ASTM D6958-20

(Test Method)Standard Test Methods for Evaluating Side-Bonding Potential of Wood Coatings

Standard Test Methods for Evaluating Side-Bonding Potential of Wood Coatings

SIGNIFICANCE AND USE

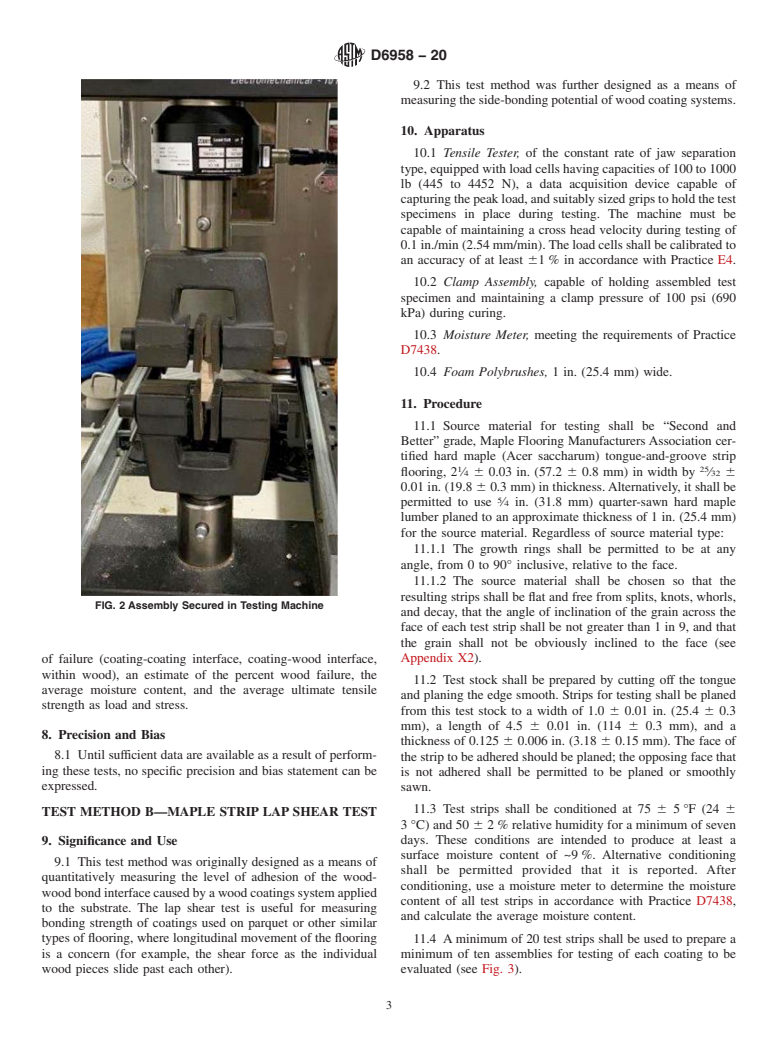

4.1 This test method was originally designed as a means of quantitatively measuring the level of adhesion of the wood-wood interface caused by a wood coatings system applied to the substrate. The tensile test is useful in measuring bonding strength of coatings, such as gymnasium coatings, in which the wood strip flooring primarily expands or contracts in response to changes across the cross-sectional width of the strip floor.

4.2 This test method was further designed as a means of measuring the side-bonding potential of wood coating systems.

SCOPE

1.1 These test methods describe an evaluation procedure for the determination of undesirable side-bonding of coatings for wood flooring. They provide two mechanical properties tests for the quantitative determination of the cohesive strength of wood coatings (tensile and lap shear).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6958 − 20

Standard Test Methods for

1

Evaluating Side-Bonding Potential of Wood Coatings

This standard is issued under the fixed designation D6958; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

4

1. Scope 2.3 National Wood Flooring Association (NWFA):

Technical Publication C200 Problems, Causes, and Cures

1.1 These test methods describe an evaluation procedure for

the determination of undesirable side-bonding of coatings for

3. Terminology

wood flooring. They provide two mechanical properties tests

for the quantitative determination of the cohesive strength of

3.1 Definitions—For general definitions of terms related to

wood coatings (tensile and lap shear).

wood, refer to Terminology D9.

1.2 The values stated in inch-pound units are to be regarded

3.2 Definitions of Terms Specific to This Standard:

as standard. The values given in parentheses are mathematical

3.2.1 panelization—condition caused by side-bonding, ex-

conversions to SI units that are provided for information only

cessive installation adhesive, substrate movement, or other

and are not considered standard.

factors where localized gaps develop between flooring strips

1.3 This standard does not purport to address all of the

while adjacent boards remain in tight contact acting as a

safety concerns, if any, associated with its use. It is the

composite panel instead of individual strips.

responsibility of the user of this standard to establish appro-

3.2.2 panelization failure—conditionwherelocalizedexces-

priate safety, health, and environmental practices and deter-

sive gaps beyond specified limits develop between some strip

mine the applicability of regulatory limitations prior to use.

flooring boards due to panelization.

