ISO 105-P:1978

(Main)Textiles — Tests for colour fastness — Part P: Colour fastness to heat treatments

Textiles — Tests for colour fastness — Part P: Colour fastness to heat treatments

Textiles — Essais de solidité des teintures — Partie P: Solidité des teintures aux traitements thermiques

General Information

Relations

Standards Content (Sample)

105lP

International Standard

INTERNATIONAL ORGANIZATION COR STANOARDIZATION.MEXAYHAPOflHAfl OPTAHMBAUHA no CTAHAAPTM3AUHHWRGANlSATlON INTERNATIONALE DE NORMALISATION

Textiles - Tests for colour fastness -

L

Part P: Colour fastness to heat treatments

Textiles - Essais de solidit6 des teintures - Partie P: Solidité des teintures aux traitements thermiques

First edition - 1978-12-15

Updated and reprinted - 1982-09-01

1 Lu UDC 677.016.47 Ref. No. IS0 1051P-1978 (E)

CO

E

Descriptors : textiles, dyes, tests, colour fastness, visual inspection, synthetic fibres, thermal tests, dry heat tests, water vapour tests, pleating.

Price based on 6 pages

---------------------- Page: 1 ----------------------

Foreword

IS0 (the International Organization for Standardization) is a worldwide federation of

national standards institutes (IS0 member bodies). The work of developing Inter-

national Standards is carried out through IS0 technical committees. Every member

body interested in a subject for which a technical committee has been set up has the

right to be represented on that committee. International organizations, governmental

and non-governmental, in liaison with ISO, also take part in the work.

Draft International Standards adopted by the technical committees are circulated to

the member bodies for approval before their acceptance as International Standards by

the IS0 Council.

International Standard IS0 105/P was developed by Technical Committee ISO/TC 38,

Textiles.

It was submitted directly to the IS0 Council, in accordance with sub-clause 5.10.1 of

part 1 of the Directives for the technical work of ISO.

This part of IS0 105 cancels and replaces group P of IS0 105-1978, originally published

as parts 2 and 5 of IS0 Recommendation R 105/1V-1968.

NOTE - International Standard IS0 105 is presented in the form of parts. Each of these parts

corresponds to a group and is split up into its different component sections. This form facilitates

the replacement of existing sections by successive editions as necessa n/.

