ISO/TR 26946:2011

(Main)Standard method for porosity measurement of thermally sprayed coatings

Standard method for porosity measurement of thermally sprayed coatings

ISO/TR 26946:2011 describes a method for characterizing the porosity of thermally sprayed coatings by metallographical examination. This method is particularly applicable to oxide coatings, such as Al2O3, ZrO2 and TiO2, produced by plasma spray. It also considers the purposes to test the size, shape and density of pores for thermally sprayed coatings.

Méthode normalisée de mesure de la porosité des revêtements obtenus par projection thermique

General Information

Standards Content (Sample)

TECHNICAL ISO/TR

REPORT 26946

First edition

2011-11-15

Standard method for porosity

measurement of thermally sprayed

coatings

Méthode normalisée de mesure de la porosité des revêtements obtenus

par projection thermique

Reference number

©

ISO 2011

© ISO 2011

All rights reserved. Unless otherwise specified, no part of this publication may be reproduced or utilized in any form or by any means,

electronic or mechanical, including photocopying and microfilm, without permission in writing from either ISO at the address below or

ISO's member body in the country of the requester.

ISO copyright office

Case postale 56 CH-1211 Geneva 20

Tel. + 41 22 749 01 11

Fax + 41 22 749 09 47

E-mail copyright@iso.org

Web www.iso.org

Published in Switzerland

ii © ISO 2011 – All rights reserved

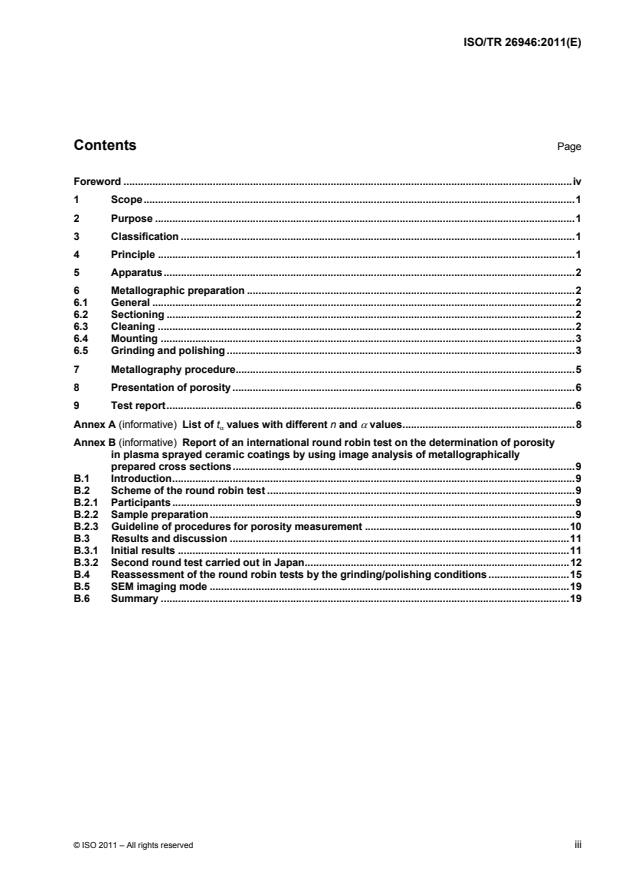

Contents Page

Foreword . iv

1 Scope . 1

2 Purpose . 1

3 Classification . 1

4 Principle . 1

5 Apparatus . 2

6 Metallographic preparation . 2

6.1 General . 2

6.2 Sectioning . 2

6.3 Cleaning . 2

6.4 Mounting . 3

6.5 Grinding and polishing . 3

7 Metallography procedure. 5

8 Presentation of porosity . 6

9 Test report . 6

Annex A (informative) List of t values with different n and values . 8

Annex B (informative) Report of an international round robin test on the determination of porosity

in plasma sprayed ceramic coatings by using image analysis of metallographically

prepared cross sections . 9

B.1 Introduction . 9

B.2 Scheme of the round robin test . 9

B.2.1 Participants . 9

B.2.2 Sample preparation . 9

B.2.3 Guideline of procedures for porosity measurement . 10

B.3 Results and discussion . 11

B.3.1 Initial results . 11

B.3.2 Second round test carried out in Japan . 12

B.4 Reassessment of the round robin tests by the grinding/polishing conditions . 15

