ISO 10368:1992

(Main)Freight thermal containers — Remote condition monitoring

Freight thermal containers — Remote condition monitoring

Establishes the information and interfaces required to permit complying central monitoring and control systems employed by one carrier or terminal to interface and communicate with complying remote communication devices of differing manufacture and configuration used by other carriers and terminals. Gives the data-logging formats and message protocols, performance requirements for the monitoring, communication and control system, and the system compatibility requirements.

Conteneurs à caractéristiques thermiques — Système de pilotage à distance des groupes frigorifiques

General Information

Relations

Standards Content (Sample)

Internationale

STANDAR0 10368

First edi tion

1992-07-0 1

---- --

eppp---.--- ---------- --~--

Freight thermal Containers -- IRemote condition

monitoring

Conieneurs 3 caract&istiyues fhermiques --- Systeme de pilotage 2

distance des groupes frigorifiques

__m-p-.------

-- __-_, ---.- _--1__ ---

-- -.--- -- ___--_____

.___ ,v__l__l________. - __- ---- --- .---. -*-ev.----- -.--. --_-e-v

-----.-_-_-

_--- .--._ _----

~-. _. -___-

_~- .-~

Reference number

--

-.__---.- _____ --.- ___-__ ISO 10368: 1992(E)

---------------------- Page: 1 ----------------------

ISO 10368:1992(E)

Contents

paw

1

Section 1 General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .~.~.~.~.

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .-.

1

Normative references . .

1.2

1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

Section 2 Performance requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

2.1 Scope . .

................................ 3

22 . Reyuirements .

3

..............................................................

2.2.1 System coniponents

3

2.2.2 Performance function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

2.2.3 ?erformance constraints . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Section 3 System compatibility requirements . . . .1.1.1.~.

.................................. 8

3.1 Scope .

8

3.2 Cornmunications protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .*.-.

. . . . . . . . . . .I. 9

3.2.1 MMU to MDCU communications

MDCU to LRCD communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

3.2.2

3.2.3 MDCU to HRCD communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.2.4 RCD to controller communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

3.2.5 State diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

3.2.6 Error detection algorithm . . . . . .-._. 52

52

3.3 Data-logging formats . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53

3.3.1 Control words . . . . . . . . . . .1~.

53

3.3.2 Headers . . . . . . . . . . . . . . . . .*. . . . . . . . . . . . . . . . . . .

54

3.3.3 Readings .,.,.

3.3.4 Block 0 definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . s. 59

3.3.5 Event marks . . . . . . . . .*.*. 59

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

0 ISO 1992

All rights reserved. No part of this publication may be reproduced or utilized in any ferm

or by any means, electronie or mechanical, including photocopying and microfilm, without

Permission in writing from the publisher.

International Organization for Standardization

Case Postale 56 l CH-1211 Geneve 20 * Switzerland

Printed in Switzerland

ii

---------------------- Page: 2 ----------------------

ISO 10368:1992(E)

