ISO 10364:2007

(Main)Structural adhesives — Determination of the pot life (working life) of multi-component adhesives

Structural adhesives — Determination of the pot life (working life) of multi-component adhesives

ISO 10364:2007 specifies methods for determining the pot life of multi-component adhesives in order to be able to determine whether the pot life conforms to the minimum specified working life required of an adhesive. The test methods described are suitable for assessing all multi-component adhesives, and especially epoxy-based and polyurethane-based adhesives, but they are not suitable for some acrylic-based adhesives. The methods can also be used for assessing non-structural adhesives.

Adhésifs structuraux — Détermination de la durée de vie en pot (délai d'utilisation) d'adhésifs multicomposants

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 10364

Second edition

2007-09-01

Structural adhesives — Determination of

the pot life (working life) of multi-

component adhesives

Adhésifs structuraux — Détermination de la durée de vie en pot (délai

d'utilisation) d'adhésifs multicomposants

Reference number

ISO 10364:2007(E)

©

ISO 2007

---------------------- Page: 1 ----------------------

ISO 10364:2007(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2007

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2007 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 10364:2007(E)

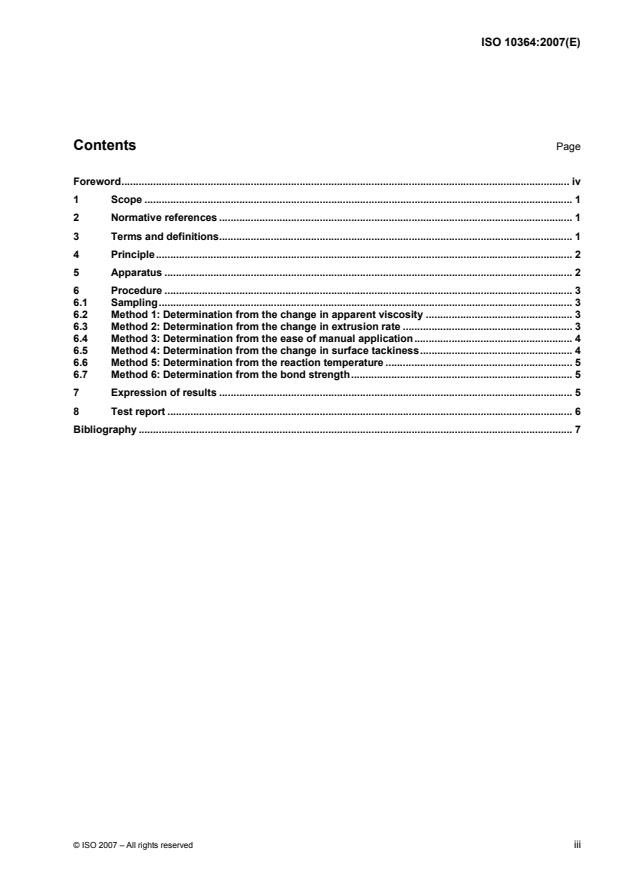

Contents Page

Foreword. iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions. 1

4 Principle. 2

5 Apparatus . 2

6 Procedure . 3

6.1 Sampling. 3

6.2 Method 1: Determination from the change in apparent viscosity . 3

6.3 Method 2: Determination from the change in extrusion rate . 3

6.4 Method 3: Determination from the ease of manual application. 4

6.5 Method 4: Determination from the change in surface tackiness. 4

6.6 Method 5: Determination from the reaction temperature . 5

6.7 Method 6: Determination from the bond strength. 5

7 Expression of results . 5

8 Test report . 6

Bibliography . 7

© ISO 2007 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 10364:2007(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO 10364 was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 11, Products.

This second edition cancels and replaces the first edition (ISO 10364:1993), which has been technically

revised. The revision is based on EN 14022, prepared by the European Committee for Standardization (CEN),

Technical Committee CEN/TC 193, Adhesives.

iv © ISO 2007 – All rights reserved

---------------------- Page: 4 ----------------------

INTERNATIONAL STANDARD ISO 10364:2007(E)

Structural adhesives — Determination of the pot life (working

life) of multi-component adhesives

SAFETY STATEMENT — Persons using this document should be familiar with normal laboratory

practice, if applicable. This document does not purport to address all of the safety concerns, if any,

associated with its use. It is the responsibility of the user to establish appropriate safety and health

practices and to ensure compliance with any regulatory requirements.

