ISO 10794:2018

(Main)Space systems — Programme management — Material, mechanical parts and processes

Space systems — Programme management — Material, mechanical parts and processes

This document defines the programme management requirements for material, mechanical parts and processes for projects covering mission definition, design, development, production and operations of space systems, including disposal. This document covers the following: — management, including organization, reviews, acceptance status and documentation control; — selection criteria and rules; — evaluation, validation and qualification, or verification testing; — procurement and receiving inspection; and — utilization criteria and rules. This document applies to all space deliverable products and all programme phases.

Systèmes spatiaux — Management de programme — Matériaux, éléments mécaniques et procédés

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10794

Second edition

2018-05

Space systems — Programme

management — Material, mechanical

parts and processes

Systèmes spatiaux — Management de programme — Matériaux,

éléments mécaniques et procédés

Reference number

©

ISO 2018

© ISO 2018

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Fax: +41 22 749 09 47

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2018 – All rights reserved

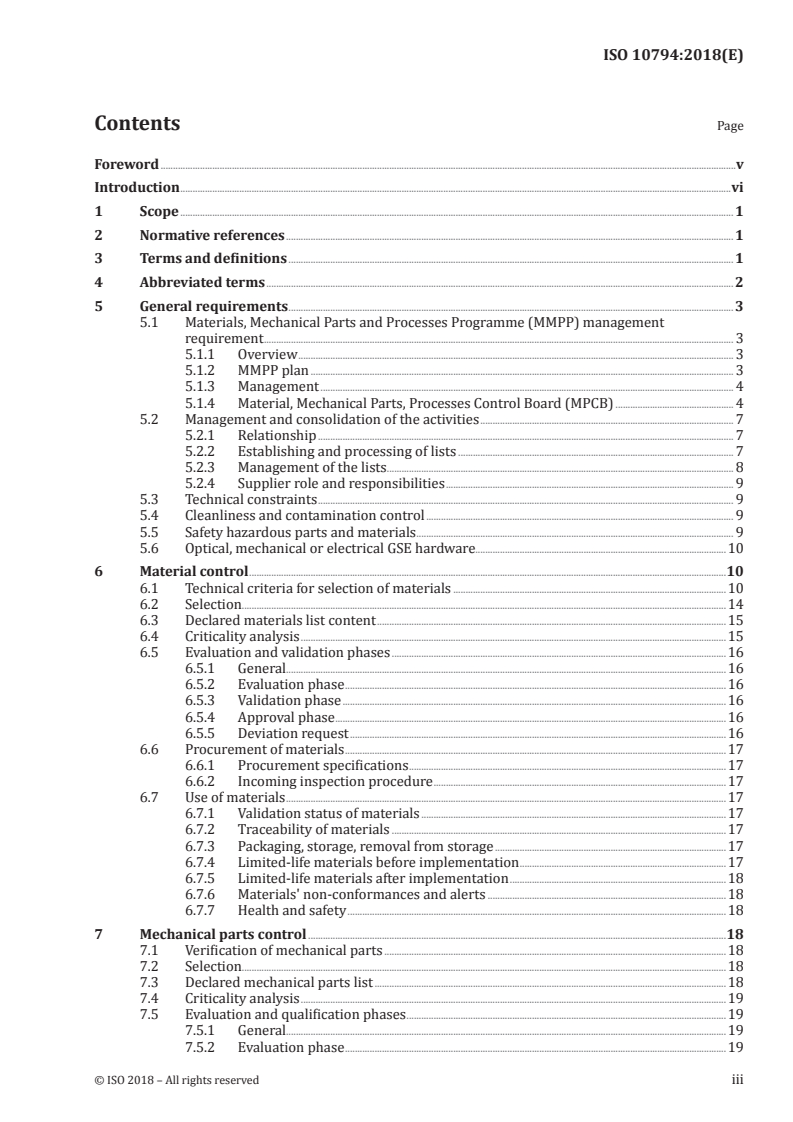

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Abbreviated terms . 2

5 General requirements . 3

5.1 Materials, Mechanical Parts and Processes Programme (MMPP) management

requirement . 3

5.1.1 Overview . 3

5.1.2 MMPP plan . 3

5.1.3 Management . 4

5.1.4 Material, Mechanical Parts, Processes Control Board (MPCB) . 4

5.2 Management and consolidation of the activities . 7

5.2.1 Relationship . 7

5.2.2 Establishing and processing of lists . 7

5.2.3 Management of the lists . . 8

5.2.4 Supplier role and responsibilities . 9

5.3 Technical constraints . 9

5.4 Cleanliness and contamination control . 9

5.5 Safety hazardous parts and materials . 9

5.6 Optical, mechanical or electrical GSE hardware . .10

6 Material control .10

6.1 Technical criteria for selection of materials .10

6.2 Selection.14

6.3 Declared materials list content .15

6.4 Criticality analysis .15

6.5 Evaluation and validation phases .16

6.5.1 General.16

6.5.2 Evaluation phase .16

6.5.3 Validation phase .16

6.5.4 Approval phase .16

6.5.5 Deviation request .16

6.6 Procurement of materials .17

6.6.1 Procurement specifications .17

6.6.2 Incoming inspection procedure .17

6.7 Use of materials .17

6.7.1 Validation status of materials .17

6.7.2 Traceability of materials .17

6.7.3 Packaging, storage, removal from storage .17

