ISO/PAS 30005:2010

(Main)Ships and marine technology — Ship recycling management systems — Information control for hazardous materials in the manufacturing chain of shipbuilding and ship operations

Ships and marine technology — Ship recycling management systems — Information control for hazardous materials in the manufacturing chain of shipbuilding and ship operations

ISO/PAS 30005:2010 provides guidance for the management, communication, and maintenance of information in an effective, standardized, and compatible manner in accordance with the requirements of the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships.

Navires·et·technologie·maritime·—·Systèmes·de·management·du·recyclage·des·navires·—·Contrôle·des·informations·sur·les·matières·dangereuses·intervenant·dans·la·chaîne·de·construction·du·navire·et·durant·le·service·du·navire

General Information

Relations

Standards Content (Sample)

PUBLICLY ISO/PAS

AVAILABLE 30005

SPECIFICATION

First edition

2010-09-01

Ships and marine technology — Ship

recycling management systems —

Information control for hazardous

materials in the manufacturing chain of

shipbuilding and ship operations

Navires et technologie maritime — Systèmes de management du

recyclage des navires — Contrôle des informations sur les matières

dangereuses intervenant dans la chaîne de construction du navire et

durant le service du navire

Reference number

ISO/PAS 30005:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO/PAS 30005:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/PAS 30005:2010(E)

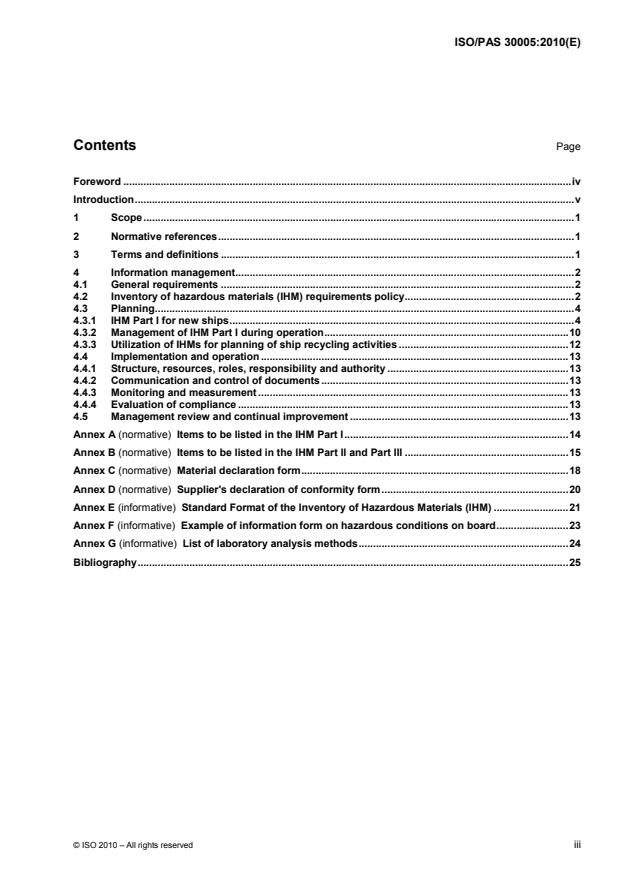

Contents Page

Foreword .iv

Introduction.v

1 Scope.1

2 Normative references.1

3 Terms and definitions .1

4 Information management.2

4.1 General requirements .2

4.2 Inventory of hazardous materials (IHM) requirements policy.2

4.3 Planning.4

4.3.1 IHM Part I for new ships.4

4.3.2 Management of IHM Part I during operation.10

4.3.3 Utilization of IHMs for planning of ship recycling activities .12

4.4 Implementation and operation .13

4.4.1 Structure, resources, roles, responsibility and authority .13

4.4.2 Communication and control of documents.13

4.4.3 Monitoring and measurement .13

4.4.4 Evaluation of compliance .13

4.5 Management review and continual improvement .13

Annex A (normative) Items to be listed in the IHM Part I.14

Annex B (normative) Items to be listed in the IHM Part II and Part III .15

Annex C (normative) Material declaration form.18

Annex D (normative) Supplier's declaration of conformity form.20

Annex E (informative) Standard Format of the Inventory of Hazardous Materials (IHM) .21

Annex F (informative) Example of information form on hazardous conditions on board.23

Annex G (informative) List of laboratory analysis methods.24

Bibliography.25

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/PAS 30005:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

⎯ an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

⎯ an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/PAS 30005 was prepared by Technical Committee ISO/TC 8, Ships and marine technology.

