ISO/IEC 19798:2006

(Main)Method for the determination of toner cartridge yield for colour printers and multi-function devices that contain printer components

Method for the determination of toner cartridge yield for colour printers and multi-function devices that contain printer components

The scope of ISO/IEC 19798:2006 is limited to evaluation of toner cartridge page yield for toner-containing cartridges (i.e. all-in-one toner cartridges and toner cartridges without a photoconductor) for colour electrophotographic printers. It can also be applied to the printer component of any multifunctional device that has a digital input printing path, including multi-function devices that contain electro-photographic printer components.

Méthode pour la détermination du rendement de cartouche de toner pour les imprimantes couleur et pour les dispositifs multifonctionnels qui contiennent des composants d'imprimantes

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO/IEC

STANDARD 19798

First edition

2006-12-15

Method for the determination of toner

cartridge yield for colour printers and

multi-function devices that contain

printer components

Méthode pour la détermination du rendement de cartouche de toner

pour les imprimantes couleur et pour les dispositifs multifonctionnels qui

contiennent des composants d'imprimantes

Reference number

ISO/IEC 19798:2006(E)

©

ISO/IEC 2006

---------------------- Page: 1 ----------------------

ISO/IEC 19798:2006(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

© ISO/IEC 2006

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO/IEC 2006 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/IEC 19798:2006(E)

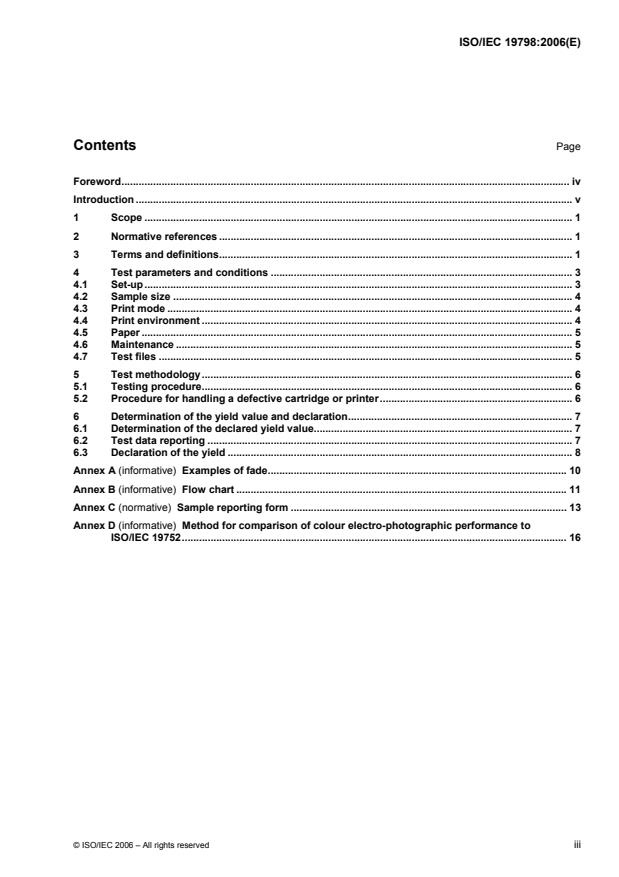

Contents Page

Foreword. iv

Introduction . v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Test parameters and conditions . 3

4.1 Set-up. 3

4.2 Sample size . 4

4.3 Print mode . 4

4.4 Print environment . 4

4.5 Paper . 5

4.6 Maintenance . 5

4.7 Test files . 5

5 Test methodology. 6

5.1 Testing procedure. 6

5.2 Procedure for handling a defective cartridge or printer. 6

6 Determination of the yield value and declaration. 7

6.1 Determination of the declared yield value. 7

6.2 Test data reporting . 7

6.3 Declaration of the yield . 8

Annex A (informative) Examples of fade. 10

Annex B (informative) Flow chart . 11

Annex C (normative) Sample reporting form . 13

Annex D (informative) Method for comparison of colour electro-photographic performance to

ISO/IEC 19752. 16

© ISO/IEC 2006 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/IEC 19798:2006(E)

Foreword

ISO (the International Organization for Standardization) and IEC (the International Electrotechnical

Commission) form the specialized system for worldwide standardization. National bodies that are members of

ISO or IEC participate in the development of International Standards through technical committees

established by the respective organization to deal with particular fields of technical activity. ISO and IEC

technical committees collaborate in fields of mutual interest. Other international organizations, governmental

and non-governmental, in liaison with ISO and IEC, also take part in the work. In the field of information

technology, ISO and IEC have established a joint technical committee, ISO/IEC JTC 1.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of the joint technical committee is to prepare International Standards. Draft International

Standards adopted by the joint technical committee are circulated to national bodies for voting. Publication as

an International Standard requires approval by at least 75 % of the national bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO and IEC shall not be held responsible for identifying any or all such patent rights.

