ISO/TR 7147:1985

(Main)Plain bearings — Testing of the tribological behaviour of plastics

Plain bearings — Testing of the tribological behaviour of plastics

Paliers lisses — Essai du comportement tribologique des plastiques

General Information

Relations

Standards Content (Sample)

TECHNICAL REPORT 7147

Published 1985-12-15

INTERNATIONAL ORGANIZATION FOR STANDARDIZATI~N- ME>K,QYHAPOaHAR OPrAHM3AWfl no CTAHAAPTM3A~M1/1.ORGANISATION INTERNATIONALE DE NORMALISATION

Plain bearings - Testing of the tribological behaviour of

plastics

Paliers lisses - Essai du comportemen t tribologique des plas tiques

ISO (International Organization for Standardization) is a worldwide federation of national Standards bodies WO member bodies). The

work of preparing International Standards is normally carried out through ISO technical committees. Esch member body interested in

a subject for which a technical committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

The main task of ISO technical committees is to prepare International Standards. In exceptional circumstances a technical committee

may propose the publication of a technical report of one of the following types :

-

type 1, when the necessary support within the technical committee cannot be obtained for the publication of an International

Standard, despite repeated efforts;

-

type 2, when the subject is still under technica I development requiring wider exposure;

-

type 3, when a technical committee has tolle cted data of a different kind from that which is normally published as an

International Standard (“state of the art”, for example).

Technical reports are accepted for publication directly by ISO Council. Technical reports types 1 and 2 are subject to review within

three years of publication, to decide if they tan be transformed into International Standards. Technical reports type 3 do not

necessarily have to be reviewed until the data they provide is considered no longer valid or useful.

ISO/TR 7147 was prepared by Technical Committee ISO/TC 123, Plain bearings.

The reasons which led to the decision to publish this document in the form of a technical report type 2 are explained in the

Introduction.

0 Introduction

As several research institutes are still carrying out tests on the tribological behaviour of plastics for plain bearings and, consequently,

results are not yet available, it has been decided, for the time being, to publish work on the test System in the form of a Technical

Report.

When the test results from the different institutes are available, the Status of this Technical Report will be re-assessed.

1 Scope and field of application

This Technical Report specifies uniform instructions for the testing of tribologically-stressed plain bearing elements manufactured

from solid plastics.

‘The test values will give useful information for practical application only if all Parameters of influence are identical.

Ref. No. ISO/TR 7147-1985 (E)

UDC 678.5/.8 : 621.178.162

Descriptors : bearings, plain bearings, plastics, tests, friction tests, wear tests.

0 International Organkation for Standardkation, 1985 Q

Price based on 10 pages

Printed in Switzerland

---------------------- Page: 1 ----------------------

ISO/TR 7147-1985 (E)

The purpose of this Technical Report is to obtain, under specified and exactly defined operating conditions, reproducible measured

values for wear and the coefficient of friction as regards plastics/steel or plastics/plastics sliding couples. Consequently, to obtain

comparability of these values, exact indications are necessary concerning directly acting influences, such as the form of the specimen,

the condition of surface and material or the sliding couple. This Technical Report, therefore, defines the forms that test specimens

shall take and specifies uniform manufacturing processes for the test specimens. In Order also to eliminate the secondary influences

created by the nature of the test System (e.g. conditions of thermal conduction, vibrations, driving vibrations, mounting conditions)

the complete test equipment and basic construction and Performance requirements have also been standardized.

2 References

ISO 291, Plastics - Standard a tmospheres for conditioning and testing.

ISO 527, Plastics - Determination o f tensile properties. 1)

ISO 4378, P/ain bearings; Terms, definitions and classifica tion -

Part 7: Design, bearing materials and their properties.

Part 2: Friction and wear.

Part 3: 1 ubrica tion.

l SO 6691, Plain bearings - Thermoplastics - Classifica tion, designa tion, recommenda tions. 2)

3 Symbols

nominal contact surface, in Square millimetres

AO

coeff icient of f riction

f

normal forte, in newtons

F”

friction forte, in newtons

Ff

k - wear coefficient, in cubic millimetres per newton kilometre

nominal specific load, in newtons per Square millimetre

P

mean radius of sliding way, in millimetres

%

sliding distance, in kilometres

temperature of the disc, in degrees Celsius

td

U sliding velocity, in metres per second

linear wear of test material, in micrometres

WI

volumetric wear of test material, in cubic millimetres

WV

linear wear rate, in micrometres per kilometre

wllS

volumetric wear rate, in cubic millimetres per kilometre

wv!s

4 Definitions

4.1 dry friction : Condition initially degreased and cleaned sliding surfaces are in contact with each

of f riction where two

without external lubrication.

