ISO 4427-3:2019

(Main)Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 3: Fittings

Plastics piping systems for water supply, and for drainage and sewerage under pressure — Polyethylene (PE) — Part 3: Fittings

This document specifies the fittings made from polyethylene (PE) for buried or above ground applications, intended for the conveyance of water for human consumption, raw water prior to treatment, drainage and sewerage under pressure, vacuum sewer systems, and water for other purposes. NOTE 1 The intended uses include sea outfalls, laid in water and connection between pipes suspended below bridges. This document also specifies the test parameters for the test methods referred to in this document. In conjunction with the other parts of the ISO 4427 series, this document is applicable to PE fittings, to joints with components of PE or other materials, intended to be used under the following conditions: a) a maximum allowable operating pressure (PFA) up to and including 25 bar[1]; b) an operating temperature of 20 °C as the reference temperature. NOTE 2 For other operating temperatures, guidance is given in ISO 4427‑1:2019, Annex A. This document covers a range of maximum allowable operating pressures and gives requirements concerning colours. NOTE 3 It is the responsibility of the purchaser or specifier to make the appropriate selections from these aspects, taking into account their particular requirements and installation practices or codes. This document is applicable to fittings of the following types: 1. fusion fittings; a. electrofusion fittings; b. spigot end fittings (for butt fusion using heated tools and electrofusion socket fusion); c. socket fusion fittings (see Annex A); 2. mechanical fittings; a. compression fittings; b. flanged fittings; 3. fabricated fittings (see Annex B). [1] 1 bar = 0,1 MPa = 105 Pa; 1 MPa = 1 N/mm2.

Systèmes de canalisations en plastique destinés à l'alimentation en eau et aux branchements et collecteurs d'assainissement sous pression — Polyéthylène (PE) — Partie 3: Raccords

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 4427-3

Second edition

2019-08

Plastics piping systems for water

supply, and for drainage and sewerage

under pressure — Polyethylene (PE) —

Part 3:

Fittings

Systèmes de canalisations en plastique destinés à l'alimentation

en eau et aux branchements et collecteurs d'assainissement sous

pression — Polyéthylène (PE) —

Partie 3: Raccords

Reference number

©

ISO 2019

© ISO 2019

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2019 – All rights reserved

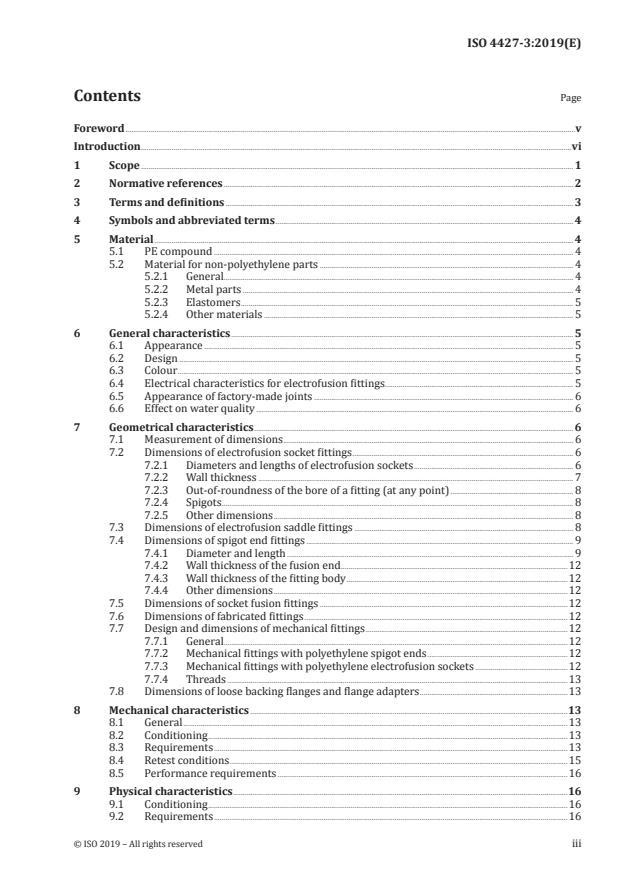

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 2

3 Terms and definitions . 3

4 Symbols and abbreviated terms . 4

5 Material . 4

5.1 PE compound . 4

5.2 Material for non-polyethylene parts . 4

5.2.1 General. 4

5.2.2 Metal parts . 4

5.2.3 Elastomers . 5

5.2.4 Other materials . 5

6 General characteristics . 5

6.1 Appearance . 5

6.2 Design . 5

6.3 Colour . 5

6.4 Electrical characteristics for electrofusion fittings . 5

6.5 Appearance of factory-made joints . 6

6.6 Effect on water quality . 6

7 Geometrical characteristics . 6

7.1 Measurement of dimensions . 6

7.2 Dimensions of electrofusion socket fittings . 6

7.2.1 Diameters and lengths of electrofusion sockets . 6

7.2.2 Wall thickness . 7

7.2.3 Out-of-roundness of the bore of a fitting (at any point) . 8

7.2.4 Spigots . . 8

7.2.5 Other dimensions . 8

7.3 Dimensions of electrofusion saddle fittings . 8

7.4 Dimensions of spigot end fittings . 9

7.4.1 Diameter and length . 9

7.4.2 Wall thickness of the fusion end .12

7.4.3 Wall thickness of the fitting body .12

7.4.4 Other dimensions .12

7.5 Dimensions of socket fusion fittings .12

7.6 Dimensions of fabricated fittings .12

7.7 Design and dimensions of mechanical fittings .12

7.7.1 General.12

7.7.2 Mechanical fittings with polyethylene spigot ends .12

7.7.3 Mechanical fittings with polyethylene electrofusion sockets .12

7.7.4 Threads .13

7.8 Dimensions of loose backing flanges and flange adapters .13

8 Mechanical characteristics .13

8.1 General .13

8.2 Conditioning .13

8.3 Requirements .13

8.4 Retest conditions .15

8.5 Performance requirements .16

9 Physical characteristics .16

9.1 Conditioning .16

9.2 Requirements .16

10 Chemical resistance of fittings in contact with chemicals .17

11 Performance requirements .17

12 Marking .17

12.1 General .17

12.2 Minimum required marking .17

12.3 Fusion system recognition .18

13 Packaging .18

Annex A (normative) Socket fusion fittings .19

Annex B (normative) Fabricated fittings .21

Annex C (informative) Examples of typical terminal connections for electrofusion fittings .28

Annex D (normative) Short-term pressure test method .31

Annex E (normative) Tensile test for fitting/pipe assemblies .33

Bibliography .35

iv © ISO 2019 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.