ISO 9022-23:2013

(Main)Optics and photonics — Environmental test methods — Part 23: Low pressure combined with cold, ambient temperature and dry and damp heat

Optics and photonics — Environmental test methods — Part 23: Low pressure combined with cold, ambient temperature and dry and damp heat

ISO 9022-23:2013 specifies the methods relating to the environmental tests of optical instruments including additional assemblies from other fields (e.g. mechanical, chemical, and electronic devices), under equivalent conditions, for their ability to resist the influence of low air pressure combined with cold, including the potential condensation and freezing of water, ambient temperature, and dry or damp heat. ISO 9022-23:2013 is applicable to optical instruments including additional assemblies from other fields, designed for operation and/or transport in high mountainous areas or on board aircraft or missiles.

Optique et photonique — Méthodes d'essais d'environnement — Partie 23: Essais combinés basse pression et froid, température ambiante et chaleur sèche et humide

General Information

Relations

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 9022-23

First edition

2013-12-15

Optics and photonics —

Environmental test methods —

Part 23:

Low pressure combined with cold,

ambient temperature and dry and

damp heat

Optique et photonique — Méthodes d’essais d’environnement —

Partie 23: Essais combinés basse pression et froid, température

ambiante et chaleur sèche et humide

Reference number

ISO 9022-23:2013(E)

©

ISO 2013

---------------------- Page: 1 ----------------------

ISO 9022-23:2013(E)

COPYRIGHT PROTECTED DOCUMENT

© ISO 2013

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Case postale 56 • CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2013 – All rights reserved

---------------------- Page: 2 ----------------------

ISO 9022-23:2013(E)

