ISO 8312:2015

(Main)Rubber compounding ingredients - Stearic acid - Definition and test methods

Rubber compounding ingredients - Stearic acid - Definition and test methods

ISO 8312:2015 defines stearic acid (including blends of stearic and palmitic acid) for use as a compounding ingredient in the rubber industry and specifies the test methods for describing its properties. Classification of stearic acid and stearic acid/palmitic acid blends according to iodine value and typical chemical and physical properties for such materials for use in the rubber industry are given in Annex L. Annex L is given for information only. In this International Standard, the atomic absorption spectrometric method is the preferred method.

Ingrédients de mélange du caoutchouc — Acide stéarique — Définition et méthodes d'essai

General Information

- Status

- Published

- Publication Date

- 17-Sep-2015

- Current Stage

- 9093 - International Standard confirmed

- Start Date

- 10-Jun-2025

- Completion Date

- 13-Dec-2025

Relations

- Effective Date

- 04-Nov-2015

Overview

ISO 8312:2015 - Rubber compounding ingredients - Stearic acid - Definition and test methods - defines stearic acid (and stearic/palmitic blends) for use as a compounding ingredient in the rubber industry and specifies the test methods used to describe its chemical and physical properties. The standard sets out sampling rules, a list of required analyses, and the content for a compliant test report. Atomic absorption spectrometric (AAS) methods are stated as the preferred technique for metal determinations.

Key technical topics and requirements

- Scope and definition

- Covers stearic acid and blends with palmitic acid intended for rubber compounding.

- Annex L provides an informational classification by iodine value and typical properties (Annex L is informative only).

- Sampling

- Sampling shall follow ISO 15528 using a stainless‑steel sampling device.

- Required physical and chemical tests

- Acid value (ISO 660)

- Saponification value (ISO 3657)

- Titre (melting point) (ISO 935)

- Fatty acid composition (ISO 5508 and ISO 12966-2)

- Volatile matter at 105 °C (ISO 662)

- Ash at 550 °C ± 25 °C (Annex A)

- Iodine value (ISO 3961)

- Unsaponifiable matter (ISO 3596)

- Mineral acidity (Annex F)

- Metal impurities - copper, manganese, iron, nickel (preferred AAS methods in Annexes B–E; molecular absorption alternatives in Annexes G–K)

- Analytical specifics

- Example: ash determination uses muffle ashing at 550 °C ± 25 °C (Annex A).

- Example: copper by AAS measured at 324.7 nm after ash digestion (Annex B).

- Test report

- Must identify the product, reference ISO 8312, list measured values (ash, metals, mineral acidity, and other tests), note unusual features and any deviations, and include test dates.

Practical applications

- Quality control of incoming stearic acid for rubber compounding to ensure consistent processing and product performance.

- Supplier specification and acceptance testing for raw material procurement.

- Analytical laboratory procedures for routine metal and impurity determinations using AAS or molecular methods.

- Product classification and R&D when comparing stearic and stearic/palmitic blends based on iodine value and composition (informational Annex L).

Who should use ISO 8312:2015

- Rubber compounders and manufacturers

- Raw material suppliers and traders of stearic/palmitic blends

- Quality assurance and QC laboratories

- Test labs performing regulatory or supplier qualification testing

- Standards and specification authors in the rubber and polymer industries

Related standards (normative references)

Relevant ISO methods referenced include ISO 660, ISO 662, ISO 935, ISO 3596, ISO 3657, ISO 3961, ISO 5508, ISO 12966-2 and ISO 15528, among others used for specific tests and apparatus requirements.

Frequently Asked Questions

ISO 8312:2015 is a standard published by the International Organization for Standardization (ISO). Its full title is "Rubber compounding ingredients - Stearic acid - Definition and test methods". This standard covers: ISO 8312:2015 defines stearic acid (including blends of stearic and palmitic acid) for use as a compounding ingredient in the rubber industry and specifies the test methods for describing its properties. Classification of stearic acid and stearic acid/palmitic acid blends according to iodine value and typical chemical and physical properties for such materials for use in the rubber industry are given in Annex L. Annex L is given for information only. In this International Standard, the atomic absorption spectrometric method is the preferred method.

