ISO/DIS 12696

(Main)Cathodic protection of steel in concrete

Cathodic protection of steel in concrete

Protection cathodique de l'acier dans le béton

General Information

RELATIONS

Standards Content (sample)

DRAFT INTERNATIONAL STANDARD

ISO/DIS 12696

ISO/TC 156 Secretariat: SAC

Voting begins on: Voting terminates on:

2021-02-15 2021-05-10

Cathodic protection of steel in concrete

Protection cathodique de l'acier dans le béton

ICS: 77.140.15; 77.060

THIS DOCUMENT IS A DRAFT CIRCULATED

This document is circulated as received from the committee secretariat.

FOR COMMENT AND APPROVAL. IT IS

THEREFORE SUBJECT TO CHANGE AND MAY

NOT BE REFERRED TO AS AN INTERNATIONAL

STANDARD UNTIL PUBLISHED AS SUCH.

IN ADDITION TO THEIR EVALUATION AS

ISO/CEN PARALLEL PROCESSING

BEING ACCEPTABLE FOR INDUSTRIAL,

TECHNOLOGICAL, COMMERCIAL AND

USER PURPOSES, DRAFT INTERNATIONAL

STANDARDS MAY ON OCCASION HAVE TO

BE CONSIDERED IN THE LIGHT OF THEIR

POTENTIAL TO BECOME STANDARDS TO

WHICH REFERENCE MAY BE MADE IN

Reference number

NATIONAL REGULATIONS.

ISO/DIS 12696:2021(E)

RECIPIENTS OF THIS DRAFT ARE INVITED

TO SUBMIT, WITH THEIR COMMENTS,

NOTIFICATION OF ANY RELEVANT PATENT

RIGHTS OF WHICH THEY ARE AWARE AND TO

PROVIDE SUPPORTING DOCUMENTATION. ISO 2021

---------------------- Page: 1 ----------------------

ISO/DIS 12696:2021(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2021

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2021 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/DIS 12696:2021(E)

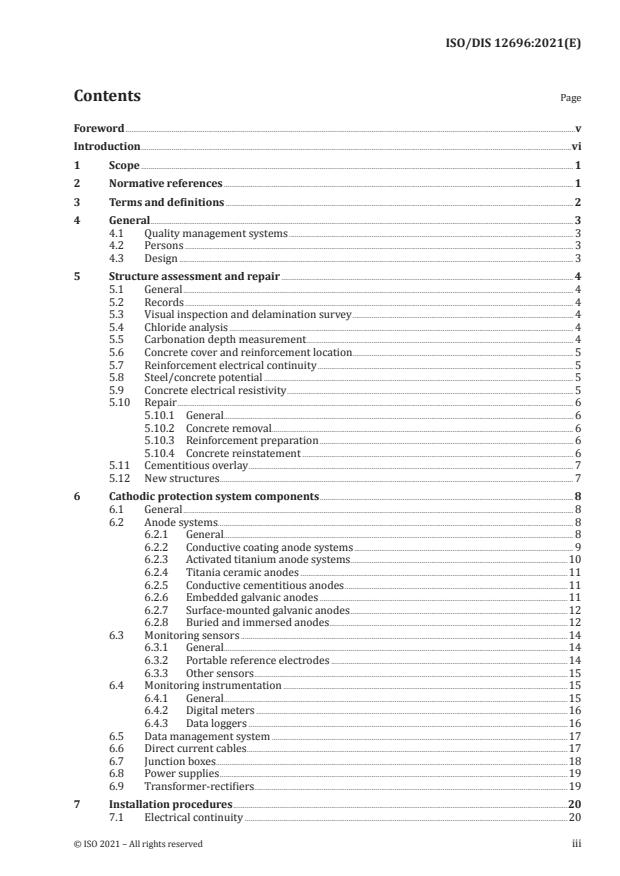

Contents Page

Foreword ..........................................................................................................................................................................................................................................v

Introduction ................................................................................................................................................................................................................................vi

1 Scope ................................................................................................................................................................................................................................. 1

2 Normative references ...................................................................................................................................................................................... 1

3 Terms and definitions ..................................................................................................................................................................................... 2

4 General ............................................................................................................................................................................................................................ 3

4.1 Quality management systems .................................................................................................................................................... 3

4.2 Persons .......................................................................................................................................................................................................... 3

4.3 Design ............................................................................................................................................................................................................. 3