ISO/IEC 19798 was prepared by Joint Technical Committee ISO/IEC JTC 1, Information technology,

Subcommittee SC 28, Office equipment.

iv © ISO/IEC 2006 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/IEC 19798:2006(E)

Introduction

The purpose of this International Standard is to provide a process for determining the cartridge page yield for

a given colour electro-photographic printer model (i.e. all-in-one toner cartridges and toner cartridges without a

photoconductor) using a standard office consumer type test suite. This test suite is not focused on printing of

photographs, but is intended to be a sampling typical office consumer pages.

This International Standard prescribes the following:

• The test method that manufacturers, test labs, etc. use to determine cartridge yield;

• The method for determination of declared yield values from the test results; and

• The appropriate method of describing the yield of cartridges in documentation supplied to the

consumer by the manufacturer.

The cartridge yield is determined by an end of life judgment, or signalled with either of two phenomena: fade

caused by depletion of the useable toner in the cartridge; or automatic printing stop caused by a Toner Out

detection function.

This International Standard will be used for the measurement of one of the contributions to cost per page

(CPP). This International Standard does not directly measure CPP, only the yield of the magenta, cyan,

yellow and black toner cartridges. In most cases, these are not the only contributors to the CPP. It is beyond

the scope of this document to provide a methodology for calculation of CPP.

© ISO/IEC 2006 – All rights reserved v

---------------------- Page: 5 ----------------------

INTERNATIONAL STANDARD ISO/IEC 19798:2006(E)

Method for the determination of toner cartridge yield for colour

printers and multi-function devices that contain printer

components

1 Scope

The scope of this International Standard is limited to evaluation of toner cartridge page yield for toner-

containing cartridges (i.e. all-in-one toner cartridges and toner cartridges without a photoconductor) for colour

electro-photographic printers. This International Standard can also be applied to the printer component of any

multifunctional device that has a digital input printing path, including multi-function devices that contain

electro-photographic printer components.

This International Standard is only intended for the measurement of toner cartridge page yield when printing

on plain paper using cyan, magenta, yellow and black toner cartridges. No other claims can be made from this

testing regarding quality, reliability, etc.

This International Standard is not for use with printers whose minimum printable size is equal to or greater

than A3 or for photo only printers.

NOTE Application of this International Standard for yield measurement of toner replenishment systems (i.e. toner

cartridge- and bottle type systems where the toner reservoir is internal to the printing system and not user-replaceable)

requires some procedural modifications specifically noted herein. This International Standard is intended for equipment

used in the office space and does not apply to production volume or large format printing machines where the major cost

of ownership is not caused by the consumable yield measured in this International Standard.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO/IEC 24712, Colour test pages for the measurement of office equipment consumable yield

ISO/IEC 19752, Information technology — Method for the determination of toner cartridge yield for

monochromatic electrophotographic printers and multi-function devices that contain printer components

3 Terms and definitions

For the purposes of ISO/IEC 19798, the following terms and definitions apply.

3.1

fade

phenomenon in which a noticeable reduction in density (increase in lightness) uniformity in the the bars

around sides of the diagnostic page occurs

NOTE 1 This does not have to be a distinct gap.

© ISO/IEC 2006 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/IEC 19798:2006(E)

NOTE 2 In this test, fade is defined as a noticeably lighter area, 3mm or greater located in the bars around the

diagnostic page of the test suite. Generally, the lightening will occur parallel to the paper movement direction during

th

printing. The determination of the change in lightness is to be made referenced to the 100 page (Diagnostic Page)

printed for each cartridge in testing. For examples of fade, please consult Annex A.

3.2

shake procedure

in the case that the cartridge user’s manual instructs cartridge shaking and its method, shaking the cartridge is

performed according to the manual instructions

NOTE If a shake procedure is used in testing it will be noted in the report.

3.3

toner low

warning generated by the printing system when it has determined that the amount of toner is such that a

cartridge change may be required soon

NOTE It does not indicate that the system is out of toner.

3.4

toner out

signal generated by the printing system when the useable toner in the system is depleted and the printer will

not continue printing without user intervention

NOTE For the purpose of this test, the toner out signal will only be used if it causes the printer to stop printing.

3.5

end of life

when the printer declares "Toner Out" or when fade is observed

NOTE 1 The general intent of this definition is to allow two shake procedures near end of life and to declare end of life

at the first fade after the two shake procedures. Nominally, the shake procedures are to be executed at print fade.

However, if the printer is equipped with a toner low device, then the first, second or both shake procedures can be

executed at toner low instead of at fade as a convenience for the tester. If the cartridge user’s guide does not specify a

shake procedure, then the shake procedures are not performed and end of life occurs at the first fade. Any faded pages

printed during the test are to be excluded from the cartridge page count.

NOTE 2 If the printer is equipped with a toner out device, then end of life occurs when the printer declares toner out.

However, when fade occurs before toner out and no shake procedure is specified, then end of life is declared at the fade.

If a shake procedure is specified for a printer with a toner out device, then up to two shake procedures can be executed as

described in Note 1 when fade occurs before toner out. In this case, if fade occurs after two shake procedures but before

toner out, then end of life is declared at the third fade. If toner out occurs at any time during testing, the cartridge is

considered to be at end of life.