6.7.4 Limited-life materials before implementation .17

6.7.5 Limited-life materials after implementation .18

6.7.6 Materials' non-conformances and alerts .18

6.7.7 Health and safety .18

7 Mechanical parts control .18

7.1 Verification of mechanical parts .18

7.2 Selection.18

7.3 Declared mechanical parts list .18

7.4 Criticality analysis .19

7.5 Evaluation and qualification phases .19

7.5.1 General.19

7.5.2 Evaluation phase .19

7.5.3 Qualification phase .20

7.5.4 Approval phase .20

7.5.5 Deviation request .20

7.6 Procurement of mechanical parts .20

7.6.1 General.20

7.6.2 Procurement specification .20

7.6.3 Source inspection .20

7.6.4 Incoming inspection procedure .21

7.7 Use of mechanical parts .21

7.7.1 Qualification status of mechanical parts .21

7.7.2 Traceability of mechanical parts .21

7.7.3 Packaging, storage, removal from storage .21

7.7.4 Limited-life mechanical parts or parts subject to wearout .21

7.7.5 Mechanical parts non-conformances and alerts .21

8 Process control .21

8.1 Specifications or procedures .21

8.2 Process selection and training .21

8.3 Declared processes list content .22

8.4 Criticality analysis .23

8.5 Evaluation and verification phase .23

8.5.1 General.23

8.5.2 Evaluation phase .23

8.5.3 Verification phase.23

8.5.4 Approval phase .24

8.5.5 Deviation request .24

8.6 Use of a process .24

8.6.1 Verification status of a process .24

8.6.2 Re-verification of a process .24

8.6.3 Implementation of a process .24

8.6.4 Traceability of processes .25

8.6.5 Process non-conformances and alerts .25

8.6.6 Mandatory inspection points (MIPs).25

8.6.7 Packaging, storage, removal from storage .25

Annex A (informative) Relationship between materials, mechanical parts,processes

activities and programme phase .26

Annex B (normative) Declared materials list — Document requirements definition .28

Annex C (normative) Declared mechanical parts list — Document requirements definition .33

Annex D (normative) Declared processes list — Document requirements definition .38

Annex E (normative) Request for approval (RFA) — Document requirements definition .42

Bibliography .46

iv © ISO 2018 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT) see the following

URL: www .iso .org/iso/foreword .html

This document was prepared by Technical Committee ISO/TC 20, Aircraft and space vehicles,

Subcommittee SC 14, Space systems and operations.

This edition of ISO 10794:2018 cancels and replaces the edition ISO 10794:2011, which has been

technically revised and includes the following changes:

— bacterial and fungus growth has been added;

— Hydrogen embrittlement has been added; and

— manned environment has been added.