5 Structure assessment and repair ........................................................................................................................................................ 4

5.1 General ........................................................................................................................................................................................................... 4

5.2 Records .......................................................................................................................................................................................................... 4

5.3 Visual inspection and delamination survey ................................................................................................................... 4

5.4 Chloride analysis ................................................................................................................................................................................... 4

5.5 Carbonation depth measurement ........................................................................................................................................... 4

5.6 Concrete cover and reinforcement location................................................................................................................... 5

5.7 Reinforcement electrical continuity ..................................................................................................................................... 5

5.8 Steel/concrete potential ................................................................................................................................................................. 5

5.9 Concrete electrical resistivity ..................................................................................................................................................... 5

5.10 Repair .............................................................................................................................................................................................................. 6

5.10.1 General...................................................................................................................................................................................... 6

5.10.2 Concrete removal............................................................................................................................................................. 6

5.10.3 Reinforcement preparation .................................................................................................................................... 6

5.10.4 Concrete reinstatement ............................................................................................................................................. 6

5.11 Cementitious overlay ......................................................................................................................................................................... 7

5.12 New structures ........................................................................................................................................................................................ 7

6 Cathodic protection system components .................................................................................................................................... 8

6.1 General ........................................................................................................................................................................................................... 8

6.2 Anode systems ......... ................................................................................................................................................................................ 8

6.2.1 General...................................................................................................................................................................................... 8

6.2.2 Conductive coating anode systems .................................................................................................................. 9

6.2.3 Activated titanium anode systems .................................................................................................................10

6.2.4 Titania ceramic anodes ...........................................................................................................................................11

6.2.5 Conductive cementitious anodes ....................................................................................................................11

6.2.6 Embedded galvanic anodes .................................................................................................................................11

6.2.7 Surface-mounted galvanic anodes .................................................................................................................12

6.2.8 Buried and immersed anodes............................................................................................................................12

6.3 Monitoring sensors ..........................................................................................................................................................................14

6.3.1 General...................................................................................................................................................................................14

6.3.2 Portable reference electrodes ...........................................................................................................................14

6.3.3 Other sensors ...................................................................................................................................................................15

6.4 Monitoring instrumentation ....................................................................................................................................................15

6.4.1 General...................................................................................................................................................................................15

6.4.2 Digital meters ..................................................................................................................................................................16

6.4.3 Data loggers ......................................................................................................................................................................16

6.5 Data management system ..........................................................................................................................................................17

6.6 Direct current cables .......................................................................................................................................................................17

6.7 Junction boxes .......................................................................................................................................................................................18

6.8 Power supplies .....................................................................................................................................................................................19

6.9 Transformer-rectifiers ......... ..........................................................................................................................................................19

7 Installation procedures ..............................................................................................................................................................................20

7.1 Electrical continuity ........................................................................................................................................................................20

© ISO 2021 – All rights reserved iii---------------------- Page: 3 ----------------------

ISO/DIS 12696:2021(E)

7.2 Performance monitoring system ..........................................................................................................................................21

7.3 Connections to steel in concrete ...........................................................................................................................................22

7.4 Concrete repairs associated with the cathodic protection components ............................................22

7.5 Surface preparation for anode installation..................................................................................................................22

7.6 Anode installation .............................................................................................................................................................................22

7.7 Connections to the anode system ........................................................................................................................................23

7.8 Anode overlay, surface sealant or decorative coating application ..........................................................23

7.9 Electrical installation ......................................................................................................................................................................24

7.10 Testing during installation .........................................................................................................................................................24

8 Commissioning ....................................................................................................................................................................................................25

8.1 Visual inspection ................................................................................................................................................................................25

8.2 Pre-energizing measurements ...............................................................................................................................................25

8.3 Initial energizing of impressed current systems ....................................................................................................26

8.4 Initial adjustment of impressed current systems ..................................................................................................26

8.5 Initial performance assessment ............................................................................................................................................26

8.6 Criteria of protection: Interpretation of performance assessment data ............................................28

9 System records and documentation ..............................................................................................................................................29

9.1 Quality and test records ...............................................................................................................................................................29

9.2 Installation and commissioning report ..........................................................................................................................29

9.3 Operation and maintenance manual .................................................................................................................................29

10 Operation and maintenance ..................................................................................................................................................................30

10.1 Intervals and procedures ............................................................................................................................................................30

