ISO/TS 21354:2020

(Main)Measurement of multiphase fluid flow

Measurement of multiphase fluid flow

This document establishes a common basis for, and assistance in, the classification of applications and multiphase meters, as well as guidance and recommendations for the implementation and use of such meters. The so-called in-line multiphase flow meters (MPFMs) that directly measure the oil, water and gas flow rates, as well as the partial- and full-separation MPFMs are the main focus of this document. Conventional two- or three-phase separators are not included in this document. Only limited reference is made to wet-gas meters, since although wet-gas flow is a subset of multiphase flow, wet-gas measurement is covered by ISO/TR 11583 and ISO/TR 12748.

titre manque

General Information

Overview

ISO/TS 21354:2020 provides a technical specification for the measurement of multiphase fluid flow in oil & gas production systems. It establishes a common basis for classifying applications and multiphase flow meters (MPFMs) and gives guidance and recommendations for their implementation and use. The document focuses on in-line MPFMs that directly measure oil, water and gas flow rates and on partial- and full-separation MPFMs. Conventional two- or three-phase separators are excluded. Wet-gas meters are only referenced briefly (see ISO/TR 11583 and ISO/TR 12748).

Key topics and requirements

- Scope and terminology: standardized terms, symbols and subscripts for multiphase metering and metrology.

- Multiphase flow fundamentals: flow regime maps (vertical and horizontal), slip effects and classification of multiphase flows.

- Performance specification: technical descriptions, sensor/primary device specs, output formats, measuring ranges, rated and limiting conditions.

- Measurement uncertainty: evaluation methodology, influence quantities, repeatability, stability and frequency response.

- Production and MPFM envelopes: plotting production and measuring envelopes on two-phase and composition maps to guide selection and design.

- Testing, calibration and adjustment: factory acceptance testing (FAT), static and dynamic performance verification, test facilities, in‑situ testing, blind tests and reporting.

- Installation and commissioning: field installation considerations, electrical and site integration, commissioning and start‑up procedures.

- Operational verification: baseline monitoring and ongoing verification during operation.

Practical applications and users

ISO/TS 21354 is practical for:

- Oil & gas operators specifying MPFMs for well surveillance, production allocation, well testing and fiscal/non-fiscal measurement.

- Instrumentation and MPFM vendors preparing technical offers, FAT plans and performance documentation.

- Flow assurance and production engineers using flow maps and production envelopes for equipment selection and optimization.

- Metrology teams and test facilities designing calibration plans, blind tests and uncertainty assessments.

- Regulatory and commercial stakeholders interested in measurement uncertainty, custody transfer considerations and allocation metering.

Benefits

- Harmonizes terminology and specification practices for multiphase metering.

- Supports reliable selection, testing and commissioning of MPFMs.

- Helps quantify measurement uncertainty for operational and commercial decisions.

Related standards

- ISO/TR 11583 (wet‑gas metering)

- ISO/TR 12748 (wet‑gas measurement)

Keywords: multiphase flow, MPFM, multiphase meters, measurement uncertainty, factory acceptance testing, production envelope, fluid metering, well testing, multiphase flow measurement.

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 21354

First edition

2020-11

Measurement of multiphase fluid flow

Reference number

©

ISO 2020

© ISO 2020

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting

on the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address

below or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii © ISO 2020 – All rights reserved

