ASTM F1668-96(2002)

(Guide)Standard Guide for Construction Procedures for Buried Plastic Pipe

Standard Guide for Construction Procedures for Buried Plastic Pipe

SCOPE

1.1 This guide describes installation techniques and considerations for open-cut construction of buried pipe. Although this guide was developed for plastic pipe, the concepts of providing the appropriate soil support, care in handling, correct joining techniques, proper soil compaction methods, and prevention of installation damage may apply to any pipe.

1.1.1 Plastic pipe refers to thermoplastic and fiberglass pipe.

1.1.2 Thermoplastic pipe refers to pipe fabricated from polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile-butadiene styrene (ABS), polybutylene (PB), or polypropylene (PP). A list of ASTM specifications for these products is given in Appendix X2.

1.1.3 Fiberglass pipe refers to a glass-fiber-reinforced thermosetting-resin pipe. A list of ASTM specifications for these products is given in Appendix X2.

Note 1 —Appendix X2 cannot be considered inclusive because there may be unlisted, recently adopted ASTM specifications for new products that may be installed using this guide.

Note 2—Only a few of the ASTM specifications listed in include the associated fittings. While this guide applies to the installation of pipe, couplings, and fittings, no attempt was made to list all the possible fitting specifications that may be used in conjunction with the pipe specifications. Consult each specification or manufacturer for appropriate fitting standards.

1.1.4For simplification, the term pipe will be used in this document to mean pipe sections, fittings, and couplings.

1.2 This guide contains general construction information applicable for plastic pipe and supplements the installation standards for the various types of pipe as described in Practices D 2321, D 2774, D 3839, F 690, F 1176, and Guide F 645.

1.3 Flexible pipe, such as thermoplastic and fiberglass, are typically designed to rely on the stiffness of the soil surrounding the pipe for support. The contract documents should describe the requirements of an appropriate soil support system. The construction practices described in this guide can be instrumental in attaining the required soil stiffness.

1.3.1 A discussion of the interaction between a buried pipe and the surrounding soil and the importance of attaining proper soil support is in .

1.3.2 Following these guidelines will be helpful in preventing local deformations in the pipe.

1.4 This guide does not cover underwater installation, pipe that needs to be supported on piling, perforated pipe used for drainage, or gas pipelines.

1.5 Pipelines through areas described as "expansive soils," "collapsing soils," landfills or water-logged land (such as swamps) should be constructed using site-specific installation procedures and are not discussed in this guide.

1.6 This guide is not intended to cover all situations. Specific pipe characteristics, fluid transported, local site conditions, environmental concerns, or manufacturer's recommendations may require different guidelines.

1.7 The construction practices presented in this guide may be affected by the installation requirements of owners, specifying organizations, or regulatory agencies for pipelines crossing roads and highways, other pipelines or cables, or waterways such as streams, drainage channels, or floodways.

1.8 Culverts or pipe that are used as passages through water retaining embankments (for example, earth dams) may be constructed using the principles of this guide, if appropriate provisions are made to prevent water movement along the outside of the pipe (using impervious soils, cutoff collars, head walls, etc.).

1.9 The values stated in SI units are to be regarded as the standard. The inch-pound units in parentheses are given for information only.

Note 3—There is no similar or equivalent ISO standard covering the primary subject matter of this guide.

1.10 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this ...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:F 1668–96 (Reapproved 2002)

Standard Guide for

Construction Procedures for Buried Plastic Pipe

This standard is issued under the fixed designation F 1668; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope system. The construction practices described in this guide can

be instrumental in attaining the required soil stiffness.

1.1 This guide describes installation techniques and consid-

1.3.1 A discussion of the interaction between a buried pipe

erationsforopen-cutconstructionofburiedpipe.Althoughthis

andthesurroundingsoilandtheimportanceofattainingproper

guidewasdevelopedforplasticpipe,theconceptsofproviding

soil support is in Appendix X1.

the appropriate soil support, care in handling, correct joining

1.3.2 Following these guidelines will be helpful in prevent-

techniques, proper soil compaction methods, and prevention of

ing local deformations in the pipe.

installation damage may apply to any pipe.

