ISO/PAS 30007:2010

(Main)Ships and marine technology — Measures to prevent asbestos emission and exposure during ship recycling

Ships and marine technology — Measures to prevent asbestos emission and exposure during ship recycling

ISO/PAS 30007:2010 provides effective methods for minimizing the dangers of asbestos during ship recycling, reducing both the release of asbestos into the environment and worker exposure to asbestos. It helps ship recyclers to fulfil the requirements of the Hong Kong International Convention for the Safe and Environmentally Sound Recycling of Ships, 2009

Navire et technologie maritime — Mesures préventives concernant l'émission et l'exposition à l'amiante lors du recyclage des navires

General Information

Relations

Standards Content (Sample)

PUBLICLY ISO/PAS

AVAILABLE 30007

SPECIFICATION

First edition

2010-06-01

Ships and marine technology —

Measures to prevent asbestos emission

and exposure during ship recycling

Navire et technologie maritime — Mesures préventives concernant

l'émission et l'exposition à l'amiante lors du recyclage des navires

Reference number

ISO/PAS 30007:2010(E)

©

ISO 2010

---------------------- Page: 1 ----------------------

ISO/PAS 30007:2010(E)

PDF disclaimer

This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but

shall not be edited unless the typefaces which are embedded are licensed to and installed on the computer performing the editing. In

downloading this file, parties accept therein the responsibility of not infringing Adobe's licensing policy. The ISO Central Secretariat

accepts no liability in this area.

Adobe is a trademark of Adobe Systems Incorporated.

Details of the software products used to create this PDF file can be found in the General Info relative to the file; the PDF-creation

parameters were optimized for printing. Every care has been taken to ensure that the file is suitable for use by ISO member bodies. In

the unlikely event that a problem relating to it is found, please inform the Central Secretariat at the address given below.

COPYRIGHT PROTECTED DOCUMENT

© ISO 2010

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2010 – All rights reserved

---------------------- Page: 2 ----------------------

ISO/PAS 30007:2010(E)

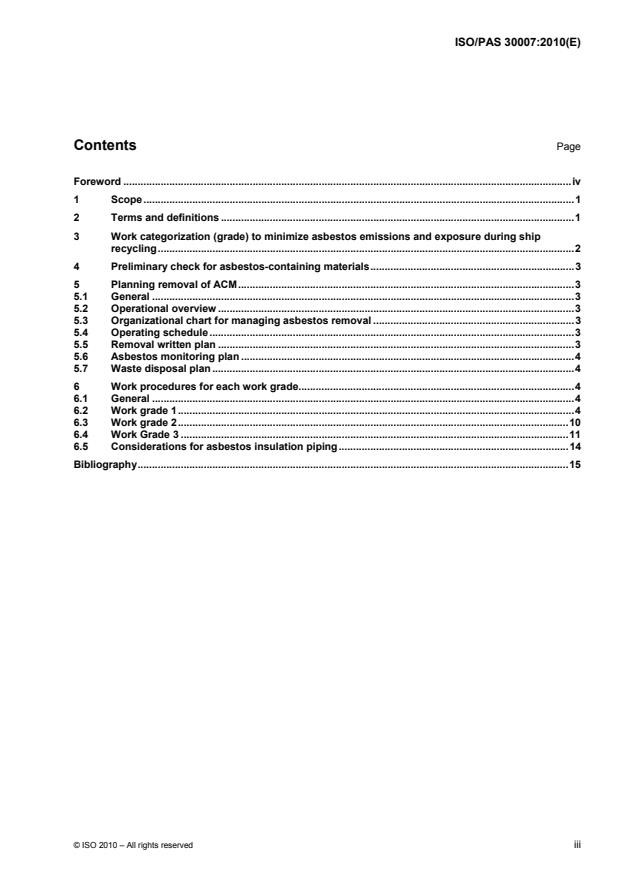

Contents Page

Foreword .iv

1 Scope.1

2 Terms and definitions .1

3 Work categorization (grade) to minimize asbestos emissions and exposure during ship

recycling.2

4 Preliminary check for asbestos-containing materials.3

5 Planning removal of ACM.3

5.1 General .3

5.2 Operational overview .3

5.3 Organizational chart for managing asbestos removal .3

5.4 Operating schedule.3

5.5 Removal written plan .3

5.6 Asbestos monitoring plan .4

5.7 Waste disposal plan.4

6 Work procedures for each work grade.4

6.1 General .4

6.2 Work grade 1.4

6.3 Work grade 2.10

6.4 Work Grade 3 .11

6.5 Considerations for asbestos insulation piping.14

Bibliography.15

© ISO 2010 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO/PAS 30007:2010(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In other circumstances, particularly when there is an urgent market requirement for such documents, a

technical committee may decide to publish other types of document:

