IEC 62772:2023

(Main)Composite hollow core station post insulators with a.c. voltage greater than 1 000 V and d.c. voltage greater than 1 500 V - Definitions, test methods and acceptance criteria

Composite hollow core station post insulators with a.c. voltage greater than 1 000 V and d.c. voltage greater than 1 500 V - Definitions, test methods and acceptance criteria

IEC 62772:2023 applies to composite hollow core station post insulators consisting of a load-bearing insulating tube (core) made of resin impregnated fibres, insulating filler material (solid, liquid, gaseous – pressurized or unpressurized), a housing (outside the insulating tube) made of polymeric material (for example silicone or ethylene-propylene) and fixing devices at the ends of the insulating tube. Composite hollow core station post insulators as defined in this standard are intended for general use in substations in both, outdoor and indoor environments, operating with a rated AC voltage greater than 1 000 V and a frequency not greater than 100 Hz or for use in direct current systems with a rated voltage greater than 1 500 V DC. The object of this document is:

- to define the terms used;

- to specify test methods;

- to specify acceptance criteria.

Isolateurs supports composites creux présentant une tension alternative supérieure à 1 000 V et une tension continue supérieure à 1 500 V - Définitions, méthodes d'essai et critères d'acceptation

L'IEC 62772:2023 s’applique aux isolateurs supports composites creux qui sont constitués d’un tube (noyau) isolant en fibres imprégnées de résine supportant la charge mécanique, d’un matériau de charge interne (solide, liquide, gaz, sous pression ou pas), d’un revêtement en polymère à l’extérieur du tube isolant (par exemple silicone ou éthylène-propylène) et de dispositifs de fixation à ses extrémités. Les isolateurs supports composites creux, tels que définis dans la présente norme, sont destinés à l’utilisation générale dans les postes, tant en extérieur qu’en intérieur. Ils fonctionnent avec une tension alternative assignée de plus de 1 000 V en courant alternatif et à une fréquence maximale de 100 Hz, ou sont utilisés dans les systèmes à courant continu avec une tension assignée supérieure à 1 500 V en courant continu. Le présent document a pour objet:

- de définir les termes utilisés;

- de spécifier des méthodes d’essai;

- de spécifier les critères d’acceptation.

General Information

- Status

- Published

- Publication Date

- 14-Nov-2023

- Technical Committee

- TC 36 - Insulators

- Drafting Committee

- MT 24 - TC 36/MT 24

- Current Stage

- PPUB - Publication issued

- Start Date

- 15-Nov-2023

- Completion Date

- 22-Sep-2023

Relations

- Effective Date

- 05-Sep-2023

Overview

IEC 62772:2023 defines composite hollow core station post insulators for substations operating at AC voltages > 1 000 V (≤ 100 Hz) and DC voltages > 1 500 V. This second edition (Edition 2.0, 2023‑11) is a technical revision that updates terms and definitions, harmonizes required tests, revises selected test procedures and expands annexes (qualification of fillers; load definitions). The standard covers definitions, required test methods, and acceptance criteria for insulators comprising a resin‑impregnated fiber core, insulating filler (solid/liquid/gaseous), polymeric housing (e.g., silicone, EPDM) and end fittings.

Key topics and requirements

IEC 62772:2023 structures its conformity checks and technical content around clearly defined test classes and component evaluations:

- Classification of tests: design tests, type tests, sample tests and routine tests.

- Design and interface tests: verification of interfaces and end‑fitting connections, reference disruptive‑discharge voltage, thermal‑mechanical and water‑immersion pre‑stress.

- Mechanical tests: maximum design cantilever load (MDCL), torsion (MDToL), specified tension/compression and buckling tests, bending and assembled core load tests.

- Electrical tests: dry lightning impulse, switching impulse (dry/wet), dry and wet power‑frequency withstand voltages, internal pressure tests.

- Material and ageing tests: housing hardness, accelerated weathering, tracking and erosion (including 1 000 h salt‑fog AC test), flammability, hydrophobicity transfer.

- Core and filler integrity: porosity/dye‑penetration, water diffusion tests (core alone and core with housing), qualification procedures for fillers, routine seal leak‑rate tests.

- Documentation and marking: identification, transport, storage and installation information, and test reporting requirements.

Practical applications and who uses this standard

IEC 62772:2023 is intended for anyone involved in the design, manufacture, testing, procurement and operation of station post insulators in substations:

- Manufacturers - design validation, type approval and material qualification.

- Test laboratories and certification bodies - reference test procedures and acceptance criteria for certification and type testing.

- Utilities and asset owners - procurement specifications, acceptance testing, and lifecycle assurance.

- Design and installation engineers - guidance on mechanical/electrical load limits, installation, transport and storage conditions.

- Regulatory/compliance teams - harmonized requirements for international projects.

Related standards

- IEC 62217 - general requirements for polymeric insulator materials and interfaces.

- IEC 61462 - composite hollow insulators (pressurized/unpressurized) - definitions and design recommendations.

- IEC 62231 - composite station post insulators for substations.

- IEC TR 62039 - referenced for hydrophobicity transfer and related methods.

Keywords: IEC 62772:2023, composite hollow core station post insulators, test methods, acceptance criteria, substations, AC >1000 V, DC >1500 V, hydrophobicity, water diffusion, end fittings.

IEC 62772:2023 RLV - Composite hollow core station post insulators with a.c. voltage greater than 1 000 V and d.c. voltage greater than 1 500 V - Definitions, test methods and acceptance criteria Released:11/15/2023 Isbn:9782832278994

IEC 62772:2023 - Composite hollow core station post insulators with a.c. voltage greater than 1 000 V and d.c. voltage greater than 1 500 V - Definitions, test methods and acceptance criteria Released:15. 11. 2023

Frequently Asked Questions

IEC 62772:2023 is a standard published by the International Electrotechnical Commission (IEC). Its full title is "Composite hollow core station post insulators with a.c. voltage greater than 1 000 V and d.c. voltage greater than 1 500 V - Definitions, test methods and acceptance criteria". This standard covers: IEC 62772:2023 applies to composite hollow core station post insulators consisting of a load-bearing insulating tube (core) made of resin impregnated fibres, insulating filler material (solid, liquid, gaseous – pressurized or unpressurized), a housing (outside the insulating tube) made of polymeric material (for example silicone or ethylene-propylene) and fixing devices at the ends of the insulating tube. Composite hollow core station post insulators as defined in this standard are intended for general use in substations in both, outdoor and indoor environments, operating with a rated AC voltage greater than 1 000 V and a frequency not greater than 100 Hz or for use in direct current systems with a rated voltage greater than 1 500 V DC. The object of this document is: - to define the terms used; - to specify test methods; - to specify acceptance criteria.

IEC 62772:2023 applies to composite hollow core station post insulators consisting of a load-bearing insulating tube (core) made of resin impregnated fibres, insulating filler material (solid, liquid, gaseous – pressurized or unpressurized), a housing (outside the insulating tube) made of polymeric material (for example silicone or ethylene-propylene) and fixing devices at the ends of the insulating tube. Composite hollow core station post insulators as defined in this standard are intended for general use in substations in both, outdoor and indoor environments, operating with a rated AC voltage greater than 1 000 V and a frequency not greater than 100 Hz or for use in direct current systems with a rated voltage greater than 1 500 V DC. The object of this document is: - to define the terms used; - to specify test methods; - to specify acceptance criteria.