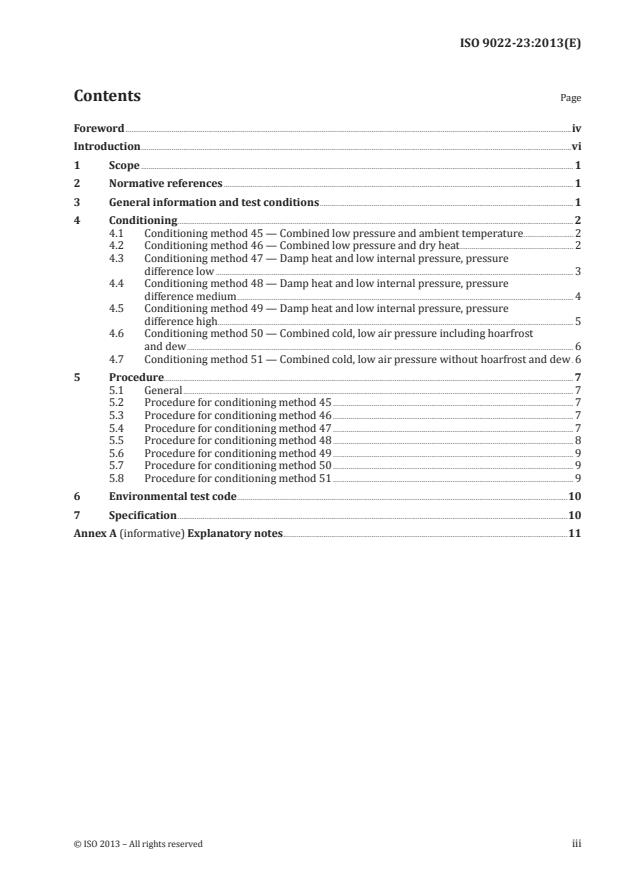

Contents Page

Foreword .iv

Introduction .vi

1 Scope . 1

2 Normative references . 1

3 General information and test conditions . 1

4 Conditioning . 2

4.1 Conditioning method 45 — Combined low pressure and ambient temperature . 2

4.2 Conditioning method 46 — Combined low pressure and dry heat . 2

4.3 Conditioning method 47 — Damp heat and low internal pressure, pressure

difference low . 3

4.4 Conditioning method 48 — Damp heat and low internal pressure, pressure

difference medium . 4

4.5 Conditioning method 49 — Damp heat and low internal pressure, pressure

difference high . 5

4.6 Conditioning method 50 — Combined cold, low air pressure including hoarfrost

and dew . 6

4.7 Conditioning method 51 — Combined cold, low air pressure without hoarfrost and dew . 6

5 Procedure. 7

5.1 General . 7

5.2 Procedure for conditioning method 45 . 7

5.3 Procedure for conditioning method 46 . 7

5.4 Procedure for conditioning method 47 . 7

5.5 Procedure for conditioning method 48 . 8

5.6 Procedure for conditioning method 49 . 9

5.7 Procedure for conditioning method 50 . 9

5.8 Procedure for conditioning method 51 . 9

6 Environmental test code .10

7 Specification .10

Annex A (informative) Explanatory notes .11

© ISO 2013 – All rights reserved iii

---------------------- Page: 3 ----------------------

ISO 9022-23:2013(E)

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical Barriers

to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 172, Optics and photonics, Subcommittee SC 1,

Fundamental standards.

This edition cancels and replaces ISO 9022-5:1994, ISO 9022-18:1994, and ISO 9022-21:1998, which have

been technically revised.

ISO 9022 consists of the following parts, under the general title Optics and photonics — Environmental

test methods:

— Part 1: Definitions, extent of testing

— Part 2: Cold, heat and humidity

— Part 3: Mechanical stress

— Part 4: Salt mist

— Part 6: Dust

— Part 7: Resistance to drip or rain

— Part 8: High pressure, low pressure, immersion

— Part 9: Solar radiation

— Part 11: Mould growth

— Part 12: Contamination

— Part 14: Dew, hoarfrost, ice

— Part 17: Combined contamination, solar radiation

— Part 20: Humid atmosphere containing sulfur dioxide or hydrogen sulfide

iv © ISO 2013 – All rights reserved

---------------------- Page: 4 ----------------------

ISO 9022-23:2013(E)

— Part 22: Combined cold, dry heat or temperature change with bump or random vibration

— Part 23: Low pressure combined with cold, ambient temperature and dry and damp heat

© ISO 2013 – All rights reserved v

---------------------- Page: 5 ----------------------

ISO 9022-23:2013(E)

Introduction

Optical instruments are affected during their use by a number of different environmental parameters

which they are required to resist without significant reduction in performance and to remain within

defined specifications.

The type and severity of these parameters depend on the conditions of use of the instrument (for

example, in the laboratory or workshop) and on its geographical location. The environmental effects

on optical instrument performance in the tropics and subtropics are totally different from those found

when they are used in arctic regions. Individual parameters cause a variety of different and overlapping

effects on instrument performance.

The manufacturer attempts to ensure, and the user naturally expects, that instruments will resist the

likely rigours of their environment throughout their life. This expectation can be assessed by exposure

of the instrument to a range of simulated environmental parameters under controlled laboratory

conditions. The severity of these conditions is often increased to obtain meaningful results in a relatively

short period of time.

In order to allow assessment and comparison of the response of optical instruments to appropriate

environmental conditions, ISO 9022 contains details of a number of laboratory tests which reliably

simulate a variety of different environments. The tests are based largely on IEC standards, modified

where necessary to take into account features special to optical instruments.

It should be noted that, as a result of continuous progress in all fields, optical instruments are no longer

only precision-engineered optical products, but, depending on their range of application, also contain

additional assemblies from other fields. For this reason, the principal function of the instrument must

be assessed to determine which International Standard should be used for testing. If the optical function

is of primary importance, then ISO 9022 is applicable, but if other functions take precedence, then the

appropriate International Standard in the field concerned should be applied. Cases can arise where

application both of ISO 9022 and other appropriate International Standards will be necessary.

vi © ISO 2013 – All rights reserved

---------------------- Page: 6 ----------------------

INTERNATIONAL STANDARD ISO 9022-23:2013(E)

Optics and photonics — Environmental test methods —

Part 23:

Low pressure combined with cold, ambient temperature

and dry and damp heat

1 Scope

This part of ISO 9022 specifies the methods relating to the environmental tests of optical instruments

including additional assemblies from other fields (e.g. mechanical, chemical, and electronic devices),

under equivalent conditions, for their ability to resist the influence of low air pressure combined with

cold, including the potential condensation and freezing of water, ambient temperature, and dry or damp

heat.