ISO 8312:2015 defines stearic acid (including blends of stearic and palmitic acid) for use as a compounding ingredient in the rubber industry and specifies the test methods for describing its properties. Classification of stearic acid and stearic acid/palmitic acid blends according to iodine value and typical chemical and physical properties for such materials for use in the rubber industry are given in Annex L. Annex L is given for information only. In this International Standard, the atomic absorption spectrometric method is the preferred method.

ISO 8312:2015 is classified under the following ICS (International Classification for Standards) categories: 83.040.20 - Rubber compounding ingredients. The ICS classification helps identify the subject area and facilitates finding related standards.

ISO 8312:2015 has the following relationships with other standards: It is inter standard links to ISO 8312:1999. Understanding these relationships helps ensure you are using the most current and applicable version of the standard.

You can purchase ISO 8312:2015 directly from iTeh Standards. The document is available in PDF format and is delivered instantly after payment. Add the standard to your cart and complete the secure checkout process. iTeh Standards is an authorized distributor of ISO standards.

Standards Content (Sample)

INTERNATIONAL ISO

STANDARD 8312

Second edition

2015-09-15

Rubber compounding ingredients —

Stearic acid — Definition and test

methods

Ingrédients de mélange du caoutchouc — Acide stéarique —

Définition et méthodes d’essai

Reference number

©

ISO 2015

© ISO 2015, Published in Switzerland

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized otherwise in any form

or by any means, electronic or mechanical, including photocopying, or posting on the internet or an intranet, without prior

written permission. Permission can be requested from either ISO at the address below or ISO’s member body in the country of

the requester.