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

ISO/PAS 30005:2010(E)

Introduction

This Publicly Available Specification has been developed in response to demand from industry for a ship

recycling standard.

This Publicly Available Specification is based on the methodology known as Plan-Do-Check-Act (PDCA).

PDCA can be described as follows.

⎯ Plan: establish the objectives and processes necessary to deliver results in accordance with the

organization's ship recycling policy.

⎯ Do: implement the processes.

⎯ Check: monitor and measure processes against recycling policy, objectives, targets, legal and other

requirements, and report results.

⎯ Act: take actions to continually improve performance of the recycling management system.

© ISO 2010 – All rights reserved v

---------------------- Page: 5 ----------------------

PUBLICLY AVAILABLE SPECIFICATION ISO/PAS 30005:2010(E)

Ships and marine technology — Ship recycling management

systems — Information control for hazardous materials in the

manufacturing chain of shipbuilding and ship operations

1 Scope

This Publicly Available Specification provides guidance for the management, communication, and

maintenance of information in an effective, standardized, and compatible manner in accordance with the

requirements of the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of

Ships.

2 Normative references

The following referenced documents are indispensable for the application of this document. For dated

references, only the edition cited applies. For undated references, the latest edition of the referenced

document (including any amendments) applies.

MEPC.179(59), Guidelines for the development of the inventory of hazardous materials

SR/CONF/45, Hong Kong International Convention for the Safe and Environmentally Sound Recycling of

Ships, 2009

ISO/IEC 17025, General requirements for the competence of testing and calibration laboratories

3 Terms and definitions

For the purposes of this document, the terms and definitions given in SR/CONF/45, MEPC.179(59), and the

following apply.

3.1

upstream supplier

supplier which provides goods to a downstream supplier

3.2

downstream supplier

supplier which manufactures finished components, products or materials of any kind providing them to a

customer for its final use or application

3.3

existing ship

not a new ship

© ISO 2010 – All rights reserved 1

---------------------- Page: 6 ----------------------

ISO/PAS 30005:2010(E)

3.4

new ship

ship for which

a) the building contract is placed on or after the date on which the Hong Kong Convention enters into force,

or

b) in the absence of a building contract, the keel is laid, or which is at a similar stage of construction, six

months or more after the date on which the Hong Kong Convention enters into force, or

c) the delivery is 30 months or more after the date on which the Hong Kong Convention enters into force

3.5

new installation

installation of systems, equipment, insulation, or other material on a ship after the date on which the Hong

Kong Convention enters into force

3.6

hazardous material

HazMat

material or substance which is liable to create hazards to human health and/or the environment

4 Information management

4.1 General requirements

Information of hazardous material (HazMat) present on board ships is collected and managed in the form of

an inventory of hazardous materials (IHM). Although the information gathering process differs between new

and existing ships, in order to control the use of hazardous materials the person responsible shall

a) ensure that prohibitions and/or restrictions for the installation or use of hazardous materials listed in

Appendix 1 of the Hong Kong Convention, SR/CONF/45, on board ships are considered, and

b) prohibit and/or restrict the installation or use of such materials on ships, whilst in ports, newbuilding

shipyards, ship repair yards, or offshore terminals, and

c) take effective measures to ensure that ships comply with those requirements.

The control of hazardous materials information for ships shall be done by continuous maintenance and

periodical checks of IHM. Each ship shall have on board a verified/certified IHM.

4.2 Inventory of hazardous materials (IHM) requirements policy

The IHM shall consist of three different parts, namely Part I, Part II and Part III (see Annexes A and B) and be

specific to each ship.

a) Part I lists materials contained in ship structure or equipment. Materials which include hazardous

materials listed in Tables A.1 and A.2 are listed in Part I. Once prepared and certified, it shall be

maintained during the whole life cycle of a ship.

b) Part II lists operationally generated wastes. Items listed in Table B.1 correspond to Parts II and III of the

IHM. It shall be developed prior to or at the latest at final voyage, when a ship is destined to be recycled.

c) Part III includes potentially hazardous materials that are listed in Tables B.1 and B.2, in stores and items

excluded from IHM Part I falling under the exclusions of Table B.2. It shall be developed prior to or at the

latest at final voyage, when a ship is destined to be recycled.

2 © ISO 2010 – All rights reserved

---------------------- Page: 7 ----------------------

ISO/PAS 30005:2010(E)

The related hazardous materials that can be found on board, including their location and quantity, are grouped

in Tables A.1 and A.2, and Tables B.1 and B.2.