1.4 This guide does not cover underwater installation, pipe

1.1.1 Plasticpipereferstothermoplasticandfiberglasspipe.

that needs to be supported on piling, perforated pipe used for

1.1.2 Thermoplastic pipe refers to pipe fabricated from

drainage, or gas pipelines.

polyvinyl chloride (PVC), polyethylene (PE), acrylonitrile-

1.5 Pipelines through areas described as “expansive soils,”

butadiene styrene (ABS), polybutylene (PB), or polypropylene

“collapsing soils,” landfills or water-logged land (such as

(PP).Alist ofASTM specifications for these products is given

swamps) should be constructed using site-specific installation

in Appendix X2.

procedures and are not discussed in this guide.

1.1.3 Fiberglass pipe refers to a glass-fiber-reinforced

1.6 This guide is not intended to cover all situations.

thermosetting-resin pipe. A list of ASTM specifications for

Specific pipe characteristics, fluid transported, local site con-

these products is given in Appendix X2.

ditions, environmental concerns, or manufacturer’s recommen-

NOTE 1—Appendix X2 cannot be considered inclusive because there

dations may require different guidelines.

may be unlisted, recently adopted ASTM specifications for new products

1.7 The construction practices presented in this guide may

that may be installed using this guide.

be affected by the installation requirements of owners, speci-

NOTE 2—Only a few of theASTM specifications listed inAppendix X2

fying organizations, or regulatory agencies for pipelines cross-

include the associated fittings. While this guide applies to the installation

ofpipe,couplings,andfittings,noattemptwasmadetolistallthepossible ing roads and highways, other pipelines or cables, or water-

fitting specifications that may be used in conjunction with the pipe

ways such as streams, drainage channels, or floodways.

specifications. Consult each specification or manufacturer for appropriate

1.8 Culverts or pipe that are used as passages through water

fitting standards.

retaining embankments (for example, earth dams) may be

1.1.4 For simplification, the term pipe will be used in this

constructed using the principles of this guide, if appropriate

document to mean pipe sections, fittings, and couplings. provisions are made to prevent water movement along the

1.2 This guide contains general construction information

outside of the pipe (using impervious soils, cutoff collars, head

applicable for plastic pipe and supplements the installation walls, etc.).

standardsforthevarioustypesofpipeasdescribedinPractices

1.9 The values stated in SI units are to be regarded as the

D 2321, D 2774, D 3839, F 690, F 1176, and Guide F 645. standard. The inch-pound units in parentheses are given for

1.3 Flexible pipe, such as thermoplastic and fiberglass, are

information only.

typically designed to rely on the stiffness of the soil surround-

NOTE 3—There is no similar or equivalent ISO standard covering the

ing the pipe for support. The contract documents should

primary subject matter of this guide.

describe the requirements of an appropriate soil support

1.10 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

This guide is under the jurisdiction ofASTM Committee F17 on Plastic Piping

Systems and is the direct responsibility of Subcommittee F17.61 on Water.

priate safety and health practices and determine the applica-

Current edition approved Sept. 10, 1996. Published November 1996. Originally

bility of regulatory limitations prior to use.

published as F 1668 – 95. Last previous edition F 1668 – 95.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1668–96 (2002)

2. Referenced Documents Weight of Soils and Calculation of Relative Density

D 4564 Test Method for Density of Soil in Place by the

2.1 ASTM Standards:

Sleeve Method

D8 Terminology Relating to Materials for Roads and Pave-

D 4643 Test Method for Determination of Water (Moisture)

ments

Content of Soils by the Microwave Oven Method

D 653 Terminology Relating to Soil, Rock, and Contained

D 4944 Test Method for Field Determination of Water

Fluids

(Moisture) Content of Soil by the Calcium Carbide Gas

D 883 Terminology Relating to Plastics

Pressure Tester Method

D 1600 Terminology for Abbreviated Terms Relating to

D 4959 Test Method for Determination of Water (Moisture)