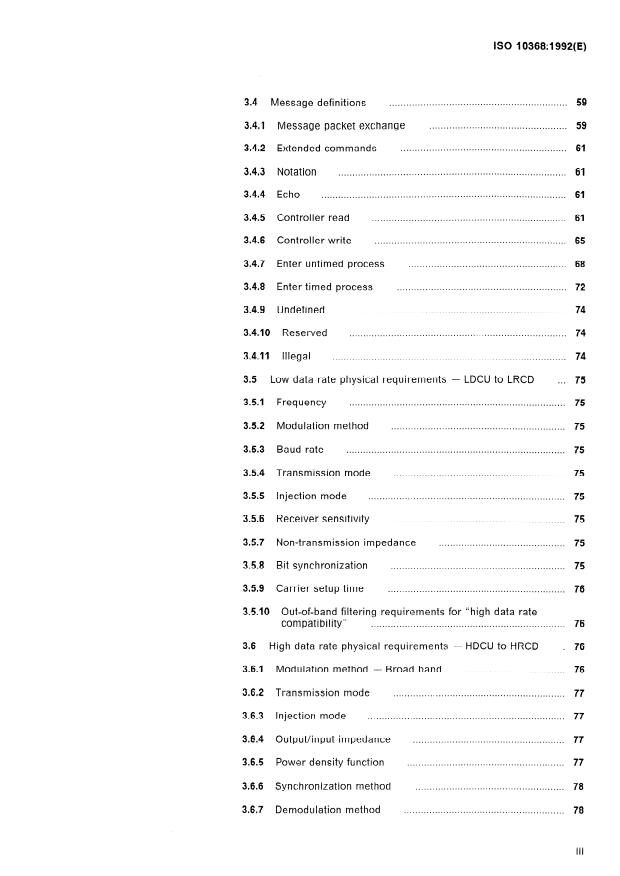

. . . . . . . . . . . . . . . . . . . . . . .-. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

3.4 Message definitions

............. .................................... 59

3.4.1 Message packet exchange

3.4.2 Extended commands . . . 61

.................................................................................

3.4.3 Notation 61

Echo . .

3.4.4 61

.....................................................................

3.4.5 Controller read 61

3.4.6 Controller write . 65

3.4.7 Enter untimed process . .

68

....... .......................... ......... ..................

3.4.8 Enter timed process 72

........................

3.4.9 Undefined . . . 74

3.4.10 Reserved . 74

3.4.11 Illegal . . 74

3.5 Low data rate physical requirements - LDCU to LRCD . 75

3.5.1 Frequency . 75

3.5.2 Modulation method . . . . . . . . . . . . . . . . .* *.,.,.

75

3.53 Baud rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.5.4 Transmission mode . . . . . . . . . . . . . . . . .~.-.

75

3.5.5 lnjection mode ,.~.,.,.

75

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5.6 Receiver sensitivity 75

. . . . . . . . . . . . . . . . . . . . . . . .s.

3.5.7 Non-transmission impedance 75

3.5.8 Bit synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

3.5.9 Carrier setup time . . . . . . . . . . . . . . .m. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

3.5.10 Out-of-band filtering requirements for “high data rate

I-.,,.~*.,.

compatibility” 76

3.6 High data rate phvsical requirements - HDCU to HRCD . 76

.

3.6.1 Modulation method - Broad band . . . . .-. 76

3.6.2 Transmission mode . . 77

3.6.3 Injec:tion mode . . 77

.................................................. 77

3.6.4 OutpuVinput impedance .

3.6.5 Power density function . . 77

3.6.6 Synchronization method . . 78

......................... ...........................

3.6.7 Demodulation method . 78

. . .

lli

---------------------- Page: 3 ----------------------

ISO 10368:1992(E)

78

.............................................................

3.6.8 Receiver sensitivity

78

.................................................................

3.6.9 Data link protocol

3.6.10 Out-of-band filtering requirements for “low data rate”

85

.......................................................................

compatibility

Annex

88

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .s.

. . . . . . . . . . . .r.

A Bibliography

---------------------- Page: 4 ----------------------

ISO 10368:1992(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide

federation of national Standards bodies (ISO member bodies). The work

of preparing International Standards is norrnally carried out through ISO

technical committees. Esch member body interested in a subject for

which a technical committee has been established has the right to be

represented on that committee. International organizations, govern-

mental and non-governmental, in liaison with ISO, also take part in the

work. ISO collaborates closely with the International Electrotechnical

Commission (IEC) on all matters of electrotechnical standardization.

Draft International Standards adopted by the technical committees are

circulated to the member bodies for voting. Publication as an Inter-

national Standard requires approval by at least 75% of the member

bodies casting a vote.

International Standard ISO 10368 was prepared by Technical Committee

ISWTC 104, Freight Containers, Sub-Committee SC 2, Specific purpose

Containers.

