ISO 23478:2022

(Main)Bamboo structures — Engineered bamboo products — Test methods for determination of physical and mechanical properties

Bamboo structures — Engineered bamboo products — Test methods for determination of physical and mechanical properties

This document specifies test methods suitable for determining the following mechanical properties of engineered bamboo products: a) modulus of elasticity in bending; b) shear modulus; c) bending strength; d) modulus of elasticity in tension parallel to the fibre; e) tension strength parallel to the fibre; f) modulus of elasticity in compression parallel to the fibre; g) compression strength parallel to the fibre; h) modulus of elasticity in tension perpendicular to the fibre; i) tension strength perpendicular to the fibre; j) modulus of elasticity in compression perpendicular to the fibre; k) compression strength perpendicular to the fibre and shear strength; i) shear strength parallel to the fibre. In addition, the determination of dimensions, moisture content and density are specified. This document is applicable to prismatic shapes of glued laminated bamboo and bamboo scrimber intended to resist flexure, shear, axial loads, or combinations thereof.

Structures en bambou — Produits en bambou reconstitués — Méthodes d’essai pour la détermination des propriétés physiques et mécaniques

General Information

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 23478

First edition

2022-06

Bamboo structures — Engineered

bamboo products — Test methods

for determination of physical and

mechanical properties

Structures en bambou — Produits en bambou reconstitués —

Méthodes d’essai pour la détermination des propriétés physiques et

mécaniques

Reference number

© ISO 2022

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

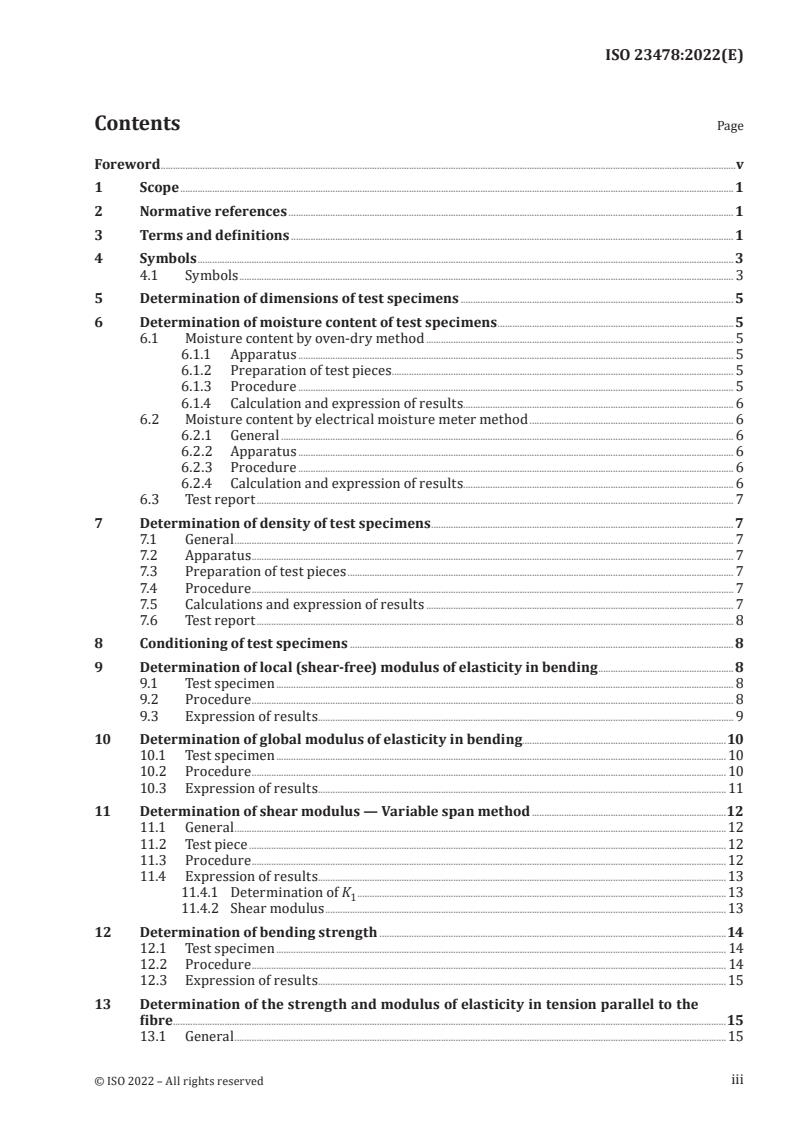

Contents Page

Foreword .v

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Symbols . 3

4.1 Symbols . 3

5 Determination of dimensions of test specimens . 5

6 Determination of moisture content of test specimens . 5

6.1 Moisture content by oven-dry method . 5

6.1.1 Apparatus . 5

6.1.2 Preparation of test pieces . 5

6.1.3 Procedure . 5

6.1.4 Calculation and expression of results. 6

6.2 Moisture content by electrical moisture meter method . 6

6.2.1 General . 6

6.2.2 Apparatus . 6

6.2.3 Procedure . 6

6.2.4 Calculation and expression of results. 6

6.3 Test report . 7

7 Determination of density of test specimens . 7

7.1 General . 7

7.2 Apparatus . 7

7.3 Preparation of test pieces . 7

7.4 Procedure . 7

7.5 Calculations and expression of results . 7

7.6 Test report . 8

8 Conditioning of test specimens . 8

9 Determination of local (shear-free) modulus of elasticity in bending .8

9.1 Test specimen . 8

9.2 Procedure . 8

9.3 Expression of results . . 9

