ISO/TS 5660-3:2012

(Main)Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 3: Guidance on measurement

Reaction-to-fire tests — Heat release, smoke production and mass loss rate — Part 3: Guidance on measurement

ISO/TS 5660-3:2012 examines the measurement limitations and applications of the cone calorimeter data as currently used for building products, and recommends ways in which some of these may be overcome for other types of products for other application areas. It compiles information from a large body of experience with regard to the use of the instrument. This information is presented as a set of guidelines, which will help to standardize the use of the cone calorimeter in this wider scope. Particular guidance is given on aspects of specimen preparation and on the behaviour, such as melting, spalling and intumescing, of specimens exposed to radiant heat. The relevance of specimen thickness and the use of substrate, and methods of fixing to substrate, are also discussed. Advice is given on approaches to testing a variety of "non-standard" products. Recommendations are made on techniques of calibration of the apparatus, selection of appropriate heat flux levels and ignition protocols.

Essais de réaction au feu — Débit calorifique, taux de dégagement de fumée et taux de perte de masse — Partie 3: Lignes directrices relatives au mesurage

General Information

Relations

Standards Content (Sample)

TECHNICAL ISO/TS

SPECIFICATION 5660-3

First edition

2012-12-01

Reaction-to-fire tests — Heat release,

smoke production and mass loss rate —

Part 3:

Guidance on measurement

Essais de réaction au feu — Débit calorifique, taux de dégagement de

fumée et taux de perte de masse —

Partie 3: Lignes directrices relatives au mesurage

Reference number

©

ISO 2012

© ISO 2012

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any

means, electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the

address below or ISO’s member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2012 – All rights reserved

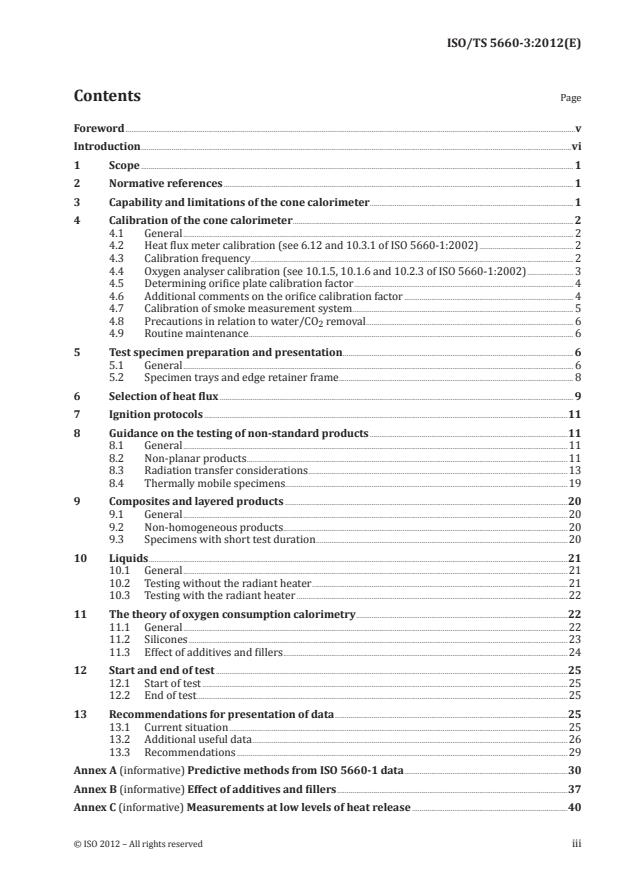

Contents Page

Foreword .v

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 Capability and limitations of the cone calorimeter . 1