Annex A of this International Standard is for information only.

---------------------- Page: 5 ----------------------

ISO 10368:1992(E)

Introduction

During the preparation of this International Standard, information was

gathered on Patents upon which application of this Standard might de-

pend.

For the low data rate System of 3.5, the relevant Patents were identified

as belonging to

Thermo King Corporation

314 W. 90th Street

Minneapolis, Minnesota 55420

USA

For the high data rate System of 3.6, the relevant Patents were identified

as belonging to

Adaptive Networks Incorporated

1505 Commonwealth Ave.

Suite 30

Brighton, Massachusetts 02135

USA

ISO cannot give authoritative or comprehensive information about the

evidente, validity or scope of patent and Iike rights. The patent holders

have stated that licences will be granted under reasonable terms and

conditions. Communications on this subject should be addressed to ei-

ther Thermo Kinq Corporation or Adaptive Networks Incorporated.

\

---------------------- Page: 6 ----------------------

- Remote condition monitoring

Freight thermal Containers

Section 1: General

1.1 Scope

This International Standard establishes the information and interfaces required to permit complying central

monitoring and control Systems employed by one carrier or terminal to interface and communicate with com-

plying remote communication devices of differing manufacture and configuration used by other carriers and

.

terminals.

The data-logging formats and message protocols outlined in this International Standard apply to all currently

available data rate transmission techniques. These formats and protocols also apply to all future techniques

designed to be an ISO Standard compatible System.

The Performance requirements for the monitoring, communication and control System are given in section 2.

The System compatibility requirements are given in section 3. All sections of this International Standard apply

to all implernentations, except where specified.

1.2 Normative references

The following Standards contain provisions which, through reference in this text, constitute provisions of this

International Standard. At the time of publication, the editions indicated were valid. All Standards are subject

to revision, and Parties to agreements based on this International Standard are encouraged to investigate the

possibility of applying the most recent editions of the Standards indicated below. Members of IEC and ISO

maintain registers of currently valid International Standards.

ISO 1496.2:1988, Series I freight Containers - Specification anal testing -- Part 2: Thermal Containers.

ISO 971 l-2: 1990, Freight Containers - Information related to Containers on board vessels - Part 2: Telex data

transmission.

1.3 Definitions

For the purposes of this International Standard, the following definitions apply.

1.3.1 remote communications device (RCD): Device which is physically a part. of the refrigeration rnachinery

and which communicates with any complying central monitoring and control Systems (CMCSs) using the re-

frigeration machinery power distribution System as the data transmission medium. See figures 1 and 2.

1

---------------------- Page: 7 ----------------------

ISO 10368:1992(E)

There are two distinct types of RCD:

- a stand-alone remote communications device (sRCD) (see 1.3.9);

- an integrated remote communications device (iRCD) (see 1.3.10).

An sRCD is defined as a device which cannot implement the hardware write messages defined in 3.4.6.1.

1.3.2 central monitoring and control System (CMCS): System consisting of hardware and Software which

monitors and controls one or more remote communications devices (RCDs). A typical System consists sf at

least

a) Operator interface devices,

b) a master monitoring unit (MMU), and

c) power line data link equipment, such as a multiple data rate central control unit (MDCU).

1.3.3 master monitoring unit (MMU): Central processing unit such as a Computer which contains specific

hardware and Software to control the entire remote condition monitoring System. lt is the interface between the

human Operator and the network.

1.3.4 multiple data rate central control unit (MDCU): Device which forms the link between the master moni-

toring unit (MMU) and the three-Phase power line bus which contains the individual remote communications

devices (RCDs). An MDCU consists of two components as follows:

central control un it capable of receiving and transmitting at the data rates which meet the requirements

a) a

of . this International Standard;

b) a central control interface.

1.3.5 high data rate remote communications device (HRCD): Remote communications device (RCD) which

transmits data at a high data rate, e.g. 19 200 baud.