Introduction

This document is intended for application by the management in space programmes and applications.

The formation of this document takes into account the existing International Standards prepared by

ISO/TC 176, notably ISO 9000, ISO 9001 and ISO 9004, and the content of ISO 14300-1 and ISO 14300-2.

This document specifies the requirements and statements applicable to materials, mechanical parts

and processes to satisfy the mission performance requirements.

This document also specifies the documentation requirements and the procedures relevant to obtaining

approval for the use of materials, mechanical parts and processes in the fabrication of space systems

and associated equipment.

vi © ISO 2018 – All rights reserved

INTERNATIONAL STANDARD ISO 10794:2018(E)

Space systems — Programme management — Material,

mechanical parts and processes

1 Scope

This document defines the programme management requirements for material, mechanical parts and

processes for projects covering mission definition, design, development, production and operations of

space systems, including disposal.

This document covers the following:

— management, including organization, reviews, acceptance status and documentation control;

— selection criteria and rules;

— evaluation, validation and qualification, or verification testing;

— procurement and receiving inspection; and

— utilization criteria and rules.

This document applies to all space deliverable products and all programme phases.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 14300-2, Space systems — Programme management — Part 2: Product assurance

ISO 27025, Space systems — Programme management — Quality assurance requirements

ISO 23461, Space systems — Programme management — Non-conformance control system

ISO 9000, Quality management systems — Fundamentals and vocabulary

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 9000 and the following apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— IEC Electropedia: available at http: //www .electropedia .org/

— ISO Online browsing platform: available at https: //www .iso .org/obp

3.1

critical material

material that is new to an individual company or non-validated for the particular application and

environment, or that has caused problems during previous use that remain unresolved

3.2

critical mechanical part

mechanical part that requires specific attention or control due to fracture mechanics aspects and

limited-life aspects, or with which the contractor has no previous experience of using the mechanical

part in the specific application and environment or are new or non-qualified, or that has caused

problems during previous use that remain unsolved

3.3

critical process

process new to an individual company or non-verified for the application in question or has caused

problems during previous use that remain unresolved

3.4

mechanical part

piece of hardware that is not electrical, electronic or electromechanical and that performs a simple

elementary function or part of a function in such a way that it can be evaluated as a whole against

expected requirements of performance and cannot be disassembled without destroying this capability

3.5

process

set of interrelated or interacting activities that transforms inputs into outputs

Note 1 to entry: See ISO 9000.

Note 2 to entry: In this document, “process” means the manufacturing process of product, i.e. set of interrelated

resources and activities which transforms a material or semi-finished product into a semi-finished product or

final product.

3.6

request for approval

document by which the supplier or user asks the competent body for permission to use a critical

material, part or process

3.7

special process

process where quality cannot be completely ensured by inspection of the end article only

4 Abbreviated terms

The following abbreviated terms are defined and used within this document.

AA Aluminium Association

AOCS attitude and orbit control system

ATOX atomic oxygen

AISI American Iron and Steel Institute

CDA Copper Development Association

CDR critical design review

CFRP carbon fibre reinforced polymer

CI configuration item number (as per project definition)

DML declared materials list

DMPL declared mechanical parts list

2 © ISO 2018 – All rights reserved

DPL declared processes list

DRD document requirements definition

EEE electrical, electronic and electromechanical

ESA European Space Agency

GOX gaseous oxygen

GSE ground support equipment

LEO low earth orbit

LOX liquid oxygen

MIP mandatory inspection point

MMPP materials, mechanical parts and processes

MPCB Material, Mechanical Parts and Process Control Board

NASA National Aeronautics and Space Administration

NCR non-conformance report

NRB non-conformance review board

PA product assurance

PDR preliminary design review

PID process identification document

PMP parts, materials, processes

QR qualification review

QRR qualification review report

RFA request for approval

RFD request for deviation

SCC stress corrosion cracking

5 General requirements

5.1 Materials, Mechanical Parts and Processes Programme (MMPP) management

requirement

5.1.1 Overview

The general MMPP activity within the framework of a project is summarized in Figures 1 and 2.

