ISO/TS 13434:2020

(Main)Geosynthetics — Guidelines for the assessment of durability

Geosynthetics — Guidelines for the assessment of durability

This document provides guidelines for the assessment of the durability of geosynthetics, the object of which is to provide the design engineer with the necessary information, generally defined as changes in material properties or as partial safety factors, to ensure that the expected design life of a geosynthetic can be achieved with confidence. This document is not applicable to products designed to survive for only a limited time, such as erosion-control fabric based on natural fibres. This document is applicable to the durability of the geosynthetics and not to the durability of the geotechnical structure as a whole. NOTE The calculation of reduction factors for soil reinforcement applications is described in ISO/TR 20432.

Géosynthétiques — Lignes directrices concernant la durabilité

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 13434

Second edition

2020-10

Geosynthetics — Guidelines for the

assessment of durability

Géosynthétiques — Lignes directrices concernant la durabilité

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

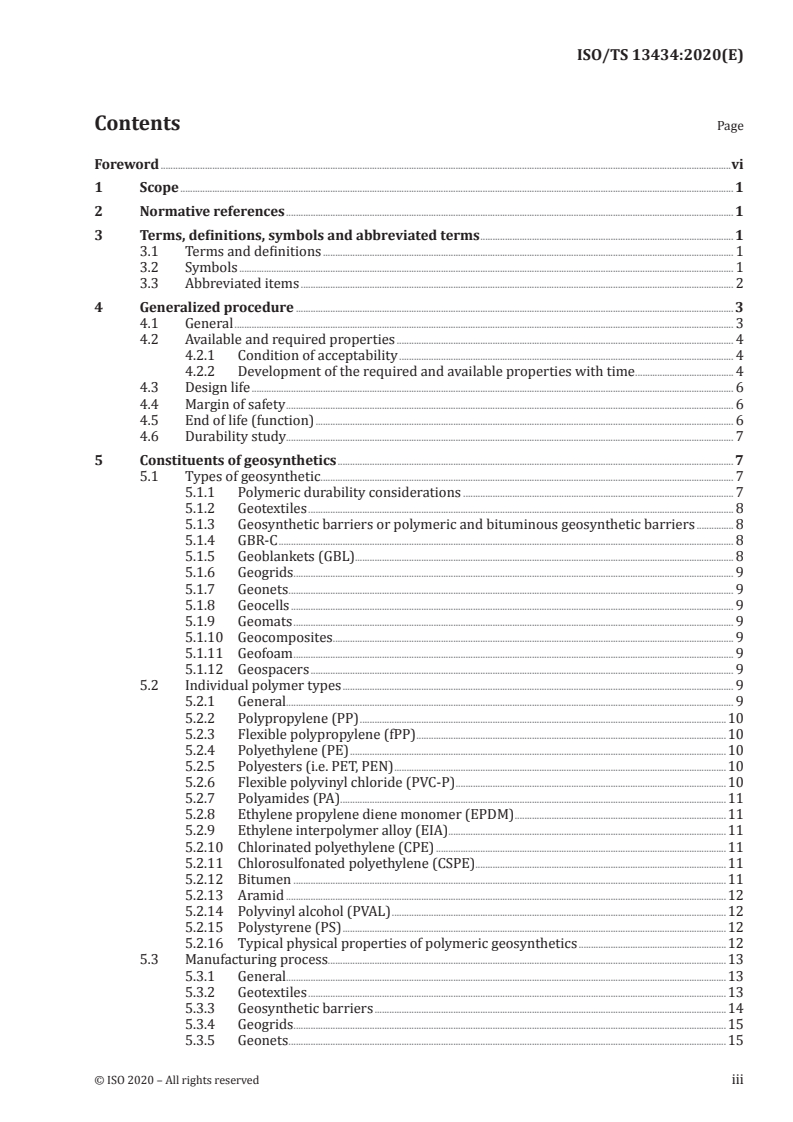

Contents Page

Foreword .vi

1 Scope . 1

2 Normative references . 1

3 Terms, definitions, symbols and abbreviated terms . 1

3.1 Terms and definitions . 1

3.2 Symbols . 1

3.3 Abbreviated items . 2

4 Generalized procedure . 3

4.1 General . 3

4.2 Available and required properties . 4

4.2.1 Condition of acceptability . 4

4.2.2 Development of the required and available properties with time . 4

4.3 Design life . 6

4.4 Margin of safety . 6

4.5 End of life (function) . 6

4.6 Durability study . 7

5 Constituents of geosynthetics . 7

5.1 Types of geosynthetic . . 7

5.1.1 Polymeric durability considerations . 7

5.1.2 Geotextiles . 8

5.1.3 Geosynthetic barriers or polymeric and bituminous geosynthetic barriers . 8

5.1.4 GBR-C . 8

5.1.5 Geoblankets (GBL). 8

5.1.6 Geogrids. 9

5.1.7 Geonets . 9

5.1.8 Geocells . 9

5.1.9 Geomats . 9

5.1.10 Geocomposites . 9

5.1.11 Geofoam . 9

5.1.12 Geospacers . 9

5.2 Individual polymer types . 9

5.2.1 General. 9

5.2.2 Polypropylene (PP) .10

5.2.3 Flexible polypropylene (fPP) .10

5.2.4 Polyethylene (PE) .10

5.2.5 Polyesters (i.e. PET, PEN) .10

5.2.6 Flexible polyvinyl chloride (PVC-P) .10

5.2.7 Polyamides (PA).11

5.2.8 Ethylene propylene diene monomer (EPDM) .11

5.2.9 Ethylene interpolymer alloy (EIA).11

5.2.10 Chlorinated polyethylene (CPE) .11

5.2.11 Chlorosulfonated polyethylene (CSPE).11

5.2.12 Bitumen .11

5.2.13 Aramid .12

5.2.14 Polyvinyl alcohol (PVAL) .12

5.2.15 Polystyrene (PS) .12

5.2.16 Typical physical properties of polymeric geosynthetics .12

5.3 Manufacturing process.13

5.3.1 General.13

5.3.2 Geotextiles .13

5.3.3 Geosynthetic barriers .14

5.3.4 Geogrids.15