1.3.6 low data rate remote communications device (LRCD): Remote communications device (RCD) which

communicates data at a low data rate, e.g. 1 200 baud.

1.3.7 high data rate central control unit (HDCU): Device which links the master monitoring unit (MMU) and the

power line network, communicating with the high data rate remote communications devices (HRCDs).

1.3.8 low data rate central control unit (LDCU): Device which links the master monitoring unit (MMU) and the

power line network, communicating with the low data rate remote communications devices (LRCDs).

1.3.9 stand-alone remote communications device (sRCD): Slave remote communications device (RCD) which,

with limited capabilities, merely monitors a Container refrigeration unit. An sRCD ca11 be either high or low data

rate.

1.3.10 integrated remote communications device (iRCD): Slave remote communications device (RCD) which

interfaces to a refrigeration unit controller via an EIA RS232-C serial interface and tan control the refrigeration

machinery. An iRCD tan be either high or low data rate.

1.3.11 controller: Device that monitors and controls the refrigeration machinery.

---------------------- Page: 8 ----------------------

ISO 10368:1992(E)

Section 2: Performance requirements

2.1 Scope

This ante requirements and contra System

section specifies the perform l of centra monitoring s (CMCS

9

nece d evices

ssary for them to i nterface and communicate with complying remote com munications (RCDs).

2.2 Requirements

2.2.1 System components

2.2.1.1 Remote condition monitoring System components

A Single remote condition monitoring System consists of a maximum of one master monitoring unit (MMU) and

one multiple data rate central control unit (MDCU). See figure 1 a).

2.2.1.2 Multiple data rate central control unit (MDCU)

An MDCU may include one high data rate central control unit (HDCU) and one low data rate central control unit

(LDCU). lf an HDCU and an LDCU are both present, the HDCU and LDCU are joined together by a central control

unit (CCU) interface, and the three components together form the MDCU.

2.2.1.3 MMUIMDCU interface

The preferred method of connecting the MMU to the MDCU complex is through a Single port as shown in

figure 1 a). However, certain expansion paths may require multiple connections as shown in figure 1 b).

2.2.1.4 High and low data rate remote communications devices (HRCDs and LRCDs)

HRCDs and LRCDs shall be able to coexist on the Same power line network and not interfere with simultaneous

communications with either the HDCU or the LDCU.

2.2.1.5 MDCU components

An MDCU may consist of either a Single HDCU (to communicate with the HRCDs on the network) or a Single

LDCU (to communicate with LRCDs on the network). However, all signalling protocols, data-logging formats,

power levels, insertion rates and other physical requirements shall be identical to that which would be used for

a combined System and therefore must be compatible. Refer to 3.2 and 3.3 for the required protocol and data-

logging formats.

2.2.2 Performance function

2.2.2.1 Standard message

All RCDs shall respond to a minimum list of standardized enquiries (see 2.2.2.4) and commands with a stan-

dardized reply or acknowledgement.

2.2.2.2 Acknowledgement message

The RCD shall send an acknowledgement message for all commands and enquiries that are received and

understood.

2.2,2.3 “Not able” message

If the RCD is not capable of executing a command received or of responding to an enquiry because of the

shail respond with a “Not able” message.

configuration of the RCD and the thermal control machinery, it

---------------------- Page: 9 ----------------------

ISO 10368:1992(E)

HDCU

u

Master monltoring

I

*. c ’

unlt

c

IMMUI

c

m-

u LDCU

c

U

MOCU

CM;S

a) Conflauratfon A

Master monltorlng

. l

MDCU

7

3@-

------ab

-,

b) Confiquration B

H = high data rate

L

= low data rate

349 = three-Phase power malns

Figure 1

- Remote condition monitoring System components layout

---------------------- Page: 10 ----------------------

ISO 10368:1992(E)

2.2.2.4 Required enquiries

All RCDs shall respond to the following required enquiries.

