinforcing tape

applied above them.

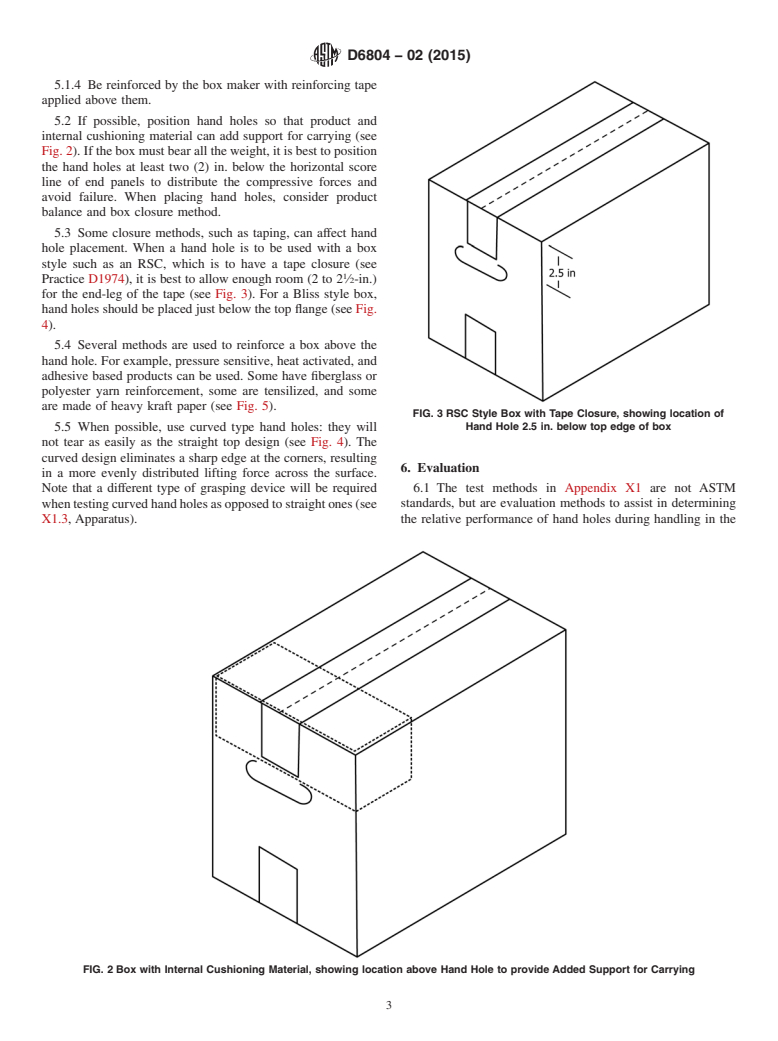

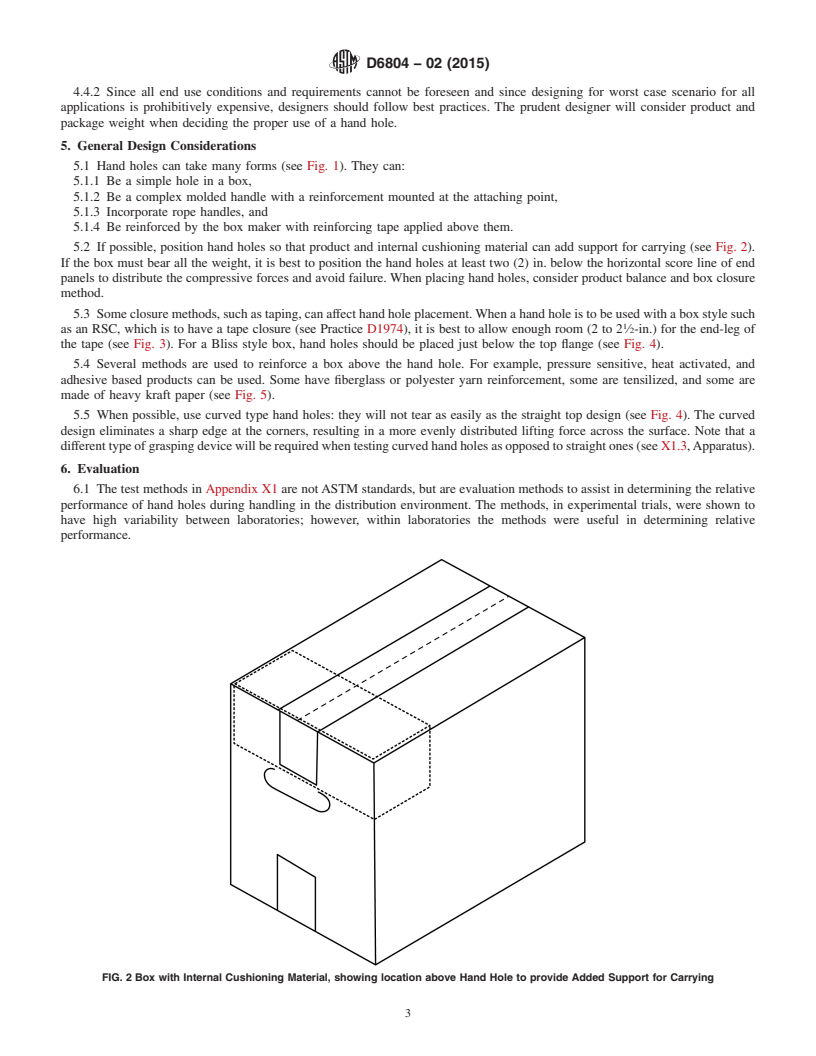

5.2 If possible, position hand holes so that product and

internal cushioning material can add support for carrying (see

Fig.2).Iftheboxmustbearalltheweight,itisbesttoposition

the hand holes at least two (2) in. below the horizontal score

line of end panels to distribute the compressive forces and

avoid failure. When placing hand holes, consider product

balance and box closure method.

