ISO 2561:2023

(Main)Plastics — Determination of residual styrene monomer in polystyrene (PS) and impact-resistant polystyrene (PS-I) by gas chromatography

Plastics — Determination of residual styrene monomer in polystyrene (PS) and impact-resistant polystyrene (PS-I) by gas chromatography

This document specifies a method for the determination of the residual styrene monomer in polystyrene (PS) and impact-resistant polystyrene (PS-I) by gas chromatography. It can also be used for the simultaneous determination of other volatile aromatic hydrocarbons in PS and PS-I.

Plastiques — Détermination du styrène monomère résiduel dans le polystyrène (PS) et le polystyrène résistant au choc (PS-I) par chromatographie en phase gazeuse

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 2561

Fourth edition

2023-11

Plastics — Determination of residual

styrene monomer in polystyrene (PS)

and impact-resistant polystyrene (PS-

I) by gas chromatography

Plastiques — Détermination du styrène monomère résiduel dans

le polystyrène (PS) et le polystyrène résistant au choc (PS-I) par

chromatographie en phase gazeuse

Reference number

© ISO 2023

All rights reserved. Unless otherwise specified, or required in the context of its implementation, no part of this publication may

be reproduced or utilized otherwise in any form or by any means, electronic or mechanical, including photocopying, or posting on

the internet or an intranet, without prior written permission. Permission can be requested from either ISO at the address below

or ISO’s member body in the country of the requester.