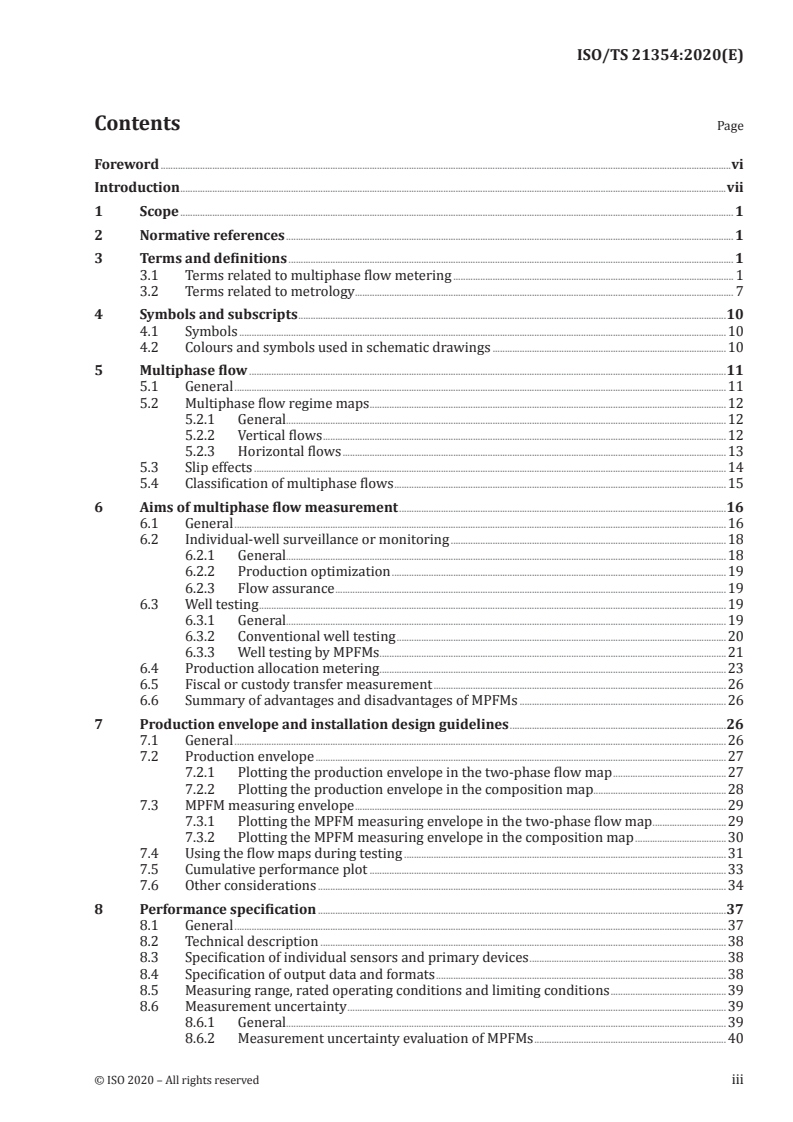

Contents Page

Foreword .vi

Introduction .vii

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

3.1 Terms related to multiphase flow metering . 1

3.2 Terms related to metrology. 7

4 Symbols and subscripts .10

4.1 Symbols .10

4.2 Colours and symbols used in schematic drawings .10

5 Multiphase flow .11

5.1 General .11

5.2 Multiphase flow regime maps .12

5.2.1 General.12

5.2.2 Vertical flows .12

5.2.3 Horizontal flows .13

5.3 Slip effects .14

5.4 Classification of multiphase flows .15

6 Aims of multiphase flow measurement .16

6.1 General .16

6.2 Individual-well surveillance or monitoring .18

6.2.1 General.18

6.2.2 Production optimization .19

6.2.3 Flow assurance .19

6.3 Well testing .19

6.3.1 General.19

6.3.2 Conventional well testing .20

6.3.3 Well testing by MPFMs.21

6.4 Production allocation metering .23

6.5 Fiscal or custody transfer measurement .26

6.6 Summary of advantages and disadvantages of MPFMs .26

7 Production envelope and installation design guidelines .26

7.1 General .26

7.2 Production envelope .27

7.2.1 Plotting the production envelope in the two-phase flow map .27

7.2.2 Plotting the production envelope in the composition map.28

7.3 MPFM measuring envelope .29

7.3.1 Plotting the MPFM measuring envelope in the two-phase flow map .29

7.3.2 Plotting the MPFM measuring envelope in the composition map .30

7.4 Using the flow maps during testing .31

7.5 Cumulative performance plot .33

7.6 Other considerations .34

8 Performance specification .37

8.1 General .37

8.2 Technical description .38

8.3 Specification of individual sensors and primary devices .38

8.4 Specification of output data and formats .38

8.5 Measuring range, rated operating conditions and limiting conditions .39

8.6 Measurement uncertainty .39

8.6.1 General.39

8.6.2 Measurement uncertainty evaluation of MPFMs .40

8.6.3 Influence quantities and sensitivity coefficients .40

8.6.4 Repeatability .41

8.6.5 Stability and frequency response .41

8.7 Guideline on MPFM performance specification .41

8.7.1 General.41

8.7.2 Technical descriptions .42

8.7.3 Specification of input data .42

8.7.4 Specification of output data .42

8.7.5 Rated operating conditions and limiting conditions .43

8.7.6 Measurement uncertainty .44

8.7.7 Two-phase flow map .46

8.7.8 Composition map .46

9 Testing, calibration and adjustment .46

9.1 General .46

9.2 Factory acceptance testing (FAT) .47

9.3 Calibration and test of MPFMs .48

9.3.1 General.48

9.3.2 Performance verification in static conditions . .48

9.3.3 Performance verification in dynamic conditions .49

9.3.4 Factory test .51

9.3.5 Test facility .51

9.3.6 In situ test.53

9.3.7 Further information on performance testing .55

9.3.8 Test report .58

9.4 Adjustment of MPFMs .60

9.4.1 General.60

9.4.2 Adjustment based on static configuration .60

9.4.3 Adjustment based on performance verification in dynamic conditions .60

9.5 Blind tests .61

9.5.1 Scope and objective of MPFM blind test .61

9.5.2 Organization and implementation .61

9.5.3 Multiphase flow loop .61

9.5.4 Test matrix .62

9.5.5 Information to be provided by MPFM vendors .63

9.5.6 Information provided to MPFM vendors .63

9.5.7 Test completion . .63

9.5.8 Test results and deliverables .64

10 Field installation and commissioning .64

10.1 General .64

10.2 Installation considerations .64

10.3 Installation and site integration .65

10.3.1 General.65