2.2.2.4.1 Identification number: For an integrally refrigerated or thermal Container this will be the Container

ISO number comprising a 4-letter alphabetical prefix and a 7-digit suffix (includinq the check digit). Where a

demountable marine Clip-on unit (MCOU) is used, the identification number will be the MCOU number in ISO

format.

2.2.2.4.2 Porthole Container number: This response will be in addition to the identification number for MCOU

Systems.

2.2.2.4.3 Potthole number Change: This is recorded in the RCD rnemory in alphanumerical format together with

the time of the Change.

2.2.2.4.4 Return air temperature: In the form of a positive or negative value, expressed in degrees Celsius to

one decimal place, within the range - 30,O “C to + 38,0 “C.

2.2.2.4.5 Supply air temperature: Expressed in the Same format as 2.2.2.4.4.

2.2.2.4.6 RCD manufacturer and type: Consisting of a unique identification number registered and controlled

by ISO, and for which ISO/TC 104 is the registration authority.

2.2.2.5 Optional Standard enquiries

ed s #halt

Other optional enquiries are standardized. RCDs and refrigeration machinery so equi respond to the

PP

following enquiries. RCDs not so equipped shall respond “Not able” (See 2.2.2.3).

ans only or Null mode,

2.2.2.5.1 Operating mode: Full cool, Partial or Lower capacity cool, Modulated coo 3 F

Defrost, Heat, Off.

2.2.2.5.2 Set-Point temperature: Expressed in the Same format as 2.2.2.4.4.

2.2.2.5.3 Alarms: High refrigeration pressure, Temperature out of range, Low compressor oil pressure,

Defrost/Heat/Overheat, Cornpressor overload, Controller failure, Sensor failure - Return air, Sensor

failure - Supply air, Power Off, Amperage draw too high, Amperage draw too low, Defrost (out of time).

(Capacity for future development, e.g. controlled atmosphere.)

2.2.2.5.4 All current alarms: In sequence of occurrence.

2.2.2.5.5 Product temperatures: For example, tank, poultry.

2.2.2.5.6 Data-logger interval: One digit in half-hour intervals up to a maximum of’ 12 h.

2.2.2.5.7 Amperage: 0 to 63,75 A in 0,25 A intervals.

If the destination changes, both the old and the current

2.2.2.5.8 Destination: Three alphanumerical digits.

destination may be declared.

2.2.2.5.9 Port of discharge: Three alphanumerical digits.

2.2.2.5.10 Origin: Three alphanumerical cligits.

2.2n2.5.11 Report results of self-check level 1: One dic$, 0 = Fail, 1 ==. Pass.

2.2.2.5.12 Report results of self-check level 12: In the format of up to 256 ASCII characters, where YE is a Single

Character between two and nine.

2.2.2.5.13 Vessel and voyage designation: (See ISO 9711-2.)

---------------------- Page: 11 ----------------------

ISO 10368:1992(E)

2.2.2.6 Commands

RCDs and refrigeration machinery if so equipped shall respond to the following commands. RCDs not so

equipped shall respond “Not able” (See 2.2.2.3).

2.2.2.6.1 Change Set-Point temperature: Expressed in the Same format as 2.2.2.4.4.

2.2.2.6.2 Initiate self-check level 1.

2.2.2.6.3 Initiate self-check level ~2: In the Same format as 2.2.2.5.12, where y1 is in the range two to nine.

2.2.2.6.4 Change identification number: Expressed in the Same format as 2.2.2.4.1.

2.2.2.6.5 Change data-logger interval: Expressed in the Same format as 2.2.2.5.6.

2.2.2.6.6

Set data-logger time and date: With the date expressed in the format year/month/day.

2.2.2.6.7 Change operating mode: Expressed in the Same format as 2.2.2.5.1.

2.2.2.6.8 Download data-logger record to central monitor.

2.2.2.6.9 Change porthole Container number: Expressed in the Same format as 2.2.2.4.3.

2.2.2.6.10 Change destination: Expressed in the Same format as 2.2.2.5.8.

2.2.2.7 Indecipherable or unserviceable messages

Indecipherable or unserviceable messages shall not Cause the RCD or CMCS to “Crash” or “bang up ”. Also,

failures of an electronie device in any RCD shall not Cause the System to “Crash” or “hang up ”.