IEC 62772:2023 is classified under the following ICS (International Classification for Standards) categories: 29.080.10 - Insulators. The ICS classification helps identify the subject area and facilitates finding related standards.

IEC 62772:2023 has the following relationships with other standards: It is inter standard links to IEC 62772:2016. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase IEC 62772:2023 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of IEC standards.

Standards Content (Sample)

IEC 62772 ®

Edition 2.0 2023-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Composite hollow core station post insulators for substations with a.c. voltage

greater than 1 000 V and d.c. voltage greater than 1 500 V – Definitions, test

methods and acceptance criteria

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

IEC 62772 ®

Edition 2.0 2023-11

REDLINE VERSION

INTERNATIONAL

STANDARD

colour

inside

Composite hollow core station post insulators for substations with a.c. voltage

greater than 1 000 V and d.c. voltage greater than 1 500 V – Definitions, test

methods and acceptance criteria

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

ICS 29.080.10 ISBN 978-2-8322-7899-4

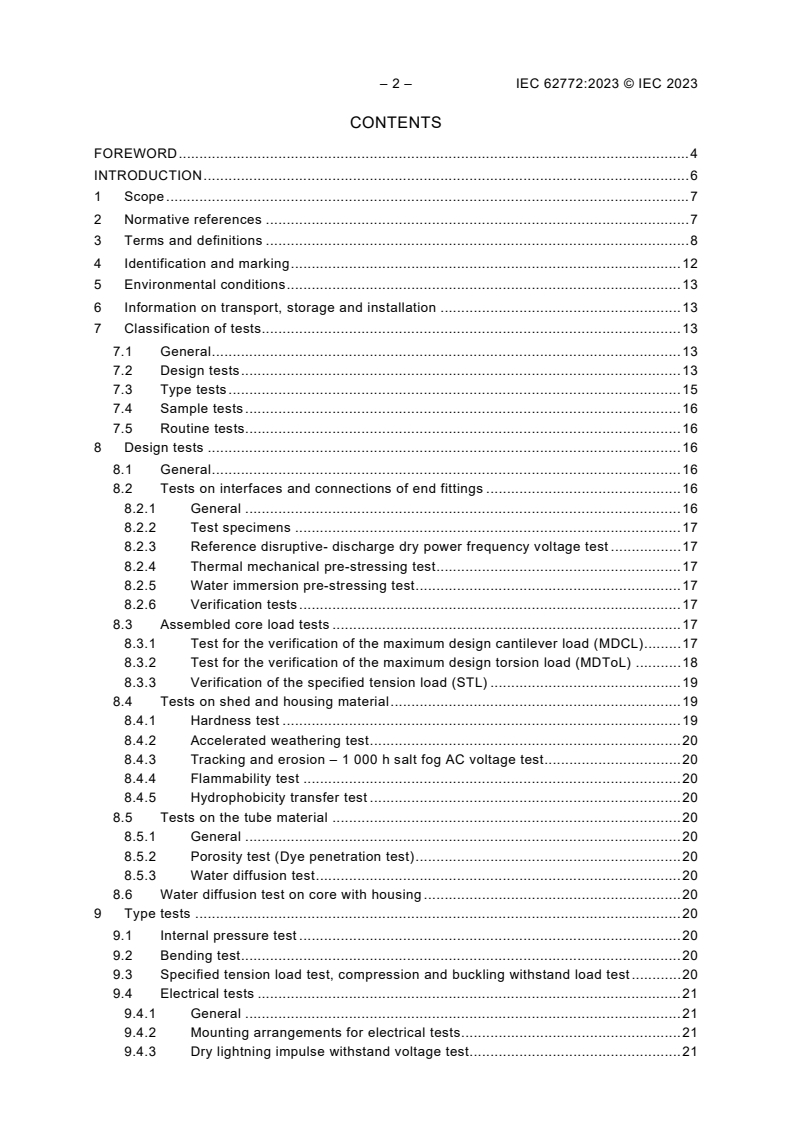

– 2 – IEC 62772:2023 RLV © IEC 2023

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Identification and marking . 13

5 Environmental conditions . 13

6 Information on transport, storage and installation . 13

7 Classification of tests. 14

7.1 General . 14

7.2 Design tests . 14

7.3 Type tests . 17

7.4 Sample tests . 18

7.5 Routine tests. 18

8 Design tests . 18

8.1 General . 18

8.2 Tests on interfaces and connections of end fittings . 18

8.2.1 General . 18

8.2.2 Test specimens . 19

8.2.3 Reference disruptive- discharge dry power frequency voltage test . 19

8.2.4 Thermal mechanical pre-stressing test . 19

8.2.5 Water immersion pre-stressing test . 19

8.2.6 Verification tests . 19

8.3 Assembled core load tests . 20

8.3.1 Test for the verification of the maximum design cantilever load (MDCL) . 20

8.3.2 Test for the verification of the maximum design torsion load (MDToL) . 20

8.3.3 Verification of the specified tension load (STL) . 21

8.4 Tests on shed and housing material . 22

8.4.1 General Hardness test . 22

8.4.2 Accelerated weathering test . 22

8.4.3 Tracking and erosion test – 1 000 h salt fog AC voltage test . 22

8.4.4 Flammability test . 22

8.4.5 Hydrophobicity transfer test . 22

8.5 Tests on the tube material . 22

8.5.1 General . 22

8.5.2 Porosity test (Dye penetration test) . 22

8.5.3 Water diffusion test . 22

8.6 Water diffusion test on core with housing . 22

9 Type tests . 23

9.1 Internal pressure test . 23

9.2 Bending test . 23

9.3 Specified tension load test, compression and buckling withstand load test . 23

9.4 Electrical tests . 23

9.4.1 General . 23

9.4.2 Mounting arrangements for electrical tests . 23

9.4.3 Dry lightning impulse withstand voltage test. 23

9.4.4 Dry or wet switching impulse withstand voltage test . 24

9.4.5 Dry power-frequency withstand voltage test . 24

9.4.6 Wet power-frequency withstand voltage test . 24

9.5 Wet switching impulse withstand voltage .

10 Sample tests . 24

11 Routine tests . 24

11.1 General . 24

11.2 Routine seal leak rate test . 24

11.2.1 General . 24

11.2.2 Test procedure . 24

11.2.3 Acceptance criteria . 25

12 Documentation . 25

Annexe A (informative) Water diffusion test Qualification of fillers . 26

A.1 General . 26

A.2 Dye penetration test with solid filler . 26

A.3 Water diffusion test with solid filler . 26

A.4 Tests on interfaces and connections of end fittings with filler . 26

Annexe B (informative) Load definitions, relationship of loads . 28

Annexe C (informative) Principle sketch of hollow insulators design assembly . 31

Bibliography . 33

Figure A.1 – Example of sample preparation for water diffusion test . 27

Figure B.1 – Definitions according to IEC 62231 . 28

Figure B.2 – Definitions according to IEC 61462 . 29

Figure B.3 – Comparison of definitions IEC 61462 vs. IEC 62231 . 30

Figure C.1 – Interface description for insulator with housing made by modular

assembly . 31

Figure C.2 – Interface description for insulator with housing made by injection

moulding and ouvermold end fitting . 32

Table 1 – Required design and type tests . 15

– 4 – IEC 62772:2023 RLV © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMPOSITE HOLLOW CORE STATION POST

INSULATORS FOR SUBSTATIONS

WITH AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

This redline version of the official IEC Standard allows the user to identify the changes

made to the previous edition IEC 62772:2016. A vertical bar appears in the margin

wherever a change has been made. Additions are in green text, deletions are in

strikethrough red text.