5.3.5 Geonets .15

5.3.6 Geocomposites .15

5.3.7 Geocells .15

5.3.8 GBR-C .15

5.4 Recycled and reworked materials .15

5.5 Additives, stabilizers, fillers and reinforcement scrims .16

5.5.1 General.16

5.5.2 Antioxidants .16

5.5.3 Acid scavengers .16

5.5.4 Metal ion deactivators .16

5.5.5 UV stabilizers .17

5.5.6 Plasticizers .17

5.5.7 Lubricants .17

5.5.8 Mineral fillers .17

5.5.9 Scrims .17

6 Environmental factors that may lead to degradation .17

6.1 The environment above ground .17

6.2 The environment below ground .18

6.3 Chemical and biological effects on a geosynthetic .19

6.3.1 General.19

6.3.2 Hydrolysis of PET and PA .20

6.3.3 Oxidation of PE and PP .20

6.3.4 Biochemical attack .20

6.3.5 Chemical effects on other geosynthetic barriers .20

6.4 Effects of load and mechanical damage .22

6.4.1 Tensile load: Creep and creep-rupture .22

6.4.2 Synergy of tensile load with environmental effects (environmental stress

cracking) .22

6.4.3 Effect of mechanical load on weathering and oxidation .23

6.4.4 Loading during installation: Mechanical damage .23

6.4.5 Normal pressure: Compressive creep and penetration .23

6.4.6 Abrasion and dynamic loading .23

7 Evidence of the durability of geosynthetics .24

7.1 Historical development .24

7.2 Empirical evidence of durability from geosynthetics extracted from the soil .24

7.2.1 Geotextiles .24

7.2.2 Geosynthetic barriers .25

7.2.3 Geogrids.27

7.3 Summary .28

8 Procedure for assessment of durability .28

8.1 General .28

8.1.1 Need for testing .28

8.1.2 Testing concepts for lifetime index tests .28

8.1.3 Scope of durability assessment .29

8.2 Procedure .29

8.2.1 Material .29

8.2.2 Function and application .29

8.2.3 Environment .29

8.2.4 Mechanism of degradation .30

8.2.5 Design life .30

8.2.6 The “end-of-life” criterion .30

8.3 Degradation during storage and installation .30

8.3.1 Weathering .30

8.3.2 Mechanical damage .31

8.4 Short-, medium-, and long-term applications .31

8.5 Assessment of long-term durability .32

8.5.1 General.32

8.5.2 Evidence from service .32

iv © ISO 2020 – All rights reserved

8.5.3 Accelerated testing .33

8.6 Prediction of durability .37

8.6.1 Statement of the durability .37

8.6.2 Level of confidence .37

8.7 Planning for future inspection .37

Bibliography .39

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

ISO/TS 13434 was prepared by Technical Committee ISO/TC 221, Geosynthetics.

This first edition cancels and replaces ISO/TS 13434:2008, which has been technically revised. The

main changes compared to the previous edition are as follows:

— standards and wording actualized;

— added product types in 5.1;

— updated subclauses 5.4, 8.4, 8.5 and Table 3.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2020 – All rights reserved

TECHNICAL SPECIFICATION ISO/TS 13434:2020(E)

Geosynthetics — Guidelines for the assessment of

durability