10.3.2 Installation requirements .66

10.3.3 Electrical connections and power requirements .66

10.3.4 Function test .66

10.3.5 Fluid calculation checks .66

10.4 Commissioning .66

10.4.1 General.66

10.4.2 Preparation .67

10.4.3 Documentation and equipment .67

10.4.4 On site authorization .67

10.4.5 Commissioning activities .67

10.5 Start-up .68

11 V erification during operation .68

11.1 General .68

11.2 Baseline monitoring .69

11.3 Self-checking, self-diagnostic capabilities and internal redundancy .70

iv © ISO 2020 – All rights reserved

11.4 Comparison with model-based multiphase flow calculations .70

11.5 Two meters in series .70

11.6 Mobile test units .71

11.7 Tracer technology .71

11.8 Injection .72

11.9 Sampling .72

11.9.1 General.72

11.9.2 Sampling for information about WLR .72

11.10 Imbalances and reconciliation factor .72

11.11 Geo-chemical fingerprinting .74

11.12 Subsea systems verification .74

Annex A (informative) Multiphase meter technologies .75

Annex B (informative) Fluid properties and hydrocarbon behaviour .87

Annex C (informative) Example of field test reference measurements .92

Bibliography .96

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www .iso .org/ directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www .iso .org/ patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to the

World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see www .iso .org/

iso/ foreword .html.

This document was prepared by Technical Committee ISO/TC 28, Petroleum and related products, fuels

and lubricants from natural or synthetic sources, Subcommittee SC 2, Measurement of petroleum and

related products.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www .iso .org/ members .html.

vi © ISO 2020 – All rights reserved

Introduction

The need for multiphase flow measurement in the oil and gas production industry has been evident for

many years. Multiphase meters have been developed since the early eighties by research organizations,

meter manufacturers, oil and gas production companies and others: different technologies and various

combinations of technologies have been employed. Some technologies have been abandoned, whereas

other meters have become commercially available: the number of applications and users is increasing.

The first Norwegian Society for Oil and Gas Measurement (NFOGM) handbook of multiphase metering

(hereafter simply called the Handbook) was published in 1995 (see Reference [16]). Since then,

multiphase flow measurement has matured. New applications of multiphase flow meters (MPFMs)

have emerged, from simply being a replacement for the conventional test separator shared by a number

of wells, towards more compact and low-cost meters with application on a one-per-well basis and

installations on shore, topside and subsea.

Since multiphase flow metering technologies and applications had developed significantly since 1995,

NFOGM updated the Handbook in 2003-5 to reflect these improvements and to make it the main

guide for state-of-the-art multiphase flow measurement. That work was financed by NFOGM and The

Norwegian Society of Chartered Technical and Scientific Professionals (Tekna).

Following calls from industry to produce an ISO document, NFOGM very generously allowed ISO to use

the Handbook as the basis for this document.

This document is intended to serve as guidance for users, designers and manufacturers of multiphase

metering systems.