10.2 System review .......................................................................................................................................................................................31

10.3 System review report .....................................................................................................................................................................31

Annex A (informative) Principles of cathodic protection and its application to steel in concrete ...32

Annex B (informative) Design Process ............................................................................................................................................................40

Annex C (informative) Notes on anode systems .....................................................................................................................................47

Annex D (informative) Notes on reference electrodes ....................................................................................................................52

Bibliography .............................................................................................................................................................................................................................56

iv © ISO 2021 – All rights reserved---------------------- Page: 4 ----------------------

ISO/DIS 12696:2021(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.This document was prepared by Technical Committee ISO/TC 156, Corrosion of metals and alloys and

CEN/TC 219, Cathodic protection of steel in concrete.This third edition cancels and replaces the second edition (ISO 12696:2016), which has been technically

revised.The main changes compared to the previous edition are as follows:

— 3.1 “steel surface ratio” has been added;

— 8.6 has been revised;

— Annex A has been revised: the figures in Annex A has been updated; A.7 has been moved to the new

Annex D and a new Clause A.7 “Benefits of Cathodic Protection Current when Criteria in 8.6 are not

fully met” has been added;— Annex B has been revised completely;

— New Annex D;

— C.5 “Hybrid anodes” has been added;

— The references in the whole document has been revised.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.© ISO 2021 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO/DIS 12696:2021(E)

Introduction

This document applies to cathodic protection of steel in concrete, with the concrete atmospherically

exposed, buried or immersed.Because the criteria of protection for steel in buried or immersed concrete are those applicable to

cathodic protection of steel in atmospherically exposed concrete, this revision of EN 12696:2016

incorporates cathodic protection of steel in buried and immersed concrete. The provision of cathodic

protection current can often be more economically provided to steel in buried and immersed concrete

by using buried or immersed anode systems detailed in International Standards for buried and

immersed steel structures, rather than the anode systems that are suitable for applications to steel

in atmospherically exposed concrete. Therefore, reference is made to other International Standards in

this respect while the cathodic protection performance criteria for steel in concrete are defined in this

document for all exposures.There are other electrochemical treatments intended to provide corrosion control for steel in concrete.

These techniques include re-alkalization and chloride extraction and are not incorporated into this

document. EN 14038-1:2016 and prEN 14038-2:2019 have been published.Cathodic protection of steel in concrete is a technique that has been demonstrated to be successful in

appropriate applications in providing cost effective long-term corrosion control for steel in concrete.

It is a technique that requires specific design calculations and definition of installation procedures in

order to be successfully implemented. This document does not represent a design code for cathodic

protection of steel in concrete, but represents a performance standard for which it is anticipated, in

order to comply with this document, a detailed design and specification for materials, installation,

commissioning and operation will be prepared by expert and experienced persons.vi © ISO 2021 – All rights reserved

---------------------- Page: 6 ----------------------

DRAFT INTERNATIONAL STANDARD ISO/DIS 12696:2021(E)

Cathodic protection of steel in concrete

1 Scope

This document specifies performance requirements for cathodic protection of steel in cement-based

concrete, in both new and existing structures. It covers building and civil engineering structures,

including carbon steel reinforcement and prestressed reinforcement embedded in the concrete. It is

applicable to uncoated steel reinforcement and to organic-coated steel reinforcement. It is not applicable

to carbon fibre reinforced concrete.This document applies to steel embedded in atmospherically exposed, buried, immersed and tidal

elements of buildings or structures.This document applies only to the applications of cathodic protection to steel in concrete which are

designed with the intention to, and can be demonstrated to, meet the Criteria of Protection as defined

in 8.6. This requires the provision of sufficient performance monitoring systems as defined in 6.3 to all

parts of the structure intended to be protected, in order to assess the extent to which the Criteria in 8.6

are met.This may exclude from the Scope of this document galvanic anodes or systems applied into patch repairs

to reduce the effects of ‘incipient anodes’. This may also exclude from the Scope of this document any

form of cathodic protection systems or other electrochemical treatments that either cannot meet the

requirements of 8.6 or are not provided with the performance monitoring systems (see 6.3) that are

necessary to assess whether the Criteria of Protection as defined in 8.6 are met.

NOTE 1 Annex A gives guidance on the principles of cathodic protection and its application to steel in concrete.