1 Scope

This document provides guidelines for the assessment of the durability of geosynthetics, the object of

which is to provide the design engineer with the necessary information, generally defined as changes in

material properties or as partial safety factors, to ensure that the expected design life of a geosynthetic

can be achieved with confidence.

This document is not applicable to products designed to survive for only a limited time, such as erosion-

control fabric based on natural fibres.

This document is applicable to the durability of the geosynthetics and not to the durability of the

geotechnical structure as a whole.

NOTE The calculation of reduction factors for soil reinforcement applications is described in ISO/TR 20432.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 10318-1, Geosynthetics — Part 1: Terms and definitions

ISO 13431, Geotextiles and geotextile-related products — Determination of tensile creep and creep rupture

behaviour

ISO 13438:2018, Geosynthetics — Screening test method for determining the resistance of geotextiles and

geotextile-related products to oxidation

3 Terms, definitions, symbols and abbreviated terms

3.1 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 10318-1 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.2 Symbols

A rate of degradation

A constant in Arrhenius equation

d 50 % soil gradation

E activation energy

M number-averaged molecular weight

n

M weight-averaged molecular weight

w

R universal gas constant (8,314 J/mol⋅K)

t glass transition temperature

g

T absolute temperature

3.3 Abbreviated items

CMD cross-machine direction

CPE chlorinated polyethylene

CSPE chlorosulfonated polyethylene

DSC differential scanning calorimetry

EIA ethylene interpolymer alloy

ENB ethylidene norbornene

EPDM ethylene propylene diene monomer

EPS expanded polystyrene

ESC environmental stress cracking

fPP flexible polypropylene

GBR-B bituminous geosynthetic barrier

GBR-C geosynthetic clay barrier

GBR-P polymeric geosynthetic barrier

HALS hindered amine light stabilizers

PE-HD high-density polyethylene

HP-OIT high-pressure oxidation induction time

KEE ketone ethylene ester

PE-LLD linear low-density polyethylene

MB modified bitumen

MD machine direction

OIT oxidation induction time

PA polyamide

PCM post-consumer material

PE polyethylene

PEN polyethylene naphthalate

2 © ISO 2020 – All rights reserved

PET polyethylene terephthalate

PIM post-industrial material

PP polypropylene

PS polystyrene

PVAL polyvinyl alcohol

PVC-P flexible polyvinyl chloride

RPP reinforced polypropylene

RWM reworked material

SBS styrene-butadiene-styrene

S-OIT oxidation induction time measured by standard method

XPS extruded polystyrene

UV ultraviolet

4 Generalized procedure

4.1 General

When a geosynthetic is used in a civil engineering structure, it is intended to perform a particular