The document can also serve as an introduction to newcomers in the field of multiphase flow

measurement, with definition of terms and a description of multiphase flow in closed conduits being

included.

Even if the individual flow rates of each constituent are of primary interest, often their ratios (e.g. water

liquid ratio, gas oil ratio) are useful as operational parameters. Total hydrocarbon mass flow rate can

be required in particular applications. Constituents other than oil, gas and water flow rates or ratios of

these are not dealt with in this document.

The performance of a multiphase flow meter in terms of uncertainty, repeatability and range is of great

importance, as this enables the user to compare different meters and evaluate their suitability for use

in specific applications. Clause 8 covers this issue in detail and proposes standard methods to describe

performance.

Testing and qualification of MPFMs are required to verify performance. Guidance is provided to help

optimize the outcome of such activities. Since MPFMs measure at line conditions, the primary output is

individual flow rates and fractions at actual conditions (i.e. at the operating pressure and temperature).

Conversion of these actual flow rates to flow rates at standard conditions requires knowledge of

composition and mass transfer between the liquid and the gas phases, which can require sampling.

The clauses logically proceed from an introduction to multiphase flow measurement, via selection

of technology, design considerations and performance specifications, to field installation and

commissioning, and finally the operation of MPFMs.

The definitions in Clause 3 have been extended and split into definitions relating to multiphase flows in

a closed conduit (see 3.1) and definitions relating to metrology that can be useful in characterizing the

performance of a multiphase flow meter.

Clause 5 provides a general introduction to multiphase flows. This clause includes extended descriptions

of flow regimes and slip effects in multiphase flows.

Clause 6 covers the aims of multiphase flow measurement, giving the reasoning for selection,

installation and operation of multiphase flow metering systems in various applications.

Clause 7 presents guidelines for designing MPFM installations using the two-phase flow map and the

composition map.

Standardized performance specification of MPFMs is essential, both for comparison of measuring

ranges and measurement uncertainties, but also for more efficient selection of technology (Clause 8).

Clause 9 covers all aspects of testing, calibration and adjustment of MPFMs.

Clause 10 provides recommended procedures and practices for field installation and commissioning

of MPFMs. Although MPFMs cannot easily be sent to a test facility for recalibration, there is a need for

regular testing to verify the meter performance.

The purpose of Clause 11 is to provide guidelines on how to verify meter performance in the field during

operation, assuming no test separator is readily available.

Annex A includes brief descriptions of the most commonly used measurement principles in MPFMs

currently available on the market. Guidance on selection of technology and maintenance requirements

is also provided. Annex B gives relevant information on hydrocarbon phase behaviour.

Aspects of safety are not dealt with in this document. It is the responsibility of the user to ensure that

the system meets applicable safety regulations.

viii © ISO 2020 – All rights reserved

TECHNICAL SPECIFICATION ISO/TS 21354:2020(E)

Measurement of multiphase fluid flow

1 Scope

This document establishes a common basis for, and assistance in, the classification of applications

and multiphase meters, as well as guidance and recommendations for the implementation and use of

such meters.

The so-called in-line multiphase flow meters (MPFMs) that directly measure the oil, water and gas

flow rates, as well as the partial- and full-separation MPFMs are the main focus of this document.

Conventional two- or three-phase separators are not included in this document. Only limited reference

is made to wet-gas meters, since although wet-gas flow is a subset of multiphase flow, wet-gas

measurement is covered by ISO/TR 11583 and ISO/TR 12748.

2 Normative references

There are no normative references in this document.

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at http:// www .electropedia .org/

3.1 Terms related to multiphase flow metering

3.1.1

actual conditions

meter in-situ process operating conditions of pressure and temperature, at which measured flow rates

are reported, without conversion to a standard or reference fluid state

3.1.2

composition map

graph with gas volume fraction (3.1.9) and water liquid ratio (3.1.42) along the x- and y-axis, respectively

Note 1 to entry: Both the GVF and WLR are at actual conditions (3.1.1).

3.1.3

dispersed flow

flow where a particular phase (3.1.23) is broken up into multiple small bubbles or droplets carried

within the body of another phase

Note 1 to entry: Examples of such flows are bubble flow and mist flow.

