ISO 26146:2012

(Main)Corrosion of metals and alloys — Method for metallographic examination of samples after exposure to high-temperature corrosive environments

Corrosion of metals and alloys — Method for metallographic examination of samples after exposure to high-temperature corrosive environments

ISO 26146:2012 covers examination of samples that have previously been exposed to corrosive environments at high temperatures. ISO 26146:2012 covers the classification, identification, and thickness measurement of any corrosion layer forming during the exposure.

Corrosion des métaux et alliages — Méthode d'étude métallographique d'échantillons soumis à des environnements corrosifs à haute température

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 26146

First edition

2012-12-15

Corrosion of metals and alloys —

Method for metallographic examination

of samples after exposure to high-

temperature corrosive environments

Corrosion des métaux et alliages — Méthode d’étude

métallographique d’échantillons soumis à des environnements

corrosifs à haute température

Reference number

©

ISO 2012

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the

address below or ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

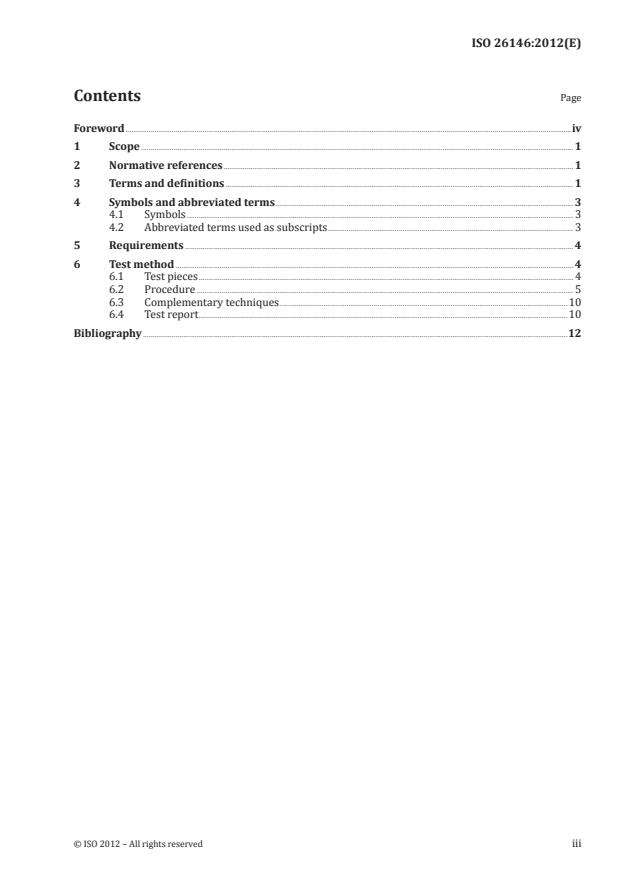

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols and abbreviated terms . 3

4.1 Symbols . 3

4.2 Abbreviated terms used as subscripts . 3

5 Requirements . 4

6 Test method . 4

6.1 Test pieces . 4

6.2 Procedure . 5

6.3 Complementary techniques .10

6.4 Test report .10

Bibliography .12

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

ISO 26146 was prepared by Technical Committee ISO/TC 156, Corrosion of metals and alloys.

iv © ISO 2012 – All rights reserved

INTERNATIONAL STANDARD ISO 26146:2012(E)

Corrosion of metals and alloys — Method for

metallographic examination of samples after exposure to

high-temperature corrosive environments

1 Scope

This International Standard covers examination of samples that have previously been exposed to

corrosive environments at high temperatures.

This International Standard covers the classification, identification, and thickness measurement of any

corrosion layer forming during the exposure.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 3611, Geometrical product specifications (GPS) — Dimensional measuring equipment: Micrometers for

external measurements — Design and metrological characteristics

ISO 13385-1, Geometrical product specifications (GPS) — Dimensional measuring equipment — Part 1:

Callipers; Design and metrological characteristics

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

NOTE Figure 1 provides a diagrammatic representation of appropriate parameters.

3.1

original metal surface

surface of the metallic sample before coating or exposure to the corrosive environment

3.2

original coating surface

surface of the coating after final processing treatment but before exposure to the corrosive environment

3.3

interdiffusion zone

region around the original interface between coating and substrate that, during exposure, has changed

composition through diffusion processes between the coating and the substrate

3.4

deposit

chemically active liquid or solid species that are placed in contact with or are deposited on the test piece

before and/or during exposure

EXAMPLE Salts, fly ashes, chars, and molten metals.

3.5

deposit thickness

distance, normal to the test piece surface, between the outer extent of corrosion product and the surface

of the deposit layer

3.6

coating

layer of material applied to a metal surface to provide protection

3.7

coating thickness

distance, normal to the test piece surface, between the original metal surface and the surface of the coating

3.8

outward growing corrosion scale

corrosion scale that grows outwards from the original metal or coating surface

3.9

inward growing corrosion scale

corrosion scale that grows inwards from the original metal or coating surface

3.10

external scale

total of outward and inward growing continuous corrosion scales

3.11

internal corrosion

corrosion products that form beneath any external scale

Note 1 to entry: These usually appear as discrete particles.