O International Organization for Standardization, 1978 O

Printed in Switzerland

II

---------------------- Page: 2 ----------------------

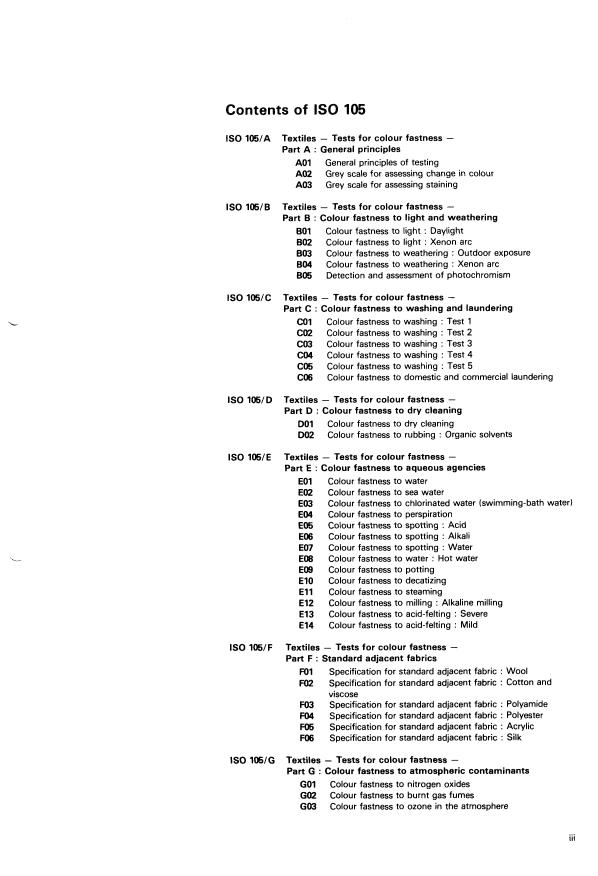

Contents of IS0 105

IS0 1E/A Textiles - Tests for colour fastness -

Part A : General principles

A01 General principles of testing

Grey scale for assessing change in colour

A02

Grey scale for assessing staining

A03

- Tests for colour fastness -

IS0 105/B Textiles

Part B : Colour fastness to light and weathering

BO1 Colour fastness to light : Daylight

Colour fastness to light : Xenon arc

BO2

Colour fastness to weathering : Outdoor exposure

BO3

BO4 Colour fastness to weathering : Xenon arc

Detection and assessment of photochromism

BO5

IS0 1O5/C Textiles - Tests for colour fastness -

Part C : Colour fastness to washing and laundering

CO1 Colour fastness to washing : Test 1

Colour fastness to washing : Test 2

CO2

CO3 Colour fastness to washing : Test 3

CO4 Colour fastness to washing : Test 4

Colour fastness to washing : Test 5

CO5

Colour fastness to domestic and commercial laundering

CO6

IS0 105/D Textiles - Tests for colour fastness -

Part D : Colour fastness to dry cleaning

DO1 Colour fastness to dry cleaning

Colour fastness to rubbing : Organic solvents

DO2

- Tests for colour fastness -

IS0 105/E Textiles

Part E : Colour fastness to aqueous agencies

E01 Colour fastness to water

Colour fastness to sea water

EO2

Colour fastness to chlorinated water (swimming-bath water)

E03

EO4 Colour fastness to perspiration

E05 Colour fastness to spotting : Acid

EO6 Colour fastness to spotting : Alkali

Colour fastness to spotting : Water

EO7

E08 Colour fastness to water : Hot water

E09 Colour fastness to potting

E10 Colour fastness to decatizing

Ell Colour fastness to steaming

Colour fastness to milling : Alkaline milling

E12

Colour fastness to acid-felting : Severe

E13

E14 Colour fastness to acid-felting : Mild

Textiles - Tests for colour fastness -

IS0 105/F

Part F : Standard adjacent fabrics

M1 Specification for standard adjacent fabric : Wool

Specification for standard adjacent fabric : Cotton and

FO2

viscose

FO3 Specification for standard adjacent fabric : Polyamide

FO4 Specification for standard adjacent fabric : Polyester

Specification for standard adjacent fabric : Acrylic

FO5

FO6 Specification for standard adjacent fabric : Silk

Textiles - Tests for colour fastness -

IS0 105/G

Part G : Colour fastness to atmospheric contaminants

Colour fastness to nitrogen oxides

GO1

GO2 Colour fastness to burnt gas fumes

GO3 Colour fastness to ozone in the atmosphere

iii

---------------------- Page: 3 ----------------------

Textiles - Tests for colour fastness -

IS0 105/J

Part J : Measurement of colour and colour differences

JO1 Method for the measurement of colour and colour differences

IS0 105/N Textiles - Tests for colour fastness -

Part N : Colour fastness to bleaching agencies

: Hypochlorite

NO1 Colour fastness to bleaching

NO2 Colour fastness to bleaching : Peroxide

NO3 Colour fastness to bleaching : Sodium chlorite : Mild

Colour fastness to bleaching : Sodium chlorite : Severe

NO4

N05 Colour fastness to stoving

Textiles - Tests for colour fastness -

IS0 105/P

Part P : Colour fastness to heat treatments

Colour fastness to dry heat (excluding pressing)