10 Determination of global modulus of elasticity in bending.10

10.1 Test specimen . 10

10.2 Procedure . 10

10.3 Expression of results . . 11

11 Determination of shear modulus — Variable span method .12

11.1 General .12

11.2 Test piece .12

11.3 Procedure .12

11.4 Expression of results . 13

11.4.1 Determination of K .13

11.4.2 Shear modulus . 13

12 Determination of bending strength .14

12.1 Test specimen . 14

12.2 Procedure . 14

12.3 Expression of results . 15

13 Determination of the strength and modulus of elasticity in tension parallel to the

fibre .15

13.1 General . 15

iii

13.2 Test specimen . 15

13.3 Procedure . 16

13.4 Expression of modulus results . 17

13.5 Expression of strength results . 17

14 Determination of the strength and modulus of elasticity in compression parallel to

the fibre of the engineered bamboo product .17

14.1 General . 17

14.2 Test specimen . 18

14.3 Procedure . 18

14.4 Expression of modulus results . 18

14.5 Expression of results . . 18

15 Determination of the strength and modulus of elasticity in compression and

tension perpendicular to the fibre of the engineered bamboo product .19

15.1 Requirements for test specimens . 19

15.2 Procedure . 19

15.3 Expression of results . 21

15.3.1 Compression strength perpendicular to the fibre . 21

15.3.2 Compression modulus perpendicular to the fibre .22

15.3.3 Tension strength perpendicular to the fibre .23

15.3.4 Tension modulus perpendicular to the fibre . 23

16 Determination of shear strength parallel to the fibre .24

16.1 Requirements for test specimens . 24

16.1.1 Fabrication . 24

16.2 Procedure . 26

16.3 Expression of results . 26

17 Test report .26

17.1 General . 26

17.2 Test specimen . 26

17.3 Test method . 27

17.4 Test results . 27

Bibliography .28

iv

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 165, Timber structures.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

v

INTERNATIONAL STANDARD ISO 23478:2022(E)

Bamboo structures — Engineered bamboo products — Test

methods for determination of physical and mechanical

properties

1 Scope

This document specifies test methods suitable for determining the following mechanical properties of

engineered bamboo products:

a) modulus of elasticity in bending;

b) shear modulus;

c) bending strength;

d) modulus of elasticity in tension parallel to the fibre;

e) tension strength parallel to the fibre;

f) modulus of elasticity in compression parallel to the fibre;

g) compression strength parallel to the fibre;

h) modulus of elasticity in tension perpendicular to the fibre;

i) tension strength perpendicular to the fibre;

j) modulus of elasticity in compression perpendicular to the fibre;

k) compression strength perpendicular to the fibre and shear strength;

i) shear strength parallel to the fibre.

