ASTM D7317-06

(Test Method)Standard Test Method for Insolubles in Used Lubricating Oils by Paper Filtration (LMOA Method)

Standard Test Method for Insolubles in Used Lubricating Oils by Paper Filtration (LMOA Method)

SCOPE

1.1 This test method covers the determination of coagulated pentane insolubles in used lubricating oils by a paper filtration method.

1.2 This test method was originally developed by the Fuels, Lubricants, and Environmental Committee (FLE) of the Locomotive Maintenance Officers Association (LMOA).

1.3 This test method is used primary for testing used diesel engine oils from railroad locomotive service. It may be applied to other samples types but precision, bias, and significance have not been determined for samples other than used railroad locomotive diesel engine oils.

1.4 This test method, in general, does not correlate with Test Method D 893 on Insolubles in Lubricating Oils, since it uses separation by centrifugation and a more concentrated solution of anti-coagulant.

1.5 The correlation between this test method and Appendix A4 (Enhanced Thermal Gravimetric Analysis (TGA) Procedure) in Test Method D 5967 has not been investigated.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.2, 7.3, and 7.4.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:D7317–06

Standard Test Method for

Insolubles in Used Lubricating Oils by Paper Filtration

(LMOA Method)

This standard is issued under the fixed designation D 7317; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope D 4057 Practice for Manual Sampling of Petroleum and

Petroleum Products

1.1 This test method covers the determination of coagulated

D 4177 Practice for Automatic Sampling of Petroleum and

pentane insolubles in used lubricating oils by a paper filtration

Petroleum Products

method.

D 5967 TestMethodforEvaluationofDieselEngineOilsin

1.2 This test method was originally developed by the Fuels,

T-8 Diesel Engine

Lubricants, and Environmental Committee (FL&E) of the

Locomotive Maintenance Officer’s Association (LMOA).

3. Terminology

1.3 This test method is used primary for testing used diesel

3.1 Definitions:

engine oils from railroad locomotive service. It may be applied

3.1.1 coagulate, v—to cause to become viscous or thick-

to other samples types but precision, bias, and significance

ened into a coherent mass.

have not been determined for samples other than used railroad

3.1.2 coagulated pentane insolubles, n—in used oil analy-

locomotive diesel engine oils.

sis, separated matter that results when a coagulant is added to

1.4 Thistestmethod,ingeneral,doesnotcorrelatewithTest

a solution of used oil in pentane.

Method D 893 on Insolubles in Lubricating Oils, since it uses

3.1.2.1 Discussion—The addition of a coagulant will aid in

separation by centrifugation and a more concentrated solution

separating finely divided materials that may have been held in

of anti-coagulant.

suspension because of the dispersant characteristics of the oil.

1.5 The correlation between this test method and Appendix

3.1.3 pentane insolubles, n—in used oil analysis, separated

A4 (Enhanced Thermal Gravimetric Analysis (TGA) Proce-

matter resulting when a used oil is mixed with pentane.

dure) in Test Method D 5967 has not been investigated.

3.1.3.1 Discussion—In this test method, the separation is

1.6 The values stated in SI units are to be regarded as the

effected by paper filtration.

standard. The values given in parentheses are for information

3.1.4 used oil, n—any oil that has been in a piece of

only.

equipment (for example, an engine, gearbox, transformer, or

1.7 This standard does not purport to address all of the

turbine), whether operated or not.

safety concerns, if any, associated with its use. It is the

3.1.4.1 Discussion—In this test method, the oil can be any

responsibility of the user of this standard to establish appro-

oil that has been used for lubrication of a locomotive diesel

priate safety and health practices and determine the applica-

engine, whether engaged in railroad or other service.

bility of regulatory limitations prior to use. For specific

warning statements, see 7.2, 7.3, and 7.4.

4. Summary of Test Method

2. Referenced Documents 4.1 Arepresentative sample of used lubricating oil is mixed

3 with pentane-coagulant solution and filtered under vacuum.

2.1 ASTM Standards:

The filter is washed with pentane, dried, and weighed to give

D 893 Test Method for Insolubles in Used Lubricating Oils

coagulated pentane insolubles.

5. Significance and Use

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

5.1 Coagulated pentane insolubles can include oil-insoluble

D02.06.0B on Physical Testing.

materials, some oil-insoluble resinous matter originating from

Current edition approved Dec. 1, 2006. Published January 2007.

oil or additive degradation, soot from incomplete diesel fuel

Locomotive Maintenance Officer’s Association (LMOA), 6047 South Mobile

Avenue, Chicago, IL 60638.

combustion, or a combination of all three.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2 A significant change in coagulated pentane insolubles

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

indicates a change in oil, and this could lead to lubrication

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. system problems.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7317–06

5.3 Coagulated pentane insolubles measurements can also 6.3 Oven, explosion-proof, capable of maintaining a tem-

assist in evaluating the performance characteristics of a used perature of 50 6 3°C.

oil or in determining the cause of equipment failure.

6.4 Oven, explosion-proof, capable of maintaining a tem-

perature of 100 6 3°C.