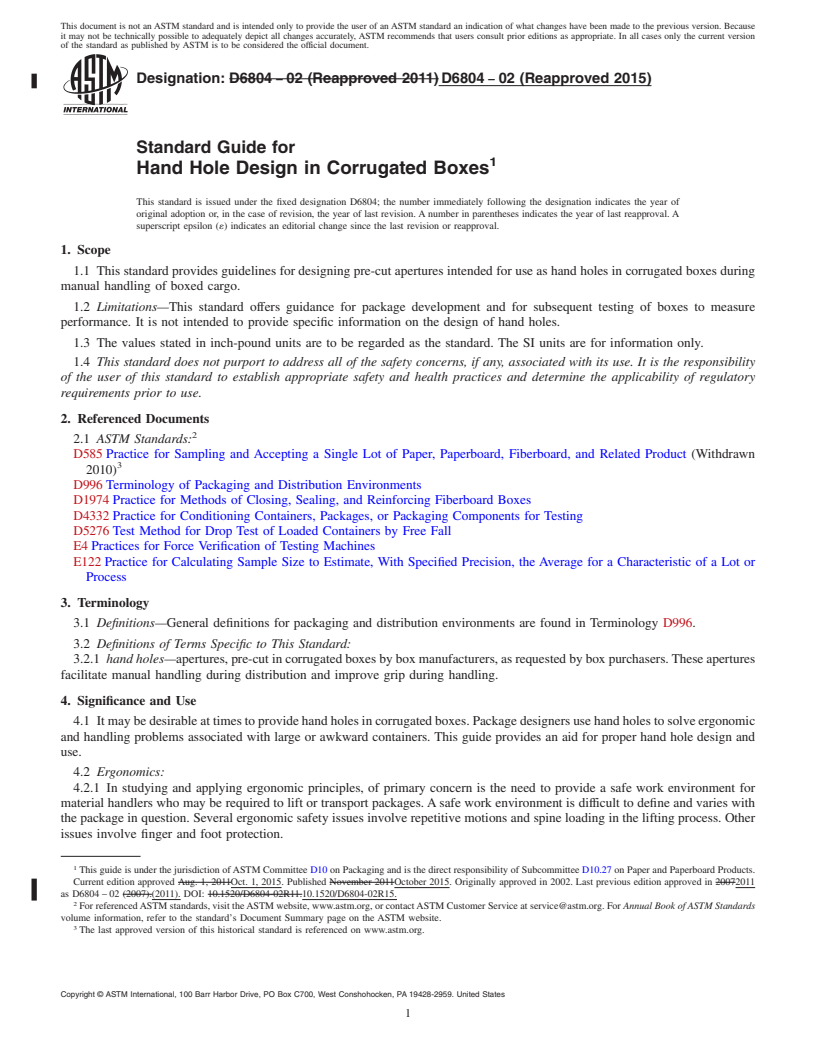

5.3 Some closure methods, such as taping, can affect hand

hole placement. When a hand hole is to be used with a box

style such as an RSC, which is to have a tape closure (see

Practice D1974), it is best to allow enough room (2 to 2 ⁄2-in.)

for the end-leg of the tape (see Fig. 3). For a Bliss style box,

hand holes should be placed just below the top flange (see Fig.

4).

5.4 Several methods are used to reinforce a box above the

hand hole. For example, pressure sensitive, heat activated, and

adhesive based products can be used. Some have fiberglass or

polyester yarn reinforcement, some are tensilized, and some

are made of heavy kraft paper (see Fig. 5).

FIG. 3 RSC Style Box with Tape Closure, showing location of

Hand Hole 2.5 in. below top edge of box

5.5 When possible, use curved type hand holes: they will

not tear as easily as the straight top design (see Fig. 4). The

curved design eliminates a sharp edge at the corners, resulting

6. Evaluation

in a more evenly distributed lifting force across the surface.

Note that a different type of grasping device will be required 6.1 The test methods in Appendix X1 are not ASTM

whentestingcurvedhandholesasopposedtostraightones(see standards, but are evaluation methods to assist in determining

X1.3, Apparatus). the relative performance of hand holes during handling in the

FIG. 2 Box with Internal Cushioning Material, showing location above Hand Hole to provide Added Support for Carrying

D6804 − 02 (2015)

FIG. 4 Bliss Style Box showing Curved Hand Hole located just below the Top Flange

