ASTM D1143-81(1994)e1

(Test Method)Standard Test Method for Piles Under Static Axial Compressive Load (Withdrawn 2006)

Standard Test Method for Piles Under Static Axial Compressive Load (Withdrawn 2006)

SCOPE

1.1 This test method covers procedures for testing vertical or batter piles individually or groups of vertical piles to determine response of the pile or pile group to a static compressive load applied axially to the pile or piles within the group. This test method is applicable to all deep foundation units that function in a manner similar to piles regardless of their method of installation. This test method is divided into the following sections: Section Referenced Documents 2 Apparatus for Applying Loads 3 Apparatus for Measuring Movements 4 Loading Procedures 5 Procedures for Measuring Pile Movements 6 Safety Requirements 7 Report 8 Precision and Bias 9

1.2 The values stated in inch-pound units are to be regarded as the standard. Note 1-Apparatus and procedures designated "optional" are to be required only when included in the project specifications or if not specified, may be used only with the approval of the engineer responsible for the foundation design. The word "shall" indicates a mandatory provision and "should" indicates a recommended or advisory provision. Imperative sentences indicate mandatory provisions. Notes, illustrations, and appendixes included herein are explanatory or advisory. Note 2-This test method does not include the interpretation of test results or the application of test results to foundation design. See Appendix XI for comments regarding some of the factors influencing the interpretation of test results. A qualified geotechnical engineer should interpret the test results for predicting pile performance and capacity. The term "failure" as used in this method indicates rapid progressive settlement of the pile or pile group under a constant load.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers procedures for testing vertical or batter piles individually or groups of vertical piles to determine response of the pile or pile group to a static compressive load applied axially to the pile or piles within the group.

Formerly under the jurisdiction of Committee D18 on Soil and Rock, this practice was withdrawn in May 2005 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D1143–81 (Reapproved 1994)

Standard Test Method for

Piles Under Static Axial Compressive Load

This standard is issued under the fixed designation D 1143; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section 10 was added editorially in May 1994.

INTRODUCTION

This standard has been prepared to cover routine methods of testing to determine if a pile has

adequate bearing capacity. The provisions permit the introduction of more detailed requirements and

procedures when required to satisfy the objectives of the test program. While the procedures herein

produce a relationship between applied load and pile settlement, the results may not represent

long-term performance.

interpretation of test results. A qualified geotechnical engineer should

1. Scope

interpret the test results for predicting pile performance and capacity. The

1.1 This test method covers procedures for testing vertical

term “failure” as used in this method indicates rapid progressive settle-

or batter piles individually or groups of vertical piles to

ment of the pile or pile group under a constant load.

determine response of the pile or pile group to a static

1.3 This standard does not purport to address all of the

compressive load applied axially to the pile or piles within the

safety concerns, if any, associated with its use. It is the

group. This test method is applicable to all deep foundation

responsibility of the user of this standard to establish appro-

units that function in a manner similar to piles regardless of

priate safety and health practices and determine the applica-

theirmethodofinstallation.Thistestmethodisdividedintothe

bility of regulatory limitations prior to use.

following sections:

Section

2. Referenced Documents

Referenced Documents 2

Apparatus for Applying Loads 3 2.1 ASTM Standards:

Apparatus for Measuring Movements 4

D 3689 Method of Testing Individual Piles Under Static

Loading Procedures 5

Axial Tensile Load

Procedures for Measuring Pile Movements 6

2.2 American National Standards Institute Standard:

Safety Requirements 7

Report 8

B30.1 Safety Code for Jacks

Precision and Bias 9

3. Apparatus forApplying Loads

1.2 The values stated in inch-pound units are to be regarded

as the standard.

3.1 General:

3.1.1 The apparatus for applying compressive loads to the

NOTE 1—Apparatus and procedures designated “optional” are to be

test pile or pile group shall be as described in 3.3, 3.4, or 3.5

required only when included in the project specifications or if not

or as otherwise specified and shall be constructed so that the

specified, may be used only with the approval of the engineer responsible

for the foundation design. The word “shall” indicates a mandatory loads are applied to the central longitudinal axis of the pile or

provision and “should” indicates a recommended or advisory provision.

pile group to minimize eccentric loading. Paragraph 3.3 is

Imperative sentences indicate mandatory provisions. Notes, illustrations,

suitable for applying axial loads to individual vertical or batter

and appendixes included herein are explanatory or advisory.

piles; 3.4 and 3.5 are suitable for applying vertical loads only.

