ASTM C144-02

(Specification)Standard Specification for Aggregate for Masonry Mortar

Standard Specification for Aggregate for Masonry Mortar

SCOPE

1.1 This specification covers aggregate for use in masonry mortar.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following precautionary caveat pertains only to the methods portion, Section 7, of this standard. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

American Association State Highway and Transportation Officials Standard

Designation: C 144 – 02 AASHTO No.: M45-70 (1974)

Standard Specification for

1

Aggregate for Masonry Mortar

This standard is issued under the fixed designation C 144; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

4

1. Scope* D 75 Practice for Sampling Aggregates

1.1 This specification covers aggregate for use in masonry

3. Materials and Manufacture

mortar.

3.1 Aggregate for use in masonry mortar shall consist of

1.2 The values stated in SI units are to be regarded as the

natural sand or manufactured sand. Manufactured sand is the

standard. The values given in parentheses are for information

product obtained by crushing stone, gravel, or air-cooled iron

only.

blast-furnace slag specially processed to ensure suitable gra-

1.3 The following precautionary caveat pertains only to the

dation.

test methods portion, Section 7, of this standard. This standard

does not purport to address all of the safety problems, if any,

NOTE 1—Care should be taken to ensure a suitable particle shape, since

associated with its use. It is the responsibility of the user of this excessive quantities of flat and elongated particles have historically caused

problems with workability.

standard to establish appropriate safety and health practices

and determine the applicability of regulatory limitations prior

4. Grading

to use.

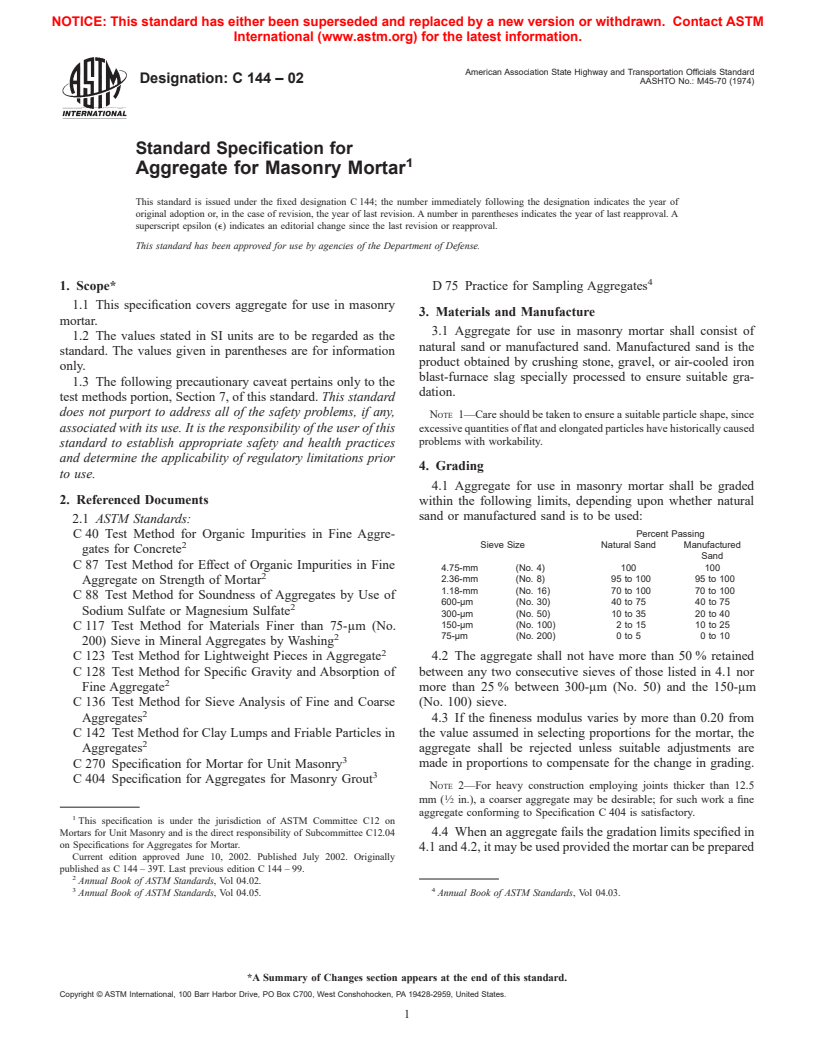

4.1 Aggregate for use in masonry mortar shall be graded

2. Referenced Documents

within the following limits, depending upon whether natural

sand or manufactured sand is to be used:

2.1 ASTM Standards:

Percent Passing

C 40 Test Method for Organic Impurities in Fine Aggre-

2 Sieve Size Natural Sand Manufactured

gates for Concrete

Sand

C 87 Test Method for Effect of Organic Impurities in Fine

4.75-mm (No. 4) 100 100

2

2.36-mm (No. 8) 95 to 100 95 to 100

Aggregate on Strength of Mortar

1.18-mm (No. 16) 70 to 100 70 to 100

C 88 Test Method for Soundness of Aggregates by Use of

600-μm (No. 30) 40 to 75 40 to 75

2

Sodium Sulfate or Magnesium Sulfate

300-μm (No. 50) 10 to 35 20 to 40

150-μm (No. 100) 2 to 15 10 to 25

C 117 Test Method for Materials Finer than 75-μm (No.

75-μm (No. 200) 0 to 5 0 to 10

2

200) Sieve in Mineral Aggregates by Washing

2

C 123 Test Method for Lightweight Pieces in Aggregate 4.2 The aggregate shall not have more than 50 % retained

C 128 Test Method for Specific Gravity and Absorption of between any two consecutive sieves of those listed in 4.1 nor

2

Fine Aggregate more than 25 % between 300-μm (No. 50) and the 150-μm

C 136 Test Method for Sieve Analysis of Fine and Coarse (No. 100) sieve.

2

Aggregates 4.3 If the fineness modulus varies by more than 0.20 from

C 142 Test Method for Clay Lumps and Friable Particles in the value assumed in selecting proportions for the mortar, the

2

Aggregates aggregate shall be rejected unless suitable adjustments are

3

C 270 Specification for Mortar for Unit Masonry made in proportions to compensate for the change in grading.

3

C 404 Specification for Aggregates for Masonry Grout

NOTE 2—For heavy construction employing joints thicker than 12.5

1

mm ( ⁄2 in.), a coarser aggregate may be desirable; for such work a fine

aggregate conforming to Specification C 404 is satisfactory.

1

This specification is under the jurisdiction of ASTM Committee C12 on

4.4 When an aggregate fails the gradation limits specified in

Mortars for Unit Masonry and is the direct responsibility of Subcommittee C12.04

on Specifications for Aggregates for Mortar.

4.1 and 4.2, it may be used provided the mortar can be prepared

Current edition approved June 10, 2002. Published July 2002. Originally

published as C 144 – 39T. Last previous edition C 144 – 99.

2

Annual Book of ASTM Standards, Vol 04.02.

3 4

Annual Book of ASTM Standards, Vol 04.05. Annual Book of ASTM Standards, Vol 04.03.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

C144–02

to comply with the aggregate ratio, water retention, and limitations set forth in Section 4, not greater than 10 % when

compressive strength requirements of the property specifica- sodium sulfate is used or 15 % when magnesium sulfate is

tions of Specificati

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.