function for a minimum expected time, called the design life. A geosynthetic is a generic term

describing a product, where at least one of the components is made from a synthetic or natural

polymer, in the form of a sheet, a strip or a three-dimensional structure, used in contact with soil and/

or other materials in geotechnical and civil engineering applications. Geosynthetic products comprise

geotextiles, geosynthetic barriers (polymeric, bituminous and geosynthetic clay liners), geogrids,

geonets, geocells, geostrips, geomats, geoblankets, geocomposites and geospacers. The eight functions

defined in ISO 10318-1 are barrier function, drainage, filtration, protection, reinforcement, separation,

stabilisation, stress relief for asphalt overlay and surface erosion control. Each function uses one or

more properties of the geosynthetic, such as tensile strength or water permeability for a geotextile and

impermeability to liquids for a geosynthetic barrier. These are referred to as functional properties.

Assessment of the durability of structures using geosynthetics requires a study of the effects of time

on the functional properties. The physical structure of the geosynthetic, the nature of the polymer

used, the manufacturing process, the physical and chemical environment, the conditions of storage

and installation, and the load supported by the geosynthetic are all parameters which govern the

durability. The main task is to understand and assess the evolution of the functional properties over the

entire design life. This problem is quite complex due to the combination and interaction of numerous

parameters present in the soil environment, and to the lack of well-documented experience.

The majority of geosynthetics, when correctly processed and stabilized, are comparatively resistant to

chemical and microbiological attack encountered in normal soil environments and for normal design

lives. For such applications, only a minimum number of screening or index tests may be necessary.

For applications in more severe environments, such as soil treated with lime or cement, landfills or

industrial-waste containments, or for applications with particularly long design lives, special tests

including “performance” tests with site-specific parameters may be required.

4.2 Available and required properties

4.2.1 Condition of acceptability

A geosynthetic will have one or more functional properties critical to its intended function, for example

tensile strength or permeability. It is then necessary to differentiate between the available and

required values of this functional property. The available property is that provided by the geosynthetic.

The required property is the minimum level necessary for the geosynthetic to perform its intended

function.

The available property is expected to change with time due to degradation of the material, as shown

in Figure 1. The necessary condition is that, at the design lifetime (Item 2 in Figure 1), the available

property exceeds the required property, which is shown for simplicity as remaining constant in time

(Item 1). This condition is satisfied under the first set of conditions (Item 3) and is not satisfied under

the second set of conditions (Item 4). These are therefore deemed to be acceptable and not acceptable,

respectively.

Key

X time

Y property of a geosynthetic, expressed as a percentage of its original value

1 minimum acceptable level of required property

2 design lifetime

3 available property under first set of conditions (acceptable)

4 available property under second set of conditions (not acceptable)

Figure 1 — Available and required properties as a function of time under two different sets of

conditions, the first acceptable and the second not acceptable

4.2.2 Development of the required and available properties with time

In practice, both the available property and the required property can vary with the successive events

that occur between manufacture of the product and the design life. Figure 2 shows a schematic example.

4 © ISO 2020 – All rights reserved

Key

X time

Y property of a geosynthetic, expressed as a percentage of its original value

1 available property

2 margin between required and available property at intermediate time

3 margin of safety at design life

4 required property

5 margin of safety between design life and time to failure

6 duration prior to installation (storage and transportation)

7 duration of installation and covering

8 duration of further construction

9 intermediate time during normal use

10 design life

11 time to failure

Figure 2 — Available and required properties of a geosynthetic during storage

and transportation, construction, backfilling and use

A new geosynthetic exhibits an initial or short-term available property as defined by a set measurement

standard. Depending on the level of quality control and quality assurance, a reduction factor may be

applied to cover variations in the initial property.

The available property is shown as line 1 in Figure 2. During storage and transportation (period 6 in

Figure 2), this property may change due to weathering, while during installation (period 7) and further

construction (period 8), it may suffer from mechanical damage. The extent of the mechanical damage

incurred during installation depends on the geosynthetic, the nature of the materials in contact with the

geosynthetic, the equipment used and the care provided by the handling team (see 6.4.4). For polymeric

geosynthetic barriers, the manufacturing process and the welding parameters during installation may

not lead to immediate degradation, but can induce residual stresses in the material which lead to a

stress-crack phenomenon and more rapid subsequent degradation.