3.1.4

emulsion

colloidal mixture of two immiscible fluids, one being dispersed in the other in the form of fine droplets

Note 1 to entry: In multiphase fluids, discrimination should be made between oil-in-water emulsion and water-

in-oil (3.1.21) emulsion; they respond differently to permittivity measurements.

3.1.5

flow regime

dynamic spatial and velocity distribution of flowing fluid phases (3.1.23) within a conduit

Note 1 to entry: This is also known as flow pattern.

Note 2 to entry: For example, in two-phase oil/water stratified flow in horizontal pipes free water occupies the

bottom of the conduit with oil (3.1.21) or oil/water mixture flowing above.

3.1.6

gas

hydrocarbons in the gaseous state at the prevailing temperature and pressure

3.1.7

gas oil ratio

GOR

ratio of gas (3.1.6) volume flow rate (3.1.38) and oil (3.1.21) volume flow rate

Note 1 to entry: Both volume flow rates should be converted to the same pressure and temperature [generally at

3 3

standard conditions (3.1.35)]. GOR is expressed in volume per volume, F , e.g. scft/bbl or m /m .

GOR

3.1.8

gas void fraction

ratio of the cross-sectional area in a conduit occupied by the gas (3.1.6) phase (3.1.23) and the cross-

sectional area of the conduit

Note 1 to entry: This is also known as gas hold-up.

3.1.9

gas volume fraction

GVF

gas (3.1.6) volume flow rate (3.1.38), relative to the multiphase volume flow rate, at actual conditions (3.1.1)

Note 1 to entry: The GVF is normally expressed as a fraction or percentage.

3.1.10

homogeneous multiphase flow

multiphase flow in which all phases (3.1.23) are evenly distributed over the cross section of a closed

conduit

Note 1 to entry: A homogeneous multiphase flow is, therefore, one in which the composition is the same at all

points in the cross section and where the liquid and gas (3.1.6) velocities are the same (no-slip). Note that bubbly

multiphase flow regimes (3.1.5) are probably the best approximation to homogeneous multiphase flow.

3.1.11

intermittent flow

flow characterized by being non-continuous in the axial direction, that is, exhibiting unsteady phase

(3.1.23) hold-up locally

Note 1 to entry: Examples of such flows are plug, churn and slug flow (see Figures 1 and 2): the flow regimes

(3.1.5) are all hydrodynamic (see 5.1) two-phase gas-liquid flow regimes.

3.1.12

liquid hold-up

ratio of the cross-sectional area in a conduit occupied by the liquid phase (3.1.23) and the cross-sectional

area of the conduit

2 © ISO 2020 – All rights reserved

3.1.13

liquid volume fraction

LVF

liquid volume flow rate (3.1.38), relative to the multiphase volume flow rate, at actual conditions (3.1.1)

Note 1 to entry: The LVF is normally expressed as a fraction or percentage.

3.1.14

Lockhart-Martinelli parameter

X

square root of the ratio of the liquid inertia to the gas (3.1.6) inertia if the phases (3.1.23) flowed alone

at actual conditions (3.1.1), that is

q ρ ρ

1−F

V ,liquid liquid liquid

GVF

X==

q ρ F ρ

V ,gas gas GVF gas

where

q is the volume flow rate of the liquid;

V,liquid

q is the volume flow rate of the gas;

V,gas

ρ is the density of the liquid;

liquid

ρ is the density of the gas;

gas

F is the GVF.

GVF

Note 1 to entry: The Lockhart-Martinelli parameter has a long and complicated history. There are several

different definitions for this parameter, and they are not equivalent. This includes the original definition by

Lockhart-Martinelli which is different from the definition stated above. The definition supplied in this document

is now commonly used. Nevertheless, this issue continues to cause confusion in the industry. The different

definitions are described in detail with historical context in References [30] and [13].

Note 2 to entry: In the second formula above, the relationship of the Lockhart-Martinelli number and the GVF

(3.1.9) is a function of the density ratio.

Note 3 to entry: An increasing value of X means an increasing liquid content or wetness of the flow.

3.1.15

mass flow rate

mass of fluid flowing through the cross section of a conduit in unit time

3.1.16

measuring envelope

areas in the two-phase flow map (3.1.37) and the composition map (3.1.2) in which the MPFM (3.1.18)

performs according to its specifications

3.1.17

multiphase flow

flow consisting of two or more phases (3.1.23) flowing simultaneously in a closed conduit

Note 1 to entry: This document deals in particular with multiphase flows of oil (3.1.21), water and gas (3.1.6) in

the entire region of 0 % – 100 % of the GVF (3.1.9) and 0 % – 100 % of the WLR (3.1.42).