— an ISO Publicly Available Specification (ISO/PAS) represents an agreement between technical experts in

an ISO working group and is accepted for publication if it is approved by more than 50 % of the members

of the parent committee casting a vote;

— an ISO Technical Specification (ISO/TS) represents an agreement between the members of a technical

committee and is accepted for publication if it is approved by 2/3 of the members of the committee casting

a vote.

An ISO/PAS or ISO/TS is reviewed after three years in order to decide whether it will be confirmed for a

further three years, revised to become an International Standard, or withdrawn. If the ISO/PAS or ISO/TS is

confirmed, it is reviewed again after a further three years, at which time it must either be transformed into an

International Standard or be withdrawn.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/PAS 30007 was prepared by Technical Committee ISO/TC 8, Ships and marine technology.

iv © ISO 2010 – All rights reserved

---------------------- Page: 4 ----------------------

PUBLICLY AVAILABLE SPECIFICATION ISO/PAS 30007:2010(E)

Ships and marine technology — Measures to prevent asbestos

emission and exposure during ship recycling

1 Scope

This Publicly Available Specification provides effective methods for minimizing the dangers of asbestos during

ship recycling, reducing both the release of asbestos into the environment and worker exposure to asbestos. It

helps ship recyclers to fulfil the requirements of The Hong Kong International Convention for the Safe and

[5]

Environmentally Sound Recycling of Ships, 2009 .

2 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

2.1

asbestos

variety of fibrous silicate minerals, namely actinolite asbestos, amosite, anthophyllite asbestos, chrysotile,

crocidolite and tremolite asbestos

2.2

asbestos-containing material

ACM

material containing more than one percent asbestos or defined material regulated by national rule

2.3

clean room

uncontaminated room having facilities for the storage of employees' street clothing and uncontaminated

materials and equipment

2.4

competent person

person capable of identifying existing asbestos hazards in the workplace and selecting the appropriate control

strategy for asbestos exposure and who has the authority to take prompt corrective measures to eliminate

them

NOTE The competent person will have appropriate training, certification and/or license that meets the requirements

of national legislation for the specific tasks undertaken.

2.5

decontamination zone

enclosed area adjacent and connected to asbestos-removal area and consisting of an equipment room

(change room), shower area and clean room, which is used for the decontamination of workers, materials, and

equipment that are contaminated with asbestos

2.6

equipment room

change room

contaminated room located within the decontamination zone that is supplied with impermeable bags or

containers for the disposal of contaminated protective clothing and equipment

© ISO 2010 – All rights reserved 1

---------------------- Page: 5 ----------------------

ISO/PAS 30007:2010(E)

2.7

high-efficiency particulate air filter

HEPA filter

filter capable of trapping and retaining around at least 99,97 % of all mono-dispersed particles of 0,3 µm in

diameter

2.8

ship recycling

activity of complete or partial dismantling of a ship at a ship recycling facility in order to recover components

and materials for reprocessing and reuse or for disposal, including processing hazardous and other materials,

and their associated operations such as storage and treatment of components and materials on site, but not

their further processing or disposal in separate facilities

2.9

inventory

inventory of hazardous materials

NOTE The inventory is a requirement for recycling ships that is specified by The Hong Kong International Convention

for the Safe and Environmentally Sound Recycling of Ships, 2009.

[ISO/PAS 30006:2010, definition 3.2]

2.10

wetting agent

water, or water to which surfactant has been added (to increase the ability of the liquid to penetrate), that is

applied to ACM to suppress dust emission during removal

3 Work categorization (grade) to minimize asbestos emissions and exposure during

ship recycling

In order to minimize the generation of asbestos dust and potential worker exposure during ship recycling

operations, the ship recycling facility's competent person shall determine the appropriate work grade in

accordance with Table 1, and shall determine corresponding working procedures in accordance with the

methodologies given in Table 2.