5.1.2 MMPP plan

The suppliers shall prepare, maintain and implement a MMPP plan, as part of the overall PA plan in

accordance with ISO 14300-2 and this document, or exist as a separate document.

The MMPP plan shall be submitted to the customer for approval.

5.1.3 Management

The supplier shall appoint a MMPP manager. The MMPP Manager shall ensure that the Materials,

Mechanical Parts and Processes used to manufacture a spacecraft or a launcher satisfy both the ground

and flight functional requirements and constraints of the project. To obtain the validation status for

materials and qualification status for parts and verification status for processes, the MMPP manager

shall present to the customer activities which were performed in conformance with this document

together with results obtained.

5.1.4 Material, Mechanical Parts, Processes Control Board (MPCB)

The MMPP manager shall organize Material, Mechanical Parts and Processes Control Board (MPCB)

with his or her suppliers at all levels, as appropriate. The MPCB activity shall start not later than at PDR.

The MMPP Manager shall agree with the customer on the MPCB’s activities at PDR. Minimum tasks of

the MPCB shall be as follows:

— coordination of the initiation and approval of RFA’s in conformance with DRD from the Annex E by

involving the relevant technical discipline;

— review and approval of test programme and related results;

— review of preliminary Declared Materials, Mechanical Parts and Processes Lists and of any available

evidence to support the approval, by the PDR;

— review and approval of Declared Materials, Mechanical Parts and Processes Lists and of the evidence

for the approval by the CDR; and

— review and approval of any change to the approved Declared Materials, Mechanical Parts and

Processes Lists.

4 © ISO 2018 – All rights reserved

Figure 1 — Materials, mechanical parts and processes flow chart (continued in Figure 2)

Figure 2 — Materials, mechanical parts and processes flow chart (continued from Figure 1)

6 © ISO 2018 – All rights reserved

Table 1 — Steps to be taken to get approval for materials, mechanical parts and processes

Approval process for materials, mechanical parts and processes (MMPP)

Materials Mechanical parts Processes

Phase

Step Comments Step Comments Step Comments

Critical analysis 1 — 1 — 1 —

Critical processes are

evaluated by testing

Mechanical parts are

Evaluation (usually Critical materials “technology samples”

tested by, for example,

by test methods are tested, e.g. including all, for

2 2 vibration, thermal 2

defined by national outgassing, SCC, example, electrical

analysis, offgassing and

agency standards) flammability. interconnection pro-

life test.

cesses and painting,

adhesive bonding.

Verification/valida-

3 Validation 3 Qualification 3 Verification

tion/qualification

By RFA (see By RFA (see Annex E) By RFA (see Annex E)

Approval 4 4 4

Annex E) or DML or DMPL/DPL or DPL

NOTE 1 Project approval is always by means of the request for approval (RFA) form and the project's de-

clared materials list (DML), declared mechanical parts list (DMPL) and declared processes list (DPL).

NOTE 2 The details for approvals of MMPP lists are contained in this document.

NOTE 3 To summarize: Materials are validated.

Mechanical parts are qualified.

Processes are verified.

And in addition: Skills training schools are customer approved.

Outside test or evaluation laboratories are customer approved.

Operators and inspectors for critical processes are trained, competent and

monitored.

5.2 Management and consolidation of the activities

5.2.1 Relationship

The relationship between materials and processes activities and programme phases is shown in

Annex A.

5.2.2 Establishing and processing of lists

5.2.2.1 Each supplier and lower-level supplier shall establish, collect, review and deliver the declared

materials, mechanical parts and processes lists including all the items intended for use in the flight

equipment. The lists shall reflect the current design at the time of issue. These lists shall contain the

materials, mechanical parts and processes used in the current design. The objectives are as follows:

— compliance with all requirements of the programme;

— verification of the results of equipment supplier activities; and

— control and monitoring the status of materials, mechanical parts and processes in conformance

with programme milestones. For additional information, see informative Annex A.

