ISO 5879:2023

(Main)Space systems — Ground test for the separation between a launch vehicle and a spacecraft — Requirements for combined separation tests, horizontal separation tests and individual falling separation tests

Space systems — Ground test for the separation between a launch vehicle and a spacecraft — Requirements for combined separation tests, horizontal separation tests and individual falling separation tests

This document provides the test requirements of three typical separation test methods, which are the combined separation test, the horizontal separation test, the individual falling separation test, for the separation between the launch vehicle (LV) and the spacecraft (or between stages of a prototype LV model). It also provides the requirements for the separation test unit, test data, test timing and sequence, pre-test simulation, test environment, exception handling, test results assessment, test documentation, test facilities, test installation, preliminary adjustment of the test setup, measurement and data acquisition. This document is applicable to test providers and interested parties to implement the separation test between the launch vehicle and the spacecraft.

Systèmes spatiaux — Essais au sol pour la séparation entre un lanceur et un engin spatial — Exigences relatives aux essais de séparation combinée, aux essais de séparation horizontale et aux essais de séparation par chute individuelle

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 5879

First edition

2023-08

Space systems — Ground test for the

separation between a launch vehicle

and a spacecraft — Requirements for

combined separation tests, horizontal

separation tests and individual falling

separation tests

Systèmes spatiaux — Essais au sol pour la séparation entre un

lanceur et un engin spatial — Exigences relatives aux essais de

séparation combinée, aux essais de séparation horizontale et aux

essais de séparation par chute individuelle

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

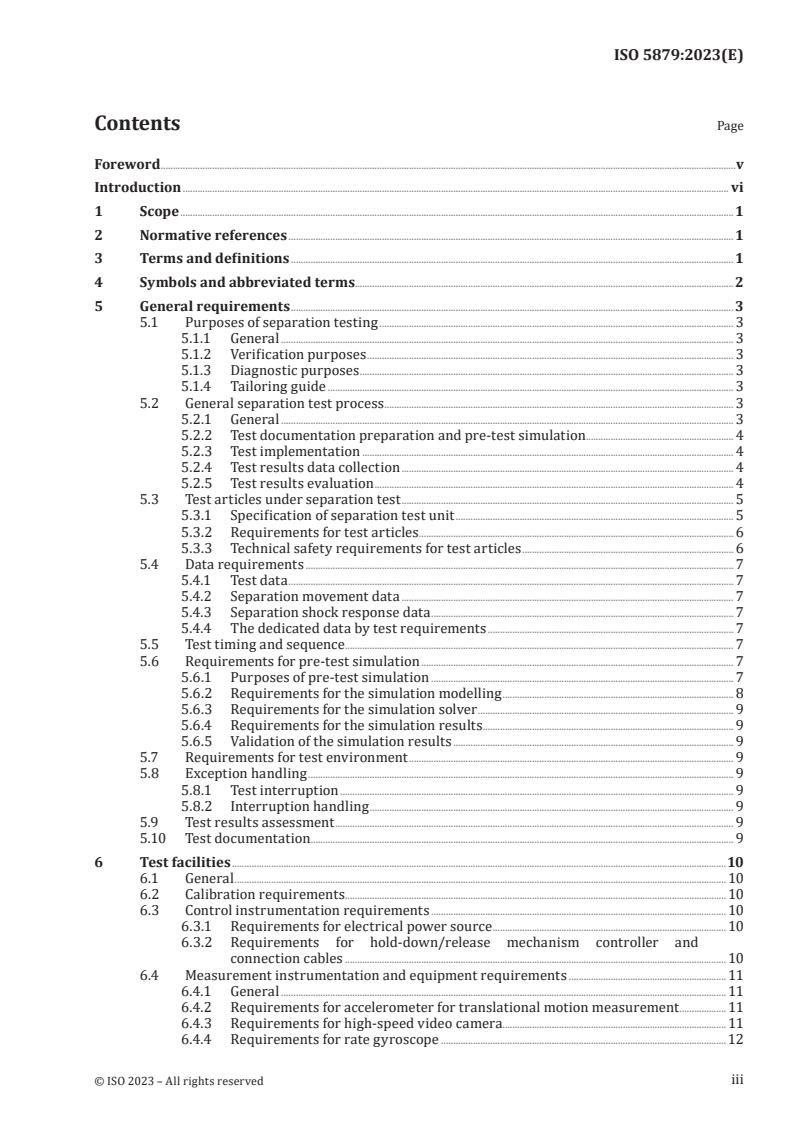

Contents Page

Foreword .v

Introduction . vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms.2

5 General requirements . 3

5.1 Purposes of separation testing . 3

5.1.1 General . 3

5.1.2 Verification purposes . 3

5.1.3 Diagnostic purposes . 3

5.1.4 Tailoring guide . 3

5.2 General separation test process . 3

5.2.1 General . 3

5.2.2 Test documentation preparation and pre-test simulation . 4

5.2.3 Test implementation . 4

5.2.4 Test results data collection . 4

5.2.5 Test results evaluation . 4

5.3 Test articles under separation test . 5

5.3.1 Specification of separation test unit . 5

5.3.2 Requirements for test articles . 6

5.3.3 Technical safety requirements for test articles . 6

5.4 Data requirements . 7

5.4.1 Test data . 7

5.4.2 Separation movement data . 7

5.4.3 Separation shock response data . 7

5.4.4 The dedicated data by test requirements . 7

5.5 Test timing and sequence . 7

5.6 Requirements for pre-test simulation . 7

5.6.1 Purposes of pre-test simulation . 7

5.6.2 Requirements for the simulation modelling . 8

5.6.3 Requirements for the simulation solver . 9

5.6.4 Requirements for the simulation results . 9