Since the difficulty of performing a task can be estimated by the type and manner of use of ACM, three work

grades have been established accordingly. See Table 1.

Table 1 — Work grading

Work grade Description

Work for removal of sprayed-on asbestos, which requires strict measures to minimize emission of

1 asbestos to environment and exposure of worker to asbestos such as thermal system insulation

or surfacing ACM

Work for removal of ACM except sprayed-on asbestos for thermal insulation for main and

2

auxiliary engines, thermal insulation for other pipes and armouring materials subjected to heat

Work for removal of ACM except sprayed-on asbestos used in accommodation and service

3 spaces; walls (ceilings, floorings and linings) and moulded seal materials for devices or piping

a

(joint sheets, gaskets, gland packing, packing and linings)

As factors such as workload, the working environment, and methodologies may vary, the competent person shall

periodically review tasks for asbestos abatement both before and during operations to determine if the work grade should

be amended.

The user shall ensure compliance with the national requirements.

a

When ACM is cut by power-tool, the work shall be categorized in work grade 2.

2 © ISO 2010 – All rights reserved

---------------------- Page: 6 ----------------------

ISO/PAS 30007:2010(E)

4 Preliminary check for asbestos-containing materials

In order to determine whether asbestos is used in the ship on which work is to be performed, the competent

person shall check

⎯ the inventory, and

⎯ the related documents and diagrams.

Equipment, systems or areas that are specified as free of asbestos need not be handled in the same way as

ACMs.

5 Planning removal of ACM

5.1 General

Prior to removal of ACM a written plan in accordance with 5.2 to 5.7 shall be made.

5.2 Operational overview

The operational overview shall specify the title of the operation, work period, details of the operation

(separately by area) and layout of work site indicated on the plan of the ship.

The overview shall specify the equipment, system or areas in which ACMs are used (based on the check

specified in Clause 4) and the work procedure summary for removal of ACM for each work grade. Additionally,

a layout for the removal zone shall be made giving dimensions and the precise location of work sites and

decontamination zones (in the case of work grade 1), negative-pressure dust collectors (in the case of work

grade 1) and the asbestos-containing waste storage.

The user shall ensure compliance with the national requirements.

Regardless of the work grade, removal of asbestos containing material should be conducted, to the maximum

extent practicable, prior to the removal of other hazardous materials or deconstruction of the vessel itself.

5.3 Organizational chart for managing asbestos removal

An organizational chart to manage asbestos removal shall be made. Especially when directly engaged in ACM

removal operations, the employer should attach the document of authorization to perform ACM removal to the

chart if necessary.

Documents showing that workers have completed the necessary training and have undergone medical

checkups for the specified operations shall be attached to the organizational chart.

5.4 Operating schedule

For items related to the operating schedule, see the removal procedure specified in Clause 6. The schedule

should indicate the number of days required for each operation.

5.5 Removal written plan

The removal written plan shall provide information in accordance with the removal procedure specified in

Clause 6, in addition to the information required by 5.5.1 and 5.5.2.

© ISO 2010 – All rights reserved 3

---------------------- Page: 7 ----------------------

ISO/PAS 30007:2010(E)

5.5.1 Equipment, tools and protective measures

The written plan shall contain a list of equipment and tools needed for removal.

The list shall specify the types and quantities of personal protective equipment required for each job (or task)

performed, including but not limited to respirators and protective clothing.

The manufacturers, product names and quantities of wetting agent shall be specified.

5.5.2 Layout of the decontamination zone

The written plan shall incorporate a layout and structural diagram of the decontamination zone [equipment

room (change room), shower area, and clean room] and other illustrations that illustrate operational specifics,

such as the location of the negative-pressure dust collector.

5.6 Asbestos monitoring plan

If asbestos monitoring (atmosphere, working environment, water, and soil) is required in accordance with

national law, there shall be a written plan to specify measuring cycles, locations, methods and designated

persons or organization.

5.7 Waste disposal plan

The waste disposal plan shall specify methods for storage, transport, and final disposal of removed ACM. The

plan shall also specify the estimated quantity of the ACM wastes.

6 Work procedures for each work grade

6.1 General

Operations for each grade shall be performed in accordance with the procedures specified in Table 2. For

additional information see 6.2 to 6.4.