NOTE 2—This test method does not include the interpretation of test

results or the application of test results to foundation design. See

NOTE 3—When a pile group is subject to vertical test loads, cap

Appendix X1 for comments regarding some of the factors influencing the

rotations and horizontal displacements could occur. The occurrence of

such movements and the necessary reactions to resist such movements if

This test method is under the jurisdiction of ASTM Committee D-18 on Soil

and Rock and is the direct responsibility of Subcommittee D18.11 on Deep

Foundations. Annual Book of ASTM Standards, Vol 04.08.

Current edition approved March 2, 1981. Published May 1981. Originally Available from American National Standards Institute, 1430 Broadway, New

published as D 1143 – 50 T. Last previous edition D 1143 – 74. York, NY 10018.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D1143

they are prohibited should be considered when designing and constructing

alternatively, the test beam(s) may be set directly on the pile

the loading apparatus for the group test.

cap or the loading material applied directly on the cap. Test

NOTE 4—If it is not feasible to apply axial test loads to a batter pile, the

beam(s) set directly on the cap shall obtain full bearing using

results of a test on a similar nearby vertical pile generally may be used to

high-strength quick-setting grout, if necessary.

evaluate the axial bearing capacity of the batter pile.

3.2 Testing Equipment:

3.1.2 Where feasible, the immediate area of the test pile or

3.2.1 Hydraulic jacks including their operation shall con-

pile group shall be excavated to the proposed pile cut-off

form to ANSI B30.1.

elevation. The test pile(s) shall be cut off or built up to the

3.2.2 Unless a calibrated load cell(s) is used, the complete

proper grade as necessary to permit construction of the

jacking system including the hydraulic jack(s), hydraulic

load-application apparatus, placement of the necessary testing,

pump, and pressure gage shall be calibrated as a unit before

and instrumentation equipment, and observation of the instru-

each test or series of tests in a test program to an accuracy of

mentation. Where necessary, the unsupported length of the test

not less than 5 % of the applied load. The hydraulic jack(s)

pile(s) shall be braced to prevent buckling without influencing

shall be calibrated over its complete range of ram travel for

the test results.

increasing and decreasing applied loads. If two or more jacks

3.1.3 If the head of the pile has been damaged during

are to be used to apply the test load, they shall be of the same

driving, the damaged portion shall be removed prior to the test.

ram diameter, connected to a common manifold and pressure

For tests on piles groups, the piles shall be capped with a

gage, and operated by a single hydraulic pump.

reinforced concrete cap designed and constructed in accor-

dance with accepted engineering practice for the anticipated NOTE 6—If it is not feasible to calibrate the complete jacking system as

a unit, the pressure gage may be calibrated independently, in which case

loads.

the jack piston(s) should be measured to verify the area(s).

NOTE 5—Consideration should be given to providing a nominal clear

3.2.3 When an accuracy greater than that obtainable with

space between the cap and the ground surface to eliminate any support

offered by the soil under short-term loading. A properly constructed steel the jacking system is required, a properly constructed load

grillage may serve as an adequate pile cap for testing purposes.

cell(s) or equivalent device(s) shall be used in series with the

hydraulic jack(s). Load cell(s) or equivalent device(s) shall be

3.1.4 In 3.3 and 3.4 and for a test on an individual pile in

calibrated prior to the test to an accuracy of not less than 2 %

3.5, a steel bearing plate(s) (test plate(s)) of sufficient thickness

of the applied load and shall be equipped with a spherical

to prevent it from bending under the loads involved (but not

lessthan2in.(50mm))shallbecenteredonthepileorpilecap bearing(s).

andsetperpendiculartothelongitudinalaxisofthepileorpiles 3.2.4 If the hydraulic jack pump is to be left unattended at

within the group, except that for tests on pile groups involving any time during the test, it shall be equipped with an automatic

theuseoftwoormoreseparateloadingpoints,atestplateshall regulator to hold the load constant as pile settlement occurs.