Plastics

Content of Soil by Direct Heating Method

D 4914 Test Methods for Density of Soil and Rock in Place

D 5080 Test Method for Rapid Determination of Percent

by the Sand Replacement Method in a Test Pit

Compaction

D 5030 Test Method for Density of Soil and Rock in Place

2.4 Joining Practices:

by the Water Replacement in a Test Pit

D 2657 Practice for Heat Joining of Polyolefin Pipe and

F 412 Terminology Relating to Plastic Piping Systems

Fittings

2.2 Pipe Installation:

D 2855 Practice for Making Solvent-Cemented Joints With

D 2321 Practice for Underground Installation of Thermo-

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

plastic Pipe for Sewers and Other Gravity-Flow Applica-

F 402 Practice for Safe Handling of Solvent Cements,

tions

Primers, and Cleaners Used for Joining Thermoplastic

D 2774 Practice for Underground Installation of Thermo-

Pipe and Fittings

plastic Pressure Piping

F 477 Specification for Elastomeric Seals (Gaskets) for

D 3839 Practice for Underground Installation of “Fiber-

Joining Plastic Pipe

glass” (Glass-Fiber ReinforcedThermosetting Resin) Pipe

F 913 Specification for Thermoplastic Elastomeric Seals

F 645 Guide for Selection, Design, and Installation of Ther-

(Gaskets) for Joining Plastic Pipe

moplastic Pressure Piping System

2.5 Other ASTM Standards:

F 690 Practice for Underground Installation of Thermoplas-

C 94/C 94M Specification for Ready-Mixed Concrete

tic Pressure Piping Irrigation Systems

D 2412 Test Method for Determination of External Loading

F 1176 Practice for Design and Installation of Thermoplas-

Characteristics of Plastic Pipe by Parallel-Plate Loading

ticIrrigationSystemswithMaximumWorkingPressureof

F 1417 Test Method for Installation Acceptance of Plastic

125 psi

Gravity Sewer Lines Using Low Pressure Air

2.3 Soil Testing:

2.6 AmericanWaterWorksAssociation(AWWA)Standards:

D 698 Test Method for Laboratory Compaction Character-

C 600 Standard for Installation of Ductile-IronWater Mains

istics of Soil Using Standard Effort (12 400 ft-lbf/ft (600

and Their Appurtenances

kn-m/m ))

C 651 Standard for Disinfecting Water Mains

D 1556 Test Method for Density and Unit Weight of Soil in

2.7 American Association of State Highway and Transpor-

Place by the Sand-Cone Method

tation Offıcials (AASHTO) Standard:

D 1557 Test Method for Laboratory Compaction Character-

Standard Specification for Highway Bridges

istics of Soil Using Modified Effort (56 000 ft-lbf/ft (2700

2.8 Uni-Bell PVC Pipe Association Standard:

kn-m/m ))

UNI-B-13 Recommended Performance Specification for

D 2167 Test Method for Density and Unit Weight of Soil in

Joint Restraint Devices for Use with Polyvinyl Chloride

Place by the Rubber Balloon Method

(PVC) Pipe

D 2216 Method for Laboratory Determination of Water

(Moisture) Content of Soil and Rock by Mass

3. Terminology

D 2487 Practice for Classification of Soils for Engineering

Purposes (Unified Soil Classification System) 3.1 Definitions—Definitions are in accordance with Termi-

D 2488 Practice for Description and Identification of Soils nologies D 8, D 653, D 883, D 1600, and F 412 unless other-

(Visual-Manual Procedure) wise indicated. Abbreviations are in accordance with Termi-

D 2922 Test Method for Density of Soil and SoilAggregate nology D 1600, unless otherwise indicated.