1) Table A.1 materials contained in ship parts, equipment and systems shall be listed in the IHM Part I

for new and existing ships (see Annex A).

2) Table A.2 materials contained in ship parts, equipment and systems shall be listed in the IHM Part I

for new ships and new installations. For existing ships, listing of these materials is voluntary

(see Annex A).

3) Table B.1 (potentially hazardous items) includes items which are potentially hazardous to the

environment and/or human health and shall be listed in IHM Parts II and III during preparations for

recycling (see Annex B).

4) Table B.2 (regular consumable goods potentially containing hazardous materials) comprises goods

which are not specifically designed for shipboard applications and can also be widely found in normal

household applications. Those items shall be listed in IHM Part III during preparations for recycling

(see Annex B).

Table 1 — The Inventory — Categorization and applicability

Shipbuilding

Preparation prior to recycling

and operating

b ab

Scope of the IHM

Part I Part II

ab

Part III

Structure and Operative

Stores

equipment wastes

c

Table A.1 materials

X

Mandatory for new ships and new installations, and existing ships

c

Table A.2 materials

X

Mandatory for new ships and new installations; voluntary for existing

ships

bc

Table B.1

X X

Potentially hazardous items

c

Table B.2

List of exclusions X

Regular consumer goods potentially containing hazardous materials

a

Applicable only directly prior to recycling/last voyage.

b

Operational relevant goods like lubricating oil, anti-seize compounds or grease, which are applied to keep normal performance of

gear, equipment, and machinery present in small amounts do not fall under the scope of IHM Part I.

c

Tables A.1, A.2, B.1 and B.2 correspond to Tables A, B, C and D in MEPC.179(59) and are reproduced here with permission.

The preparation of IHMs for new and existing ships differs.

For existing ships

a) IHM Part I shall be prepared under the responsibility of the shipowner at an early stage and at the latest

directly prior to recycling of the respective vessel,

b) Table A.1 materials shall be listed in the IHM Part I for existing ships,

c) listing of Table A.2 materials is voluntary but should be listed as far as practicable, and

d) listing of Table A.2 materials is obligatory for any installation after the initial preparation of the inventory.

© ISO 2010 – All rights reserved 3

---------------------- Page: 8 ----------------------

ISO/PAS 30005:2010(E)

For new ships

a) IHM Part I shall be prepared at the design and construction stage by the shipyard and be delivered

together with the ship, and

b) Tables A.1 and A.2 materials shall be listed in the IHM for new ships and new installations.

The maintenance of IHM Part I is required throughout the ship operational phase, especially during repair and

conversions, when any of the IHM information becomes obsolete or inaccurate. Parts II and III are to be

prepared prior to recycling.

4.3 Planning

4.3.1 IHM Part I for new ships

4.3.1.1 General

The shipyard is responsible for preparation of IHM. The shipowner shall include the requirement for IHM

preparation for new ships in ship building contract with the shipyard.

Part I of the inventory shall be developed at the design and construction stage by the shipyard. The shipyard

shall request information from its suppliers on their products' hazardous materials content by the material

declaration (MD) form (see Annex C) and the supplier's declaration of conformity (SDoC) form (see Annex D).

In order to provide this information to shipyards, suppliers must obtain information from their upstream

suppliers and provide the requested information to downstream suppliers or customers.

Suppliers shall make a statement in the form of the MD and SDoC for all their supplied products and declare

whether or not materials listed in Tables A.1 and A.2 are present in these products.

If the concentration of hazardous materials in a homogenous material is above threshold levels provided in

Tables A.1 and A.2, as listed in the MD, the quantity of the hazardous material used shall be listed in IHM

Part I, including information on where the homogeneous material is used in the equipment, system or

machinery.

NOTE Table B.2 is an overview of common appliances, which do not have to be considered in the MD, the SDoC, or

in the IHM Part I. As the appliances are not specific to maritime equipment and can widely be found elsewhere, it is

assumed that anybody involved in, e.g. recycling or waste treatment, is aware of the contained hazardous materials. Also

these appliances are often covered and regulated by other international regulations, e.g. Restriction of Hazardous

Materials (RoHS). This exclusion is only applicable as long as these appliances contain only typical components. Anything

not falling under this exemption (e.g. specially designed electronic items) has to be documented as required for other

materials and components. If found to provide more clarity, physical marking of such materials and components allowing

easy identification of specifically designed parts not falling under this exemption can be used.