This part of ISO 9022 is applicable to optical instruments including additional assemblies from other

fields, designed for operation and/or transport in high mountainous areas or on board aircraft or

missiles.

The purpose of the testing is to investigate to what extent optical, climatic, mechanical, chemical,

and electrical (including electrostatic) performance characteristics of the specimen are affected by

combined low pressure and low, ambient, or high temperature. Furthermore, the additional effects

of water condensing and freezing on the instrument or components can be determined. Examples are

instruments which are installed or externally mounted on aircraft or missiles or transported inside

aircraft or flying objects not providing any pressure equalization.

Annex A explains the intent of the different types of tests.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 9022-1, Optics and photonics — Environmental test methods — Part 1: Definitions, extent of testing

ISO 9022-2, Optics and optical instruments — Environmental test methods — Part 2: Cold, heat and humidity

ISO 9022-8, Optics and optical instruments — Environmental test methods — Part 8: High pressure, low

pressure, immersion

3 General information and test conditions

Ambient temperature as understood by this part of ISO 9022 is (23 ± 3) °C.

The values of temperatures and climatic conditions specified in Table 1 to Table 6 are selected from

ISO 9022-2, conditioning methods 10, 11, and 12.

The size of the test chamber and the setup of the specimens shall be chosen in such a way that a uniform

temperature for all specimens within the test chamber is ensured.

For conditioning methods 45, 46, 50, and 51, air circulation in low-pressure cabinets or low-pressure

chambers is required. The low-pressure chamber, itself, can either be equipped as a thermal chamber or

be installed in a thermal chamber.

© ISO 2013 – All rights reserved 1

---------------------- Page: 7 ----------------------

ISO 9022-23:2013(E)

For conditioning methods 47 to 49, a climatic test chamber is required. Three different test methods

are used to test combined damp heat and low internal pressure resistance of optical instruments. Dew

on the specimen is admissible. The individual test steps shall be performed directly one after another.

Interruption of the test is not admissible.

In addition for conditioning method 47, if condensation is produced, the specimens shall be protected

against falling drops.

In addition for conditioning method 48, a low-pressure container is also required.

In addition for conditioning method 49, the specimens shall have a test connection for evacuation and

pressure measurement, as described in ISO 9022-8.

Changes in temperature shall be effected sufficiently slowly not to cause any damage to the specimen.

Shock-type air pressure changes shall be avoided unless they are likely to be encountered in the natural

environment.

4 Conditioning

4.1 Conditioning method 45 — Combined low pressure and ambient temperature

See Table 1.

Table 1 — Degrees of severity for conditioning method 45 — Combined low pressure and

ambient temperature

Degree of severity 01 02 03 04

Test chamber tempera-

°C 23 ± 3 23 ± 3 23 ± 3 23 ± 3

ture

Pressure hPa 800 ± 30 700 ± 30 600 ± 30 500 ± 30

Time of pressure

reduction and pressure min ≤ 15

increase

a

Period of conditioning h ≥ 1

State of operation 2 2 2 2

a

With thermally active specimens after the steady-state temperature of the specimen has

been reached.

4.2 Conditioning method 46 — Combined low pressure and dry heat

See Table 2.