NOTE 3 When applied to replenishment systems (bulk toner replacement or multi-part toner systems), the intent of this

definition is to declare a quasi-end of cartridge life at a regular predetermined point. If the printer is equipped with a toner

low or toner out signal, these can be used as the point of quasi-end of life. In either case, the end of life condition chosen

must be noted in the test report.

NOTE 4 When shake procedures have been performed during the test, the test report will note for both the first and

second shake procedures whether they were done at Toner Low or at fade. Any faded pages printed during the test are to

be excluded from the cartridge page count.

NOTE 5 Application of this definition may be clarified by reference to a flow chart and examples found in Annex B.

2 © ISO/IEC 2006 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/IEC 19798:2006(E)

3.6

individual cartridge yield

value determined by counting the number of diagnostic pages (page 5) printed between cartridge installation

and end of life (as defined in 3.5) and multiplying by 5.

NOTE If the printer stops due to toner out in the middle of a test page suite, the number of the diagnostic pages

printed is counted. Then, the first diagnostic page of the suspended print job is included in the subsequent cartridge yield.

The number of test page suites counted may contain some pages that show visible fade. To simplify the testing,

determination of end of life is only made on the diagnostic page (page 5).

3.7

declared cartridge yield

value at or below the lower 90% confidence bound as prescribed in 6.1 and 6.3.

4 Test parameters and conditions

4.1 Set-up

Place the printer on a horizontal surface and set-up the printer according to the installation guide provided in

the printer user’s manual. Use the most recent printer driver available from the manufacturer's website or the

supplied driver with the printer. The driver version will be specified on the test report. Cartridge installation

shall be completed following the instructions in the cartridge installation guide. If there is a contradiction

between the printer and cartridge manuals for the cartridge installation, the cartridge manual will take

precedence except if changes are recommended for printer or driver settings

If the cartridges used in testing are toner replenishment or toner bottle types, then one set of toner cartridges

will be used to end of life in each printer before the start of the test. The pages printed to deplete these

priming cartridges do not have to be recorded and printing can be conducted at any environment. The priming

cartridges are used to bring the printing system to a set toner level condition.

NOTE: The cartridges used to bring the printing system to a set toner level condition do not have to start out full. For large

capacity systems, using a complete cartridge could result in tens of thousands of pages printed just to bring the system to

a set condition.

All image and print quality modifiers shall be at their factory pre-set configuration for the printer and default

installed condition for the driver. If the printer and driver differ, then the driver defaults shall be used. Any user

selectable toner conservation modes shall be disabled during testing. If auto media detection is available on

the printer, it shall be disabled and media-type set to plain paper. This is to avoid inaccurate sensing of the

media.

If the printer under test uses an internal PDF interpreter, it is ok to use it as long as the printer defaults are set

to not substitute fonts. If the internal interpreter is used, this shall be noted on the report.

To assure that the test page is printed correctly, any page size modifiers such as Fit to Page and font

substitution shall be turned off. If the option exists, rendering of graphics shall be performed by the printer, not

the application software or operating system. The files shall be printed using the fonts embedded in the file

and shall be printed on the page in a size corresponding to the dimensions in the test suite standard (ISO/IEC

24712). Page placement modifiers such as page centering can be used to place the image properly on the

page. If available, any colour management shall be set to the printer and driver installed defaults. If there is a

question about rendering settings affecting the yield, the setting shall be noted in the report.

NOTE: The application software (i.e. Adobe Reader), printer driver and printer may have page size modifier functions,

such as “Fit to Page”. Make sure that all of these functions are disabled.

© ISO/IEC 2006 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/IEC 19798:2006(E)

4.2 Sample size

The sample size shall be determined such that for each calculated yield value a minimum of nine physical

cartridge sets are tested using a minimum of three printers. An equal number of cartridge sets must be tested

on each printer. For example, three sets of cartridges could be tested on three printers with each printer using

three sets of cartridges. In the case of a typical four colour printer with four single colour cartridges this would

result in 36 cartridges being tested, 9 Black (K), 9 Cyan (C), 9 Magenta (M) and 9 Yellow (Y).

When testing additional engines and cartridges above the minimum, an effort shall be made to test equal

number of cartridges on each engine. For example, if an additional engine were to be tested then the

minimum number of cartridges to be tested would be 48 (3 cartridges X 4 colours X 4 engines) for a four-

cartridge system.

When testing cartridges for a commercially available product, it is recommended that cartridges and printers

be procured from various sources, or sampled from different production lots. The printers and cartridges must

be within their useful life as stated in their user’s manual.

Note: It is recommended that additional engines and/or cartridges be used in testing to allow for the possibility of a

cartridge and/or printer failure during testing.

4.3 Print mode

For reporting cartridge yield, the test will be run in semi-continuous simplex printing and set in the driver

default print mode. Each copy of the test suite shall be printed as a separate five page print job. This shall

allow for some intra-job c

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.