4.3.1.2 Documentation of otherwise required information

Volumes of pipes and machinery containing hazardous materials listed in Annex B, Table B.1, shall be

documented separately to enable the shipowner to prepare Part II and/or Part III of the IHM prior to recycling.

As far as possible, all forms required for preparation of IHM should be prepared, transmitted and processed

electronically. Hardcopies should be avoided as far as possible due to the high number of documents to be

handled.

4.3.1.3 Requirements for shipyards

The shipyard shall establish, implement and maintain procedure(s) for preparation of IHM Part I, including

a) identification of its suppliers of coating systems, components, equipment and structural elements and

materials that are used during the construction of the ship,

b) requesting from these suppliers statements on whether or not the hazardous materials in Tables A.1

and A.2 are contained (MD),

4 © ISO 2010 – All rights reserved

---------------------- Page: 9 ----------------------

ISO/PAS 30005:2010(E)

c) ensuring that its suppliers provide complete and up-to-date information and, in case the threshold levels

have been reached, providing additional information on the presence of the hazardous material like

quantity (weight/volume) and location within the supplied goods (applicable for components) in the

required form (MD),

d) ensuring that measures implemented by the suppliers for assuring accurate and up-to-date MDs are

described in the SDoC and other required entries are correct,

e) ensuring that references from MDs and SDoCs are correct,

f) ensuring that the related forms are unchangeable and provided in electronic format (e.g. pdf files) from

suppliers as shown in Annex C and Annex D; entries are to be made in original electronic form, no scans,

g) ensuring that in cases where a supplier does not provide an appropriate SDoC electronically, a signed

hardcopy of the SDoC is provided and archived by the shipyard,

h) ensuring that the information on hazardous materials of Tables A.1 and A.2 is listed in the IHM when the

concentration of them in an homogenous product exceeds the related threshold levels,

i) ensuring that only properly filled in MDs and related SDoCs are accepted,

j) directly utilizing the information from suppliers and considering calculations to determine the amount of

materials used on board (e.g. for paints), and

k) ensuring effective and accurate preparation of the IHM, which will have to be certified.

NOTE Until entry into force of the Hong Kong Convention, for any missing MD or SDoC, the presence of hazardous

materials in the components and materials can also be investigated by applying the methods applicable for existing ships.

The documentation regarding the presence and/or absence of hazardous materials shall be prepared in the

form of an MD, which must be accompanied by an SDoC. Responsibility of the provided information lies with

the company which carries out the investigation and preparation of the MD and SDoC.

The structure for gaining information via relevant documents by shipyards from the suppliers and from their

supply chain (upstream suppliers) is shown in Figure 1. The advantages of a standardized approach

throughout supply chains is to ensure the reliability for the HazMat information by traceability. By using

uniform forms within supply chains, electronic data processing becomes possible [e.g. by automatic

combination of MDs prepared by upstream suppliers (sub-MDs) into Tier I MDs (main-MDs), less re-typing

and conversion of information and forms is required, and information is handled more effectively.

MD

MD

MD

SDoC

SDoC

SDoC

Shipyard-

Downstream

Upstream

MD MD MD

Newbuilding

Suppliers

SDoC SDoC SDoC

Suppliers

Repair &

Conversion

MD MD MD

SDoC SDoC SDoC

Recycling

IHM Certifier Certificate + IHM Owner

Facility

Recertification 5 years

Figure 1 — Overview of information chains

© ISO 2010 – All rights reserved 5

---------------------- Page: 10 ----------------------

ISO/PAS 30005:2010(E)

4.3.1.4 Requirements for suppliers

4.3.1.4.1 Material declaration

Suppliers shall establish, implement and maintain procedure(s) to

a) ensure that for all their products supplied to the shipping industry, a statement on presence/absence of

materials listed in Tables A.1 and A.2 is provided in the form of an MD,

b) constantly evaluate their products in a detailed way for providing accurate and up-to-date information on

the presence of hazardous materials in the form of the MD,

c) identify their supply chain and require sub-MDs as a basis for preparation of own MDs,

d) ensure that up-to-date information is supplied by their supply chain,

e) identify missing information and establish a follow-up process for gaining missing information,

f) make sure that each homogenous material is evaluated and/or analysed,

g) support a modular data management for allowing an individual combination of information required due to

product modifications,

h) clearly identify material in stock and related information from supply chains,

NOTE 1 In case of mass articles from different suppliers, evaluation of provided information and further utilization is

appropriate when the highest content of hazardous materials of Tables A.1 and A.2 is further utilized.

i) provide a unique ID-number for identification of MD,

j) ensure that the related SDoC is identified in the MD,

k) ensure that all information (see Table 2) and forms required are available, maintained and provided

electronically, and

l) ensure that the content of MD forms may not be changed or amended. Any changes or amendments by

anyone other than the author of this form constitute a breach of copyright law.