FIG. 5 RSC Style Box showing placement of Reinforcement Material around perimeter of box, just above Hand Hole

distribution environment. The methods, in experimental trials, 7. Keywords

were shown to have high variability between laboratories;

7.1 corrugated boxes; distribution environment; hand holes;

however, within laboratories the methods were useful in

manual handling

determining relative performance.

D6804 − 02 (2015)

APPENDIX

(Nonmandatory Information)

X1. EVALUATION OF PERFORMANCE OF HAND HOLES IN CORRUGATED BOXES

X1.1 Summary of Methods X1.3.2 Method A, Jerk Test (see Fig. X1.2):

X1.3.2.1 Drop Test Apparatus, with a platform or other

X1.1.1 Method A, Jerk Test—Uses free-fall drop test appa-

featurewhichsupportsacorrugatedbox,suchthattheboxmay

ratus in conjunction with a support apparatus and grasping

be released for free-fall from a specified height. Support

device(s), imparting a sudden sharp arrested motion (jerk) to

apparatusforthegraspingdevicemustsuspendtheboxatleast

the hand hole area of a corrugated box. A grasping device

6 in. (150 mm) above the floor or test apparatus base. The

similar to that shown in Fig. X1.1 provides contact with the

support apparatus must secure the grasping device(s) so

hand hole.

essentially no yielding or elastic stretch occurs when the box

X1.1.1.1 Thismethodisapplicablefortestingbothone-and

falls and its motion is arrested by the device(s). A chain or

two-hand lifting of boxes. It is not intended for horizontal

flexible steel cable suspended from a rigid support or overhead

pulling of the box (see Method B, Tensile Test).

hoist may be used for this purpose.