IEC 62772 has been prepared by IEC technical committee 36: Insulators. It is an International

Standard.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modifications of terms and definitions;

b) modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity

transfer test; Water diffusion test on the core with housing);

c) harmonization of Table 1 (Required design and type tests) with other product standards;

d) update of Annex A (Qualification of fillers);

e) addition of a new informative Annex B (Load definitions, relationship of loads).

The text of this International Standard is based on the following documents:

Draft Report on voting

36/569/FDIS 36/587/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62772:2023 RLV © IEC 2023

INTRODUCTION

Composite hollow core station post insulators consist of an insulating hollow core (tube),

bearing the mechanical load protected by a polymeric housing, the load being transmitted to

the core by end fittings. The hollow core is filled entirely with an insulating material. The core

is made of resin impregnated fibres.

Composite hollow core station post insulators are typically applied as post insulators in

substations. In order to perform the design tests, IEC 62217 is to be applied for materials and

interfaces of the insulator. Some tests have been grouped together as "design tests", to be

performed only once on insulators which satisfy the same design conditions. For all design tests

on composite hollow core station post insulators, the common clauses defined in IEC 62217 are

applied. As far as practical, the influence of time on the electrical and mechanical properties of

the components (core material, housing, interfaces etc.) and of the complete composite hollow

core station post insulator has been considered in specifying the design tests to ensure a

satisfactory life-time under normally known stress conditions in service.

This document relates to IEC 61462, Composite hollow insulators – Pressurized and

unpressurized insulators for use in electrical equipment with rated voltage greater than 1 000 V

– Definitions, test methods, acceptance criteria and design recommendations, as well as

IEC 62231, Composite station post insulators for substations with AC voltages greater than

1 000 V up to 245 kV – Definitions, test methods and acceptance criteria. Tests and

requirements described in IEC 62231 can be used although this standard has no despite the

intended operating voltage limit for substations.

The use of polymeric housing materials that show hydrophobicity and hydrophobicity transfer

mechanism (HTM) is preferred for composite hollow core station post insulators. This is due to

the fact that the influence of diameter can be significant for hydrophilic surfaces (see also

IEC 60815-3). For instance silicone rubber is recognized as successful countermeasure against

severe polluted service conditions. The ageing performance of the polymeric housing can be

evaluated by the salt fog test standardized in IEC 62217. For the time being, no test is defined

to quantify the HTM, but CIGRE SC D.1 deals with this subject intensively and Technical

Brochure No. 442 is available for the evaluation of the retention of the hydrophobicity. For the

time being, the 1 000 h AC tracking and erosion test of IEC 62217 is used to establish a

minimum requirement for the tracking and erosion resistance, for both AC and DC.

Composite hollow core station post insulators are used in both AC and DC applications. Before

the appropriate standard for DC applications will be issued, the majority of tests listed in this

standard can also be applied to DC insulators. In spite of this, a specific tracking and erosion

test procedure for DC applications as a design test is still being considered to be developed.

Some information about the difference of AC and DC material erosion test can be found in the

CIGRE Technical Brochure 611 [8] . For the time being, the 1 000 h AC tracking and erosion

test of IEC 62217 is used to establish a minimum requirement for the tracking and erosion

resistance.

___________

Numbers in square brackets refer to the Bibliography.

COMPOSITE HOLLOW CORE STATION POST

INSULATORS FOR SUBSTATIONS

WITH AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

1 Scope

This document, which is an International Standard, applies to composite hollow core station

post insulators consisting of a load-bearing insulating tube (core) made of resin impregnated

fibres, insulating filler material (e.g. solid, liquid, foam, gaseous – pressurized or

unpressurized), a housing (outside the insulating tube) made of polymeric material (for example

silicone or ethylene-propylene) and metal fixing devices at the ends of the insulating tube.

Composite hollow core station post insulators as defined in this standard are intended for

general use in substations in both, outdoor and indoor environments, operating with a rated AC

voltage greater than 1 000 V and a frequency not greater than 100 Hz or for use in direct

current systems with a rated voltage greater than 1 500 V DC.

The object of this document is:

– to define the terms used;

– to prescribe specify test methods;

– to prescribe specify acceptance criteria.

All the tests in this document, apart from the thermal-mechanical test, are performed at normal

ambient temperature. This document does not prescribe specify tests that may be are

characteristic of the apparatus of which the composite hollow core station post insulator

ultimately may form a part (e.g. disconnector switch, reactor support, HVDC valves). Further

technical input is required in this area.

NOTE 1 "Pressurized" means a permanent gas or liquid pressure greater than 0,05 MPa (0,5 bar) gauge. The gas

can be dry air or inert gases, for example sulphur hexafluoride, nitrogen, or a mixture of such gases.

NOTE 2 "Unpressurized" means a gas or liquid pressure smaller than or equal to 0,05 MPa (0,5 bar) gauge.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60060-1:2010, High-voltage test techniques – Part 1: General definitions and test

requirements

IEC 60168:2001, Tests on indoor and outdoor post insulators of ceramic material or glass for

systems with nominal voltages greater than 1000 V

IEC 61109:2008, Insulators for overhead lines – Composite suspension and tension insulators

for AC systems with a nominal voltage greater than 1 000 V – Definitions, test methods and

acceptance criteria

– 8 – IEC 62772:2023 RLV © IEC 2023

IEC 61462:2007, Composite hollow insulators – Pressurized and unpressurized insulators for

use in electrical equipment with rated voltage greater than 1 000 V – Definitions, test methods,

acceptance criteria and design recommendations

IEC 62217:2012, Polymeric HV insulators for indoor and outdoor use – General definitions, test

methods and acceptance criteria

IEC 62231:2006, Composite station post insulators for substations with AC voltages greater

than 1 000 V up to 245 kV – Definitions, test methods and acceptance criteria

IEC TR 62039, Selection guidelines for polymeric materials for outdoor use under HV stress

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

composite hollow core station post insulator

post insulator, consisting of at least three insulating parts, namely a tube, a housing with or

without sheds, and an internal filler and a housing

Note 1 to entry: The housing may consist either of individual sheds mounted on the tube, with or without an

intermediate sheath, or directly applied in one or several pieces onto the tube. A composite hollow core station post

insulator unit is permanently equipped with fixing devices.

Note 1 to entry: End fittings are attached to the insulating tube. The housing, with or without sheds, may be omitted

in case of specific environmental conditions (e.g. indoor).

Note 2 to entry: A hollow insulator can be made from one or more permanently assembled insulating elements

3.2

post insulator

insulator intended to give rigid support to a live part which is to be insulated from earth or from

another live part

Note 1 to entry: A post insulator may be an assembly of a number of post insulator units (stack).

Note 2 to entry: Post insulators for substations are also known as station post insulators.

[SOURCE: IEC 60050-471:2007, 471-04-01, modified – addition of "(stack)" in Note 1 to entry]

3.3

tube (core)

central internal insulating part of a composite hollow core station post insulator designed to

ensure which provides the mechanical characteristics

Note 1 to entry: The tube is generally cylindrical or conical, but may have other shapes (for example barrel). The

tube is made of resin impregnated fibres. The housing, insulating filler material and sheds are not part of the core.