B.5 SEM imaging mode . 19

B.6 Summary . 19

Foreword

ISO (the International Organization for Standardization) is a worldwide federation of national standards bodies

(ISO member bodies). The work of preparing International Standards is normally carried out through ISO

technical committees. Each member body interested in a subject for which a technical committee has been

established has the right to be represented on that committee. International organizations, governmental and

non-governmental, in liaison with ISO, also take part in the work. ISO collaborates closely with the

International Electrotechnical Commission (IEC) on all matters of electrotechnical standardization.

International Standards are drafted in accordance with the rules given in the ISO/IEC Directives, Part 2.

The main task of technical committees is to prepare International Standards. Draft International Standards

adopted by the technical committees are circulated to the member bodies for voting. Publication as an

International Standard requires approval by at least 75 % of the member bodies casting a vote.

In exceptional circumstances, when a technical committee has collected data of a different kind from that

which is normally published as an International Standard (“state of the art”, for example), it may decide by a

simple majority vote of its participating members to publish a Technical Report. A Technical Report is entirely

informative in nature and does not have to be reviewed until the data it provides are considered to be no

longer valid or useful.

Attention is drawn to the possibility that some of the elements of this document may be the subject of patent

rights. ISO shall not be held responsible for identifying any or all such patent rights.

ISO/TR 26946 was prepared by Technical Committee ISO/TC 107, Metallic and other inorganic coatings.

iv © ISO 2011 – All rights reserved

TECHNICAL REPORT ISO/TR 26946:2011(E)

Standard method for porosity measurement of thermally

sprayed coatings

1 Scope

This Technical Report describes a method for characterizing the porosity of thermally sprayed coatings by

metallographical examination.

This method is particularly applicable to oxide coatings, such as Al O , ZrO and TiO , produced by plasma

2 3 2 2

spray. It also considers the purposes to test the size, shape and density of pores for thermally sprayed

coatings.

2 Purpose

The main purpose of porosity measurement is to determine the quality of a thermally sprayed coating and its

freedom from porosity, particularly on those areas of the significant surface that demand a functional

requirement.

This Technical Report provides a standard process that is suitable for determining the porosity of thermally

sprayed coatings, as part of the total quality assurance programme.

This Technical Report is also intended to provide a standard way to present the porosity of thermally sprayed

coatings.

3 Classification

The microstructure of a thermally sprayed ceramic coating is characterized by the existence of various pores,

microcracks, splat boundaries and unmelted particles, because of the nature of the process. Although different

terms are used, both the pores and the microcracks are volumetric spaces, which are free from coating

material. The pores can be divided into closed pores, open pores and micropores. Closed pores appear as

isolated clustered voids in the coating and have no connection with the surface; open pores appear as the

same voids but have a connection with the atmosphere, either directly or from one pore to another;

micropores are either closed or open pores which show dimensions only detectable on a microscopic scale.

The difference between pores and microcracks lies mostly in their aspect ratios (ratio of the major axis over

the minor axis), so, they are collectively treated as pores. The fraction of volumetric space covered by the

pores in thermally sprayed coatings is defined as porosity.

4 Principle

The porosity of thermally sprayed coatings is determined by preparing an area of the inspected coating with a

cross-section of high microscopic surface quality, which can be viewed using a light microscope or a scanning

electron microscope (suggested). A quantitative assessment of the porosity of the inspected coatings is

carried out by using an image analysis technique on the microscope.

5 Apparatus

The following equipment is necessary for the porosity measurement of thermally sprayed coatings.