2 © ISO 2013 – All rights reserved

---------------------- Page: 8 ----------------------

ISO 9022-23:2013(E)

Table 2 — Degrees of severity for conditioning method 46 — Combined low pressure and dry

heat

Degree of

01 02 03 04 05 06 07 08 09 10 11 12

severity

Test chamber

a a a

°C 40 ± 3 40 ± 3 55 ± 3 55 ± 3 63 ± 3 63 ± 3 85 ± 3 85 ± 3 40 ± 3 55 ± 3 63 ± 3 85 ± 3

temperature

Pressure hPa 100 ± 5 10 ± 1

Time of pres-

sure reduction

min ≤ 15 ≤ 80

and pressure

increase

Mean tempera-

ture change

K/min 0,2 to 2

during heating/

cooling

Exposure time h 24 72 24 72 24 72 24 72 24 24 24 24

State of opera-

1 or 2

tion

a

State of operation 1 only.

4.3 Conditioning method 47 — Damp heat and low internal pressure, pressure differ-

ence low

See Table 3 and Figure 1.

Conditioning method 47 shall be used for optical instruments where demands made on their sealing

(low pressure resistance) are low, e.g. instruments which comply with the requirements of the degrees

of severity 01, 02, 07, and 08 of conditioning method 81 in ISO 9022-8.

Table 3 — Degrees of severity for conditioning method 47 — Damp heat and low internal

pressure, pressure difference low

Degree of severity 01 02 03 04 05 06

Test chamber tem-

°C 55 ± 2 63 ± 2 70 ± 2

perature

Relative humidity % < 40

Step 1

Until the internal air of the specimen has reached a

Exposure time h temperature at least within 3 K of the test chamber

Condition 1

temperature.

Climatic conditions 40 °C ± 2 °C and 90 % to 95 % relative humidity.

Step 2

Exposure time h ≥ 1

Number of cycles 6 12 6 12 6 12

Test chamber temperature °C −10 ± 3

Condition 2

Until specimen has reached a temperature at least

Exposure time h

within 3 K of the test chamber temperature.

Test chamber temperature °C 40 ± 2

Relative humidity % < 40

Condition 3

Until specimen has reached a temperature at least

Exposure time h

within 3 K of the test chamber temperature.

State of operation 1

© ISO 2013 – All rights reserved 3

---------------------- Page: 9 ----------------------

ISO 9022-23:2013(E)

Key

1 condition 1

2 condition 2

3 condition 3

4 duration according to Table 1

5 relative humidity, < 40 %

6 relative humidity, 90 % to 95 %

7 relative humidity, < 40 %

X duration, h

T temperature, °C

Figure 1 — Cycling curve for conditioning method 47, using example of degree of severity 01

4.4 Conditioning method 48 — Damp heat and low internal pressure, pressure differ-

ence medium

See Table 4.

Conditioning method 48 shall be used for optical instruments where demands made on their sealing

(low pressure resistance) are medium, e.g. instruments which comply with the requirements of the

degrees of severity 03, 04, 09, and 10 of conditioning method 81 in ISO 9022-8.

4 © ISO 2013 – All rights reserved

---------------------- Page: 10 ----------------------

ISO 9022-23:2013(E)

Table 4 — Degrees of severity for conditioning method 48 — Damp heat and low internal

pressure, pressure difference medium

Degree of severity 01 02 03 04 05 06

Test chamber tem-

°C 40 ± 2

perature

Step 1 Test chamber

hPa 800 650 500

pressure

Condition 1

Exposure time h ≥ 1

Climatic conditions 40 °C ± 2 °C and 90 % to 95 % relative humidity.

Step 2

Exposure time h ≥ 1,5

Number of cycles 3 6 3 6 3 6

Test chamber temperature °C −10 ± 3

Condition 2

Until specimen has reached a temperature at least

Exposure time h

within 3 K of the test chamber temperature.

Test chamber temperature °C 40 ± 2

Relative humidity % < 40

Condition 3

Until specimen has reached a temperature at least

Exposure time h

within 3 K of the test chamber temperature.

State of operation 1

4.5 Conditioning method 49 — Damp heat and low internal pressure, pressure differ-

ence high

See Table 5.

Conditioning method 49 shall be used for optical instruments where demands made on their sealing

(low pressure resistance) are high, e.g. instruments which comply wit

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.