Note 2 to entry: Resin impregnated fibres are structured in such a manner as to achieve sufficient mechanical

strength. Layers of different fibres may be used to fulfil special requirements.

3.4

filler

insulating material filling the entire internal space (e.g. solid, liquid, foam, gaseous –

pressurized or unpressurized) of the hollow core station post insulator which has no load

bearing function

3.5

fixing device (end fitting)

integral component or formed part of an insulator intended to connect it to a supporting

structure, or to a conductor, or to an item of equipment, or to another insulator

Note 1 to entry: Where the end fitting is metallic, the term "metal fitting" is normally used.

[SOURCE: IEC 60050-471:2007, 471-01-06, modified – addition of "fixing device" in term]

3.6

coupling

part of the end fitting which transmits the load to the accessories external to the insulator

[SOURCE: IEC 62217:2012, 3.1314]

3.7

connection zone

zone where the mechanical load is transmitted between the insulating body and the end fitting

[SOURCE: IEC 62217:2012, 3.1213]

3.8

housing

external insulating part of composite hollow core station post insulator providing necessary

creepage distance and protecting the tube from the environment

Note 1 to entry: If an intermediate sheath is used it forms a part of the housing.

[SOURCE: IEC 62217:2012, definition 3.7, modified ("composite insulator" replaced by

"composite hollow core station post insulator", "protecting core" replaced by "protecting the

tube")]

3.9

shed

insulating part, projecting from the insulator trunk, intended to increase the creepage distance

Note 1 to entry: The shed can be with or without ribs.

[SOURCE: IEC 60050-471:2007, 471-01-15]

3.10

insulator trunk

central insulating part of an insulator from which the sheds protrude project

Note 1 to entry: Also known as shank on smaller insulators.

[SOURCE: IEC 60050-471:2007, 471-01-11]

3.11

creepage distance

shortest distance or the sum of the shortest distances along the surface of an insulator between

two conductive parts which normally have the operating voltage between them

– 10 – IEC 62772:2023 RLV © IEC 2023

Note 1 to entry: The surface of any non-insulating jointing material is not considered as forming part of the creepage

distance.

Note 2 to entry: If a high resistance coating is applied to parts of the insulating part of an insulator, such parts are

considered to be effective insulating surfaces and the distance over them is included in the creepage distance.

[SOURCE: IEC 60050-471:2007, 471-01-04, modified – removal of Note 2 to entry]

3.12

arcing distance

shortest distance in the air external to the insulator between the metallic parts which normally

have the operating voltage between them

[SOURCE: IEC 60050-471:2007, 471-01-01]

3.13

interface

contact surface between the different materials

Note 1 to entry: Various interfaces occur in most composite insulators (cf. Annex C), e.g.

– between housing and end fittings,

– between various parts of the housing; e.g. between sheds, or between sheath and sheds,

– between core tube and housing

– between core tube and filler.

[SOURCE: IEC 62217:2012, 3.11, modified – addition of "contact"]

3.14

damage limit of the tube under mechanical stress

limit below which mechanical loads can be applied, at normal ambient temperature, without

micro damage to the composite tube

Note 1 to entry: Applying such loads means that the tube is in a reversible elastic phase. If the damage limit of the

tube is exceeded, the tube is in an irreversible plastic phase, which means permanent damage to the tube which may

not be visible at a macroscopic level (for a quantitative definition see Annex C of IEC 61462:1997).

3.15

maximum mechanical load

MML

highest cantilever bending load which is expected to be applied to the composite hollow core

station post insulators in accordance with IEC 61462

Note 1 to entry: The MML of the composite hollow core station post insulator is specified by the insulator

manufacturer.

3.16

specified mechanical load

SML

cantilever bending load specified by the manufacturer that is used in the mechanical tests, in

accordance with IEC 61462 and which is verified during a type test at normal ambient

temperature

Note 1 to entry The load is normally applied by bending at normal ambient temperature.

Note 2 1 to entry: The SML forms the basis of the selection of composite hollow station post insulators with regard

to external loads.

3.17

specified cantilever load

SCL

cantilever load which can to be withstood by the insulator when tested under the prescribed

specified conditions in accordance with IEC 62231

3.18

maximum design cantilever load

MDCL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

Note 1 to entry: In the context of this standard (IEC 62772) MDCL is considered to be equal to 1,25 times MML as

determined in IEC 61462:1997, Clause 8 or 0,5 times of SML. For more information to load philosopies and

relationships, see Annex B.

3.19

specified torsion load

SToL

torsion load level which can be withstood by the insulator when tested under the prescribed

specified conditions in accordance with IEC 62231

3.20

maximum design torsion load

MDToL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

3.21

specified tension load

STL

tension load which can be withstood by the insulator when tested under the prescribed specified

conditions in accordance with IEC 62231

3.22

maximum design tension load

MDTL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

3.23

specified compression load

SCoL

compression load which can to be withstood by the insulator when tested under the prescribed

specified conditions in accordance with IEC 62231

3.24

buckling load

compression load that induces buckling of the insulator core in accordance with IEC 62231

3.25

maximum design compression load

MDCoL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231 and IEC 61462

3.26

failing load of a composite hollow core station post insulator

load at ultimate failure of the insulator, maximum load that can be reached when the insulator

is tested under the prescribed specified conditions (valid for bending or pressure tests)

Note 1 to entry: Damage to the core and / or the connection zone tube is likely to occur at loads lower than the

insulator failing load.

– 12 – IEC 62772:2023 RLV © IEC 2023

3.27

deflection under cantilever load

displacement of a point on an insulator, measured perpendicularly to its axis, under the effect

of a load applied perpendicularly to this axis

Note 1 to entry: Deflection/load relationships are determined by the manufacturer.

3.28

residual deflection

difference between the initial deflection of a composite hollow core station post insulator prior

to bending load application, and the final deflection after release of the load

Note 1 to entry: The measurement of residual deflection serves for qualitative comparison with strain gauge

measurements.

3.29

residual angular displacement

difference between the initial angular displacement, if any, of one of the insulator end fitting

with respect to the other insulator end fitting measured prior to the application of the torsion

load and the final angular displacement measured after torsion load release

Note 1 to entry: The residual angular displacement may depend on the duration of application of the torsion load

and on the time duration between the torsion load release and the measurement of the displacement.

3.30

overpressure

pressure above ambient pressure within a pressurized enclosure

[SOURCE: IEC 60050-426:2020, 426-09-16]

3.31

maximum service pressure

MSP

difference between the maximum absolute internal pressure at maximum operational

temperature and the normal outside pressure

maximum overpressure in service which is specified by the equipment manufacturer

3.32

specified internal pressure

SIP

internal overpressure specified by the manufacturer which is verified during a type test at normal

ambient temperature

Note 1 to entry: The SIP forms the basis of the selection of composite hollow station post insulators with respect to

internal pressure.

Note 1 to entry The MSP of the composite hollow core station post insulator is specified by the insulator

manufacturer.

Note 2 to entry The MSP is equivalent to "design pressure" as used for ceramic hollow insulators (see IEC 62155).

Note 1 to entry: The SIP is specified as the short-time withstand design limit, under which the insulator structure

stays intact, but damages may already occur. It can be higher than 4 × MSP.