1.4 This international standard was developed in accor-

3.2.3 percent wood failure—rupturing of wood fibers in

dance with internationally recognized principles on standard-

strength tests on bonded specimens usually expressed as the

ization established in the Decision on Principles for the

percentage of total area involved which shows such failure and

Development of International Standards, Guides and Recom-

is the inverse of adhesive failure.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

3.2.4 side-bonding—bonding of adjacent strips of wood

flooring caused by the floor coating resulting in panelization.

2. Referenced Documents

2 3.2.4.1 Discussion—Side-bonding is most commonly

2.1 ASTM Standards:

caused when installed wood flooring boards have become

D9 Terminology Relating to Wood and Wood-Based Prod-

adhered to each other. Finish materials, especially water-based

ucts

products, that have seeped between the boards, and the glue

D2370 Test Method for Tensile Properties of Organic Coat-

used on the flooring tongue-and-groove joint are two common

ings

sources of side-bonding. Side-bonding wood failure can occur

D7438 Practice for Field Calibration and Application of

as side-bonded flooring boards shrink due to loss of moisture

Hand-Held Moisture Meters

after installation.

E4 Practices for Force Verification of Testing Machines

3

2.2 Maple Flooring Manufacturers Association (MFMA): 3.2.5 side-bonding wood failure—failureofthewoodwithin

Grading Rules for MFMA Hard Maple a strip, as in classic wood failure, when the movement of the

strip within the floor is restrained from moisture-related

1

These test methods are under the jurisdiction of ASTM Committee D07 on movement by side-bonding and the resulting stress overcomes

Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental

thetensilestrengthperpendiculartothegrainofthewoodstrip.

Test Methods and Properties.

Current edition approved Oct. 1, 2020. Published October 2020. Originally

3.2.6 tensile stress (nominal)—as used in Test Method

approved in 2003. Last previous edition approved in 2014 as D6958 – 03 (2014).

D2370,theloadperoriginalunitareaatwhichaspecimenfails

DOI: 10.1520/D6958-20.

or yields in a tension (pull) test.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

4

3

Available from the Maple Flooring Manufacturers Association, Inc. (MFMA), Available from the National Wood Flooring Association (NWFA), 111 Ches-

1425 Tri State Parkway, Suite 110, Gurnee

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6958 − 03 (Reapproved 2014) D6958 − 20

Standard Test Methods for

1

Evaluating Side-Bonding Potential of Wood Coatings

This standard is issued under the fixed designation D6958; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods describe an evaluation procedure for the determination of undesirable side-bonding of coatings for wood

flooring. They provide two mechanical properties tests for the quantitative determination of the cohesive strength of wood coatings

(tensile and lap shear); they also provide a wood floor simulation test for the qualitative determination of side-bonding potential

of wood coatings.shear).

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D9 Terminology Relating to Wood and Wood-Based Products

D2370 Test Method for Tensile Properties of Organic Coatings

D4444D7438 Test Method for Laboratory Standardization and CalibrationPractice for Field Calibration and Application of

Hand-Held Moisture Meters

E4 Practices for Force Verification of Testing Machines

3

2.2 British Standards:

B.S. 1204 British Standard Test for Synthetic Resin Adhesives

1

These test methods are under the jurisdiction of ASTM Committee D07 on Wood and are the direct responsibility of Subcommittee D07.01 on Fundamental Test Methods

and Properties.

Current edition approved Aug. 1, 2014Oct. 1, 2020. Published August 2014October 2020. Originally approved in 2003. Last previous edition approved in 20092014 as

D6958 – 03 (2009).(2014). DOI: 10.1520/D6958-03R14.10.1520/D6958-20.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6958 − 20

3

2.2 Maple Flooring Manufacturers Association (MFMA):

Guide Specification for Double Plywood Floor System Grading Rules for MFMA Hard Maple

Guide Specification for Sleeper and Sleeper with Plywood Floor Systems

5

2.4 Wood Flooring Manufacturers Association (NOFMA):

Cracks in Hardwood Floors

4

2.3 National Wood Flooring Association (NWFA):

Hardwood Floors Trouble Shooting ManualTechnical Publication C200 Problems, Causes, and Cures

3. Terminology

3.1 Definitions—For general definitions of terms related to wood, refer to Terminology D9.

3.2 Definitions:Definitions of Terms Specific to This Standard:

3.1.1 Definitions used in these test methods are in accordance with terminology used in Terminology D9. A few related terms not

covered in these test methods are as follows:

3.2.1 panelization—adjacent boards condition caused by side-bonding, excessive installation adhesive, substrate movement, or

other factors where localized gaps develop between flooring strips while adjacent boards remain in tight contact acting as a

composite panel instead of individual strips when subjected to changes in temperature and humidity as well as other site

conditions.strips.

3.2.2 panelization failure—the condition where localized excessive gaps beyond specified limits develop between some strip

flooring boards due to panelization.

3.2.3 percent wood failure—the rupturing of wood fibers in strength tests on bonded specimens usually expressed as the

percentage of total area involved,involved which shows s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.