4 Calibration of the cone calorimeter . 2

4.1 General . 2

4.2 Heat flux meter calibration (see 6.12 and 10.3.1 of ISO 5660-1:2002) . 2

4.3 Calibration frequency . 2

4.4 Oxygen analyser calibration (see 10.1.5, 10.1.6 and 10.2.3 of ISO 5660-1:2002) . 3

4.5 Determining orifice plate calibration factor . 4

4.6 Additional comments on the orifice calibration factor . 4

4.7 Calibration of smoke measurement system . 5

4.8 Precautions in relation to water/CO removal . 6

4.9 Routine maintenance . 6

5 Test specimen preparation and presentation .6

5.1 General . 6

5.2 Specimen trays and edge retainer frame . 8

6 Selection of heat flux .9

7 Ignition protocols .11

8 Guidance on the testing of non-standard products .11

8.1 General .11

8.2 Non-planar products .11

8.3 Radiation transfer considerations .13

8.4 Thermally mobile specimens.19

9 Composites and layered products .20

9.1 General .20

9.2 Non-homogeneous products.20

9.3 Specimens with short test duration .20

10 Liquids .21

10.1 General .21

10.2 Testing without the radiant heater .21

10.3 Testing with the radiant heater .22

11 The theory of oxygen consumption calorimetry .22

11.1 General .22

11.2 Silicones .23

11.3 Effect of additives and fillers .24

12 Start and end of test .25

12.1 Start of test .25

12.2 End of test .25

13 Recommendations for presentation of data .25

13.1 Current situation .25

13.2 Additional useful data .26

13.3 Recommendations .29

Annex A (informative) Predictive methods from ISO 5660-1 data .30

Annex B (informative) Effect of additives and fillers .37

Annex C (informative) Measurements at low levels of heat release .40

Bibliography .42

iv © ISO 2012 – All rights reserved

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International

Standards adopted by the technical committees are circulated to the member bodies for voting.

Publication as an International Standard requires approval by at least 75 % of the member bodies

casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical

experts in an ISO working group and is accepted for publication if it is approved by more than 50 %

of the members of the parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a

technical committee and is accepted for publication if it is approved by 2/3 of the members of the

committee casting a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for

a further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or

ISO/TS is confirmed, it is reviewed again after a further three years, at which time it must either be

transformed into an International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TS 5660-3 was prepared by Technical Committee ISO/TC 92, Fire safety, Subcommittee SC 1, Fire

initiation and growth.

This first edition of ISO/TS 5660-3 cancels and replaces ISO/TR 5660-3:2003.

ISO 5660 consists of the following parts, under the general title Reaction to fire tests — Heat release,

smoke production and mass loss rate:

— Part 1: Heat release rate (cone calorimeter method)

— Part 2: Smoke production rate (dynamic measurement)

— Part 3: Guidance on measurement [Technical Specification]

Introduction

The first edition of ISO 5660-1, which describes a test method for rate of heat release from building

products by means of a cone calorimeter, was published in 1993, following approximately 10 years of

development within ISO/TC 92, Fire safety, Subcommittee SC 1, Fire initiation and growth.

The cone calorimeter is a fire test instrument in which horizontal specimens are exposed to controlled

levels of radiant heating by means of a truncated cone-shaped heater. Continuous spark ignition is

provided and the time to ignition is recorded for specimens which ignite. The rate of heat release from

the burning specimen is determined from measurements of the amount of oxygen consumed from the

air flowing through the apparatus, which has been demonstrated to equate to heat release. The mass of

the specimen is also measured throughout the burning period. The specimens are usually tested under

well ventilated conditions.

Results are expressed in terms of peak and average rates of heat release, as well as total heat released

and the effective net heat of combustion. ISO 5660-1:2002 limits the specimen type to essentially flat.

Several other groups are now utilizing the cone calorimeter, and a number of new parameters in addition

to those defined in ISO 5660-1:2002 and ISO 5660-2:2002 have been defined and used. Some of these,

including smoke measurement, require that measurements be made from the beginning of the test rather

than at the onset of ignition, which is commonly used as the starting point for heat release measurement.

The cone calorimeter is also designed to allow measurement of smok

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.