6.2 Work grade 1

6.2.1 General

Asbestos removal operations of work grade 1 shall be carried out as specified in 6.2.2 to 6.2.7.

6.2.2 Preparation for work

Preparation of tools, material and equipment shall be conducted in accordance with the asbestos-removal

plan specified in Clause 5, before starting the asbestos removal operation.

4 © ISO 2010 – All rights reserved

---------------------- Page: 8 ----------------------

ISO/PAS 30007:2010(E)

Table 2 — Work procedure for each work grade

Work grade 1 Work grade 2 Work grade 3

a

Work plan

Draw up plan for removal of ACM

Competent

Competent person shall be assigned as supervisor

person

b

Special

Provide workers with special asbestos training

training

Protective Powered air-purifying respirator Same as for work grade 1, or Same as for work grade 2, or

equipment

or full face piece respirators with

Half-mask respirators with Half-mask respirators with

particulate filter (solid particle

particulate filter (solid particle particulate filter (solid particle

collecting efficiency shall be at

collecting efficiency shall be at collecting efficiency shall be at

least 99,9 %) (if possible,

least 99,0 %) can be used for least 95,0 %)

pressure-demand-type

removal without cutting and

Goggles

combination air-line mask

breaking asbestos thermal

Protective gloves

respirator)

insulations

Working clothing

Protective gloves

Goggles

Protective clothing

Protective gloves

Protective footwear

Protective clothing

Protective footwear

Emission Same as for work grade 2 Same as for work grade 3 and in Post signs, e.g. “KEEP OUT —

prevention addition ASBESTOS HAZARD”

Prepare work area: remove all Use a vacuum cleaner

non-fixed items before starting incorporating a HEPA filter.

work

Sealed disposal container for

Isolate the work site with plastic waste.

sheeting or any other physical

c

barrier

Install a negative-pressure dust

collector (in work site)

Set up decontamination zone

A small project, such the removal

of a small section with asbestos

insulation, may be worked by

using a glove bag without isolation

with plastic sheeting

During/after

Same as for work grade 2 Saturate and/or solidify materials Saturate materials with wetting

work with wetting agent (dust agent (dust suppressants), if

suppressants) moulded products containing

asbestos must be crushed, cut,

Evaluate/measure the working

or ground during removal,

environment

wetting agent shall be used.

Place waste in the specified

Clean up the work site.

sealed disposal container and

store in an interim waste storage Dispose of or wash protectors

area used by workers

Clean up the work site Draw up work records and

maintain on file.

Dispose of or wash protectors

used by workers

Create work records and maintain

on file

Waste Disposal and washing of waste varies with material; ACM and objects contaminated with asbestos shall

disposal be disposed of in accordance with the laws and regulations allowable within the country in which the

work is performed

Remark

To carry out work on piping and machinery insulated with asbestos materials, the procedure provided in

6.5 shall be taken into consideration.

a

A simplified plan can be acceptable for grade 3.

b

The training course is different for each work grade. Refer to 6.2 to 6.4 for the details of training to carry out.

c

The physical barrier (plastic sheeting) shall be sufficiently designed and placed to prevent migration of airborne asbestos fibres.

© ISO 2010 – All rights reserved 5

---------------------- Page: 9 ----------------------

ISO/PAS 30007:2010(E)

6.2.2.1 Establishment of supervising organization of removal of asbestos

a) Assignment of person responsible

The competent person shall be assigned as supervisor.

b) Establishment of organization for removal of asbestos

The organization for removal of asbestos under the supervision of the competent person shall be

established.

c) The competent person shall ensure the following.

⎯ The workers are correctly wearing appropriate protective equipment.

⎯ The dust collectors are working correctly.

⎯ There is no damage or opening of the isolating sheet.

⎯ The air pressure of the asbestos-removal area is negative relative to the outside air pressure.

⎯ The workers have received relevant education and training and have had an appropriate medical

evaluation.

⎯ The equipment and work area are monitored at appropriate intervals to ensure that the work

environment and procedures, as described above, remain satisfactory.

6.2.2.2 Preliminary education and training for workers

In the case that workers have not received education and training specific to asbestos, such training shall be

carried out prior to commencing asbestos removal work.

The

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.