In Place by Nuclear Methods (Shallow Depth) 3.1.1 The definitions and descriptions of soil are in accor-

D 3017 Test Method for Water Content of Soil and Rock In dance with the Unified Soil Classification System as presented

Place by Nuclear Methods (Shallow Depth) in Classification D 2487. Soils may be identified and described

D 4253 Test Methods for Maximum Index Density and Unit in the field using the procedures stated in Practice D 2488.

Weight of Soils Using a Vibratory Table

D 4254 Test Method for Minimum Index Density and Unit

Available from the American Water Works Association, 1401 New York Ave.,

NW, Suite 640, Washington, DC 20005.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from theAmericanAssociation of State Highway and Transportation

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Officials, 444 North Capitol St., NW, Suite 249, Washington DC 20001.

Standards volume information, refer to the standard’s Document Summary page on Available from the Uni-Bell PVC PipeAssoc., 2655Villa Creek Dr., Suite 155,

the ASTM website. Dallas, TX 75234.

F 1668–96 (2002)

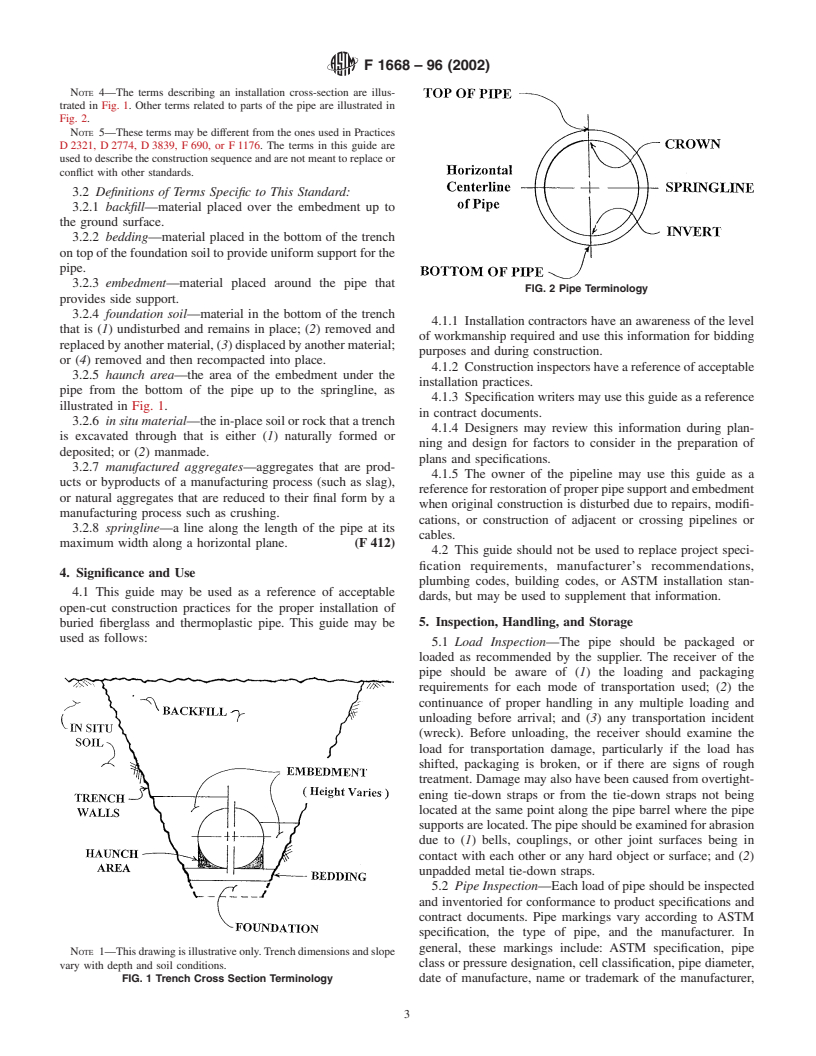

NOTE 4—The terms describing an installation cross-section are illus-

trated in Fig. 1. Other terms related to parts of the pipe are illustrated in

Fig. 2.