3.33

pressurized insulator

insulator permanently filled with gas or liquid whose maximum service pressure is greater than

0,05 MPa overpressure

3.34

unpressurized insulator

insulator is an insulator permanently filled with gas or liquid whose maximum service pressure

is smaller than or equal to 0,05 MPa overpressure

3.35

specified temperatures

highest and lowest temperature permissible for the composite hollow core station post insulator

Note 1 to entry: The specified temperatures are specified by the manufacturer.

3.36

manufacturer

individual or organization producing the composite hollow core station post insulator

3.37

equipment manufacturer

individual or organization producing the electrical equipment utilizing the composite hollow core

station post insulator

3.38

lot

group of insulators offered for acceptance from the same manufacturer, of the same design and

manufactured under similar conditions of production

Note 1 to entry: One or more lots may be offered together for acceptance: the lot(s) offered may consist of the

whole, or part, of the quantity ordered.

[SOURCE: IEC 62155:2003, 3.22, modified – removal of "hollow", removal of "or hollow

insulator bodies"]

4 Identification and marking

The manufacturer's drawing shall show the relevant dimensions and values necessary for

identifying and testing the insulator in accordance with this document. The drawing shall also

show applicable manufacturing tolerances. In addition, the relevant IEC designation, when

available, shall be stated on the drawing.

Each composite hollow core station post insulator shall be marked with the name or trade mark

of the manufacturer and the year of manufacture. In addition, each hollow core station post

composite insulator shall be marked with the type reference and serial numbers in order to allow

identification. In addition, each insulator shall be marked with at least the maximum design

mechanical load, for example: MDCL: 4 kN. This marking shall be legible and indelible.

5 Environmental conditions

See description in IEC 62217.

6 Information on transport, storage and installation

See description in IEC 62217.

– 14 – IEC 62772:2023 RLV © IEC 2023

7 Classification of tests

7.1 General

The tests are divided into groups as follows:

7.2 Design tests

These tests are intended to verify the suitability of the design, materials and manufacturing

technology.

A composite hollow core station post insulators design is defined by:

– Materials, formulation and design of the tube, housing, filler and manufacturing method,

– material of the end fittings, their design and method of attachment,

– layer thickness of the housing over the tube (including a sheath where used).

For new designs and when changes in the design occur, re-qualification shall be done according

to Table 1.

Table 1 – Required design and type tests

THEN the following tests shall be repeated:

Design Tests Type Tests

If a new design is made or if the change in

insulator design concerns:

1 Housing materials X X X X X

a

2 Housing profile X X

3 Tube material X X X X X

b

X X X X

4 Tube design

c

Manufacturing process of housing X X X X

d

6 Manufacturing process of tube X X X X X

7 End fitting material X X X

e

X X X

8 End fitting method of attachment to tube

9 Tube-housing-end fitting interface design X X X

10 Filling material and / or method X X X X

a

The following variation of the housing profile within following tolerances do not constitute a change:

Overhang of sheds: ±10 %; Spacing: ±10 %; Mean inclination of sheds: ±3°; Thickness at root and tip of sheds:

±15 %; Shed repetition: identical.

b

Liner, winding angle

c

Curing and moulding method (e.g. extrusion, injection, single shed assembly…)

d

Pultrusion, wet filament winding, vacuum impregnation, including surface preparation

e

Applications: bending, pressure, combined pressure-bending

f

one sample smallest OD and smallest wall thickness, and one sample largest OD and smallest wall thickness

Assembled core load test,

f

only 8.3.1

Interfaces and connections

of end fittings

Hardness test

Accelerated weathering test

Tracking and erosion test

Flammability test

Dye penetration test

Water diffusion test

Mechanical type tests

Electrical type tests

– 16 – IEC 62772:2023 RLV © IEC 2023

a)

IF the change in insulator

THEN the following tests shall be repeated:

design concerns:

Design tests Type tests

IEC 6277 IEC 62772

2:-, :-,

IEC 62

IEC 62772:-, 8.4 IEC 627

IEC 62 IEC 62

8.5 8.6 772:-,

72:-,

772:-, 772:-,

Tests on shed and housing

8.2 8.3.1

Tests on Tests on 9.1,

material 9.4

the tube tube with 9.2,

material housing 9.3

1 Housing

Materials, formulation

d) d) d) e) a)

1a or manufacturing

X X X X X X X

process

c)

1b Assembly process X

X

b)

1c Profile

X X

2 Tube

Material, formulation

a)

or manufacturing

2a X X X X X

X

process

2b Design X X X X

3 End fitting

Material or assembly

3a X X X

process

End fitting connection

3b

X X

zone design

4 Interface

Primer material and

a)

4a

X X

application method

Tube and end-fitting

4b

X X X

assembly process

Tube/housing/end fitting

4c X X X X

interface design

Filling material or

X X

method

Interfaces and

connections of end

fittings

Assembled core load

test

Hardness test

Accelerated

weathering test

Tracking and erosion

test

Flammability test

Hydrophobicity

transfer test

Porosity test (Dye

penetration test)

Water diffusion test

Water Diffusion Test

on Core with

Housing

Electrical type tests

Mechanical type

tests

a)

Explanation

Not necessary if it can be demonstrated that the change has no influence on the property

a) e)

to : considered in the test; material tests could be used to show the equivalence

Additional

b)

Not necessary if thickness of the housing surrounding the core (including a sheath where

information for

used) is equal or greater than that of the parent insulator. Following relative numbers as

which specific

tolerances are provided as reference, which do not constitute a change of the profile:

changes testing

needs to be done

– overhang: ±10 %

– thickness at base and tip: ±15 %

– spacing: ±15 %

– shed inclinations: ±3°

– shed repetition: identical.

These relatively small tolerances serve as reference, however cause a high test demand due

to the variety of today`s profiles. Alternatively, a technical agreement between manufacturer

and user in agreement with chapter 9.1 is possible if the equivalence of the profile evaluated in

the tracking and erosion test to the profile in question can be shown. A possible method is the

interpolation of results with different profiles.

c)

Not necessary if it can be demonstrated that the change has no influence on the property

considered in the test.

d)

Not necessary for change in manufacturing process without material change

e)

Applicable to materials that shall show this property

Explanation

Housing manufacturing process:

1 6

to : Technical General manufacturing method such as injection moulding, modular process etc.

explanation of

Housing assembly process:

hollow core

If shed and sheath are mounted separately to the tube, incl. type and method of bonding

insulator

shed-sheath

components

Tube manufacturing method: Pultrusion, wet filament winding, vacuum impregnation,

including surface preparation

Liner and winding angle

See Annex C for further explanation

See Annex A for further explanation

7.3 Type tests

Type test

...

IEC 62772 ®

Edition 2.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Composite hollow core station post insulators with a.c. voltage greater than

1 000 V and d.c. voltage greater than 1 500 V – Definitions, test methods and

acceptance criteria

Isolateurs supports composites creux présentant une tension alternative

supérieure à 1 000 V et une tension continue supérieure à 1 500 V – Définitions,

méthodes d'essai et critères d'acceptation

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form

or by any means, electronic or mechanical, including photocopying and microfilm, without permission in writing from

either IEC or IEC's member National Committee in the country of the requester. If you have any questions about IEC

copyright or have an enquiry about obtaining additional rights to this publication, please contact the address below or

your local IEC member National Committee for further information.