5.6.5 Validation of the simulation results . 9

5.7 Requirements for test environment . 9

5.8 Exception handling . 9

5.8.1 Test interruption . 9

5.8.2 Interruption handling . 9

5.9 Test results assessment . 9

5.10 Test documentation . . 9

6 Test facilities .10

6.1 General . 10

6.2 Calibration requirements. 10

6.3 Control instrumentation requirements . 10

6.3.1 Requirements for electrical power source . 10

6.3.2 Requirements for hold-down/release mechanism controller and

connection cables . 10

6.4 Measurement instrumentation and equipment requirements . 11

6.4.1 General . 11

6.4.2 Requirements for accelerometer for translational motion measurement . 11

6.4.3 Requirements for high-speed video camera. 11

6.4.4 Requirements for rate gyroscope .12

iii

6.4.5 Requirements for timing measurement system.12

6.4.6 Requirements for optical displacement measurement system .12

6.4.7 Requirements for shock measurement system .13

6.5 Testing fixture requirements . 14

6.5.1 General . 14

6.5.2 Requirements for the test scaffolding . 14

6.5.3 Requirements for the angular rotation mechanism .15

6.5.4 Requirements for the release mechanism between test fixture and test

articles .15

6.5.5 Test article capture system requirements . 15

6.6 Technical safety requirements for test facilities . 16

6.6.1 Consolidation and support of test scaffolding . 16

6.6.2 Confirmation of safety status of test facilities . 16

6.6.3 Test area . 16

7 Test installation .16

7.1 General . 16

7.2 Test articles installation requirements . 16

7.2.1 Installation process . 16

7.2.2 Functional constraints . 16

7.3 Sensors installation requirements . 16

7.3.1 Accelerometers for translational motion measurement installation

requirements . 16

7.3.2 Rate gyroscopes installation requirements . 17

7.3.3 shock accelerometers installation requirements . 17

7.4 High-speed video camera installation requirements . 17

7.4.1 Camera arrangement . 17

7.4.2 Installation location . 18

7.4.3 Purpose . 18

7.4.4 Luminance . 18

7.5 Technical safety requirements for test installation . 18

7.5.1 Training and qualification . 18

7.5.2 Working high above the ground . 18

8 Requirements for the preliminary adjustment of the test setup .18

9 Measurement and data acquisition requirements .18

9.1 General . 18

9.2 Acquisition and processing requirements for the dedicated data by test

requirements . . . 19

9.3 Acquisition and processing requirements for separation movement data . 19

9.3.1 Noise reduction . . . 19

9.3.2 Data format . 19

9.4 Acquisition and processing requirements for shock response data . 19

9.4.1 Shock response data. 19

9.4.2 Detection of anomalies . 19

9.4.3 Processing requirements . 19

9.4.4 SRS values . 19

9.4.5 Time data format . . 19

9.4.6 Shock response spectrum . 20

Annex A (informative) Overview and interdependencies of test methods .21

Annex B (informative) Combined separation test.23

Annex C (informative) Individual falling separation test .25

Annex D (informative) Horizontal separation test .27

Annex E (informative) The implementation of separation test .30

Bibliography .32

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO document should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