4.2 coefficient of friction: Ratio of the friction forte between two bodies to the normal forte pressing these bodies together, i.e. :

Ff

f -

= Fn

4.3 wear rate: The linear or volumetric wear of the test material referred to the sliding distance, i.e. :

Wi WV

wlls = --j- Or wvls = -j-

-~-

1) At present at the Stage of draft. (Revision of ISO/R 5271966.)

At present at the Stage of draft.

2)

2

---------------------- Page: 2 ----------------------

ISO/TR 7147-1985 (El

nominal specific load or volumetric wear rate referred to the normal

4.4 wea r coefficient: The linear wear rate referred to the

forte, i.e. :

wllS wvls

=-

x 10-3 = - x 10-3

k

P Cl ’

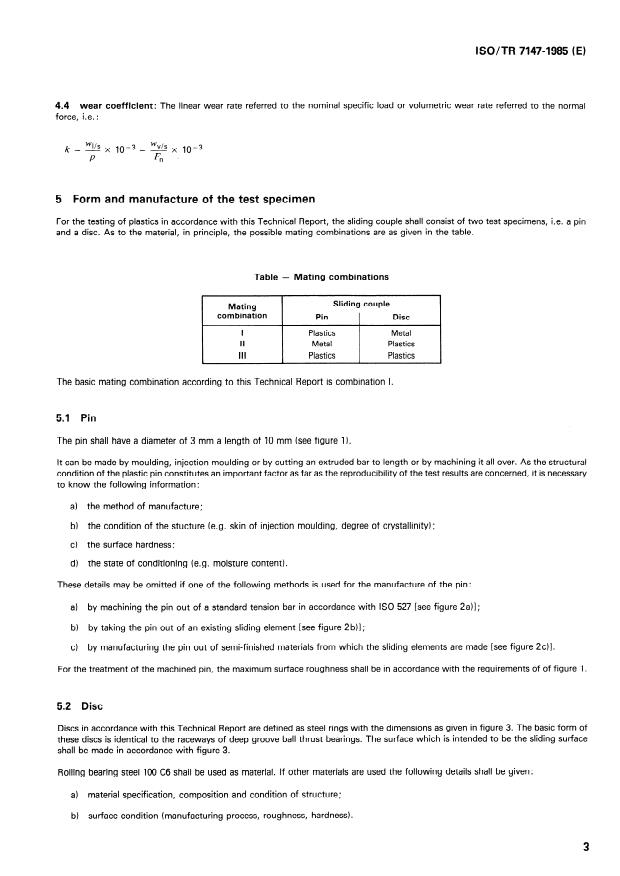

5 Form and manufacture of the test specimen

the testing plastics in accordance with this Technical Report, the sliding couple shall consist of two test specimens, i.e. a pin

For of

in the table.

and a disc. As to the material, in principle, the possible mating combinations are as given

Ta ble - Mating combinations

Sliding couple

Mating

combination

Pin Disc

I I

I Plastics Metai

II Metal Plastics

Ill Plastics Plastics

The basic mating combination according to this Technical Report is combination 1.

5.1 Pin

The pin shall have a diameter of 3 mm a length of 10 mm (see figure 1).

lt tan be made by moulding, injection moulding or by cutting an extruded bar to length or by machining it all over. As the structural

condition of the plastic pin constitutes an important factor as far as the reproducibility of the test results are concerned, it is necessary

to know the following information:

a) the method of manufacture;

b) the condition of the stucture (e.g. skin of injection moulding, degree of crystallinity);

c) the surface hardness;

d) the state of conditioning (e.g. moisture content).

These details may be omitted if one of the following methods is used for the manufacture of the pin:

a) by machining the pin out of a Standard tension bar in accordance with ISO 527 [see figure 2a)l;

b) by taking the pin out of an existing sliding element [sec figure 2b)l;

c) by manufacturing the pin out of semi-finished materials from which the sliding elements are made [sec figure 2c)l.

For the treatment of the machined pin, the maximum surface roughness shall be in accordance with the requirements of of figure 1.

5.2 Disc

Discs in accordance with this Technical Report are defined as steel rings with the dimensions as given in figure 3. The basic form of

these discs is identical to the raceways of deep groove ball thrust bearings. The surface which is intended to be the sliding surface

shall be made in accordance with figure 3.

Rolling bearing steel 100 C6 shall be used as material. If other materials are used the following details shall be given:

a) material specification, composition and condition of structure;

Id surface condition (manufacturing process, roughness, hardness).

---------------------- Page: 3 ----------------------

ISO/TR 7147-1985 (E)

Dimensions in millimetres

Dimensions in millimetres

-iii

E

3

0

.-

cn

.-

:

;5,

Figure 1 - Test specime

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.