3.12

grain boundary corrosion

corrosion product that grows along metal grain boundaries as a particular form of internal corrosion

3.13

de-alloyed zone

zone beneath the corrosion scale(s) that exhibits a decrease in the concentration of scale-forming

alloy elements

Note 1 to entry: This may be manifested as the dissolution of precipitates originally present in the microstructure.

3.14

metal loss

distance between the original test piece surface and the boundary with unaffected alloy

3.15

remaining sound metal

section of metal that has not been affected by corrosion

2 © ISO 2012 – All rights reserved

a) Uncoated b) Coated

Key

1 substrate

2 de-alloyed zone

3 internal corrosion

4 external scale

5 deposit

6 interdiffusion zone

7 coating

Figure 1 — Identification of individual layers to be measured in exposed test pieces

4 Symbols and abbreviated terms

4.1 Symbols

x thickness of individual layer

t metal thickness

4.2 Abbreviated terms used as subscripts

The identification of individual layers is through the use of the following subscripts:

0 initial

og outward growing part of the external corrosion scale

ig inward growing part of the external corrosion scale

tot total thickness of external scale (x = x + x )

tot og ig

in internal corrosion

gb grain boundary corrosion

d deposit

c coating

da de-alloyed

ml metal loss compared to original dimensions

rm remaining sound metal

5 Requirements

The minimum requirement for measurement accuracy is to achieve an uncertainty at the 95 % confidence

limit of ±5 µm or 5 % of the measured material loss, whichever is the lesser for all errors, i.e. calibration,

misalignment, both in the vertical and horizontal directions, and measurement.

Measurements shall be carried out under an optical microscope with an X-Y moving stage or with

graticule and cross wires. The precision of the measurement system shall be to a precision of ±1 µm.

The measurement system shall be fully calibrated to include orthogonality, traceable to certified length

standards at intervals no greater than 12 months. The system shall be checked against secondary

standards at the beginning and the end of each series of measurements.

6 Test method

6.1 Test pieces

The size(s) and shape(s) of the test pieces adopted are governed by the type and form of material

received from the various suppliers, e.g. wrought products (bar, rod, plate, strip) or cast products (sticks

of varying shapes).

Three basic forms of test piece are considered appropriate, i.e. rod, disc, or block. These simple geometries

are easier to measure and hence less prone to errors.

Machine tolerances should preferably be better than ±0,05 mm; however, on larger test pieces, this

requirement may be relaxed.

Reference marks are not usually made on test pieces exposed in the laboratory. However, for special

cases or other exposures, e.g. probes in plant, test pieces may contain reference positions sufficient

to identify a specific point within the measurement plane, both pre- and post-exposure. The reference

marks serve as a datum, thus ensuring that repeat measurements are made at identical positions on the

test piece. This can be achieved by use of a reference mark and reference groove. These reference marks

and grooves vary with test piece geometry. Figure 2 shows the reference mark and groove for a block

sample; similar marks and grooves may be placed on other sample geometries.

4 © ISO 2012 – All rights reserved

Key

1 reference mark

2 reference groove

Figure 2 — Example of reference mark on block sample

6.2 Procedure

6.2.1 Examination prior to exposure

The dimensions of the uncorroded sample shall be measured prior to exposure. The dimensions of the

test piece shall be measured with a precision of ±0,02 mm by means of the measuring instruments

specified in ISO 3611 and ISO 13385-1. Measurements should be taken at a minimum of eight equidistant

positions across the intended section for the post-test measurements.

This forms the basis of the definition of the original metal surface.

6.2.2 Preparation of cross-sections

Dimensional changes of the test piece after exposure shall be determined by preparing a metallographic

cross-section. Particular care should be taken in preparation of this cross-section to ensure that the

test piece is mounted and polished parallel to the intended plane of the cross-section and all corrosion

products and deposits are retained. The procedure recommended is as follows.

In order to retain the corrosion product and deposit, the test piece shall be protected with an appropriate

coating. A deposited metallic coating or thermoplastic resin may be suitable depending on the system

to be investigated.

Specimen supports may be included in the mount to ensure that the section surface remains planar. The

artefacts described below may fulfil this purpose.

The test piece may be sectioned before or after mounting. Rod and tube test pieces should be sectioned to

a circular cross-section normal to the primary axis. Disc test pieces should be cut parallel to the primary

axis. Block test pieces should be cut parallel to the longest side. Sectioning details are shown in Figure 3.

If there is a requirement to reveal a cross-section at a specific plane relative to the surface by a reference

mark, the cut should be made at a sufficient distance from that plane to allow for removal of material

during grinding and polishing (see Figure 3).

Key

1 sectioning cutting

2 reference groove

Figure 3 — Sectioning procedure for test pieces with reference mark

In order to verify that the test piece has been mounted and polished parallel to the intended plane of the

cross-section, one or more reference artefacts of known dimensions should be included in the mount.

Flat test pieces (disc and square geometries) may be mounted together with a metal sheet of constant

and known thickness (±1 µm) clamped parallel to the test piece. Rod-shaped test pieces may use a

similar metal sheet of known thickness that has been bent through a known angle (90° is convenient)

and the test piece held in the corner. Alternatively, a series of spheres may be positioned around the test

piece in the mount. An illustration of the use of comparison artefacts to check the alignment of polishi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.