In addition, the determination of dimensions, moisture content and density are specified.

This document is applicable to prismatic shapes of glued laminated bamboo and bamboo scrimber

intended to resist flexure, shear, axial loads, or combinations thereof.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 22157, Bamboo structures — Determination of physical and mechanical properties of bamboo culms

— Test methods

ISO 21625, Vocabulary related to bamboo and bamboo products

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 22157, ISO 21625 and the

following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

3.1

bamboo scrimber

panel or structural member made of compressed bamboo fibre bundle strips or compressed bamboo

fibre bundle sheet

[SOURCE: ISO 21625:2020, 3.2.17]

Key

1 width, b

2 depth, h

indicates parallel to fibre orientation

Figure 1 — Example of bamboo scrimber

3.2

bamboo strip

bamboo piece with outer and inner layers intact, made by cutting bamboo culm in longitudinal direction

3.3

bamboo lamina

thin and flat bamboo piece with rectangular cross-section, processed from bamboo strip (3.2) by

removing the outer and inner layers of the bamboo culm wall

3.4

engineered bamboo member

assembly of individual elements made of bamboo

3.5

glued laminated bamboo

structural member formed by bonding together bamboo strips (3.2) with their fibres running essentially

parallel

[SOURCE: ISO 21625:2020, 3.3.1.14]

3.6

non-structural joint

non-structural connection (e.g. butt, hook joint) to support manufacturing process and is not designed

to transfer stress across the connection

3.7

traveller specimen

specimen identical to, and stored and conditioned identically to specimens to be tested used to obtain

properties whose testing method affects the specimen

Note 1 to entry: Traveller specimens are usually used for determination of moisture content and density.

[SOURCE: ISO 22157:2019, 3.12]

a) Horizontal board orientation b) Vertical board orientation

Key

b width, b

h depth, h

1 bamboo lamina

indicates parallel to fibre orientation

Figure 2 — Example of glued laminated bamboo

4 Symbols

4.1 Symbols

A cross-sectional area, in square millimetres;

a distance between a loading position and the nearest support in a bending test, in millimetres;

b width of cross-section in a bending test, or the smaller dimension of the cross-section, in

millimetres;

E modulus of elasticity in compression parallel to the fibre, in Newton per square millimetre;

c,0

E modulus of elasticity in compression perpendicular to the fibre, in Newton per square mil-

c,90

limetre;

E global modulus of elasticity in bending, in Newton per square millimetre;

m,g

E apparent modulus of elasticity in bending, in Newton per square millimetre;

m,app

E modulus of elasticity in tension parallel to the fibre, in Newton per square millimetre;

t,0

E modulus of elasticity in tension perpendicular to the fibre, in Newton per square millimetre;

t,90

F load, in Newtons;

F maximum compressive load perpendicular to the fibre, in Newtons;

c,90,max

F estimated maximum compressive load perpendicular to the fibre, in Newtons;

c,90,max,est

F maximum load, in Newtons;

max

F estimated maximum load, in Newtons;

max,est

F maximum tensile load perpendicular to the fibre, in Newtons;

t,90,max

F yield load, in Newtons;

y

F maximum (ultimate) load applied in test, in Netwons;

ult

f compressive strength parallel to the fibre, in Newton per square millimetre;

c,0

f compressive strength perpendicular to the fibre, in Newton per square millimetre;

c,90

f bending strength, in Newton per square millimetre;

m

f tensile strength parallel to the fibre, in Newton per square millimetre;

t,0

f tensile strength perpendicular to the fibre, in Newton per square millimetre;

t,90

G shear modulus, in Newton per square millimetre;

h depth of cross-section in a bending test, or the larger dimension of the cross-section, in

millimetres;

h gauge length, in millimetres;

h test specimen height in perpendicular to fibre tests, in millimetres;

t

I second moment of area, in millimetres to the fourth power;

l span in bending, or length of test specimen between the testing machine grips in compression

and tension, in millimetres;

l gauge length for the determination of modulus of elasticity or shear modulus, in millimetres;

m mass of the test piece before drying, in grams;

e

m initial mass before drying, in grams;

i

m final oven-dry mass, in grams;

S section modulus, in millimetres to the third power;

V volume of the test piece, in millimetres to the third power;

V volume of the test piece in the absolutely dry condition, in millimetres to the third power;

w moisture content;

Δ displacement, in millimetres;

δ

change in slope;

ρ density under conditions of test, in grams per millimetre to the third power;

test

ρ dry density, in grams per millimetre to the third power.