NOTE 2 As an exemption, when a shipbuilder purchases more material or products than what is installed on one ship,

the shipbuilder can fill in an “amount” column by themselves to specify what has been used for the particular ship, as the

suppliers usually don't know if the delivered material/product is used for one or more ships.

Table 2 — Information required in MD

Entry Description

Date of declaration The preparation date of the report is written here

MD ID Number Provision of a unique ID number for identification of MDs is necessary; see 4.3.1.4.3.1

Other information Remarks are noted here

Supplier (respondent) Name, address, contact person, telephone numbers and SDoC ID No. is written in this part

information

Product information Product name, product number (if available), product information, amount and unit of the

product shall be provided

Material information

2 3

Unit It has to be stated which unit (whether 1 piece or 1 kg/m/m /m ) of the mentioned product

contains the amount of hazardous materials listed in Tables A.1 and A.2

6 © ISO 2010 – All rights reserved

---------------------- Page: 11 ----------------------

ISO/PAS 30005:2010(E)

Table 2 (continued)

Entry Description

Tables A.1 and A.2

Yes/No Statement on whether the hazardous material present is above or below the threshold

level; “Yes” or “No” has to be filled in

If the entry is “Yes”, the following additional information is required

Mass: Mass of hazardous material contained

Unit: Dimension of the given mass (e.g. gram, kilogram, milligram)

Information on where it is used: where exactly the hazardous material is used and/or

additional information found to be helpful

In case the hazardous materials of concern are not contained above the related threshold

levels in Tables A.1 or A.2 a “No” entry is required

MDs shall be prepared by the suppliers even when no hazardous materials are contained above the related

threshold levels.

NOTE 3 Unintentional presence of hazardous materials in the form of trace contaminants does not fall under the scope

of MDs.

NOTE 4 Any spare parts containing materials listed in Tables A.1 and A.2 that are above the threshold levels are

required to be listed in Part III of the inventory at a later stage by the shipowner, therefore they do not need to be

accompanied by an MD or SDoC.

Volumes of pipes and machinery containing hazardous materials listed in Table B.1 shall be documented

separately to enable the shipowner to prepare Part II and/or Part III of the IHM prior to recycling.

NOTE 5 For assuring a unified and effective product data management system, any relevant information within supply

chains should be based on the same SDoC and MD forms as far as practicable. The forms are legal statements from

suppliers and in case investigations are carried out, the source of information can easily be identified. This can be legally

relevant.

NOTE 6 For downstream suppliers of complex machinery and equipment, it can be beneficial to provide separate MDs

for major functional units. This can be achieved by definition of system boundaries and preparation of separate MDs

accordingly. Customer specific MD preparation and also later maintenance of IHM during operational phase of a ship can

be eased.

NOTE 7 In case of homogeneous material containing hazardous materials above the threshold levels listed in

Table A.1 and/or Table A.2 received from the supply chain, the total amount of this material used for

manufacturing/production is to be documented in the MD. The related concentration of the hazardous material can be

provided as additional information under “Remarks”. It is not appropriate to multiply the concentration of the hazardous

material listed in the sub-MD by the total amount of material used for manufacturing/production, as this leads to the

amount of the pure hazardous material, which is not relevant.

4.3.1.4.2 Supplier's declaration of conformity (SDoC)

Suppliers shall establish, implement and maintain procedure(s) to

a) prepare an SDoC for products supplied by them,

b) provide an SDoC efficiently to requesting customers,

c) ensure that required information is provided in the SDoC (see Table 3),

d) create a unique ID number for identification of SDoC and allow referencing to it by the MD,

© ISO 2010 – All rights reserved 7

---------------------- Page: 12 ----------------------

ISO/PAS 30005:2010(E)

e) ensure that the SDoC is signed by a representative; in case of lack of legally sound signature system, the

electronic SDoC shall be “signed” by typing in the name of the representative and additionally a signed

hardcopy of the SDoC shall be made available to the customer, and

f) ensure that all information and forms required are available, maintained and provided electronically.

Table 3 — Information required in SDoC

Entry Description

SDoC ID number A unique number produced by the downstream supplier/supplier for identificat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.