Droits de reproduction réservés. Sauf indication contraire, aucune partie de cette publication ne peut être reproduite ni

utilisée sous quelque forme que ce soit et par aucun procédé, électronique ou mécanique, y compris la photocopie et

les microfilms, sans l'accord écrit de l'IEC ou du Comité national de l'IEC du pays du demandeur. Si vous avez des

questions sur le copyright de l'IEC ou si vous désirez obtenir des droits supplémentaires sur cette publication, utilisez

les coordonnées ci-après ou contactez le Comité national de l'IEC de votre pays de résidence.

IEC Secretariat Tel.: +41 22 919 02 11

3, rue de Varembé info@iec.ch

CH-1211 Geneva 20 www.iec.ch

Switzerland

About the IEC

The International Electrotechnical Commission (IEC) is the leading global organization that prepares and publishes

International Standards for all electrical, electronic and related technologies.

About IEC publications

The technical content of IEC publications is kept under constant review by the IEC. Please make sure that you have the

latest edition, a corrigendum or an amendment might have been published.

IEC publications search - webstore.iec.ch/advsearchform IEC Products & Services Portal - products.iec.ch

The advanced search enables to find IEC publications by a Discover our powerful search engine and read freely all the

variety of criteria (reference number, text, technical publications previews. With a subscription you will always have

committee, …). It also gives information on projects, replaced access to up to date content tailored to your needs.

and withdrawn publications.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

The world's leading online dictionary on electrotechnology,

Stay up to date on all new IEC publications. Just Published

containing more than 22 300 terminological entries in English

details all new publications released. Available online and once

and French, with equivalent terms in 19 additional languages.

a month by email.

Also known as the International Electrotechnical Vocabulary

(IEV) online.

IEC Customer Service Centre - webstore.iec.ch/csc

If you wish to give us your feedback on this publication or need

further assistance, please contact the Customer Service

Centre: sales@iec.ch.

A propos de l'IEC

La Commission Electrotechnique Internationale (IEC) est la première organisation mondiale qui élabore et publie des

Normes internationales pour tout ce qui a trait à l'électricité, à l'électronique et aux technologies apparentées.

A propos des publications IEC

Le contenu technique des publications IEC est constamment revu. Veuillez vous assurer que vous possédez l’édition la

plus récente, un corrigendum ou amendement peut avoir été publié.

Recherche de publications IEC - IEC Products & Services Portal - products.iec.ch

webstore.iec.ch/advsearchform Découvrez notre puissant moteur de recherche et consultez

La recherche avancée permet de trouver des publications IEC gratuitement tous les aperçus des publications. Avec un

en utilisant différents critères (numéro de référence, texte, abonnement, vous aurez toujours accès à un contenu à jour

comité d’études, …). Elle donne aussi des informations sur les adapté à vos besoins.

projets et les publications remplacées ou retirées.

Electropedia - www.electropedia.org

IEC Just Published - webstore.iec.ch/justpublished

Le premier dictionnaire d'électrotechnologie en ligne au monde,

Restez informé sur les nouvelles publications IEC. Just

avec plus de 22 300 articles terminologiques en anglais et en

Published détaille les nouvelles publications parues.

français, ainsi que les termes équivalents dans 19 langues

Disponible en ligne et une fois par mois par email.

additionnelles. Egalement appelé Vocabulaire

Electrotechnique International (IEV) en ligne.

Service Clients - webstore.iec.ch/csc

Si vous désirez nous donner des commentaires sur cette

publication ou si vous avez des questions contactez-nous:

sales@iec.ch.

IEC 62772 ®

Edition 2.0 2023-11

INTERNATIONAL

STANDARD

NORME

INTERNATIONALE

colour

inside

Composite hollow core station post insulators with a.c. voltage greater than

1 000 V and d.c. voltage greater than 1 500 V – Definitions, test methods and

acceptance criteria

Isolateurs supports composites creux présentant une tension alternative

supérieure à 1 000 V et une tension continue supérieure à 1 500 V – Définitions,

méthodes d'essai et critères d'acceptation

INTERNATIONAL

ELECTROTECHNICAL

COMMISSION

COMMISSION

ELECTROTECHNIQUE

INTERNATIONALE

ICS 29.080.10 ISBN 978-2-8322-7404-0

– 2 – IEC 62772:2023 © IEC 2023

CONTENTS

FOREWORD . 4

INTRODUCTION . 6

1 Scope . 7

2 Normative references . 7

3 Terms and definitions . 8

4 Identification and marking . 12

5 Environmental conditions . 13

6 Information on transport, storage and installation . 13

7 Classification of tests. 13

7.1 General . 13

7.2 Design tests . 13

7.3 Type tests . 15

7.4 Sample tests . 16

7.5 Routine tests. 16

8 Design tests . 16

8.1 General . 16

8.2 Tests on interfaces and connections of end fittings . 16

8.2.1 General . 16

8.2.2 Test specimens . 17

8.2.3 Reference disruptive- discharge dry power frequency voltage test . 17

8.2.4 Thermal mechanical pre-stressing test . 17

8.2.5 Water immersion pre-stressing test . 17

8.2.6 Verification tests . 17

8.3 Assembled core load tests . 17

8.3.1 Test for the verification of the maximum design cantilever load (MDCL) . 17

8.3.2 Test for the verification of the maximum design torsion load (MDToL) . 18

8.3.3 Verification of the specified tension load (STL) . 19

8.4 Tests on shed and housing material . 19

8.4.1 Hardness test . 19

8.4.2 Accelerated weathering test . 20

8.4.3 Tracking and erosion – 1 000 h salt fog AC voltage test . 20

8.4.4 Flammability test . 20

8.4.5 Hydrophobicity transfer test . 20

8.5 Tests on the tube material . 20

8.5.1 General . 20

8.5.2 Porosity test (Dye penetration test) . 20

8.5.3 Water diffusion test . 20

8.6 Water diffusion test on core with housing . 20

9 Type tests . 20

9.1 Internal pressure test . 20

9.2 Bending test . 20

9.3 Specified tension load test, compression and buckling withstand load test . 20

9.4 Electrical tests . 21

9.4.1 General . 21

9.4.2 Mounting arrangements for electrical tests . 21

9.4.3 Dry lightning impulse withstand voltage test. 21

9.4.4 Dry or wet switching impulse withstand voltage test . 21

9.4.5 Dry power-frequency withstand voltage test . 21

9.4.6 Wet power-frequency withstand voltage test . 21

10 Sample tests . 21

11 Routine tests . 22

11.1 General . 22

11.2 Routine seal leak rate test . 22

11.2.1 General . 22

11.2.2 Test procedure . 22

11.2.3 Acceptance criteria . 22

12 Documentation . 23

Annex A (informative) Qualification of fillers . 24

A.1 General . 24

A.2 Dye penetration test with solid filler . 24

A.3 Water diffusion test with solid filler . 24

A.4 Tests on interfaces and connections of end fittings with filler . 24

Annex B (informative) Load definitions, relationship of loads . 26

Annex C (informative) Principle sketch of hollow insulators design assembly . 29

Bibliography . 31

Figure A.1 – Example of sample preparation for water diffusion test . 25

Figure B.1 – Definitions according to IEC 62231 . 26

Figure B.2 – Definitions according to IEC 61462 . 27

Figure B.3 – Comparison of definitions IEC 61462 vs. IEC 62231 . 28

Figure C.1 – Interface description for insulator with housing made by modular

assembly . 29

Figure C.2 – Interface description for insulator with housing made by injection

moulding and ouvermold end fitting . 30

Table 1 – Required design and type tests . 14

– 4 – IEC 62772:2023 © IEC 2023

INTERNATIONAL ELECTROTECHNICAL COMMISSION

____________

COMPOSITE HOLLOW CORE STATION POST

INSULATORS WITH AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

FOREWORD

1) The International Electrotechnical Commission (IEC) is a worldwide organization for standardization comprising

all national electrotechnical committees (IEC National Committees). The object of IEC is to promote international

co-operation on all questions concerning standardization in the electrical and electronic fields. To this end and

in addition to other activities, IEC publishes International Standards, Technical Specifications, Technical Reports,