Introduction

The separation between the launch vehicle and the spacecraft on orbit is a critical activity for a

successful orbit injection. Any failure during the separation can cause serious consequences. A

separation test on ground between the spacecraft and the launch vehicle is an effective way to

simulate and test the characteristics of the separation, to reveal the risk of failure of the separation

system between the launch vehicle and the spacecraft, and to improve the separation function during

the separation on orbit. This document provides three typical separation test methods, which are the

combined separation test, the horizontal separation test and the individual falling separation test, for

different application scenarios.

The overview and interdependencies of test methods are illustrated in Annex A. For the testing of

separation movements and separation dynamics between launch vehicle and spacecraft with zero-

gravity effect or no acceleration conditions at the time of separation, the separation test may take

the form of combined separation test or horizontal separation test as illustrated in Annex B and

Annex D respectively. For the testing of separation with purposes of fit-check and shock-response-level

confirmation, the test may take the form of individual falling separation test as illustrated in Annex C.

Apart from these three separation test methods, there are many other methods of verifying separation

systems and processes, such as modelling the systems or processes, comparing similarity with existing

systems or processes, which may apply to different scenarios with consistency. This document does

not deny the use of these useful methods in the simulating and testing of the characteristics of the

separation.

The technical requirements in this document may be tailored to meet the objectives of tests as the

separation objectives can be different for different projects or for different development stages.

vi

INTERNATIONAL STANDARD ISO 5879:2023(E)

Space systems — Ground test for the separation between

a launch vehicle and a spacecraft — Requirements for

combined separation tests, horizontal separation tests and

individual falling separation tests

1 Scope

This document provides the test requirements of three typical separation test methods, which are

the combined separation test, the horizontal separation test, the individual falling separation test, for

the separation between the launch vehicle (LV) and the spacecraft (or between stages of a prototype

LV model). It also provides the requirements for the separation test unit, test data, test timing and

sequence, pre-test simulation, test environment, exception handling, test results assessment, test

documentation, test facilities, test installation, preliminary adjustment of the test setup, measurement

and data acquisition.

This document is applicable to test providers and interested parties to implement the separation test

between the launch vehicle and the spacecraft.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14620-1:2018, Space systems — Safety requirements — Part 1: System safety

ISO 15864:2021, Space systems — General test methods for spacecraft, subsystems and units

ISO 22137, Space systems — Program management — Test reviews

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminology databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

combined separation test

test in which a combination of spacecraft parts and launch vehicle parts drops simultaneously from the

hanging point

Note 1 to entry: The test articles finish the separation movements before being captured during the separation

test.

3.2

fit check

check to verity the matching consistencies of the electrical interface and the mechanical interface

between the spacecraft and the launch vehicle to some degree

Note 1 to entry: This check usually consists of an electrical interface check and a mechanical interface check

between the spacecraft and the launch vehicle before the separation test.

3.3

horizontal separation test

test in which a combination of spacecraft parts and launch vehicle parts is separated horizontally

3.4

individual falling separation test

test in which a combination of spacecraft parts and launch vehicle parts is separated vertically and

either spacecraft parts or launch vehicle parts fall down from the combination

3.5

launch vehicle stages separation system

assembly of functionally related subsystems and/or units for the separation between launch vehicle

stages

3.6

mating and unlocking device

device that connects the spacecraft and the launch vehicle together before separation and disconnects

the linkage between the spacecraft and the launch vehicle at the time of separation

3.7

separation impulse device

device that provides the energy to separate the spacecraft from the launch vehicle

3.8

separation system between launch vehicle and spacecraft

assembly of functionally related subsystems and/or units for the separation between launch vehicle

and spacecraft

3.9

test article

spacecraft, subsystem or unit on which a test is conducted

Note 1 to entry: For this document the definition is extended to address also launch vehicle system, subsystem or

unit.