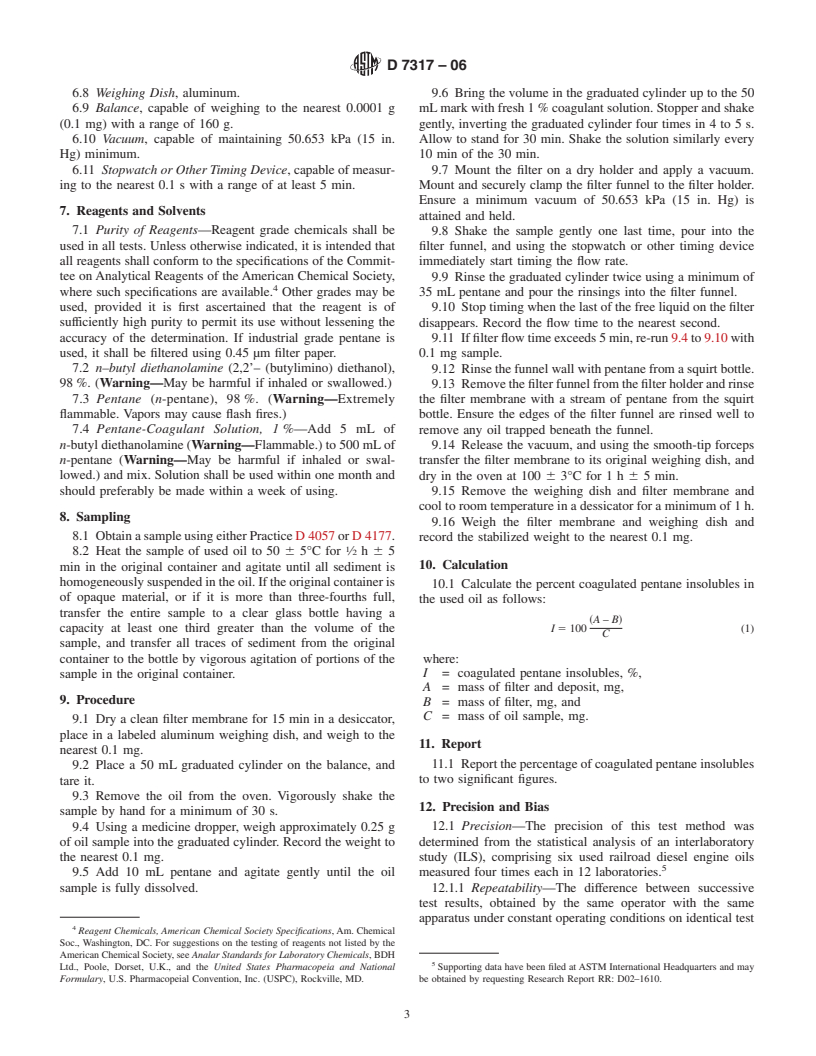

6. Apparatus (see Fig. 1)

6.5 Filtering Flask,1L.

6.1 Smooth-tip Forceps. 6.6 Filter Holders, borosilicate glass.

6.2 Graduated Cylinder, 50 mL with stopper. 6.7 Filter Membrane, 0.45 µm.

FIG. 1 Paper Filtration Apparatus

D7317–06

6.8 Weighing Dish, aluminum. 9.6 Bring the volume in the graduated cylinder up to the 50

6.9 Balance, capable of weighing to the nearest 0.0001 g mLmark with fresh 1 % coagulant solution. Stopper and shake

(0.1 mg) with a range of 160 g. gently, inverting the graduated cylinder four times in 4 to 5 s.

6.10 Vacuum, capable of maintaining 50.653 kPa (15 in. Allow to stand for 30 min. Shake the solution similarly every

Hg) minimum. 10 min of the 30 min.

6.11 Stopwatch or Other Timing Device, capable of measur- 9.7 Mount the filter on a dry holder and apply a vacuum.

ing to the nearest 0.1 s with a range of at least 5 min. Mount and securely clamp the filter funnel to the filter holder.

Ensure a minimum vacuum of 50.653 kPa (15 in. Hg) is

7. Reagents and Solvents

attained and held.

7.1 Purity of Reagents—Reagent grade chemicals shall be

9.8 Shake the sample gently one last time, pour into the

used in all tests. Unless otherwise indicated, it is intended that filter funnel, and using the stopwatch or other timing device

all reagents shall conform to the specifications of the Commit-

immediately start timing the flow rate.

tee onAnalytical Reagents of theAmerican Chemical Society, 9.9 Rinse the graduated cylinder twice using a minimum of

where such specifications are available. Other grades may be

35 mL pentane and pour the rinsings into the filter funnel.

used, provided it is first ascertained that the reagent is of 9.10 Stop timing when the last of the free liquid on the filter

sufficiently high purity to permit its use without lessening the disappears. Record the flow time to the nearest second.

accuracy of the determination. If industrial grade pentane is 9.11 Iffilterflowtimeexceeds5min,re-run9.4to9.10with

used, it shall be filtered using 0.45 µm filter paper. 0.1 mg sample.

7.2 n–butyl diethanolamine (2,2’– (butylimino) diethanol), 9.12 Rinsethefunnelwallwithpentanefromasquirtbottle.

98 %. (Warning—May be harmful if inhaled or swallowed.) 9.13 Removethefilterfunnelfromthefilterholderandrin

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.