3.1.18

multiphase flow meter

MPFM

device for measuring the individual oil (3.1.21), water and gas (3.1.6) flow rates in a multiphase flow

(3.1.17)

Note 1 to entry: The total package of measurement devices for composition and velocity, including possible

conditioning unit, should be considered as an integral part of the meter.

3.1.19

multiphase mixture velocity

ratio of the multiphase volume flow rate (3.1.20) and the cross-sectional area of the conduit

Note 1 to entry: This is a fictitious velocity: only in homogeneous multiphase flow (3.1.10) does this velocity have a

meaningful value. Multiphase mixture velocity is the sum of gas (3.1.6) superficial velocity and liquid superficial

velocity.

3.1.20

total volume flow rate

multiphase volume flow rate

total volume flowing through the cross-sectional area of a conduit per unit time

3.1.21

oil

hydrocarbons in the liquid state at the prevailing temperature and pressure conditions

3.1.22

oil-continuous flow

flow in which water is distributed as droplets surrounded by oil (3.1.21)

Note 1 to entry: Electrically, the mixture acts as an insulator.

3.1.23

phase

one constituent in a mixture of several

Note 1 to entry: In particular, the term refers to oil (3.1.21), gas (3.1.6) or water in a mixture of any number of the

three. It is recognized that the terminology of the multiphase industry is different from that in much of science.

3.1.24

phase area fraction

cross-sectional area locally occupied by one of the phases (3.1.23) of a multiphase flow (3.1.17), relative

to the cross-sectional area of the conduit at the same local position

3.1.25

phase flow rate

amount of one phase (3.1.23) of a multiphase flow (3.1.17) flowing through the cross section of a conduit

in unit time

Note 1 to entry: The phase flow rate may be specified as phase volume flow rate (3.1.38) or as phase mass flow

rate (3.1.15).

3.1.26

phase volume fraction

phase (3.1.23) volume flow rate (3.1.38) of one of the phases of a multiphase flow (3.1.17), relative to the

multiphase volume flow rate (3.1.20), at actual conditions (3.1.1)

3.1.27

production envelope

areas in the two-phase flow map (3.1.37) and the composition map (3.1.2) that are determined by a

number of well trajectories or specified as possible flow rates and compositions that occur in a certain

application

4 © ISO 2020 – All rights reserved

3.1.28

proving

set of operations that establish, under specified conditions, the relationship between the values of

quantities indicated by a device and the corresponding values as determined by a traceable reference

device (proving system)

3.1.29

reconciliation

process whereby pieces of information that include some redundancy are matched together to satisfy

constraint formulae

Note 1 to entry: In oil (3.1.21) and gas (3.1.6) production, reconciliation is the process in which oil, water and

gas (3.1.6) production figures that have not been measured with high accuracy (3.2.1) are recalculated to match

production figures that have been measured with high accuracy (e.g. custody transfer measurements).

3.1.30

reference conditions

conditions, in terms of pressure and temperature, at which fluid properties or volume flow rates (3.1.38)

are expressed

3.1.31

salinity

amount of dissolved salts that are present in water

Note 1 to entry: Salinity is normally expressed in units g/kg.

Note 2 to entry: Sodium and chloride are the predominant ions in seawater, and the concentrations of magnesium,

calcium, and sulfate ions are also substantial.

3.1.32

slip

flow condition that exists when the phases (3.1.23) have different average velocities

Note 1 to entry: The slip may be quantitatively expressed by the average phase velocity difference between the

phases. See 5.3.

3.1.33

slip ratio

ratio between two phase-average velocities

Note 1 to entry: See 5.3.

3.1.34

slip velocity

phase (3.1.23) velocity difference between two phases

Note 1 to entry: See 5.3.

3.1.35

standard conditions

conditions, in terms of pressure and temperature, at which fluid properties or volume flow rates (3.1.38)

are expressed

EXAMPLE 101,325 kPa and 15 °C.