3.10

separation test unit

assembly of test articles which undergoes separation test

4 Symbols and abbreviated terms

CoG centre of gravity

LV launch vehicle

SC spacecraft

SDOF single degree of freedom

SRS shock response spectrum

ζ damping ratio

5 General requirements

5.1 Purposes of separation testing

5.1.1 General

The separation testing is conducted for two types of purposes, which are verification purposes and

diagnostic purposes. A verification purpose is to verify conformity of characteristics of a separation

system between the LV and the SC (or between stages of a prototype LV model) with the specified

requirements. A diagnostic purpose is testing for physical system or operational design analysis.

5.1.2 Verification purposes

Verification purposes typically include:

a) to verify the functionality and characteristics of the separation system design and compatibility of

interfaces, including mechanical and electrical interfaces (e.g. fit check), between the LV and the SC,

as specified in ISO 14303:2002, Clauses 4 and 5;

b) to measure the parameters of separation relative movement, such as separation velocity,

acceleration, angular motion, separation displacement;

c) to measure the separation clearances between the separating hardware;

d) to measure the separation characteristic action timing during the separation process, such as time

to commence, time to clear.

5.1.3 Diagnostic purposes

Diagnostic purposes typically include:

a) to check and revise the separation analysis computational model and basic assumptions used in

the separation analysis;

b) to measure the shock levels on the points that are relevant to the launch vehicle side or to the

spacecraft side, and to check if the spacecraft is able to withstand the shock environment;

c) to test the separation function of the device (e.g. mating and unlocking device) designed for

separation of structural elements;

d) to test the distancing function provided by the separation impulse device;

e) to test purposes demanded by the test requirements, such as flexible-body distortion loads, which

are relevant to the launch vehicle side or to the spacecraft side during the separation process.

5.1.4 Tailoring guide

The purposes of separation testing in 5.1.2 and 5.1.3 may be tailored as the separation purposes can be

different for different projects or for different development stages.

5.2 General separation test process

5.2.1 General

The general separation test process flow is shown in Figure 1. The test process typically includes:

a) test documentation preparation and pre-test simulation;

b) test implementation;

c) test result data collection;

d) development and issuing of a test results assessment report.

5.2.2 Test documentation preparation and pre-test simulation

The test documents, which include documents of test plan, test specification, test procedure as defined

in ISO 15864:2021, 4.9, shall be prepared.

The test requirements for test articles, test facilities, test installation, preliminary adjustment of test

setup, measurement and data acquisition, as required in a separation test, shall be defined in the test

specification documents.

The documents of test specification and test procedure should be reviewed by the relevant sides to

make sure the documents conform to the test requirements. The test documentation review in the test

process flow shall be in line with the requirements of ISO 22137.

Pre-test simulation, which is specified in 5.6, shall meet the requirements of the test specification

documents and support the making of the test procedure documentation.

5.2.3 Test implementation

Test implementation typically includes the following procedures: test preparation, test execution,

follow-up activities after test, as illustrated in Annex E for a separation test.

5.2.4 Test results data collection

The test results data collection shall meet both the test data requirements, which are specified in 5.4,

and the measurement and data acquisition requirements, which are specified in Clause 9.

5.2.5 Test results evaluation

The test results shall be evaluated to assess whether the test results meet the test objectives as

specified in 5.9.

If the test results meet the test objectives, the test process may step into "Issue the test report

documentation" and end of the test process as shown in Figure 1.

If the test results do not meet the test objectives, a selection can be made between three ways to react

corresponding to the failures as shown in Figure 1.

a) If the failure is due to systems or interfaces design problems, the test should move to the step of

“redesign of the relevant systems or interfaces between the LV and SC”, then move to the step of

“test plan”, and proceed with the whole test process.

b) If the failure is due to test procedure problems, the test should move to the step of “test procedure

documentation review” to figure out whether the test procedure documentation meet the test

requirements given in the test specification documentation, then move to next step as shown in

Figure 1.

c) If the failure is due to test specification problems, the test should move to the step of “test

specification review” to figure out whether the test specification documentation meet the test

requirements given in the test plan documentation, then move to next step as shown in Figure 1.