Publicly Available Specifications (PAS) and Guides (hereafter referred to as "IEC Publication(s)"). Their

preparation is entrusted to technical committees; any IEC National Committee interested in the subject dealt with

may participate in this preparatory work. International, governmental and non-governmental organizations liaising

with the IEC also participate in this preparation. IEC collaborates closely with the International Organization for

Standardization (ISO) in accordance with conditions determined by agreement between the two organizations.

2) The formal decisions or agreements of IEC on technical matters express, as nearly as possible, an international

consensus of opinion on the relevant subjects since each technical committee has representation from all

interested IEC National Committees.

3) IEC Publications have the form of recommendations for international use and are accepted by IEC National

Committees in that sense. While all reasonable efforts are made to ensure that the technical content of IEC

Publications is accurate, IEC cannot be held responsible for the way in which they are used or for any

misinterpretation by any end user.

4) In order to promote international uniformity, IEC National Committees undertake to apply IEC Publications

transparently to the maximum extent possible in their national and regional publications. Any divergence between

any IEC Publication and the corresponding national or regional publication shall be clearly indicated in the latter.

5) IEC itself does not provide any attestation of conformity. Independent certification bodies provide conformity

assessment services and, in some areas, access to IEC marks of conformity. IEC is not responsible for any

services carried out by independent certification bodies.

6) All users should ensure that they have the latest edition of this publication.

7) No liability shall attach to IEC or its directors, employees, servants or agents including individual experts and

members of its technical committees and IEC National Committees for any personal injury, property damage or

other damage of any nature whatsoever, whether direct or indirect, or for costs (including legal fees) and

expenses arising out of the publication, use of, or reliance upon, this IEC Publication or any other IEC

Publications.

8) Attention is drawn to the Normative references cited in this publication. Use of the referenced publications is

indispensable for the correct application of this publication.

9) Attention is drawn to the possibility that some of the elements of this IEC Publication may be the subject of patent

rights. IEC shall not be held responsible for identifying any or all such patent rights.

IEC 62772 has been prepared by IEC technical committee 36: Insulators. It is an International

Standard.

This second edition cancels and replaces the first edition published in 2016. This edition

constitutes a technical revision.

This edition includes the following significant technical changes with respect to the previous

edition:

a) modifications of terms and definitions;

b) modifications of tests procedures included in IEC TR 62039 and IEC 62217 (Hydrophobicity

transfer test; Water diffusion test on the core with housing);

c) harmonization of Table 1 (Required design and type tests) with other product standards;

d) update of Annex A (Qualification of fillers);

e) addition of a new informative Annex B (Load definitions, relationship of loads).

The text of this International Standard is based on the following documents:

Draft Report on voting

36/569/FDIS 36/587/RVD

Full information on the voting for its approval can be found in the report on voting indicated in

the above table.

The language used for the development of this International Standard is English.

This document was drafted in accordance with ISO/IEC Directives, Part 2, and developed in

accordance with ISO/IEC Directives, Part 1 and ISO/IEC Directives, IEC Supplement, available

at www.iec.ch/members_experts/refdocs. The main document types developed by IEC are

described in greater detail at www.iec.ch/publications.

The committee has decided that the contents of this document will remain unchanged until the

stability date indicated on the IEC website under webstore.iec.ch in the data related to the

specific document. At this date, the document will be

• reconfirmed,

• withdrawn,

• replaced by a revised edition, or

• amended.

IMPORTANT – The "colour inside" logo on the cover page of this document indicates that it

contains colours which are considered to be useful for the correct understanding of its

contents. Users should therefore print this document using a colour printer.

– 6 – IEC 62772:2023 © IEC 2023

INTRODUCTION

Composite hollow core station post insulators consist of an insulating hollow core (tube),

bearing the mechanical load protected by a polymeric housing, the load being transmitted to

the core by end fittings. The hollow core is filled entirely with an insulating material. The core

is made of resin impregnated fibres.

Composite hollow core station post insulators are typically applied as post insulators in

substations. In order to perform the design tests, IEC 62217 is to be applied for materials and

interfaces of the insulator. Some tests have been grouped together as "design tests", to be

performed only once on insulators which satisfy the same design conditions. For all design tests

on composite hollow core station post insulators, the common clauses defined in IEC 62217 are

applied. As far as practical, the influence of time on the electrical and mechanical properties of

the components (core material, housing, interfaces etc.) and of the complete composite hollow

core station post insulator has been considered in specifying the design tests to ensure a

satisfactory life-time under normally known stress conditions in service.

This document relates to IEC 61462, Composite hollow insulators – Pressurized and

unpressurized insulators for use in electrical equipment with rated voltage greater than 1 000 V

– Definitions, test methods, acceptance criteria and design recommendations, as well as

IEC 62231, Composite station post insulators for substations with AC voltages greater than

1 000 V up to 245 kV – Definitions, test methods and acceptance criteria. Tests and

requirements described in IEC 62231 can be used despite the intended operating voltage limit

for substations.

The use of polymeric housing materials that show hydrophobicity and hydrophobicity transfer

mechanism (HTM) is preferred for composite hollow core station post insulators. This is due to

the fact that the influence of diameter can be significant for hydrophilic surfaces (see also

IEC 60815-3). For instance silicone rubber is recognized as successful countermeasure against

severe polluted service conditions. For the time being, the 1 000 h AC tracking and erosion test

of IEC 62217 is used to establish a minimum requirement for the tracking and erosion

resistance, for both AC and DC.

Composite hollow core station post insulators are used in both AC and DC applications. Before

the appropriate standard for DC applications will be issued, the majority of tests listed in this

standard can also be applied to DC insulators. In spite of this, a specific tracking and erosion

test procedure for DC applications as a design test is still being considered to be developed.

Some information about the difference of AC and DC material erosion test can be found in the

CIGRE Technical Brochure 611 [8] . For the time being, the 1 000 h AC tracking and erosion

test of IEC 62217 is used to establish a minimum requirement for the tracking and erosion

resistance.

___________

Numbers in square brackets refer to the Bibliography.

COMPOSITE HOLLOW CORE STATION POST

INSULATORS WITH AC VOLTAGE GREATER THAN

1 000 V AND DC VOLTAGE GREATER THAN 1 500 V –

DEFINITIONS, TEST METHODS AND ACCEPTANCE CRITERIA

1 Scope

This document, which is an International Standard, applies to composite hollow core station

post insulators consisting of a load-bearing insulating tube (core) made of resin impregnated

fibres, insulating filler material (solid, liquid, gaseous – pressurized or unpressurized), a

housing (outside the insulating tube) made of polymeric material (for example silicone or

ethylene-propylene) and fixing devices at the ends of the insulating tube. Composite hollow

core station post insulators as defined in this standard are intended for general use in

substations in both, outdoor and indoor environments, operating with a rated AC voltage greater

than 1 000 V and a frequency not greater than 100 Hz or for use in direct current systems with

a rated voltage greater than 1 500 V DC.