5.2.2.2 The following constraints should be assessed:

— requirements originating from the functional specifications;

— requirements and conditions specific to the project;

— maximum use of the materials and processes described in approved data sources, e.g. national

agency standards, and items already approved on similar projects; and

— use of project related preferred lists, if available.

5.2.2.3 An analysis of the criticality of these preliminary lists shall be performed as such that, after

checking the conformity of the materials, mechanical parts and processes against all the project

requirements, allow them to be classified into three categories:

— critical items, subject to evaluation, validation, qualification, or verification programmes;

— items that are not critical but which do not conform to one or more project requirements; and

— non-critical items.

For items classified as critical, a request for approval shall be submitted in conformance with

Annex E. For items classified as not critical but which are not in conformance with one or more project

requirements, a justified deviation request should be drafted.

5.2.3 Management of the lists

The supplier shall document all materials in the Declared materials list in conformance with Annex B.

The supplier shall document all mechanical parts in the Declared mechanical parts list in conformance

with Annex C.

The supplier shall document all processes in the Declared process list in conformance with Annex D.

The supplier shall process the lists of lower-level suppliers to ensure exchangeability, traceability,

searchability, sortability, storability and retrievability for that set of lists, before submitting it to the

customer.

These lists shall be updated during the course of the project. The preliminary lists shall include the

items from suppliers' preliminary requirements and are used to identify those that are critical

(available for the PDR).

The as-designed lists shall include the items from the baseline's various design files, available for the CDR.

Any change after CDR or QR shall be reflected in the list and shall be in accordance with Figure 2.

The MMPP manager is responsible within the programme to ensure that all the information needed is

given and that the approval status is consistent with technical and scheduling objectives and that the

data are exchangeable.

Where no project requirements exist for a separate DMPL, the mechanical parts can be entered into a

separate section of the DML.

The materials of, for example, bearings, screw and nuts that are made up of a few materials, can be

listed in the DMPL. The materials (metals and plastics) of complex parts can be listed in the DML with,

for example, outgassing, toxicity, flammability, corrosion and stress corrosion values and reference to

the DMPL item.

The supplier shall establish, collect, review and deliver the declared materials, mechanical parts and

processes lists in an electronic format in conformance with Annex B, Annex C, and Annex D.

The supplier shall demonstrate that the lists have been formally approved prior to their delivery to the

customer.

8 © ISO 2018 – All rights reserved

5.2.4 Supplier role and responsibilities

5.2.4.1 The supplier shall be responsible for the following tasks:

— obtaining the correct and complete lists from lower-level suppliers;

— providing provisional and, later, definitive approval for each list; and

— submitting the project declared lists for approval prior to initiation of the hardware phase,

before CDR.

The lists specified in the requirement by the suppliers shall include all the information described in this

document. Amendments to the lists shall be implemented through established change procedures.

5.2.4.2 The following documentation shall be delivered to the customer upon request:

— RFA with reference and issue in conformance with DRD in Annex E;

— evaluation reports; and

— deviation requests.

The material, mechanical parts or process justification files shall be made available to the customer

upon request either on the supplier site, or by any other process agreed by both parties.

NOTE For example, by non-disclosure agreement.

5.3 Technical constraints

Mechanical parts, materials and processes shall satisfy the mission's functional requirements and

constraints. Mechanical parts, materials and processes shall satisfy both ground environment

constraints (e.g. manufacture, tests, storage, maintenance, transport and integration) as well as flight

requirements and flight constraints (launch and orbit).

The estimated availability of the parts and products obtained from materials and processes used shall

be compatible with the space system's life cycle (tests, storage and mission).

5.4 Cleanliness and contamination control

The supplier shall establish and maintain a contamination and cleanliness control programme

including, as a minimum:

— cleaning procedures; and

— cleanliness monitoring procedures or methods.

The risks of chemical or particle pollution generated by parts, materials or processes used shall

be identified and reduced in accordance with mission requirements (cleanliness or contamination

analysis).

For cleanliness- or contamination-critical applications, a chemical and particle requirement

specification and a specific cleanliness control plan shall be established.