NOTE 5—These terms may be different from the ones used in Practices

D 2321, D 2774, D 3839, F 690, or F 1176. The terms in this guide are

used to describe the construction sequence and are not meant to replace or

conflict with other standards.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 backfill—material placed over the embedment up to

the ground surface.

3.2.2 bedding—material placed in the bottom of the trench

on top of the foundation soil to provide uniform support for the

pipe.

3.2.3 embedment—material placed around the pipe that

FIG. 2 Pipe Terminology

provides side support.

3.2.4 foundation soil—material in the bottom of the trench

4.1.1 Installation contractors have an awareness of the level

that is (1) undisturbed and remains in place; (2) removed and

of workmanship required and use this information for bidding

replacedbyanothermaterial,(3)displacedbyanothermaterial;

purposes and during construction.

or (4) removed and then recompacted into place.

4.1.2 Constructioninspectorshaveareferenceofacceptable

3.2.5 haunch area—the area of the embedment under the

installation practices.

pipe from the bottom of the pipe up to the springline, as

4.1.3 Specification writers may use this guide as a reference

illustrated in Fig. 1.

in contract documents.

3.2.6 in situ material—the in-place soil or rock that a trench

4.1.4 Designers may review this information during plan-

is excavated through that is either (1) naturally formed or

ning and design for factors to consider in the preparation of

deposited; or (2) manmade.

plans and specifications.

3.2.7 manufactured aggregates—aggregates that are prod-

4.1.5 The owner of the pipeline may use this guide as a

ucts or byproducts of a manufacturing process (such as slag),

referenceforrestorationofproperpipesupportandembedment

or natural aggregates that are reduced to their final form by a

when original construction is disturbed due to repairs, modifi-

manufacturing process such as crushing.

cations, or construction of adjacent or crossing pipelines or

3.2.8 springline—a line along the length of the pipe at its

cables.

maximum width along a horizontal plane. (F 412)

4.2 This guide should not be used to replace project speci-

fication requirements, manufacturer’s recommendations,

4. Significance and Use

plumbing codes, building codes, or ASTM installation stan-

4.1 This guide may be used as a reference of acceptable

dards, but may be used to supplement that information.

open-cut construction practices for the proper installation of

5. Inspection, Handling, and Storage

buried fiberglass and thermoplastic pipe. This guide may be

used as follows:

5.1 Load Inspection—The pipe should be packaged or

loaded as recommended by the supplier. The receiver of the

pipe should be aware of (1) the loading and packaging

requirements for each mode of transportation used; (2) the

continuance of proper handling in any multiple loading and

unloading before arrival; and (3) any transportation incident

(wreck). Before unloading, the receiver should examine the

load for transportation damage, particularly if the load has

shifted, packaging is broken, or if there are signs of rough

treatment. Damage may also have been caused from overtight-

ening tie-down straps or from the tie-down straps not being

located at the same point along the pipe barrel where the pipe

supportsarelocated.Thepipeshouldbeexaminedforabrasion

due to (1) bells, couplings, or other joint surfaces being in

contact with each other or any hard object or surface; and (2)

unpadded metal tie-down straps.

5.2 Pipe Inspection—Each load of pipe should be inspected

and inventoried for conformance to product specifications and

contract documents. Pipe markings vary according to ASTM

specification, the type of pipe, and the manufacturer. In

general, these markings include: ASTM specification, pipe

NOTE 1—Thisdrawingisillustrativeonly.Trenchdimensionsandslope

class or pressure designation, cell classification, pipe diameter,

vary with depth and soil conditions.

FIG. 1 Trench Cross Section Terminology date of manufacture, name or trademark of the manufacturer,

F 1668–96 (2002)

and plant identification. In some circumstances, the plant 5.5 Storage—Store the pipe in accordance with the manu-

inspector’s approval mark may also be required. Pipe intended facturer’s recommendations. Depending on the material, typi-

for the conveyance of potable water is evaluated

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.