3.1.36

superficial phase velocity

quotient of the phase (3.1.23) volume flow rate (3.1.38) and the pipe cross-sectional area

3.1.37

two-phase flow map

graph with superficial velocities of gas (3.1.6) and liquid along the x- and y-axes, respectively

Note 1 to entry: An example is the Mandhane flow map (see Reference [37]) for horizontal multiphase flow

(3.1.17).

Note 2 to entry: Alternatively, the actual gas (3.1.6) and actual liquid volume flow rates (3.1.38) can be used.

3.1.38

volume flow rate

volume of fluid flowing through the cross section of a conduit in unit time

3.1.39

water-continuous flow

flow in which oil (3.1.21) is distributed as droplets surrounded by water

Note 1 to entry: Electrically, the mixture acts as a conductor.

3.1.40

water cut

WC

water volume flow rate (3.1.38), relative to the total liquid volume flow rate [oil (3.1.21) and water],

both converted to volumes at standard pressure and temperature

Note 1 to entry: The WC is normally expressed as a percentage.

3.1.41

water fraction meter

WFM

device for measuring the phase (3.1.23) area fraction of water of a multiphase flow (3.1.17) through a

cross section of a conduit

Note 1 to entry: The phase area fraction (3.1.24) is expressed as a percentage of the total pipe area.

3.1.42

water liquid ratio

WLR

water volume flow rate (3.1.38), relative to the total liquid volume flow rate [oil (3.1.21) and water], at

actual conditions (3.1.1)

3.1.43

water volume fraction

WVF

water volume flow rate (3.1.38), relative to the multiphase volume flow rate, at actual conditions (3.1.1)

Note 1 to entry: The WVF is normally expressed as a fraction or percentage.

Note 2 to entry: A small absolute error (3.2.4) in the value of the WVF may be a large relative error, e.g. where

the measured and reference values of the WVF are 1 % and 0,5 % respectively, the absolute error is only 0,5 %,

but the relative error is 100 %; in this example the measured water volume flow rate is twice the reference value

although the absolute error is only 0,5 %.

Note 3 to entry: F F × F = F × (1 − F )

WVF = WLR LVF WLR GVF

Note 4 to entry: where

F is the WVF;

WVF

F is the LVF;

LVF

F is the WLR.

WLR

6 © ISO 2020 – All rights reserved

3.1.44

well trajectory

production profile of a well over time in a two-phase flow map (3.1.37) and composition map (3.1.2)

3.1.45

wet gas

gas (3.1.6) containing free liquids

Note 1 to entry: Generally wet gases are defined as gas/liquid systems with a Lockhart-Martinelli parameter

(3.1.14) lower than approximately 0,3.

Note 2 to entry: Hydrocarbon gas that contains heavy components that condense during further processing

(but at a particular pressure and temperature, behaving as a pure gas) is not considered to be a wet gas from a

measurement point of view.

3.2 Terms related to metrology

3.2.1

accuracy

closeness of agreement between a measured quantity v

...

Frequently Asked Questions

ISO/TS 21354:2020 is a technical specification published by the International Organization for Standardization (ISO). Its full title is "Measurement of multiphase fluid flow". This standard covers: This document establishes a common basis for, and assistance in, the classification of applications and multiphase meters, as well as guidance and recommendations for the implementation and use of such meters. The so-called in-line multiphase flow meters (MPFMs) that directly measure the oil, water and gas flow rates, as well as the partial- and full-separation MPFMs are the main focus of this document. Conventional two- or three-phase separators are not included in this document. Only limited reference is made to wet-gas meters, since although wet-gas flow is a subset of multiphase flow, wet-gas measurement is covered by ISO/TR 11583 and ISO/TR 12748.

This document establishes a common basis for, and assistance in, the classification of applications and multiphase meters, as well as guidance and recommendations for the implementation and use of such meters. The so-called in-line multiphase flow meters (MPFMs) that directly measure the oil, water and gas flow rates, as well as the partial- and full-separation MPFMs are the main focus of this document. Conventional two- or three-phase separators are not included in this document. Only limited reference is made to wet-gas meters, since although wet-gas flow is a subset of multiphase flow, wet-gas measurement is covered by ISO/TR 11583 and ISO/TR 12748.

ISO/TS 21354:2020 is classified under the following ICS (International Classification for Standards) categories: 75.180.30 - Volumetric equipment and measurements. The ICS classification helps identify the subject area and facilitates finding related standards.

You can purchase ISO/TS 21354:2020 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...