5 Determination of dimensions of test specimens

The dimensions of the test specimen shall be measured to a precision of 1 % of the least cross-sectional

dimensions of the member. All measurements shall be made when the test specimens are conditioned as

specified in Clause 8. If the width or thickness varies within a test specimen, these dimensions should

be recorded as the average of three separate measurements taken at different positions on the length of

each specimen.

6 Determination of moisture content of test specimens

6.1 Moisture content by oven-dry method

6.1.1 Apparatus

6.1.1.1 Balance, suitable to weigh a specimen with a precision of at least 0,5 % of the specimen mass.

6.1.1.2 Oven, capable of drying specimen to the absolute dry condition.

6.1.2 Preparation of test pieces

Specimens for determination of moisture content shall be prepared immediately after each mechanical

test. The number of specimens shall be equal to the number of test pieces for the physical or mechanical

test. If traveller specimens are used, these shall be prepared immediately after each mechanical test,

and placed in the drying oven.

The moisture content of the test specimen shall be determined on a section taken from the test

specimen. For engineered bamboo products the section shall be of full cross-section. For perpendicular

to fibre test specimens the moisture content shall be determined from the whole specimen.

In strength tests for bending, shear, tension parallel and perpendicular to fibre and compression

parallel and perpendicular to fibre, the moisture content of the test specimen shall be determined near

the place of failure.

6.1.3 Procedure

The test pieces shall be weighed with a precision of at least 0,5 % of the dry specimen mass prior to

being placed in an oven at a temperature of (103 ± 2) °C. The initial mass is m .

i

After 24 h, the mass shall be recorded at regular intervals of not less than 2 h. The drying shall be

considered to be complete when the difference between successive determinations of mass does not

exceed 0,5 % of the measured mass. The final oven-dry mass is m .

The following modifications for bamboo scrimber shall be made. After 48 h, the mass shall be recorded

at regular intervals of not less than 6 h. The drying shall be considered to be complete when the

difference between successive determinations of mass do not exceed 0,1 % of the measured mass. The

final oven-dry mass is m .

6.1.4 Calculation and expression of results

The moisture content, w, of each test piece shall be calculated with Formula (1) as the loss in mass,

expressed as a percentage of the oven-dry mass:

mm−

i0

w = ×100 (1)

m

where

m is the initial mass of the test piece before drying;

i

m is the oven-mass of the test piece.

Both m and m are measured with a precision of at least 0,5 % of the dry specimen mass for laminated

i 0

bamboo and of at least 0,1 % of the dry specimen mass for bamboo scrimber.

The calculated value of w shall be taken as representative of the test specimen as a whole.

6.2 Moisture content by electrical moisture meter method

6.2.1 General

Alternatively, it can be sufficiently accurate to measure moisture content by means of a moisture meter,

provided that the meter is calibrated against moisture content measurements using the oven-dry

method described in 6.1. Commercial conductivity moisture meters are generally only reliable for wood

moisture content between about 5 % and 30 %.

6.2.2 Apparatus

6.2.2.1 Moisture meter, of any design calibrated for laminated bamboo and bamboo scrimber (using

the oven-dry method described in 6.1), and capable of making an individual measurement with an error

of not more than 2 % at moisture contents from 7 % to 30 %.

6.2.3 Procedure

Measure the moisture content of the test piece or traveller specimen at a location within the specimen.

Measurements should be taken either at freshly cut cross-sections, or by driving deep, sharp probes

into the specimen.

The area at which measurements are made shall not contain any contaminants or visible defects. Drive

the electrodes into the cross-section so that the line between the tips of the needles intersects the

specimen.