X1.1.2 Method B, Tensile Test—Uses tensile testing ma-

X1.3.2.2 Anelasticcordmaybeusedtotakeuptheslackin

chines having a constant free-running crosshead speed or

the chain or cable to make sure the grasping device(s) stays in

constant extension rate to determine the maximum load carry-

the hand hole(s). The cord shall be stiff en

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6804 − 02 (Reapproved 2011) D6804 − 02 (Reapproved 2015)

Standard Guide for

Hand Hole Design in Corrugated Boxes

This standard is issued under the fixed designation D6804; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This standard provides guidelines for designing pre-cut apertures intended for use as hand holes in corrugated boxes during

manual handling of boxed cargo.

1.2 Limitations—This standard offers guidance for package development and for subsequent testing of boxes to measure

performance. It is not intended to provide specific information on the design of hand holes.

1.3 The values stated in inch-pound units are to be regarded as the standard. The SI units are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

requirements prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D585 Practice for Sampling and Accepting a Single Lot of Paper, Paperboard, Fiberboard, and Related Product (Withdrawn

2010)

D996 Terminology of Packaging and Distribution Environments

D1974 Practice for Methods of Closing, Sealing, and Reinforcing Fiberboard Boxes

D4332 Practice for Conditioning Containers, Packages, or Packaging Components for Testing

D5276 Test Method for Drop Test of Loaded Containers by Free Fall

E4 Practices for Force Verification of Testing Machines

E122 Practice for Calculating Sample Size to Estimate, With Specified Precision, the Average for a Characteristic of a Lot or

Process

3. Terminology

3.1 Definitions—General definitions for packaging and distribution environments are found in Terminology D996.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 hand holes—apertures, pre-cut in corrugated boxes by box manufacturers, as requested by box purchasers. These apertures

facilitate manual handling during distribution and improve grip during handling.

4. Significance and Use

4.1 It may be desirable at times to provide hand holes in corrugated boxes. Package designers use hand holes to solve ergonomic

and handling problems associated with large or awkward containers. This guide provides an aid for proper hand hole design and

use.

4.2 Ergonomics:

4.2.1 In studying and applying ergonomic principles, of primary concern is the need to provide a safe work environment for

material handlers who may be required to lift or transport packages. A safe work environment is difficult to define and varies with

the package in question. Several ergonomic safety issues involve repetitive motions and spine loading in the lifting process. Other

issues involve finger and foot protection.

This guide is under the jurisdiction of ASTM Committee D10 on Packaging and is the direct responsibility of Subcommittee D10.27 on Paper and Paperboard Products.

Current edition approved Aug. 1, 2011Oct. 1, 2015. Published November 2011October 2015. Originally approved in 2002. Last previous edition approved in 20072011

as D6804 – 02 (2007).(2011). DOI: 10.1520/D6804-02R11.10.1520/D6804-02R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6804 − 02 (2015)

4.2.2 In distribution centers or warehouses, low back disorders have been identified as areas of elevated risk. Low back

problems continue to represent the most common and costly musculoskeletal disorders in the work place.

4.2.3 One method used to reduce the concern of distance of lift (spinal loading) is to bring the reach of the material handler’s

hands closer to the body. With large or awkward boxes, placing hand holes in a more advantageous position can solve this problem.

4.3 NIOSH:

4.3.1 The National Institute for Occupational Safety and Health (NIOSH) has published Work Practices Guide for Manual

Lifting. This document may be of assistance in developing proper hand holes and their placement for a specific package.

4.4 Improper Use of Hand Holes:

4.4.1 Because of past lawsuits involving the use and misuse of hand holes, the corrugated box industry prefers the term access

hole instead of hand hole on specifications. This terminology may have to be agreed upon between supplier and user.Fig. 1

“Effects of Box Features on Spine Loading during Warehouse Order Selecting,” Marras, Granata, Davis, Allread, and Jorgensen, The Institute for Ergonomics, Ohio State

University.

NIOSH Technical Report No. 81-122 from the US Department of Health and Human Sevices.

FIG. 1 Common Hand Hole Types

D6804 − 02 (2015)

4.4.2 Since all end use conditions and requirements cannot be foreseen and since designing for worst case scenario for all

applications is prohibitively expensive, designers should follow best practices. The prudent designer will consider product and

package weight when deciding the proper use of a hand hole.