The object of this document is:

– to define the terms used;

– to specify test methods;

– to specify acceptance criteria.

All the tests in this document, apart from the thermal-mechanical test, are performed at normal

ambient temperature. This document does not specify tests that are characteristic of the

apparatus of which the composite hollow core station post insulator ultimately may form a part

(e.g. disconnector switch, reactor support, HVDC valves).

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies.

For undated references, the latest edition of the referenced document (including any

amendments) applies.

IEC 60168, Tests on indoor and outdoor post insulators of ceramic material or glass for systems

with nominal voltages greater than 1000 V

IEC 61109, Insulators for overhead lines – Composite suspension and tension insulators for AC

systems with a nominal voltage greater than 1 000 V – Definitions, test methods and acceptance

criteria

IEC 61462, Composite hollow insulators – Pressurized and unpressurized insulators for use in

electrical equipment with rated voltage greater than 1 000 V – Definitions, test methods,

acceptance criteria and design recommendations

IEC 62217, Polymeric HV insulators for indoor and outdoor use – General definitions, test

methods and acceptance criteria

IEC 62231:2006, Composite station post insulators for substations with AC voltages greater

than 1 000 V up to 245 kV – Definitions, test methods and acceptance criteria

IEC TR 62039, Selection guidelines for polymeric materials for outdoor use under HV stress

– 8 – IEC 62772:2023 © IEC 2023

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following

addresses:

• IEC Electropedia: available at http://www.electropedia.org/

• ISO Online browsing platform: available at http://www.iso.org/obp

3.1

composite hollow core station post insulator

post insulator, consisting of at least three insulating parts, namely a tube, a housing with or

without sheds, and an internal filler

Note 1 to entry: End fittings are attached to the insulating tube. The housing, with or without sheds, may be omitted

in case of specific environmental conditions (e.g. indoor).

Note 2 to entry: A hollow insulator can be made from one or more permanently assembled insulating elements

3.2

post insulator

insulator intended to give rigid support to a live part which is to be insulated from earth or from

another live part

Note 1 to entry: A post insulator may be an assembly of a number of post insulator units (stack).

Note 2 to entry: Post insulators for substations are also known as station post insulators.

[SOURCE: IEC 60050-471:2007, 471-04-01, modified – addition of "(stack)" in Note 1 to entry]

3.3

tube (core)

central internal insulating part of a composite hollow core station post insulator which provides

the mechanical characteristics

Note 1 to entry: The housing, insulating filler material and sheds are not part of the core.

Note 2 to entry: Resin impregnated fibres are structured in such a manner as to achieve sufficient mechanical

strength. Layers of different fibres may be used to fulfil special requirements.

3.4

filler

insulating material filling the entire internal space (solid, liquid, gaseous – pressurized or

unpressurized) of the hollow core station post insulator

3.5

fixing device (end fitting)

integral component or formed part of an insulator intended to connect it to a supporting

structure, or to a conductor, or to an item of equipment, or to another insulator

Note 1 to entry: Where the end fitting is metallic, the term "metal fitting" is normally used.

[SOURCE: IEC 60050-471:2007, 471-01-06, modified – addition of "fixing device" in term]

3.6

coupling

part of the end fitting which transmits the load to the accessories external to the insulator

[SOURCE: IEC 62217:2012, 3.14]

3.7

connection zone

zone where the mechanical load is transmitted between the insulating body and the end fitting

[SOURCE: IEC 62217:2012, 3.13]

3.8

housing

external insulating part of composite hollow core station post insulator providing necessary

creepage distance and protecting the tube from the environment

Note 1 to entry: If an intermediate sheath is used it forms a part of the housing.

[SOURCE: IEC 62217:2012, 3.7]

3.9

shed

insulating part, projecting from the insulator trunk, intended to increase the creepage distance

Note 1 to entry: The shed can be with or without ribs.

[SOURCE: IEC 60050-471:2007, 471-01-15]

3.10

insulator trunk

central insulating part of an insulator from which the sheds project

Note 1 to entry: Also known as shank on smaller insulators.

[SOURCE: IEC 60050-471:2007, 471-01-11]

3.11

creepage distance

shortest distance or the sum of the shortest distances along the surface of an insulator between

two conductive parts which normally have the operating voltage between them

Note 1 to entry: The surface of any non-insulating jointing material is not considered as forming part of the creepage

distance.

[SOURCE: IEC 60050-471:2007, 471-01-04, modified – removal of Note 2 to entry]

3.12

arcing distance

shortest distance in the air external to the insulator between the metallic parts which normally

have the operating voltage between them

[SOURCE: IEC 60050-471:2007, 471-01-01]

3.13

interface

contact surface between the different materials

Note 1 to entry: Various interfaces occur in most composite insulators (cf. Annex C), e.g.

– between housing and end fittings,

– between various parts of the housing; e.g. between sheds, or between sheath and sheds,

– between tube and housing

– between tube and filler.

[SOURCE: IEC 62217:2012, 3.11, modified – addition of "contact"]

– 10 – IEC 62772:2023 © IEC 2023

3.14

damage limit of the tube under mechanical stress

limit below which mechanical loads can be applied, at normal ambient temperature, without

micro damage to the composite tube

Note 1 to entry: Applying such loads means that the tube is in a reversible elastic phase. If the damage limit of the

tube is exceeded, the tube is in an irreversible plastic phase, which means permanent damage to the tube which may

not be visible at a macroscopic level (for a quantitative definition see Annex C of IEC 61462).

3.15

maximum mechanical load

MML

highest cantilever bending load which is expected to be applied to the composite hollow core

station post insulators in accordance with IEC 61462

Note 1 to entry: The MML of the composite hollow core station post insulator is specified by the insulator

manufacturer.

3.16

specified mechanical load

SML

cantilever bending load specified by the manufacturer that is used in the mechanical tests, and

which is verified during a type test at normal ambient temperature

Note 1 to entry: The SML forms the basis of the selection of composite hollow station post insulators with regard

to external loads.

3.17

specified cantilever load

SCL

cantilever load to be withstood by the insulator when tested under the specified conditions in

accordance with IEC 62231

3.18

maximum design cantilever load

MDCL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

Note 1 to entry: For more information to load philosopies and relationships, see Annex B.

3.19

specified torsion load

SToL

torsion load level which can be withstood by the insulator when tested under the specified

conditions in accordance with IEC 62231

3.20

maximum design torsion load

MDToL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

3.21

specified tension load

STL

tension load which can be withstood by the insulator when tested under the specified conditions

in accordance with IEC 62231

3.22

maximum design tension load

MDTL

load level above which damage to the insulator begins to occur and that should not be exceeded

in service in accordance with IEC 62231

3.23

specified compression load

SCoL

compression load to be withstood by the insulator when tested under the specified conditions

in accordance with IEC 62231

3.24

buckling load

compression load that induces buckling of the insulator core in accordance with IEC 62231

3.25

maximum design compression load

MDCoL