Make at least three measurements in each measuring area, 10 mm to 15 mm apart, to avoid any error

due to the electrodes piercing an invisible defect.

6.2.4 Calculation and expression of results

Calculate the mean of the three individual measurements closest in their values, and express the

average moisture content, w, as a percentage by mass, to the nearest 1 %.

6.3 Test report

The moisture content shall be reported in the test report in accordance with 17.4.

7 Determination of density of test specimens

7.1 General

This clause specifies the method for determining the density, as mass by volume.

7.2 Apparatus

7.2.1 Measuring instrument, capable of determining the dimensions of the test pieces with a

precision of 0,1 mm.

7.2.2 Balance, suitable to weigh a specimen with a precision of at least 0,5 % of the specimen mass.

7.2.3 Equipment, for the determination of the moisture content in accordance with 6.1.

7.3 Preparation of test pieces

For perpendicular to fibre test specimens, the density of the test specimens shall be determined prior

to testing based on the whole test specimen.

For parallel to fibre and bending test specimens, the density shall be determined immediately after

each mechanical test. The density shall be determined on a portion of the cross-section or the entire

cross-section taken from the test specimen near the place of failure. The section shall be measured

based on a minimum sample volume with at least three laminae in section and 50 mm in length.

For perpendicular to fibre test specimens, the density of the test specimens shall be determined prior

to test from the measurements of mass and volume of the whole test specimen.

The number of specimens shall be equal to the number of test pieces for the physical or mechanical test.

If traveller specimens are used, these shall be prepared immediately after each mechanical test.

7.4 Procedure

Measure the dimensions of the test pieces with a precision of at least 0,1 mm and calculate the volume,

b × h × l.

For the density at the time of test, ρ , determine the mass of the test piece, m , to a precision of 0,5 %

test e

of the specimen mass.

For the dry density, ρ , dry the test pieces to a constant oven-dry mass (see 6.1.3). Carry out the

weighing operations immediately after drying. Determine the mass of the oven-dry test pieces, m , to a

precision of 0,5 % of the specimen mass.

7.5 Calculations and expression of results

The density at the time of test, ρ , shall be calculated from Formula (2):

test

m

e

ρ = (2)

test

V

where

m is the mass of the test piece before drying;

e

V is the volume of the test piece.

The dry density, ρ , of each test piece in the absolutely dry condition shall be calculated from

Formula (3):

m

ρ = (3)

V

where

m is the oven-dry mass of the test piece;

V is the volume of the test piece in the absolutely dry condition.

7.6 Test report

The density shall be reported in the test report in accordance with 17.4.

8 Conditioning of test specimens

All tests shall be carried out on pieces, which are conditioned at the standard environment of 23 ± 3 °C

and 65 ± 5 % relative humidity.

A test piece is conditioned when it attains constant mass. Constant mass is considered to be attained

when the results of two successive weight measurements, carried out at an interval of 6 h, do not differ

by more than 0,1 % of the mass of the test piece.

Where the test piece to be tested is not readily conditioned to the above standard environment that fact

shall be reported.

For small specimens, unless otherwise protected, test pieces shall not be removed from the conditioning

environment more than 1 h before testing.

NOTE 1 Test pieces can be stored in the test area for up to 24 h provided they are close piled and wrapped in

vapour tight sheeting.

9 Determination of local (shear-free) modulus of elasticity in bending

9.1 Test specimen

The test piece shall have a minimum length of 19 times the depth of the section. Where this is not

possible, the span of the beam shall be reported.

9.2 Procedure

The test specimen shall be a simply supported span of 18 ± 3 times the specimen depth as shown

in Figure 3. Load shall be applied at two points spaced 6 times the specimen depth apart arranged

symmetrically about the centre line of the specimen span.

NOTE 1 Small steel plates having a width equal to the beam width and a length not greater than one-half of the

depth of the test specimen can be inserted between the specimen and the loading heads or supports to minimize

local indentation.

Lateral restraint shall be provided at the supports and points of load application. This restraint shall

permit the specimen to deflect without frictional resistance.