After backfilling (period 8), the operating life of the material starts. During the operating life, the

geosynthetic is subjected to chemical, biological or physical actions due to the soil, its constituents,

and its air, water and organic content, resulting in a gradual reduction in the available property until

the design life (Item 10 in Figure 2) is reached. The available property will diminish further if the

geosynthetic remains in place beyond its design life.

The required property is shown as line 4 in Figure 2. During storage and transportation (period 6

in Figure 2), a minimum required property, generally strength, is needed to resist handling loads.

Installation and compaction (period 7) may require a strength higher than that required for the

remainder of the design life. During further construction (period 8), the load will increase from a lower

level, increasing the required strength. When finally in use, the required property will remain constant.

It should be noted that the available property can diminish due to the level of constraints or the applied

load: the greater the applied stress, the shorter the time to failure. This is a particularly important

phenomenon that is described in 6.4, particularly in 6.4.1. Thus, there can be an interaction between the

required property and the available property. There is no absolute available property curve as shown

schematically in the graph by the presence of the two curves.

It should also be noted that there may be more than one functional property. For example, a filter or

separator will have a minimum required strength to survive installation and construction, while in

operation the required property will be the permeability or opening size. The above analysis should be

performed for both properties.

The testing techniques and the assessment methods for estimating the property curves is presented

and discussed in later subclauses. Index test methods are intended to ensure a minimum level of

durability and do not constitute a comprehensive assessment procedure. Where this is needed, it will

be necessary to carry out further performance tests more closely related to service conditions. These

tests may also include investigations on samples extracted from sites where the same product has

been used for several years in a similar environment. Procedures have been developed, such as those

described in ISO 13437. As in other fields of engineering, confidence in the durability of geosynthetics

is developing as the technology matures and the results of long-term service experience accumulate.

Examples of experience to date are described in Clause 6.

4.3 Design life

The design life is specified on the time axis (Item 2 in Figure 1, Item 10 in Figure 2). It is set by the client

(or a design code) and is decided at the design stage. Codes generally propose several fixed durations,

according to whether the structure is meant for short-term use (typically a few years and not exceeding

five years), temporary use (generally less than 25 years) or permanent use (over 25 years, and generally

50 to >100 years). The nature of the structure, the environmental risk involved and the consequences

of failure may influence this duration (example: 70 years for a wall, 100 years for an abutment and

beyond 100 years for landfills). Many geosynthetics have a temporary function although the structure

is permanent; for example, an embankment over a weak soil may require a geotextile or geogrid

reinforcement until the embankment has settled.

4.4 Margin of safety

At the end of the anticipated design life, the designer has to ensure a certain margin of safety (generally

also indicated by codes), such that failure (Item 11 in Figure 2) is predicted to be well beyond the

design life (Item 10). Item 3, the difference between the predicted available property and the predicted

required property, represents the margin of safety for that component. This can be expressed as a ratio.

The ratio can also be expressed in terms of the time to reach the end of life if the geosynthetic were to

be left in service after the end of its design life (Item 5). These two representations of safety, the ratio of

required and available property at the design life, and the ratio of the predicted end of life to design life,

should be considered together because, in combination, they give a better idea of the real level of safety

that exists.

The calculation of reduction factors for soil reinforcement applications is described in ISO/TR 20432.

4.5 End of life (function)

The end of life is the point on the time axis where the available property curve meets the required

property curve (Item 11 in Figure 2). At this point, the product is predicted not to fulfil its function.

Residual service may remain either if the expected loads are overestimated, or if they imply a

6 © ISO 2020 – All rights reserved

combination of degradation mechanisms that may not all have reached their maximum values.

Whatever the case, beyond that point on the graph, the possibility of end of function or failure is high.