Figure 1 — General separation test process

5.3 Test articles under separation test

5.3.1 Specification of separation test unit

5.3.1.1 Acceptance test

The separation test unit for an acceptance test comprises the following test articles: a flight model or

proto-flight model of a separation system between launch vehicle and spacecraft, a flight model or

proto-flight model of a certain part of a spacecraft and a flight model or proto-flight model of a certain

part of a launch vehicle.

5.3.1.2 Development test

In a development test between the SC and the LV, the separation test unit comprises the following test

articles: a prototype model of a separation system between launch vehicle and spacecraft, a mock-up of

a certain part of spacecraft and a mock-up of a certain part of a launch vehicle.

In a development test between stages of a prototype LV model, the separation test unit comprises the

following test articles: the mock-ups of two connecting launch vehicle stages and a prototype model of

the corresponding launch vehicle stages separation system.

5.3.2 Requirements for test articles

5.3.2.1 Technical characteristics

Technical characteristics of the test articles shall conform to the test specification documentation.

5.3.2.2 Interfaces

The mechanical and electrical interfaces at the separation surfaces of the test articles shall be identical

to those of the prototype model or the flight model, depending on different test purposes as defined in

5.3.1.

5.3.2.3 Substitutes

Some parts of test articles may be substituted by the mock-up parts when these mock-up parts do not

interfere with the purposes of the separation test.

5.3.2.4 Mass and stiffness

The mass and stiffness characteristics of the separation parts of test articles shall be identical to those

of the prototype model or the flight model, depending on different test purposes, when measuring the

separation motion parameters of the test.

5.3.2.5 Specification of difference between the SC/LV mock-up model and the flight model

The SC/LV mock-up model should be the structurally and/or physically similar items presenting a

simplified reproduction of a test object of SC/LV or its part intended for test.

The SC/LV flight model or proto-flight model is dedicated to be launched and operated in orbit and

should be subjected to acceptance testing.

While it is not always feasible to conduct full-scale mock-up tests, a reduced mock-up may be used in

the separation test where relevant technical characteristics of the reduced mock-up model should be

designed to be identical to those of the prototype model or the flight model.

5.3.2.6 Markings

There shall be obvious marks on the test articles for the high-speed video shooting.

5.3.3 Technical safety requirements for test articles

5.3.3.1 Confirmation

The test article’s technical safety status shall be confirmed before test.

5.3.3.2 Handling

The operators shall follow the relevant technical safety rules under the consideration of the

requirements of ISO 14620-1:2018, 8.3 in planning and executing the handling of the test articles, such

as hoisting, placement, transporting, installation.

5.3.3.3 Grounding

The test articles shall be electrically grounded. IEC 62305-3 provides information on the ground

resistance.

5.3.3.4 Safety protection

There shall be safety protection measures to protect the test articles from damaging both during and

after the process of the test.

5.4 Data requirements

5.4.1 Test data

Depending on the purpose of the test campaign, separation movement data and/or separation shock

response data, and/or the dedicated data by test requirements, shall be acquired.

5.4.2 Separation movement data

Separation movement data shall include translational acceleration, separation velocity, separation

displacement, angular velocity, attitude angle of the LV test articles and the SC test articles.

Separation movement data may be measured directly or obtained by processing the measured data.

5.4.3 Separation shock response data

Separation shock response data shall include shock acceleration time history data and shock response

spectrum data.

5.4.4 The dedicated data by test requirements

The dedicated data to be acquired, such as flexible-body distortion loads, shall be specified by the test

requirements, as the data can be different for different types of separation test.

5.5 Test timing and sequence

Timing and sequence shall be synchronized for every system involved in the test. Synchronization

accuracy shall be suitable to meet the test requirements.

5.6 Requirements for pre-test simulation

5.6.1 Purposes of pre-test simulation

Pre-test simulation shall:

a) evaluate kinematics of the test articles before the separation test;

b) determine the parameters of separation movement sensors, such as the measurements ranges,

accuracy. and the placement of the separation movement sensors;

c) determine the installation positions of high-speed cameras to get the most appropriate shooting

angle of field of view;

d) determine the placement of test articles capture systems to secure the safe recovery of the test

articles;

e) validate the analytical method and basic assumptions used in the separation by cross checking

the results between ground tests and simulation; the validated method is then used to verify that

requirements are met under worst-case flight conditions.