ISO copyright office

Ch. de Blandonnet 8 • CP 401

CH-1214 Vernier, Geneva, Switzerland

Tel. +41 22 749 01 11

Fax +41 22 749 09 47

copyright@iso.org

www.iso.org

ii © ISO 2015 – All rights reserved

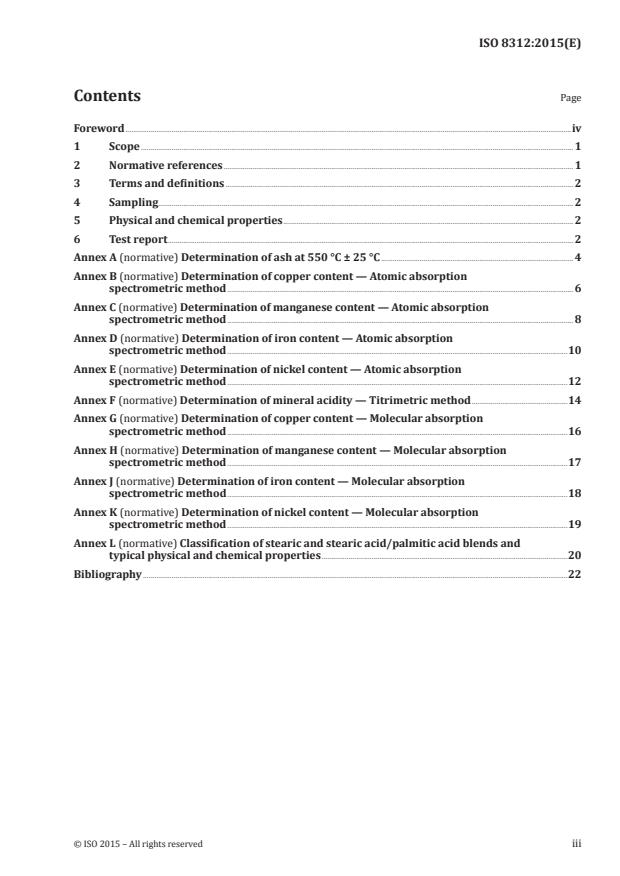

Contents Page

Foreword .iv

1 Scope . 1

2 Normative references . 1

3 Terms and definitions . 2

4 Sampling . 2

5 Physical and chemical properties . 2

6 Test report . 2

Annex A (normative) Determination of ash at 550 °C ± 25 °C . 4

Annex B (normative) Determination of copper content — Atomic absorption

spectrometric method . 6

Annex C (normative) Determination of manganese content — Atomic absorption

spectrometric method . 8

Annex D (normative) Determination of iron content — Atomic absorption

spectrometric method .10

Annex E (normative) Determination of nickel content — Atomic absorption

spectrometric method .12

Annex F (normative) Determination of mineral acidity — Titrimetric method .14

Annex G (normative) Determination of copper content — Molecular absorption

spectrometric method .16

Annex H (normative) Determination of manganese content — Molecular absorption

spectrometric method .17

Annex J (normative) Determination of iron content — Molecular absorption

spectrometric method .18

Annex K (normative) Determination of nickel content — Molecular absorption

spectrometric method .19

Annex L (normative) Classification of stearic and stearic acid/palmitic acid blends and

typical physical and chemical properties .20

Bibliography .22

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards

bodies (ISO member bodies). The work of preparing International Standards is normally carried out

through ISO technical committees. Each member body interested in a subject for which a technical

committee has been established has the right to be represented on that committee. International

organizations, governmental and non-governmental, in liaison with ISO, also take part in the work.

ISO collaborates closely with the International Electrotechnical Commission (IEC) on all matters of

electrotechnical standardization.

The procedures used to develop this document and those intended for its further maintenance are

described in the ISO/IEC Directives, Part 1. In particular the different approval criteria needed for the

different types of ISO documents should be noted. This document was drafted in accordance with the

editorial rules of the ISO/IEC Directives, Part 2 (see www.iso.org/directives).

Attention is drawn to the possibility that some of the elements of this document may be the subject of

patent rights. ISO shall not be held responsible for identifying any or all such patent rights. Details of

any patent rights identified during the development of the document will be in the Introduction and/or

on the ISO list of patent declarations received (see www.iso.org/patents).

Any trade name used in this document is information given for the convenience of users and does not

constitute an endorsement.

For an explanation on the meaning of ISO specific terms and expressions related to conformity

assessment, as well as information about ISO’s adherence to the WTO principles in the Technical

Barriers to Trade (TBT) see the following URL: Foreword - Supplementary information

The committee responsible for this document is ISO/TC 45, Rubber and rubber products, Subcommittee

SC 3, Raw materials (including latex) for use in the rubber industry.

This second edition cancels and replaces the first edition (ISO 8312:1999), of which it constitutes a

minor revision with the following changes:

— atomic absorption spectrometric method is stated as the preferred method in the Scope;

— Normative references in Clause 2 were updated and a Bibliography was added.

iv © ISO 2015 – All rights reserved

INTERNATIONAL STANDARD ISO 8312:2015(E)

Rubber compounding ingredients — Stearic acid —

Definition and test methods

WARNING — Persons using this International Standard should be familiar with normal

laboratory practice. This International Standard does not purport to address all of the

safety problems, if any, associated with its use. It is the responsibility of the user to establish

appropriate safety and health practices and to ensure compliance with any national regulatory

conditions.

1 Scope

This International Standard defines stearic acid (including blends of stearic and palmitic acid) for use

as a compounding ingredient in the rubber industry and specifies the test methods for describing its

properties.

Classification of stearic acid and stearic acid/palmitic acid blends according to iodine value and typical

chemical and physical properties for such materials for use in the rubber industry are given in Annex L.

Annex L is given for information only.

In this International Standard, the atomic absorption spectrometric method is the preferred method.

2 Normative references

The following documents, in whole or in part, are normatively referenced in this document and are

indispensable for its application. For dated references, only the edition cited applies. For undated

references, the latest edition of the referenced document (including any amendments) applies.