Load shall be applied at a constant rate and the test should be completed within approximately 300 s

but not less than 180 s.

Ideally, the load application rate is determined from the results of preliminary tests. The estimated

maximum load, F of the material under test shall be obtained either from tests on at least ten

max,est

pieces of the appropriate material and size or from appropriate existing test data. The objective is that

the average time to reach F is 300 s.

max

For the purpose of calculations, the value of F shall be determined as the proportional limit observed

max

in the test.

Figure 3 — Test arrangement for measuring local modulus of elasticity in bending

The loading equipment used shall be capable of measuring the applied load with a precision of 1 %.

The displacement, ∆, shall be taken as the average of measurements on both side faces at the neutral

axis, and shall be measured at the centre of a central gauge length of five times the depth of the section

(see Figure 3).

The measuring equipment used shall be capable of measuring deformation with a precision of 1 %.

NOTE 2 ASTM D198 provides a description of an acceptable deflection measuring device and the yoke.

9.3 Expression of results

For glued laminated bamboo, specify the orientation of the strips along the specimen length e.g.

horizontal or vertical relative to the direction of load application. See Figure 2.

For a rectangular section, the local modulus of elasticity in bending, E , is given by Formula (4):

ml,

3al FF−

1 40 10

E = (4)

ml,

ΔΔ−

4bh

40 10

where

a distance between a loading position and the nearest support, as shown in Figure 3;

b width of cross-section;

h depth of cross-section;

l gauge length, as shown in Figure 3;

F – F F , F are applied loads at 40 % and 10 % of F respectively (for F see 9.2);

40 10 40 10 max, max

Δ − Δ displacement corresponding to F and F , respectively.

40 10 40 10

The local modulus of elasticity, E shall be calculated to a precision of 1 %.

m,l

10 Determination of global modulus of elasticity in bending

10.1 Test specimen

The test piece shall have a minimum length of 19 times the depth of the section. Where this is not

possible, the span of the beam shall be reported.

10.2 Procedure

The test specimen shall be a simply supported span of (18 ± 3) times the specimen depth as shown

in Figure 4. Load shall be applied at two points spaced 6 times the specimen depth apart arranged

symmetrically about the centre line of the specimen span.

NOTE Small steel plates having a width equal to the beam width and a length not greater than one-half of the

depth of the test specimen can be inserted between the specimen and the loading heads or supports to minimize

local indentation.

Lateral restraint shall be provided at the supports and points of load application. This restraint shall

permit the specimen to deflect without frictional resistance.

Load shall be applied at a constant rate and the test should be completed within approximately 300 s

but not less than 180 s.

Ideally, the load application rate is determined from the results of preliminary tests. The estimated

maximum load, F of the material under test shall be obtained either from tests on at least ten

max,est

pieces of the appropriate material and size or from appropriate existing test data. The objective is that

the average time to reach F is 300 s.

max

For the purpose of calculations, the value of F shall be determined as the proportional limit observed

max

in the test.

Figure 4 — Test arrangement for measuring global modulus of elasticity in bending

The loading equipment used shall be capable of measuring the load to a precision of 1 % of the load

applied to the test piece or, for loads less than 10 % of the applied maximum load, with a precision of

0,1 % of the maximum applied load.

The displacement, ∆, shall be measured at the neutral axis and it shall be the mean of measurements

made on both sides of the test piece.

Displacement shall be determined with a precision of 1 %, or for displacement less than 2 mm, with a

precision of 0,02 mm.

10.3 Expression of results

For glued laminated bamboo, specify the orientation of the strips along the specimen length, e.g.

horizontal, or vertical, relative to the direction of load application. See Figure 2.

Based on requirement that beams remain below their limit of proportionality, elastic analysis may be

used.

For a rectangular section, the global modulus of elasticity in bending, E , is given by Formula (5):

mg,

FF−

a

22 40 10

E =−34la (5)

()

mg,

ΔΔ−

4bh

40 10

where

a distance between a loading position and the nearest support, as shown in Figure 4;

b width of cross-section;

h depth of cross-section;

l span in bending, as shown in Figure 4;

F – F F , F are applied loads at 40 % and 10 % of F respectively (for F see 10.2);

40 10 40 10 max, max

Δ − Δ displacement corresponding to F and F , respectively.