5.5 Safety hazardous parts and materials

Mechanical parts and materials with hazardous characteristics shall be identified, managed and

processed according to customer standards.

5.6 Optical, mechanical or electrical GSE hardware

When optical, mechanical or electrical GSE materials are used in thermal vacuum or interfacing with

flight hardware, possible degradation shall be assessed (e.g. contamination, surface degradation,

flammability, electromechanical and chemical effects).

6 Material control

6.1 Technical criteria for selection of materials

Material design data shall be generated for the intended service conditions using test and analysis

procedures approved by the customer. Material properties shall be compatible with the environments

to which they are exposed during terrestrial testing prior to launch, and during the mission.

The following requirements shall be taken into account only if the environmental conditions of the

mission require their application. The agency- or customer-specific requirements, test methods and

acceptance or rejection criteria shall be applied.

a) Temperature: Material properties shall be compatible with the thermal environment to which they

are exposed. Examples of thermal environment are also the passage through transitions, ductile-

brittle temperatures, e.g. phase transitions, ductile-brittle transition temperatures for metals, glass

transition (Tg) for polymer materials, and environmental factors which affect these properties,

such as moisture.

b) Thermal cycling and thermo optical: Materials subject to thermal cycling shall be assessed for their

ability to withstand induced thermal stress and shall be tested according to approved procedures.

Thermo optical properties shall be evaluated in conformance technical requirements. Directional

effects due to manufacturing or processing shall be evaluated via dedicated testing to be agreed

with customer.

c) Vacuum:

— Outgassing screening tests shall be carried out according to approved procedures. The screening

process applied depends on the application.

— All organic materials for use in space systems shall be evaluated to determine their outgassing

characteristics.

— The need for retest outgassing characteristics of materials used for an extended period of time

at a temperature higher than 50 °C should be mutually agreed with the customer.

d) Offgassing, toxicity: Spacecraft and associated equipment shall be manufactured from materials

and by processes that do not cause an unacceptable hazard to personnel or hardware, whether on

the ground or in space. For materials for the use in manned compartments of a spacecraft or space

segment elements, offgassing and toxicity analysis shall be performed. The levels of offgassing and

toxicity shall be agreed with customer.

e) Flammability: The materials flammability resistance shall be evaluated for the most hazardous

environment envisaged for their use, and be applicable to:

— unmanned spacecraft or space segment elements launched by a manned space transportation

system when powered on launch; and

— manned spacecraft and space segment elements.

f) Radiation:

— Materials exposed to radiation shall be assessed to determine their resistance to the radiation

dosage expected during the mission.

10 © ISO 2018 – All rights reserved

— Evaluation of materials resistance to radiation shall include the combined effects of particle

radiation and ultraviolet radiation in the normal space environment, along with any mission-

specific radiation levels.

— The effect of bleaching due to vacuum or air recovery shall be evaluated, in case ex-situ

measurements are performed.

— In case synergistic testing is not possible it shall be proven that synergistic effects caused by

radiation and temperature are not degrading the materials' properties.

— In case technical limits prevent the synergistic testing approach, it shall be so justified, and the

justification for sequential testing shall be provided.

g) Electrical charge and discharge: External surfaces of the spacecraft shall be sufficiently conductive,

interconnected and grounded to the spacecraft structure to avoid the build-up of differential

charges.

h) Corrosion: For all materials that come into contact with atmospheric gases, cleaning fluids or other

chemicals, it shall be demonstrated that the degradation of properties during their anticipated

service life is acceptable in terms of the performance and integrity requirements. All mechanical

parts, assemblies and equipment, including spares, shall be finished to provide protection from

corrosion.

i) Stress corrosion:

— Materials used for structural and load-bearing applications (subject to tensile stress) shall be

selected in conformance with approved data sources.

— Any material not covered by an approved standard shall be tested according to approved

procedures.

j) Fluid compatibility:

— Materials within the system exposed to reactive fluids, both directly and as a result of single

point failures when failure propagation effects cause hazardous operation of interfacing

hardware shall be compatible with that fluid in their application. Examples of reactive fluids

are liquid oxygen (LOX) and gaseous oxygen (GOX).

