ASTM A413/A413M-00

(Specification)Standard Specification for Carbon Steel Chain

Standard Specification for Carbon Steel Chain

SCOPE

1.1 This specification covers carbon steel chain for such applications as railroad cars, construction, industrial uses, load binding, and general purposes other than overhead lifting.

Note 1—This specification does not cover carbon steel chain for sprocket applications.

1.2 Three classes of carbon steel chain are covered:

1.2.1 Grade 30—Proof coil chain.

1.2.2 Grade 43—High test chain.

1.2.3 Grade 70—Transport chain.

1.3 The values stated in either acceptable metric units or in other units shall be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system must be used independently of the other, without combining values in any way.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: A 413/A 413M – 00 An American National Standard

Standard Specification for

Carbon Steel Chain

This standard is issued under the fixed designation A 413/A 413M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope pounds or newtons at which the chain, in the condition it leaves

the producer’s plant, has been found by representative testing

1.1 This specification covers carbon steel chain for such

to break when a constantly increasing force was applied in

applications as railroad cars, construction, industrial uses, load

direct tension to a straight length of chain on a standard testing

binding, and general purposes other than overhead lifting.

machine. Breaking force values are a statistical attribute test

NOTE 1—This specification does not cover carbon steel chain for

and are not a guarantee that all chain segments per lot will

sprocket applications.

endure these loads. Breaking force loads shall not be used as

1.2 Three classes of carbon steel chain are covered:

criteria for service or design purposes.

1.2.1 Grade 30—Proof coil chain.

3.1.2 lot—for the purpose of acceptance testing, a lot shall

1.2.2 Grade 43—High test chain.

consist of 3000 ft [1000 m], or fraction thereof, of the same

1.2.3 Grade 70—Transport chain.

grade and size chain. If a continuous length of chain exceeds

1.3 The values stated in either acceptable metric units or in

3000 ft [1000 m], it shall also be considered a lot.

other units shall be regarded separately as standard. The values

3.1.3 proof test—a quality control tensile test applied to

stated in each system may not be exact equivalents; therefore,

chain for the purpose of verifying weld and material quality. It

each system must be used independently of the other, without

is the minimum force in pounds or newtons which the chain

combining values in any way.

has withstood at the time it left the producer, under a test in

which a constantly increasing force has been applied in direct

2. Referenced Documents

tension to a straight length of chain. Proof test loads are a

2.1 ASTM Standards:

manufacturing integrity test and shall not be used as criteria for

A 29/A 29M Specification for Steel Bars, Carbon and

service or design purposes.

Alloy, Hot-Wrought and Cold-Finished, General Require-

3.1.4 working load limit (WLL)—the maximum combined

ments for

static and dynamic load in pounds or kilograms that shall be

E 30 Test Methods for Chemical Analysis of Steel, Cast

applied in direct tension to an undamaged straight length of

Iron, Open-Hearth Iron and Wrought Iron

chain.

E 44 Definitions of Terms Relating to Heat Treatment of

4. Ordering Information

Metals

E 350 Test Methods for Chemical Analysis of Carbon Steel,

4.1 It shall be the responsibility of the purchaser to specify

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron and

all requirements that are necessary for material ordered under

Wrought Iron

this specification. Such requirements may include, but are not

E 415 Test Method for Optical Emission Vacuum Spectro-

limited to, the following:

metric Analysis of Carbon and Low-Alloy Steel

4.1.1 Product to conform to Specification A 413 or A 413M

and date of issue,

3. Terminology

4.1.2 Grade of chain,

3.1 Definitions of Terms Specific to This Standard:

4.1.3 Nominal size of chain (in. or mm),

3.1.1 breaking force, minimum—the minimum force in

4.1.4 Quantity of chain (ft or m),

4.1.5 Length of each piece, if required,

4.1.6 Finish, if required,

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

4.1.7 Certification of test(s), if required, and

A01.27 on Steel Chain.

4.1.8 Acceptance of inspection by purchaser, if required.

Current edition approved March 10, 2000. Published April 2000. Originally

published as A 413–57T. Last previous edition A 413–96.

5. Material Requirements

Annual Book of ASTM Standards, Vol 01.05.

Discontinued. See 1995 Annual Book of ASTM Standards, Vol 03.05.

5.1 Heat Analysis—The selection of the steel is left to the

Discontinued. See 1993 Annual Book of ASTM Standards, Vol 01.02.

judgment of the individual chain manufacturer provided the

Annual Book of ASTM Standards, Vol 03.05.