40 10 40 10

The local modulus of elasticity, E shall be calculated to a precision of 1 %.

m,g

11 Determination of shear modulus — Variable span method

11.1 General

This method involves the determination of the apparent modulus of elasticity, E , for each test

m,app

specimen over a number of spans with the same cross-section at the centre.

11.2 Test piece

The test specimen shall have a minimum length of 19 times the depth of the section as shown in Figure 5,

with a maximum simply supported test span of (18 ± 3) times the depth of the section.

11.3 Procedure

The test specimen shall be a simple supported span loaded in centre point bending over at least four

different spans with the same cross-section at the centre of each, as shown in Figure 5. The spans shall

h

be chosen so as to have approximately equal increments of between them, within the range 0,05 to

l

0,20. The test spans shall be reported.

NOTE Small steel plates having a width equal to the beam width and a length not greater than one-half of the

depth of the test specimen can be inserted between the specimen and the loading heads or supports to minimize

local indentation.

Lateral restraint shall be provided at the supports and points of load application. This restraint shall

permit the specimen to deflect without frictional resistance.

Load shall be applied at a constant rate and the test should be completed within approximately 300 s

but not less than 180 s.

Ideally, the load application rate is determined from the results of preliminary tests. The estimated

maximum load, F of the material under test shall be obtained either from tests on at least ten

max,est

pieces of the appropriate material and size or from appropriate existing test data. The objective is that

the average time to reach F is 300 s.

max

For the purpose of calculations, the value of F shall be determined as the proportional limit observed

max

in the test.

Figure 5 — Test arrangement for measuring shear modulus

The loading equipment used shall be capable of measuring the load with a precision of 1 % of the load

applied to the test specimen.

Displacement shall be measured at the centre of the span.

The displacement measuring devices and recording system shall be such as to permit measuring

deflections with 1 % precision.

11.4 Expression of results

For glued laminated bamboo, specify the orientation of the strips along the specimen length e.g.,

horizontal, or vertical relative to the direction of load application. See Figure 2.

11.4.1 Determination of K

The apparent modulus of elasticity, E , for each test specimen is given by Formula (6):

ma, pp

lF −F

()

40 10

E = (6)

ma, pp

4bh ΔΔ−

()

40 10

where

b width of cross-section;

h depth of cross-section;

l span in bending, as shown in Figure 5;

F – F F , F are applied loads at 40 % and 10 % of F respectively (for F see 11.3);

40 10 40 10 max, max

Δ − Δ displacement corresponding to F and F , respectively.

40 10 40 10

The local modulus of elasticity, E , shall be calculated to a precision of 1 %.

m,app

h

For each specimen, the values of 1/E shall be plotted against as shown in Figure 6 and the

m,app

l

slope K of the best straight line through the points shall be determined.

11.4.2 Shear modulus

For a rectangular or square section, the shear modulus G is given by Formula (7):

12,

G= (7)

K

where K is the slope of the straight line (see Figure 6).

Figure 6 — Determination of shear modulus — Variable span method

12 Determination of bending strength

12.1 Test specimen

The test specimen shall have a minimum length to permit testing with a span of approximately 19 times

the depth of the section as shown in Figure 4, with a minimum test span of 18 times the depth of the

section. Where this is not possible, the test span shall be reported.

12.2 Procedure

The test specimen shall be a simply supported span of (18 ± 3) times the specimen depth as shown

in Figure 4. Load shall be applied at two points spaced 6 times the specimen depth apart arranged

symmetrically about the centre line of the specimen span.

NOTE Small steel plates having a width equal to the beam width and a length not greater than one-half of the

depth of the test specimen can be inserted between the specimen and the loading heads or supports to minimize

local indentation.

Lateral restraint shall be provided at the supports and points of load application. This restraint shall

permit the specimen to deflect without frictional resistance.

Load shall be applied at a constant rate and the test should be completed within approximately 300

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.