— The compatibility of materials which are or can come into contact with LOX or GOX shall be

evaluated except the case specified in the requirement.

— In case no compatibility data are available, tests shall be performed for reactive fluids other

than oxygen.

k) Galvanic compatibility: When bimetallic contacts are used, the choice of the pair of metallic

materials used shall be agreed with the customer. This also includes metal-to-conductive fibre-

reinforced materials contacts. Galvanic compatibilities shall be selected in conformance with

Table 2. Materials not listed in Table 2 shall be evaluated in a flight-simulated configuration using

an accelerated environment to be agreed by the customer.

l) Atomic oxygen:

— All materials for use on the external surfaces of spacecraft for use in low earth orbit (LEO)

altitudes, between 200 km and 700 km, shall be evaluated for their resistance to atomic oxygen

(ATOX). The flux level varies with altitude, velocity vector and solar activity. Fluence levels vary

with the duration of exposure.

— Test procedures shall be subject to the approval of the customer.

The effect of ATOX on thermo optical properties including specularity shall be evaluated.

Table 2 — Compatible couples for bimetallic contacts

Pure metals and alloys in Alumi Al Cad Cast Chr Cop Cup Gold, Gun Mag Nickel, Sil SnPb Stain Stain Steel Tita Zinc,

alphabetical order nium (pu mi iron rom per, ro Plati metal nes Monel, ver al less less (car nium Beryl

(including carbon) Copper re), um (aus ium Bra Nic num, (Cu ium Inco loys steel steel bon, and lium

al Al tenic) sses kel, Car Zn10 nel, (all), 18/ 13Cr low Tial

loys Zinc Alb bon, al Nickel/ Tin, 8 (400 al loys

al ron Rho loy), Molyb Lead (300 ser loy),

loys zes, dium Pbro denum ser ies) Cast

Sib nzes, alloys ies) iron

ron Snb

zes ron

zes

Aluminium Copper alloys 1 1 3 3 3 3 3 3 2 2 3 1 2 2 3 2 2

Al (pure) 1 3 3 3 3 3 3 2 3 3 2 3 3 3 3 2

AlZinc alloys

Cadmium 2 2 2 2 2 2 1 2 2 0 1 1 2 2 2

Cast iron (austenic) 1 1 1 2 1 3 1 2 1 1 1 2 1 3

Chromium 1 0 0 1 3 1 0 2 0 0 2 0 3

Copper, Brasses 0 2 0 3 1 1 2 1 1 3 0 3

CuproNickel 2 0 3 1 1 2 2 1 3 0 3

Albronzes

Sibronzes

Gold 2 3 2 0 3 0 1 3 0 3

Platinum,

Carbon

Rhodium

Gunmetal(CuZn10 alloy) 3 1 1 1 0 0 3 0 3

Pbronzes

Snbronzes

Magnesium 3 3 2 3 3 3 3 3

Nickel 2 2 1 0 2 1 3

Monel

Inconel

Nickel/Molybdenumalloys

Silver 3 0 0 3 0 3

SnPb alloys (all) 1 1 1 3 1

Tin, Lead

Stainless steel 18/8 1 3 0 3

(300 series)

Stainless steel 13Cr 3 0 3

(400 series)

Steel (carbon, low alloy) 0 3

Cast iron

12 © ISO 2018 – All rights reserved

Table 2 (continued)

Pure metals and alloys in Alumi Al Cad Cast Chr Cop Cup Gold, Gun Mag Nickel, Sil SnPb Stain Stain Steel Tita Zinc,

alphabetical order nium (pu mi iron rom per, ro Plati metal nes Monel, ver al less less (car nium Beryl

(including carbon) Copper re), um (aus ium Bra Nic num, (Cu ium Inco loys steel steel bon, and lium

al Al tenic) sses kel, Car Zn10 nel, (all), 18/ 13Cr low Tial

loys Zinc Alb bon, al

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...