6 steel meets the following criteria:

Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

A 413/A 413M

9.2 Breaking Force—The breaking force test specimen shall

Carbon, max, % 0.370

Phosphorus, max, % 0.048

consist of a length from the lot containing at least the number

Sulfur, max, % 0.058

of links in Table 4.

5.2 Product Analysis—The steel used may be analyzed by

9.2.1 Fixtures for securing chain in a testing machine shall

the purchaser and shall conform to the requirements of 5.1

be properly designed to support securely the shoulder of the

subject to the product analysis tolerances specified in Specifi-

link (see Note 2). The opening in the fixture shall not be more

cation A 29/A 29M. Test samples may be taken from rods,

than 125 % of the stock diameter being tested. Links engaged

bars, or finished chain. Samples for analysis shall be so taken

in the testing fixture shall not be considered part of the test

as to represent the full cross section of the specimen.

specimen.

5.3 Test Methods E 30, E 350, or E 415 shall be used for

NOTE 2—“U” bolts of the same or larger diameter and the same or

referee purposes.

greater strength may be used to secure the chain to the jaws of the testing

machine.

6. Manufacture

9.2.2 Test specimens shall meet or exceed the minimum

6.1 Welding Process—Carbon steel chain may be made by

breaking force values given in Tables 1-3 for the appropriate

the forge welding, electric welding, or gas welding process.

grade and size chain.

6.2 Heat Treatment—Grades 30 and 43 do not require heat

9.3 Elongation:

treatment, but may be heat treated at the manufacturer’s

9.3.1 All chain which is heat treated (see 6.2) must be in the

discretion. Grade 70, after welding, shall be heat treated. Heat

quenched and tempered condition before the elongation is

treatment shall include quenching and tempering as described

measured.

in Definitions E 44.

9.3.2 Elongation is to be determined as follows:

7. Dimensional Requirements

9.3.2.1 Test samples are to consist of at least the number of

7.1 The chain shall conform to the dimensional require-

links in Table 4 that constitutes the gage length. Two additional

ments specified in Tables 1-3 for the appropriate grade and size links will be required to engage the jaws of the testing machine

chain.

unless this is done by half links or another method.

7.2 Diameter—The diameter of the material from which the

9.3.2.2 Place the test sample in the testing machine and load

chain is manufactured shall not be smaller than the material

to a maximum of 10 % of the proof test force. Measure the

diameter listed in Tables 1-3 within the following tolerance:

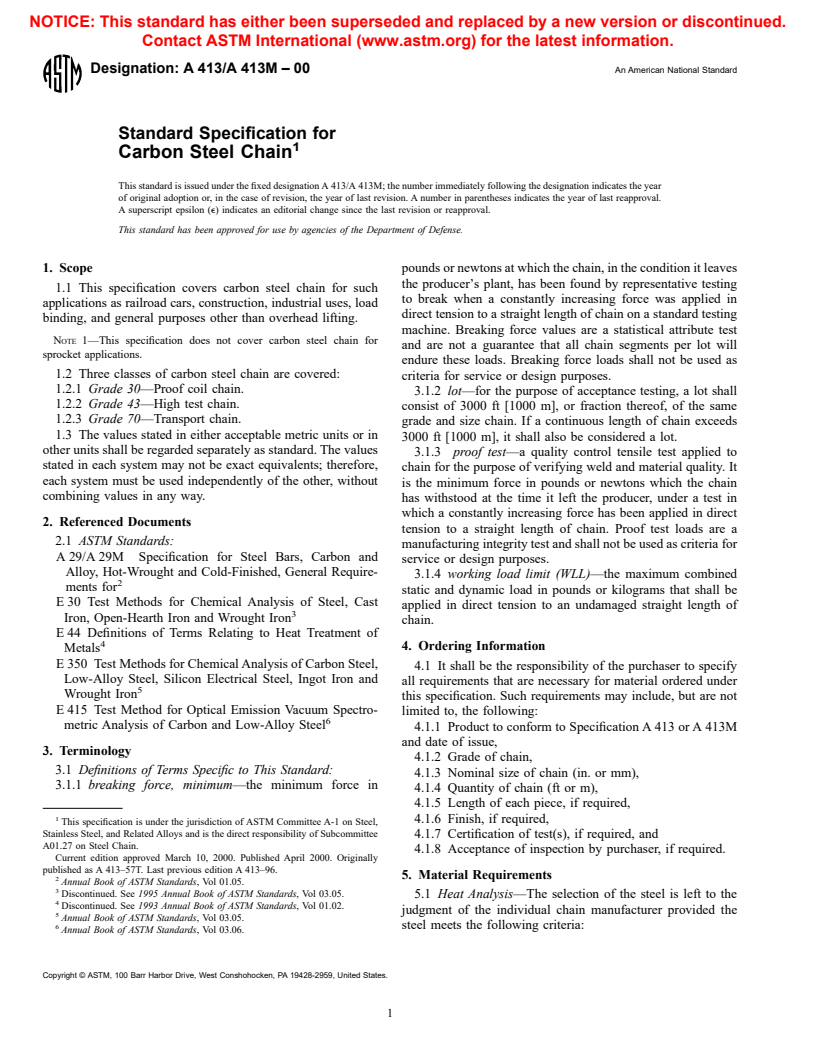

gage length (L), which does not include the links engaged in

−7 %. Oversized material may be used for all applications.

the jaws of the testing machine (see Fig. 1).

9.3.2.3 The load is then gradually and smoothly increased

8. Workmanship, Finish, and Appearance

until fracture occurs, and the maximum load applied is re-

8.1 The chain at the time of shipment shall be free of

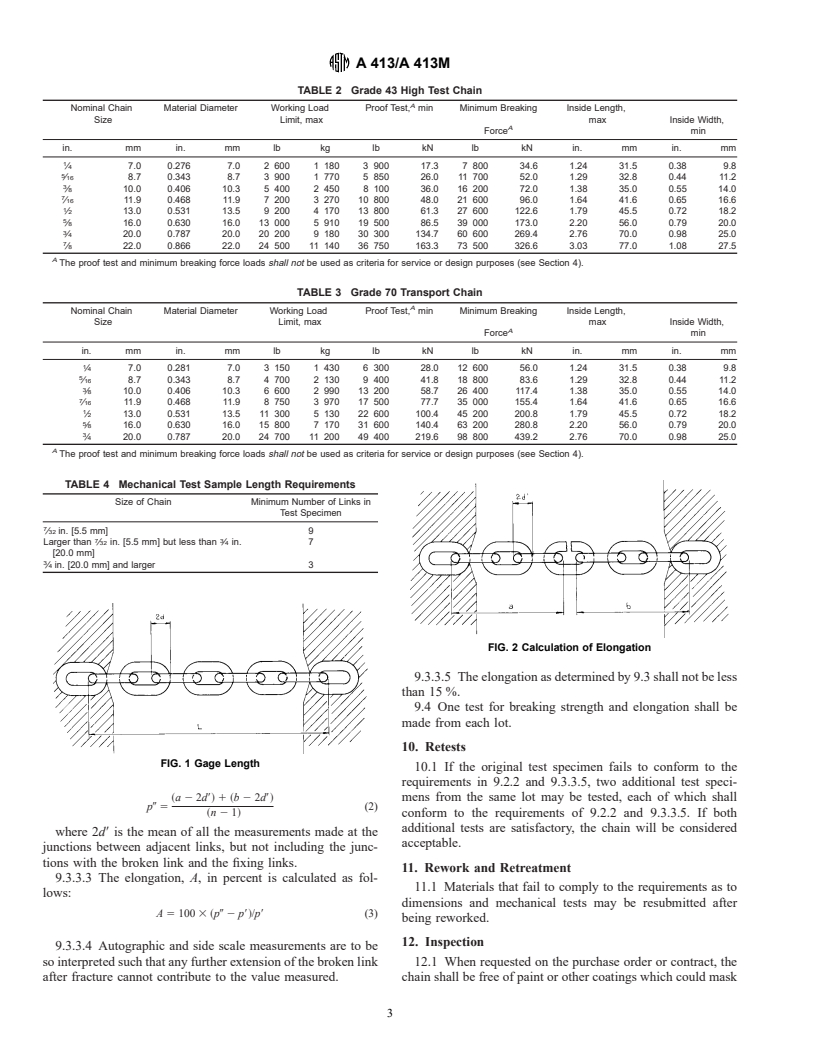

corded as the breaking force. The elongation may be deter-

discontinuities that would prevent the chain from enduring the

mined by an autographic recorder or side scale or alternatively

working load limit forces.

by measuring the broken lengths on either side of the broken

8.2 The manufacturer may apply a surface treatment or

link as shown in Fig. 2.

coating of their own choice for identification or corrosion

9.3.3 Calculation of Elongation:

resistance unless the customer specifies otherwise.

9.3.3.1 The mean pitch (p8) after seating of the links at some

load not exceeding 10 % of the manufacturing test force is

9. Mechanical Requirements

calculated as follows:

9.1 Proof Test—All chain shall be tested to at least the proof

p8 5 ~L 2 2d!/n (1)

load prescribed in Tables 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.