5.1 Cut-off wheels (recommended) or diamond wire or high pressure water-jet cutting equipment,

(according to equipment in existence) for sectioning coating samples to a proper size with minimal damage.

5.2 Cleaning apparatus, with ultrasonic equipment.

5.3 Mounting equipment.

5.4 Grinding and polishing equipment, (semi-automated or automated grinding/polishing machines are

recommended for consistent reproducibility).

5.5 Scanning electron microscope (recommended) or light microscope, for viewing the inspected

sample on a cross-section and obtaining digital images.

5.6 Computer, with analysing software for porosity evaluation on digital images.

All equipment should undergo regular maintenance and calibration to assure reliability and repeatability of the

measurement. At the same time, all metallographic personnel should have the proper training to allow them to

perform the required functions and analyses.

6 Metallographic preparation

6.1 General

Metallographic preparation of thermally sprayed coatings is critical for the porosity results. The requirements

for detail and monitoring will vary from system to system, depending upon the degree of automation in the

preparation. The basic steps for the preparation are given in 6.2 to 6.5.

6.2 Sectioning

If sectioning is required, two commonly used methods are abrasive wheel cutting or diamond wire cutting. The

first one, which is comprised of a diamond or boron nitride saw (more effective in this purpose) that breaks

down readily exposed fresh cutting surfaces, is usually best for a wide range of coatings. Sectioning should be

done with the cutting force from coating to substrate and minimal clamping pressure on the sample. It will be

better to secure the specimen for sectioning with a soft cushion, such as wood, if possible. The sectioning

wheel should be as thin as possible to minimize damage, which must be removed in subsequent steps.

Minimum pressure should be applied on the wheel to minimize possible overheating, with cooling by water if

possible. The length of the test specimen should be greater than 1 cm. At least five test specimens should be

taken from each sample in different positions.

6.3 Cleaning

Cleaning is an important step for removing all contaminants from the surface of the specimen. Three methods

or any combination are recommended.

a) Washing samples with soap and water.

b) Brushing or soaking samples in solvent, such as acetone/alcohol, followed by application of heat

treatment to drive off any internal absorption.

c) Cleaning samples by performing an initial/extra vacuum step (if using vacuum impregnation in mounting)

to volatilize any entrapped materials.

2 © ISO 2011 – All rights reserved

6.4 Mounting

For the preparation of polished cross-sections, it is necessary to mount the selected region first so that a flat

polished area with minimal edge rounding is obtained. In this case, edge retention can be improved by coating

the outer surface of the sample with an additional layer during grinding and polishing. Electroless nickel

plating or sputtering with a metal layer are commonly used. The mounting procedure/material depends on the

following:

a) time available for mounting;

b) size of porosity and level of voids in the coating, and degree of interconnected porosity;

c) required viscosity of epoxy for impregnation of porosity is important (the viscosity of the cold-mount epoxy

should be medium, especially when porosity in the coating is small and difficult to impregnate);

d) hardness of coating vs. mounting material. (The mounting medium should be chosen to allow good edge

retention and be of comparable hardness to the coating, in order to minimize difficulties during grinding

and polishing.)

Cold mounting, which can be assisted by heat, with vacuum impregnation alone and/or pressure impregnation

is recommended.

6.5 Grinding and polishing

Generally, grinding and polishing parameters that must be considered/controlled in preparation are listed in

Table 1. Additional care must be taken to remove cut-off damage during initial grinding if the sectioning step

was used, and avoid over-polishing with colloidal silica in the final steps of preparation. During grinding,

examine the prepared area at each stage to ensure that all the damage from the previous stage has been

removed. In the case of polishing, the sample is polished with diamond paste down to 1 μm grade, then

alumina paste is used with 0,3 μm grade. Further polishing with colloidal silica may be required to obtain a

scratch-free surface. After polishing, clean the sample in suitable solven

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.