NOTE 2 This document, while not specifically intended to address cathodic protection of steel in any

electrolyte except concrete, can be applied to cathodic protection of steel in other cementitious materials such as

are found, for example, in early 20th century steel-framed masonry, brick and terracotta clad buildings. In such

applications, additional considerations specific to these structures are required in respect of design, materials

and installation of cathodic protection; however, the requirements of this document can be applied to these

systems.2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies

EN 1504 (all parts), Products and systems for the protection and repair of concrete structures —

Definitions, requirements, quality control and evaluation of conformityEN 14629, Products and systems for the protection and repair of concrete structures — Test methods —

Determination of chloride content in hardened concreteEN 14630, Products and systems for the protection and repair of concrete structures — Test methods —

Determination of carbonation depth in hardened concrete by the phenolphthalein method

ISO 15257, Cathodic protection — Competence levels of cathodic protection persons — Basis for a

certification schemeIEC 60502-1, Power cables with extruded insulation and their accessories for rated voltages from 1 kV

(Um = 1,2 kV) to 30 kV (Um = 36 kV) — Part 1: Cables for rated voltages of 1 kV (Um = 1,2 kV) and 3 kV

(Um = 3,6 kV)© ISO 2021 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO/DIS 12696:2021(E)

IEC 60529, Degrees of protection provided by enclosures (IP Code)

IEC 61140, Protection against electric shock — Common aspects for installation and equipment

IEC 61558-1, Safety of power transformers, power supplies, reactors and similar products — Part 1: General

requirements and testsIEC 61558-2-1, Safety of power transformers, power supplies, reactors and similar products — Part 2-1:

Particular requirements and tests for separating transformers and power supplies incorporating separating

transformers for general applicationsIEC 61558-2-2, Safety of power transformers, power supplies, reactors and similar products — Part 2-2:

Particular requirements and tests for control transformers and power supplies incorporating control

transformersIEC 61558-2-4, Safety of transformers, reactors, power supply units and similar products for supply voltages

up to 1 100 V — Part 2-4: Particular requirements and tests for isolating transformers and power supply

units incorporating isolating transformersIEC 61558-2-13, Safety of transformers, reactors, power supply units and similar products for supply

voltages up to 1 100 V — Part 2-13: Particular requirements and tests for auto transformers and power

supply units incorporating auto transformersIEC 61558-2-16, Safety of transformers, reactors, power supply units and similar products for voltages

up to 1 100 V — Part 2-16: Particular requirements and tests for switch mode power supply units and

transformers for switch mode power supply unitsIEC 62262, Degrees of protection provided by enclosures for electrical equipment against external

mechanical impacts (IK code)3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 8044 and EN 1504 (all parts)

and the following apply.ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp— IEC Electropedia: available at http:// www .electropedia .org/

3.1

steel surface ratio

ratio of surface area of steel to surface area of concrete

3.2

zone

part of a cathodic protection system

Note 1 to entry: Anode systems can be divided into separate zones to supply current to a fully continuous

reinforcement mesh. Alternatively, a single anode zone can supply current to separate, electrically isolated,

zones within the reinforcement system. Zones can comprise an individual anode zone for each reinforcement

zone or exposure condition. As the current provision to each of the zones in each of these alternatives can be

separately measured, all of them are generically called “cathodic protection zones” and specifically “anode zones”

or “cathode zones”.3.3

humectant

hygroscopic material, i.e. a substance that promotes the retention of moisture

Note 1 to entry: It can be applied to the surface of a galvanic anode to keep the concrete-anode interface moist.

2 © ISO 2021 – All rights reserved---------------------- Page: 8 ----------------------

ISO/DIS 12696:2021(E)

4 General

4.1 Quality management systems

The design, the installation, the energizing, the commissioning and the long-term operation of all of the

elements of cathodic protection systems for steel in concrete shall be fully documented, see Annex B.

NOTE ISO 9000 constitutes a suitable quality management systems standard which can be utilized.

Each element of the work shall be undertaken in accordance with a fully documented quality plan.

Each stage of the design shall be checked and the checking shall be documented.Each stage of the installation, energizing, commissioning and operation shall be the subject of

appropriate visual, mechanical and/or electrical testing, and all testing shall be documented.

All test instrumentation shall have valid calibration certificates traceable to National or International

standards concerning calibration.The documentation shall constitute part of the permanent records for the works.

4.2 Persons

Each aspect of the cathodic protection system design, installation, testing of the installation, energizing,

commissioning a...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.