5. General Design Considerations

5.1 Hand holes can take many forms (see Fig. 1). They can:

5.1.1 Be a simple hole in a box,

5.1.2 Be a complex molded handle with a reinforcement mounted at the attaching point,

5.1.3 Incorporate rope handles, and

5.1.4 Be reinforced by the box maker with reinforcing tape applied above them.

5.2 If possible, position hand holes so that product and internal cushioning material can add support for carrying (see Fig. 2).

If the box must bear all the weight, it is best to position the hand holes at least two (2) in. below the horizontal score line of end

panels to distribute the compressive forces and avoid failure. When placing hand holes, consider product balance and box closure

method.

5.3 Some closure methods, such as taping, can affect hand hole placement. When a hand hole is to be used with a box style such

as an RSC, which is to have a tape closure (see Practice D1974), it is best to allow enough room (2 to 2 ⁄2-in.) for the end-leg of

the tape (see Fig. 3). For a Bliss style box, hand holes should be placed just below the top flange (see Fig. 4).

5.4 Several methods are used to reinforce a box above the hand hole. For example, pressure sensitive, heat activated, and

adhesive based products can be used. Some have fiberglass or polyester yarn reinforcement, some are tensilized, and some are

made of heavy kraft paper (see Fig. 5).

5.5 When possible, use curved type hand holes: they will not tear as easily as the straight top design (see Fig. 4). The curved

design eliminates a sharp edge at the corners, resulting in a more evenly distributed lifting force across the surface. Note that a

different type of grasping device will be required when testing curved hand holes as opposed to straight ones (see X1.3, Apparatus).

6. Evaluation

6.1 The test methods in Appendix X1 are not ASTM standards, but are evaluation methods to assist in determining the relative

performance of hand holes during handling in the distribution environment. The methods, in experimental trials, were shown to

have high variability between laboratories; however, within laboratories the methods were useful in determining relative

performance.

FIG. 2 Box with Internal Cushioning Material, showing location above Hand Hole to provide Added Support for Carrying

D6804 − 02 (2015)

FIG. 3 RSC Style Box with Tape Closure, showing location of Hand Hole 2.5 in. below top edge of box

7. Keywords

7.1 corrugated boxes; distribution environment; hand holes; manual handling

D6804 − 02 (2015)

FIG. 4 Bliss Style Box showing Curved Hand Hole located just below the Top Flange

FIG. 5 RSC Style Box showing placement of Reinforcement Material around perimeter of box, just above Hand Hole

D6804 − 02 (2015)

APPENDIX

(Nonmandatory Information)

X1. EVALUATION OF PERFORMANCE OF HAND HOLES IN CORRUGATED BOXES

X1.1 Summary of Methods

X1.1.1 Method A, Jerk Test—Uses free-fall drop test apparatus in conjunction with a support apparatus and grasping device(s),

imparting a sudden sharp arrested motion (jerk) to the hand hole area of a corrugated box. A grasping device similar to that shown

in Fig. X1.1 provides contact with the hand hole.

X1.1.1.1 This method is applicable for testing both one- and two-hand lifting of boxes. It is not intended for horizontal pulling

of the box (see Method B, Tensile Test).

X1.1.2 Method B, Tensile Test—Uses tensile testing machines having a constant free-running crosshead speed or constant

extension rate to determine the maximum load carrying ability of the hand hole(s) in the tested box. Contact with the hand hole

is provided by the same type of grasping device used for Method A, and the box is fixed to the stationary portion of the machine.

X1.1.2.1 With proper fixturing, this method is applicable to testing one- and two-hand lifting, and horizontal pulling of boxes.

X1.2 Significance and Use

X1.2.1 These test methods will assist in determining whether hand holes in corrugated boxes will perform to specific level(s) of

handling force(s) expected in the distribution environment during manual handling. These forces can be static, that is, a box picked

up slowly, or dynamic, a box picked up or moved with a jerk

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.