2.2.2.8 Verification of Container identification number

The CMCS, if so equipped, shall verify the Container identification number, using the check digit (the seventh

digit of the numerical suffix) and an algorithm selected.

2.2.3 Performance constraints

2.2.3.1 Power interference

RCDs and CMCSs shall not interfere with the proper functioning of power supply requlating or control devices,

k.

such as voltage regulators or protective relaying equipment.

2.2.3.2 Marine device interference

CMCSs and RCDs, individually or as a System, shall not interfere with Standard marine navigation and com-

municatjon devices.

2.2.3.3 System size

All CMCSs shall be suitable to coordinate and report on a System of 1 024 RCDs active at the Same time on

one CMCS.

2.2.3.4 Status update

The MMU/MDCU System shall generate RCD updated Status per 2.2.2.4 at least once per hour per Container for

a System of up to 1 024 Containers active at the Same time on one CMCS.

6

---------------------- Page: 12 ----------------------

ISO 10368:1992(E)

2.2.3.5 Automatic RCD System list

The population or database of RCDs on the CMCS shall be self-qenerating. No input to the MMU, whether from

an Operator or from another Computer, shall be necessary to determine the RCDs connected to that System.

2.2.3.6 Identification of new RCDs

The MMWMDCU System shall be designed to identify an average of at least one new Container every 10 s, or

6 per minute.

2.2.3.7

Voltage and frequency requirements

RCDs shall be suitable for operating on the voltage Systems specified in ISO 1496-2.

2.2.3.8 Dual voltage requirements

No special handling shall be required for RCDs to operate on the three voltage types of refrigeration machinery.

(See ISO 1496-2:1988, subclause 7.2.)

2.2.3.9 RCD connection

The RCD shall be connected on the line side of the refrigeration machinery clisconnect or circuit breaker, if any,

so that communication is possible when the refrigeration machinery is switched Off. The RCD may have its own

disconnect switch for servicing.

2.2.3.10 Error rates

2.2.3.10.1 All CMCSs and RCDs shall be designed to meet the following error rate criteria.

The RCD/MDCU communication System may have two different types of “undetected and uncorrected” com-

munication errors. An “undetected and uncorrected” communication error is one which is not detected and

corrected within 5 min alter occurrence.

2.2.3.10.2 An error whereby an RCD executes a command which was not commanded by the MMU shall not

G

occur more often than one time in 25 x 10 messages (i.e. any power line disturbance which the receiver in-

terprets as a message), or more often than once in 10 years for each CMCS, whichever is greater.

2.2.3.10.3 An error whereby a CMCS misinterprets a message (i.e. any power line disturbance which the re-

ceiver interprets as a message) shall not occur more often than one time in 25 x IO5 messages.

---------------------- Page: 13 ----------------------

ISO 10368:1992(E)

System compatibility requirements

Section 3:

3.1 Scope

This section specifies the interface requirements for communications protocol, data-logging formats, message

definitions, and physical requirements for low data rate and high data rate (CU and CD).

3.2 Cammunieations protocol

Esch remote condition monitoring System has three interface areas as follows (see figure 2):

- MMU to MDCU interface;

- MDCU to RCD interface;

- RCD to refrigeration machinery controller interface.

Master

monl t orlng MDCU

unit (MMU)

MDCWRCD RCWcontroller

MMWMDCU

Interface interface Interface

(See 3.2.1) (See 3.2.2, 3.2.3, (See 3.2.41

3.5 and 3.6)

Figure 2 - Remote condition monitoring - Communications Mxfaces

8

---------------------- Page: 14 ----------------------

ISO 10368:1992(E)

3.2.1 MMU to MDCU communications

This subclause, in patt, defines the communications protocol to be used when the MDCU is implemented as a

discrete System component which is separate from the MMU architecture. The requirements given in this

subclause do not preclude the use of bus-based open architecture MDCU applications where the EIA RS232-C

is not appropriate.