ISO copyright office

CP 401 • Ch. de Blandonnet 8

CH-1214 Vernier, Geneva

Phone: +41 22 749 01 11

Email: copyright@iso.org

Website: www.iso.org

Published in Switzerland

ii

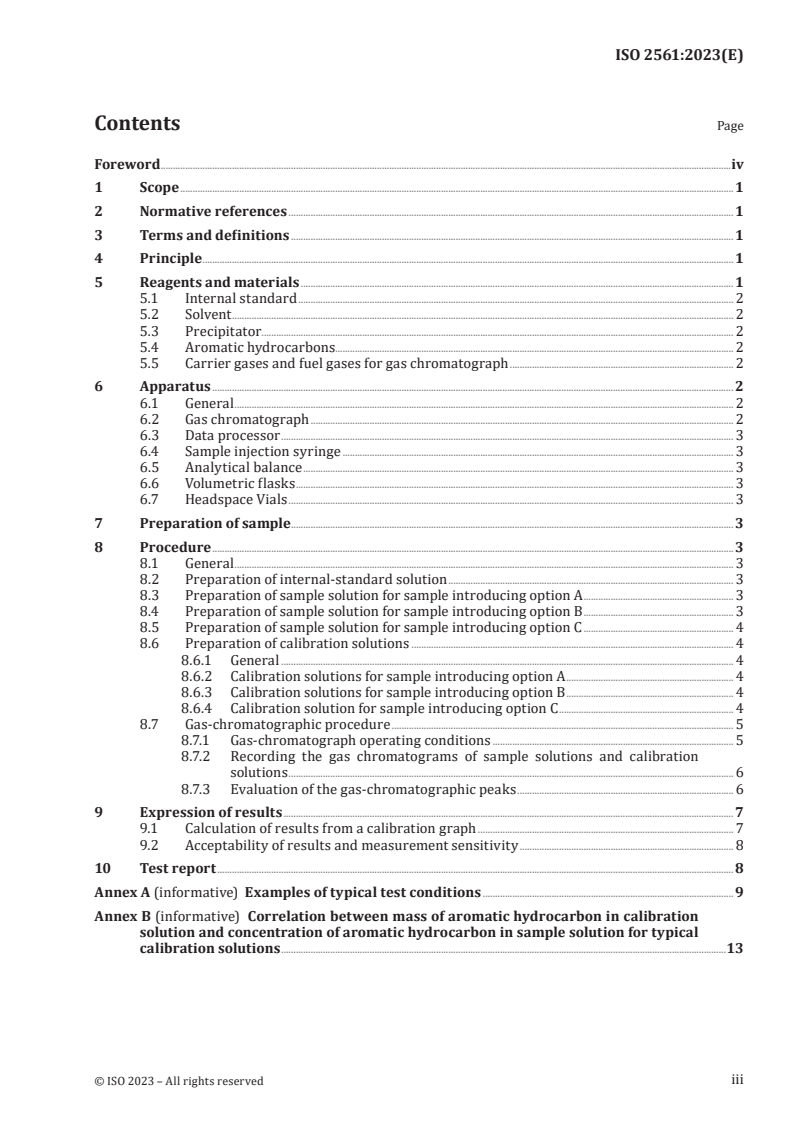

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 1

4 Principle . 1

5 Reagents and materials . 1

5.1 Internal standard . 2

5.2 Solvent . 2

5.3 Precipitator . . 2

5.4 Aromatic hydrocarbons. 2

5.5 Carrier gases and fuel gases for gas chromatograph . 2

6 Apparatus . 2

6.1 General . 2

6.2 Gas chromatograph . 2

6.3 Data processor . 3

6.4 Sample injection syringe . 3

6.5 Analytical balance . 3

6.6 Volumetric flasks . 3

6.7 Headspace Vials . 3

7 Preparation of sample . 3

8 Procedure .3

8.1 General . 3

8.2 Preparation of internal-standard solution . 3

8.3 Preparation of sample solution for sample introducing option A . 3

8.4 Preparation of sample solution for sample introducing option B . 3

8.5 Preparation of sample solution for sample introducing option C . 4

8.6 Preparation of calibration solutions . 4

8.6.1 General . 4

8.6.2 Calibration solutions for sample introducing option A . 4

8.6.3 Calibration solutions for sample introducing option B . 4

8.6.4 Calibration solution for sample introducing option C . 4

8.7 Gas-chromatographic procedure . 5

8.7.1 Gas-chromatograph operating conditions . 5

8.7.2 Recording the gas chromatograms of sample solutions and calibration

solutions . 6

8.7.3 Evaluation of the gas-chromatographic peaks . 6

9 Expression of results . 7

9.1 Calculation of results from a calibration graph . 7

9.2 Acceptability of results and measurement sensitivity . 8

10 Test report . 8

Annex A (informative) Examples of typical test conditions . 9

Annex B (informative) Correlation between mass of aromatic hydrocarbon in calibration

solution and concentration of aromatic hydrocarbon in sample solution for typical

calibration solutions .13

iii

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular, the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

ISO draws attention to the possibility that the implementation of this document may involve the use

of (a) patent(s). ISO takes no position concerning the evidence, validity or applicability of any claimed

patent rights in respect thereof. As of the date of publication of this document, ISO had not received

notice of (a) patent(s) which may be required to implement this document. However, implementers are

cautioned that this may not represent the latest information, which may be obtained from the patent

database available at www.iso.org/patents. ISO shall not be held responsible for identifying any or all

such patent rights.

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation of the voluntary nature of standards, the meaning of ISO specific terms and

expressions related to conformity assessment, as well as information about ISO's adherence to

the World Trade Organization (WTO) principles in the Technical Barriers to Trade (TBT), see

www.iso.org/iso/foreword.html.

This document was prepared by Technical Committee ISO/TC 61, Plastics, Subcommittee SC 9,

Thermoplastic materials.

This fourth edition cancels and replaces the third edition (ISO 2561:2012), which has been technically

revised.

The main changes-are as follows:

— adding headspace injection as another sample introducing option for gas chromatography.

Any feedback or questions on this document should be directed to the user’s national standards body. A

complete listing of these bodies can be found at www.iso.org/members.html.

iv

INTERNATIONAL STANDARD ISO 2561:2023(E)

Plastics — Determination of residual styrene monomer in

polystyrene (PS) and impact-resistant polystyrene (PS-I)

by gas chromatography

1 Scope

This document specifies a method for the determination of the residual styrene monomer in

polystyrene (PS) and impact-resistant polystyrene (PS-I) by gas chromatography. It can also be used

for the simultaneous determination of other volatile aromatic hydrocarbons in PS and PS-I.

2 Normative references

The following documents are referred to in the text in such a way that some or all of their content

constitutes requirements of this document. For dated references, only the edition cited applies. For

undated references, the latest edition of the referenced document (including any amendments) applies.

ISO 472, Plastics — Vocabulary

ISO 1042, Laboratory glassware — One-mark volumetric flasks

3 Terms and definitions

For the purposes of this document, the terms and definitions given in ISO 472 apply.