1 Scope

This International Standard specifies methods for determining the pot life of multi-component adhesives in

order to be able to determine whether the pot life conforms to the minimum specified working life required of

an adhesive.

NOTE 1 For the purposes of simplification, the term “pot life” is deemed to have the same meaning as “working life”

and will be used to represent both throughout this International Standard.

The test methods described are suitable for assessing all multi-component adhesives, and especially

epoxy-based and polyurethane-based adhesives, but they are not suitable for some acrylic-based adhesives.

NOTE 2 This International Standard can also be used for assessing non-structural adhesives.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

ISO 472, Plastics — Vocabulary

ISO 2555, Plastics — Resins in the liquid state or as emulsions or dispersions — Determination of apparent

viscosity by the Brookfield Test method

ISO 3219, Plastics — Polymers/resins in the liquid state or as emulsions or dispersions — Determination of

viscosity using a rotational viscometer with defined shear rate

ISO 15605, Adhesives — Sampling

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472 and the following apply.

3.1

pot life

working life

period of time during which a multi-component adhesive can be used after its component parts have been

mixed

© ISO 2007 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO 10364:2007(E)

4 Principle

This International Standard specifies six methods for the determination of the pot life of multi-component

adhesives.

In method 1, the pot life is determined from the increase in viscosity of the adhesive as it reacts. This method

is not suitable for the determination of pot lives that are shorter than 5 min.

In method 2, the pot life is determined from the decrease in the mass of mixed adhesive which is extruded in

unit time under standard conditions. This method is not suitable for the determination of pot lives that are

shorter than 5 min.

In method 3, the pot life is determined as the time taken to reach a point when the mixed adhesive can no

longer be spread by hand.

In method 4, the pot life is determined as the time taken to reach a point when the surface of the mixed

adhesive is no longer tacky, i.e. it is dry to the touch.

In method 5, the pot life is determined as the time taken by the mixed adhesive to reach a defined

temperature, the so-called critical temperature. This method is applicable to all multi-component systems.

In method 6, the pot life is determined as the time taken for the bond strength of the adhesive to drop to a

predetermined value or to decrease by a predetermined percentage. This method is not suitable for the

determination of pot lives that are shorter than 5 min.

5 Apparatus

5.1 Balance, capable of weighing up to (500 ± 0,2) g for methods 1, 2, 5 and 6 and up to (100 ± 0,2) g for

methods 3, 4 and 5.

5.2 Beaker, squat form, made of a material which does not react with the adhesive under test, with a wall

thickness which does not exceed 1 mm and with a capacity of 400 ml for methods 1 and 6, 250 ml for

method 3, 50 ml for methods 4 and 5 and 200 ml for method 5.

5.3 Spatula, made of a material which does not react with the adhesive under test and with a square, not

rounded, end.

5.4 Rotational viscometer, as specified in ISO 2555 or ISO 3219.

5.5 Water bath, capable of being maintained at constant temperature to within ± 0,1 °C for methods 2, 3

and 4 and within ± 0,2 °C for method 5 throughout the temperature range 15 °C to 30 °C.

5.6 Stopwatch, accurate to within ± 1 s.

5.7 Test enclosure, capable of being maintained at the test temperature and, if necessary, at a relative

humidity of (50 ± 5) %.

5.8 Disposable plastic cartridges, internal diameter 47 mm, length 210 mm and fitted with a threaded end

fitting and a piston, both cartridge and piston being made of a material which does not react with the adhesive

under test.

5.9 Stirrer, with a rigid, helical stirrer blade made of a material which does not react with the adhesive

under test.

5.10 Stirrer motor, electrically or pneumatically powered, whose speed can be regulated between 0 rpm

and 1 000 rpm.

2 © ISO 2007 – All rights reserved

---------------------- Page: 6 ----------------------

ISO 10364:2007(E)

5.11 Extrusion nozzle, made of material which does not react with the adhesive under test, capable of

being screwed onto the end fitting of the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.