ISO 660, Animal and vegetable fats and oils — Determination of acid value and acidity

ISO 662, Animal and vegetable fats and oils — Determination of moisture and volatile matter content

ISO 935, Animal and vegetable fats and oils — Determination of titre

ISO 1042:1998, Laboratory glassware — One-mark volumetric flasks

ISO 3596, Animal and vegetable fats and oils — Determination of unsaponifiable matter — Method using

diethyl ether extraction

ISO 3657, Animal and vegetable fats and oils — Determination of saponification value

ISO 3961, Animal and vegetable fats and oils — Determination of iodine value

ISO 4058, Magnesium and its alloys — Determination of nickel — Photometric method using

dimethylglyoxime

ISO 5508, Animal and vegetable fats and oils — Analysis by gas chromatography of methyl esters of fatty

acids

ISO 6685, Chemical products for industrial use — General method for determination of iron content —

1,10-Phenanthroline spectrophotometric method

ISO 7780:1998, Rubbers and rubber latices — Determination of manganese content — Sodium periodate

photometric methods

ISO 8053, Rubber and latex — Determination of copper content — Photometric method

ISO 12966-2, Animal and vegetable fats and oils — Gas chromatography of fatty acid methyl esters —

Part 2: Preparation of methyl esters of fatty acids

ISO 15528, Paints, varnishes and raw materials for paints and varnishes — Sampling

3 Terms and definitions

For the purposes of this document, the following terms and definitions apply.

3.1

stearic acid (for use in the rubber industry)

mixture of straight-chain saturated fatty acids composed substantially of stearic acid in the form

C H COOH and palmitic acid in the form C H COOH

17 35 15 31

4 Sampling

Sampling shall be carried out in accordance with ISO 15528, using a stainless-steel sampling device.

5 Physical and chemical properties

The physical and chemical properties shall be determined by the methods of test listed in Table 1.

Table 1 — List of physical and chemical properties of stearic acid and the methods used for

their determination

Property Test method

Acid value, mg KOH/g ISO 660

Saponification value, mg KOH/g ISO 3657

Titre value, °C

ISO 935

Fatty acids, C to C , including unsaturates, percentage (mass fraction) ISO 5508 and ISO 12966-2

16 18

Total matter volatile at 105 °C ± 3 °C, percentage (mass fraction) ISO 662, oven method

Ash at 550 °C ± 25 °C, percentage (mass fraction) Annex A

lodine value, g/100 g ISO 3961

Mineral acidity, cm /100 g Annex F

a

Copper, mg/kg Annex B or G

a

Manganese, mg/kg Annex C or H

a

Iron, mg/kg Annex D or J

Unsaponifiable matter, percentage (mass fraction) ISO 3596

a

Nickel, mg/kg Annex E or K

Note Where an atomic absorption spectrometer is not available, the molecular absorption spectrometric methods given

in Annexes G, H, J and K may be used.

a

For speed and simplicity, the methods given in Annexes B, C, D and E are recommended.

6 Test report

The test report shall include the following information:

a) all details necessary for complete identification of the product tested;

b) a reference to this International Standard, i.e. ISO 8312;

2 © ISO 2015 – All rights reserved

c) the results obtained:

— percentage ash w , from A.4;

A

— copper content w , from B.6 or from Annex G (state the method used);

Cu

— manganese content w , from C.6 or from Annex H (state the method used);

Mn

— iron content w , from D.6 or from Annex J (state the method used);

Fe

— nickel content, w , from E.6 or from Annex K (state the method used);

Ni

— mineral acidity, N , from F.5;

ma

— the results of other tests which may have been performed (see Table 1);

d) any unusual features noted during the determinations;

e) any operations not included in this International Standard, or in other International Standards

cited, which might have affected the results;

f) the dates of the tests.

Annex A

(normative)

Determination of ash at 550 °C ± 25 °C

A.1 Principle

A weighed test portion is carefully volatilized without ignition, and the residue is ashed in a furnace at

550 °C ± 25 °C. The mass of ash is determined as a percentage of the mass of the original test portion.

A.2 Apparatus

Ordinary laboratory apparatus, plus the following:

A.2.1 Silica crucible.

A.2.2 Heat-resistant non-conducting (insulating) material in plate form, approximately

150 mm × 150 mm.

A.2.3 Analytical balance, accurate to 0,1 mg.

A.2.4 Muffle furnace, capable of being maintained at a temperature of 550 °C ± 25 °C.

A.3 Procedure

A.3.1 Heat the clean silica crucible (A.2.1) to 600 °C, allow to cool in a desiccator and weigh empty to

0,1 mg.