PO1

PO2 Colour fastness to pleating : Steam pleating

IS0 105/s Textiles - Tests for colour fastness -

Part S : Colour fastness to vulcanizing

Colour fastness to vulcanizing : Hot air

SO1

Colour fastness to vulcanizing : Sulphur monochloride

SO2

SO3 Colour fastness to vulcanizing : Open steam

IS0 105/x Textiles - Tests for colour fastness -

Part X : Tests not included in parts A to S or part 2

xo1 Colour fastness to carbonizing : Aluminium chloride

Colour fastness to carbonizing : Sulphuric acid

X02

xo3 Colour fastness to chlorination

Colour fastness to mercerizing

XO4

Colour fastness to organic solvents

X05

XO6 Colour fastness to soda boiling

X07 Colour fastness to cross-dyeing : Wool

XO8 Colour fastness to degumming

XO9 Colour fastness to formaldehyde

XI0 Assessment of migration of textile colours into polyvinyl

chloride coatings

Colour fastness to hot pressing

XI 1

XI2 Colour fastness to rubbing

XI3 Colour fastness of wool dyes to processes using chemical

means for creasing, pleating and setting

Textiles - Tests for colour fastness -

IS0 105/2

Part 2 : Colorant characteristics

201 Colour fastness to metals in the dye-bath : Chromium salts

Colour fastness to metals in the dye-bath : Iron and copper

202

IV

---------------------- Page: 4 ----------------------

IS0 105-Pol-1978 (E)

INTERNATIONAL STANDARD

Textiles - Tests for colour fastness

PO1 Colour fastness to dry heat (excluding pressing)

allows the composite specimen to be set in a flat position

1 SCOPE AND FIELD OF APPLICATION

under a pressure of 4 f 1 kPa at a pre-selected and

1.1 This method is intended for determining the resistance

uniformly distributed temperature (see clause 8).

of the colour of textiles of all kinds and in all forms to the

action of dry heat, excluding pressing.

4.2 Two adjacent fabrics, each of a size adapted to that of

the heating device, one piece made of the same kind of

1.2 Three tests differing in temperature are provided; one

fibre as that of the textile to be tested, or that

i

or more of them may be used, depending on the

predominating in the case of blends, the second piece made

requirements and the stability of the fibres.

of polyester fibre unless otherwise specified.

1.3 When this method is used for assessing colour change

4.3 Grey scales for assessing change in colour and staining

and staining in dyeing, printing and finishing processes, it

(see clause 3).

should be recognized that other chemical and physical

factors may influence the results.

5 TEST SPECIMEN

2 PRINCIPLE

5.1 If the textile to be tested is fabric, place a specimen of

a size adapted to that of the heating device between the

A specimen of the textile in contact with specified adjacent

two adjacent fabrics (4.2) and sew along one of the shorter

fabrics is heated by close contact with a medium which is

sides to form a composite specimen.

heated to the required temperature. The change in colour

of the specimen and the staining of the adjacent fabrics are

5.2 If the textile to be tested is yarn, knit it into fabric

assessed with the grey scales.

and treat it as in 5.1 or form a layer of parallel lengths of

it between the two adjacent fabrics (4.21, the amount of

yarn taken being approximately equal to half the combined

3 REFERENCES

mass of the adjacent fabrics. Sew along two opposite sides

IS0 IQ5 :

to hold the yarn in place and to form a composite

specimen.

L

Section A01 , General principles of testing.

Section AQ2, Grey scale for assessing change in colour.

5.3 If the textile to be tested is loose fibre, comb and

compress an amount approximately equal to half the

Section AQ3, Grey scale for assessing staining.

combined mass of the adjacent fabrics (4.2) into a sheet

of the required size. Place the sheet between the two

IS0 139, Textiles - Standard atmospheres for conditioning

adjacent fabrics and sew along all four sides to hold the

and testing.

fibre in place and to form a composite specimen.

4 APPARATUS

6 PROCEDURE

Heating device equipped with two heated plates with

4.1

6.1 Place the composite specimen in the heating device

an electrical heating system, accurately controllable, which

UDC 677.016.47 First edition - 1978-12-15

Descriptors : textiles, dyes, tests, colour fastness, visual inspection, synthetic fibres, thermal tests, dry heat tests, pleating.

Approved by member bodies of : Australia; Belgium; Brazil; Bulgaria; Canada; Chile; Czechoslovakia; Denmark; Egypt, Arab Rep. of;

Germany, F.R.; Hungary; India; Iran; Israel; Japan

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.