4.6 Durability study

The design and durability assessment of a structure using a geosynthetic can be summarized as follows:

— defining the function(s) of the geosynthetic;

— making the inventory of the constraints imposed by the application (environmental, physical,

chemical);

— defining the design life of the geosynthetic;

— quantifying the required properties of the geosynthetic (e.g. strength, permeability, impermeability,

seam integrity);

— defining the geosynthetic properties;

— making sure that the estimated available properties at the end of the design life are greater than the

required properties.

5 Constituents of geosynthetics

5.1 Types of geosynthetic

5.1.1 Polymeric durability considerations

The durability of a polymeric geosynthetic depends upon the unit weight, the formulation from which

it is made, on any additives and fillers compounded with it, on the polymer microstructure, the fibre

geometry and fabric layout for geotextiles, the unit weight, and thickness of geosynthetic barriers, and

the quality of joints and junctions. The geosynthetic should be chemically and biologically resistant if it

is to be suitable for long-term applications.

The polymers used to manufacture geosynthetics are generally thermoplastic materials which may

be amorphous or semi-crystalline. An amorphous polymer has a randomly coiled structure which, at

the glass transition temperature, t , undergoes significant change from a stiff, glassy, brittle response

g

to loads below the glass transition temperature to a more ductile, rubbery response above t . Most

g

polymers used in geotextiles are semi-crystalline, that is they contain small, more or less oriented

crystallites, alternating with amorphous material. Since the change in behaviour only affects the

amorphous regions, the glass transition is less marked for a semi-crystalline polymer. At a higher

temperature, however, the crystallites melt, which produces an abrupt change in properties. Values of t

g

and melting temperature are given in Table 1 for the polymers most commonly used in geosynthetics. In

civil engineering applications, polyesters are used below their t while polypropylene and polyethylene

g

are used above t . Any acceleration of laboratory tests crossing a transition, such as t , should be

g g

avoided or, if this is not possible, an appropriate factor of safety should be applied.

Mechanical drawing of polymers, e.g. for forming tapes, fibres or filaments, leads to increased

orientation that results in higher tensile properties, improved durability and reduction of the changes

in properties at the glass transition temperature. As the molecules become more oriented, the fibres

become stronger. The crystallites are retained and the ratio of crystalline regions and amorphous

regions should be properly balanced to produce the physical properties necessary for fibres used in

geotextiles, or for the ribs of extruded geogrids (see 5.1.5). The increased orientation and associated

higher density leads to higher environmental resistance. The durability assessment should consider

whether any change in this morphology is likely during the service life of the product, and whether

such a change will lead to a significant change in properties. Thermal analysis techniques have proved

useful in measuring such changes.

Any polymer, whether amorphous or semi-crystalline, consists of long-chain molecules

(macromolecules), each containing many chemical units. Each unit may be composed of one or more

monomers, the number of which determines the length of the polymeric chain and resulting molecular

weight. The nature and the number of the monomer distribution determine the length and structure

of the polymeric chain. These factors can affect physical properties such as the tensile strength and

modulus, impact strength, flexibility and heat resistance, as well as the durability properties. The

mechanical and physical properties of the plastics are also influenced by the bonds within and between

chains, chain branching, and the degree of crystallinity.

Crystallinity has a strong effect on polymer properties, especially the mechanical properties, because

the tightly packed molecules within the crystallites result in dense regions with high intermolecular

cohesion and higher resistance to penetration by chemicals. An increase in the degree of crystallinity

leads directly to an increase in rigidity and yield or tensile strength, hardness and softening point, and

to a decrease in liquid permeability and gas diffusion.

Durability of all geosynthetics is influenced by fibre or rib diameter or surface-to-volume ratio.

Resistance to oxidation and UV exposure is generally dependent on fibre or rib diameter or thickness

since the rate of oxidative/photo-oxidative reactions is often limited by the rate of diffusion of oxygen,

especially at elevated testing temperatures. Evaporation and extraction of additives is also inversely

related to surface-to-volume ratio. These factors should be taken into account in the design of suitable

testing procedures and in considering the results of established tests. The choice of te

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.