A.3.2 Place about 10 g of sample in this crucible and re-weigh to 0,1 mg. Place in a hole in the sheet of

heat-resistant material (A.2.2).

A.3.3 Heat the crucible and contents gently in order to volatilize the test portion, taking care to ensure

that the vapour does not ignite and that hot gases from the burner do not enter the crucible.

A.3.4 When all volatile material has been removed, place the crucible in the muffle furnace (A.2.4),

maintained at 550 °C ± 25 °C, and ignite the contents for 30 min.

A.3.5 Place the crucible in a desiccator and allow to cool.

A.3.6 Re-weigh the crucible to the nearest 0,1 mg.

A.3.7 Repeat the operations specified in A.3.3, A.3.4 and A.3.5, until successive mass determinations

differ by less than 2 mg.

A.3.8 Retain the ash obtained in A.3.6 if subsequent use can be made in another test.

4 © ISO 2015 – All rights reserved

A.4 Expression of results

Calculate the percentage ash, w , in accordance with Formula (A.1):

A

mm−

w = ×100 (A.1)

A

m

where

w is the percentage ash;

A

m is the mass, in grams, of the test portion;

m is the mass, in grams, of the empty crucible;

m is the mass, in grams, of the crucible and ash.

Annex B

(normative)

Determination of copper content — Atomic absorption

spectrometric method

B.1 Principle

Ash made in accordance with Annex A is dissolved in hydrochloric acid and the solution made up to

standard volume. The absorbance is measured at 324,7 nm in an atomic absorption spectrometer. The

copper content is determined by reference to a calibration graph prepared by measuring the absorbance

of standard copper solutions.

B.2 Reagents

During the analysis, use only reagents of recognized analytical grade, and only distilled water or water

of equivalent purity.

B.2.1 Hydrochloric acid, a mass fraction of 10 % solution.

B.2.2 Copper, standard solution corresponding to 10 mg of Cu per dm .

B.3 Apparatus

Ordinary laboratory apparatus, plus the following:

B.3.1 Atomic absorption spectrometer, fitted with a copper hollow-cathode lamp.

3 3

B.3.2 One-mark volumetric flasks, two of capacity 10 cm and six of capacity 50 cm , complying with

the requirements of ISO 1042:1998, class A.

B.4 Procedure

B.4.1 Obtain a sample of ash by conducting the determination specified in Annex A.

B.4.2 Dissolve the ash so obtained in 5 cm of dilute hydrochloric acid (B.2.1). Transfer the solution

quantitatively to a 10 cm one-mark volumetric flas

...

ISO 8312:2015은 고무 산업에서 복합 재료로 사용되는 스테아릭 산과 팔미틱 산의 혼합물을 정의하고 그 특성을 기술하기 위한 시험 방법을 명시하는 표준이다. 본 표준은 요오드 값에 따라 스테아릭 산과 스테아릭 산/팔미틱 산 혼합물을 분류하며, 이들 재료를 이용한 고무 산업에서의 일반적인 화학적 및 물리적 특성에 대한 정보를 부록 L에 제시한다. 국제 표준인 이 표준에서는 원자 흡수 분광법이 선호되는 시험 방법으로 정의되어 있다.

ISO 8312:2015 is a standard that defines and specifies the test methods for stearic acid, including blends with palmitic acid, which are used as compounding ingredients in the rubber industry. This standard provides classification criteria based on iodine value and gives information about the chemical and physical properties of stearic acid and stearic acid/palmitic acid blends in Annex L. The preferred test method for analyzing the properties of stearic acid is the atomic absorption spectrometric method.

ISO 8312:2015は、ゴム工業での混合材料として使用されるステアリン酸およびパルミチン酸のブレンドについて定義し、その特性を記述するための試験方法を指定する国際規格です。本規格では、ヨウ素価に基づいてステアリン酸およびステアリン酸/パルミチン酸ブレンドを分類し、その材料の化学的および物理的特性に関する情報を付録Lで提供しています。ステアリン酸の特性を分析するための推奨される試験方法は、原子吸光分光法です。

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.

Loading comments...