The MMU communicates with the MDCU via a full duplex EIA RS232-C serial interface. The baud rate shall be

at least two times the baud rate of the fastest RCD in the System. A typical communications baud rate is

4 800 baud. Esch Character transferred requires 1 Start bit (low logic level), 8 data bits, and 1 stop bit (high logic

level). The minimum time delay required between packets is one Character time. This, therefore, restricts

deadtime between any 2 bytes in a packet to less than one Character delay.

The messages for succeeding interfaces are embedded in the formats of earlier stages (see figure3). These

messages may be intended for action by the MDCU only. These messages are described fully in 3.2.1.1. If the

message contains embedded data intended for an RCD, the format is a s described in 3.2.1.3. Similarly, em-

bedded data intended for the refriqeration machinery is described in 3.2.1.5 and 3.2.4. Note that the field length,

in bytes, is also defined in figure 3.

1 2

1 2 1

Message

Packet

Task No.

SYNC STX Data ( (,.,,(I (See 32.1)

length

1

\

\

\

\

2 \

Reply Length *) Packet (See 3.2.2 and 3.2.3)

/-

/-

Routlng byte

-/’ (See 3.2.4)

Format ot each analog output or channel

Least slgniflcant

-bit

Most slgnlf lcant

Mask bit3’ --

bit

ue of fleld

[Esch bit = W256) %l

1) Interactlve 1 and 2 commands only.

21 Devlce commands only.

31 Mask bit equals 1 if thei*e Is u Change In the field or 0 if there Is no Change.

Figure 3 - Message format overview

9

---------------------- Page: 15 ----------------------

ISO 10368:1992(E)

The information transfer format from the MMU to the MDCU is as shown in figure4.

Figure 4 - Information transfer format from the MMU to the MDCU

The inform

ation transfer format returned to the MMU from the MDCU is as shown in figure5.

SYNC Packet

RePlY

Data CRC

STX Task No.

(optional) length

tYPe

--

No. of

1 2

bytes 1 2 1 1-

-- -- ---

Figure 5 - Information transfer format returned to the MMU from the MDCU

ihe fields in figures 4 and 5 are defined as follows.

SYNC An optional synchronization field. lt tan be any nurnber of bytes, the contents of which is

16H. The MDCU Strips all SYNC characters from the Start of a message.

STX

Delimits the Start of a valid message. lt indicates that the next 2 bytes are the packet length.

Packet length A 2 byte unsigned integer which gives the packet length in bytes not including the SYNC, STX

or CRC fields. lt is transmitted high byte followed by low byte.

Task No. A 1 byte number assigned to the job before transmission to the MDCU. lt is not used by the

MDCU and is defined by the application. The MDCU reply will contain the Same value in this

field.

Task numbers shall be assigned sequentially by the MMU from 0 to 254 and then resume at

0. Task number 255 is reserved for the MDCU reset command.

Xmit type

A 1 byte command directing the MDCU as to the type of proces!;ir+ \Nhich is to be performed

on the data. The assignments are discussed in 3.2.1.1.

A 1 byte command response from the MDCU indicating the success or failure Status of the

RePlY tY Pe

corresponding job received by fhe MDCIJ. The assignments are discussed in 3.2.1.2.

Data

Variable length data field in which the contents are dependent on the type of message to be

processed. The contents are defined in 3.2.1.1 and 3.2.1.2 for each appropriate command.

CRC A 16 bit error check field generated by using the CRC-16 polynomial:

p + x15 + x* -l- 1

The optional SYNC characters arc not included in the CRC calculation.

3.2.1.1 MMU to MDCU transmit command types

There are two groups

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.