5.6.2 Requirements for the simulation modelling

5.6.2.1 Computational model

The computational model shall allow effective and reasonable simulation of the whole separation

process under consideration of the test requirements.

5.6.2.2 Coordinate systems

The coordinate systems for separation pre-test simulation shall be defined to be advantageous to

express the separation motion model in the simulation.

5.6.2.3 Sloshing/flexibility effect

The sloshing effect or the flexibility effect of the test articles during the separation process shall be

evaluated before the modelling of the test articles to decide if the sloshing effect or the flexibility effect

shall be included in the modelling.

5.6.2.4 Timing and sequence

The separation timing and sequence shall be set to duplicate the separation timing and sequence of the

separation test.

5.6.2.5 Initial conditions

The initial conditions shall be set to duplicate the initial conditions of the separation test.

5.6.2.6 Boundary conditions

As far as possible, the main boundary conditions modelling (e.g. constraint, contact) shall duplicate the

separation test boundary conditions.

5.6.2.7 Mass characteristics

The main mass characteristics (e.g. mass, CoG location, moment of inertia) of the test articles models

shall be set to duplicate the main mass characteristics of the physical test articles as far as possible.

5.6.2.8 Geometrical characteristics

The main geometry characteristics of the models shall conform to the main geometry characteristics

of the real test articles in the scenario of measuring the separation clearances between the separating

models or in other proper scenarios.

5.6.2.9 Separation impulse

As far as possible, the modelling of separation impulses shall duplicate the separation impulses in the

separation test.

5.6.3 Requirements for the simulation solver

The settings of optional parameters for the simulation solver, such as integrator type, simulation time

length, integral step size, integral accuracy, shall meet the simulation requirements.

5.6.4 Requirements for the simulation results

The simulation results shall include:

a) attitude angle of separation articles over time during the separation process;

b) attitude angular velocity of separation articles over time during the separation process;

c) critical clearance between separation articles over time during the separation process;

d) relative distance between separation articles over time during the separation process;

e) relative velocity between separation articles over time during the separation process.

The requirements for the simulation results may be tailored as the separation test purposes can be

different for different projects or for different development stages.

5.6.5 Validation of the simulation results

The validation of the simulation results shall include:

a) comparison of the results between separation test and the simulation method;

b) comparison of the results between different simulation methods.

5.7 Requirements for test environment

The test environment shall be specified in line with requirements of the test, usually including

temperature, atmosphere pressure, relative humidity, cleanliness and other requirements.

5.8 Exception handling

5.8.1 Test interruption

If any of the following situations appears, the test shall be interrupted:

a) test equipment failure;

b) the technical requirements are not met;

c) test articles failure.

5.8.2 Interruption handling

The requirements for retest in ISO 15864:2021, 4.8 shall be considered for the interruption handling.

5.9 Test results assessment

There shall be an assessment for the completeness, validity and correctness of test execution, test

results and data measured during the separation test with respect to the test objectives.

5.10 Test documentation

As defined in ISO 15864:2021, 4.9, the test documentation shall include a test plan, a test specification,

test procedures, test data, a test report and test logs

The test documentation may be tailored to fulfil the objectives of test.

6 Test facilities

6.1 General

Test facilities typically include control instrumentation, measurement instrumentation and equipment

and testing fixture.

6.2 Calibration requirements

Control and measurement instrumentation as specified in 6.3 and 6.4 shall be calibrated periodically

under consideration of ISO 15864:2021, 4.10.3.

6.3 Control instrumentation requirements

The main function of control instrumentation and equipment is, in line with the test timing, to

send release instructions (e.g. pyrotechnic devices ignition instructions) to the hold-down/release

mechanism controller to start the separation movement. Control instrumentation and equipment

typically include: electrical power source, hold-down/release mechanism controller (e.g. pyrotechnic

devices ignition controller) and connection cables.

6.3.1 Requirements for electrical power source

The output power, electric current and voltage of the electrical source shall conform to the test

requirements.

6.3.2 Requirements for hold-down/release mechanism controller and connection cables

6.3.2.1 Function

The hold-down/release mechanism controller shall allow hold-down/release mechanism timing

controlling.

6.3.2.2 Resolution

The timing resolution for the hold-down/release mechanism controller shall meet the test requirements

and shall be indicated.

6.3.2.3

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...