ISO and IEC maintain terminological databases for use in standardization at the following addresses:

— ISO Online browsing platform: available at https:// www .iso .org/ obp

— IEC Electropedia: available at https:// www .electropedia .org/

4 Principle

PS or PS-I sample is dissolved in solvent containing an internal standard. To obtain separation of

styrene and other volatile materials, gas chromatography method is employed, in which three sample

introducing options are available:

— Option A: a small volume of the polymer solution is injected directly into a gas chromatograph.

— Option B: a small volume of the supernatant solution remaining after precipitation of polymer by

addition of a precipitator is injected into a gas chromatograph.

— Option C: a small volume of vapor of the polymer solution under thermal equilibrium is injected into

a gas chromatograph.

5 Reagents and materials

Use only reagents of recognized analytical grade, unless otherwise specified.

5.1 Internal standard

The internal standard shall be selected based on consideration of the retention times of the materials

contained in the polymer sample and solvent. Recommended candidates are n-butylbenzene,

cyclopentanol, 1,2,4-trimetylbenzene and 1,4-diethylbenzene of sufficient purity for analytical use.

5.2 Solvent

Use dimethylformamide, butanone, dichloromethane, or tetrahydrofuran. Tetrahydrofuran is used only

for method A. Only dimethylformamide is used in method C.

5.3 Precipitator

Use 2,2,4-trimethylpentane or ethanol.

5.4 Aromatic hydrocarbons

Use styrene and other aromatic hydrocarbons such as ethylbenzene, cumene or α-methylstyrene, if

required. Styrene shall be checked for self-polymerizaiton before use. The criterion for acceptance is

that the mixture of styrene and ethanol of the same volume shall be clear. When determining the content

of other aromatic hydrocarbons in the sample, other aromatic hydrocarbons such as ethylbenzene,

cumene or α-methylstyrene shall be used.

5.5 Carrier gases and fuel gases for gas chromatograph

Hydrogen, helium or nitrogen, according to the type of detector used, shall be used as carrier gas. Use

hydrogen and air as fuel gases. If detectors are used which require carrier gases and fuel gases other

than those mentioned, the carrier gases and fuel gases shall be specified.

WARNING — Strict observance of safety regulations is essential when using hydrogen.

6 Apparatus

6.1 General

Normal laboratory equipment and the following apparatus are required. Typical operating conditions

are described in Annex A.

6.2 Gas chromatograph

6.2.1 Injection port. Use an injection port for liquid samples or gas samples. When using a capillary

column, an injection port with splitter may be applicable.

6.2.2 Headspace sampler. only used in method C, including backflush capability, thermostated

sample tray, and associated accessories fulfil these requirements while providing for automatic

sequential sampling of headspace vapors.

6.2.3 Column. The column diameter and length, as well as the packing material and stationary phase

shall be selected based on consideration of column resolution and calibration curve linearity. Both

packed columns and capillary columns are acceptable. Capillary columns are recommended in the light

of accuracy.

6.2.4 Detector. Use a suitable detector.

NOTE The most commonly used detector is a hydrogen flame ionization detector (FID).

6.3 Data processor

Use a recorder or microcomputer to record the signals from the detector.

6.4 Sample injection syringe

Use a micro-syringe of the 1 μl to 50 μl type. A micro-syringe integrated with the auto-injector may

also be used.

6.5 Analytical balance

Shall be accurate to the nearest 0,1 mg.

6.6 Volumetric flasks

Volumetric flasks as standardized in ISO 1042 shall be used.

6.7 Headspace Vials

Vials matching the headspace sampler shall be used, including a lid with a sealing gasket and vial sealer.

NOTE The volume of headspace sample bottle is usually 10 ml, 20 ml or 22 ml.

7 Preparation of sample

The sample may be taken from material in the form of powder, pellets or moulded parts. In order to

ensure the desired accuracy of the sample mass, large pieces of sample shall be reduced to smaller

fragments.

8 Procedure

8.1 General

During the dilution processes described below, the temperature of each solution shall remain under

25 °C.

8.2 Preparation of internal-standard solution

Weigh 200 mg of internal standard (5.1), to the nearest 1 mg, into a 1 000 ml volumetric flask (6.6).

Then add solvent (5.2) to make exactly 1 000 ml, stopper tightly and mix well.

8.3 Preparation of sample solution for sample introducing option A

Weigh 0,5 g of sample, to the nearest 1 mg, into a volumetric flask (6.6) having a volume between 25 ml

and 100 ml. Using a syringe or a pipette, add 20 ml of the internal standard solution pre

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...