be used at each loading point and such plates shall be arranged 3.2.5 Calibration reports shall be furnished for all testing

symmetrically about the centroid of the group. For tests on equipment for which calibration is required, and shall show the

individual piles, the size of the test plate shall be not less than temperature at which the calibration was done.

the size of the pile butt nor less than the area covered by the

NOTE 7—Considerations should be given to employing a dual load-

base(s) of the hydraulic jack(s); for tests on pile groups, the

measuring system (gage and load cell) to provide as a check and as a

size of the test plate(s) shall be not less than twice the area

back-up in case one system malfunctions. Hydraulic jack rams should

covered by the base(s) of the hydraulic jack(s).

have sufficient travel to provide for anticipated pile settlements, deflec-

tions of the test beam, and elongation of connections to anchoring devices

3.1.5 For tests on precast or cast-in-place concrete piles or

with 3.3. The use of a single high-capacity jack is preferred to the use of

on pile groups, the test plate when used shall be set in

multiple jack(s). If a multiple jacking system is used, each jack should be

high-strength quick-setting grout. For tests on individual steel

fitted with a pressure gage (in addition to the master gage) in order to

H-piles, the test plate shall be welded to the pile. For tests on

detect malfunctions.

individual timber piles, the test plate may be set directly on the

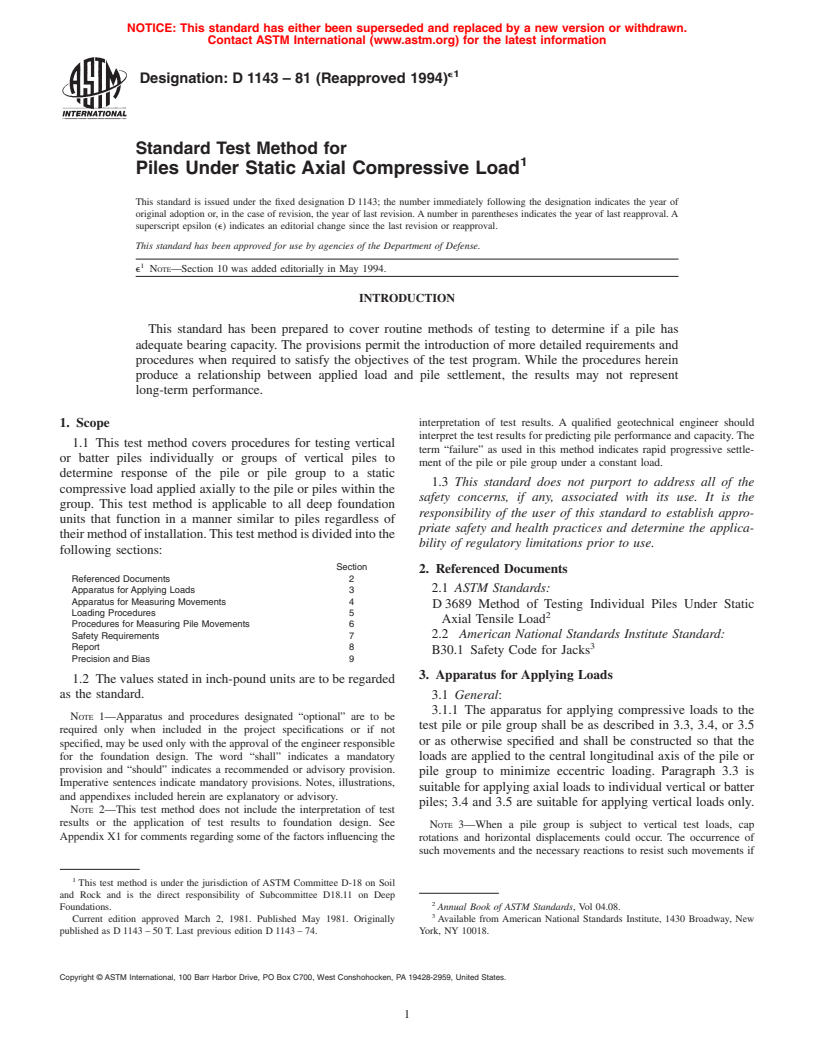

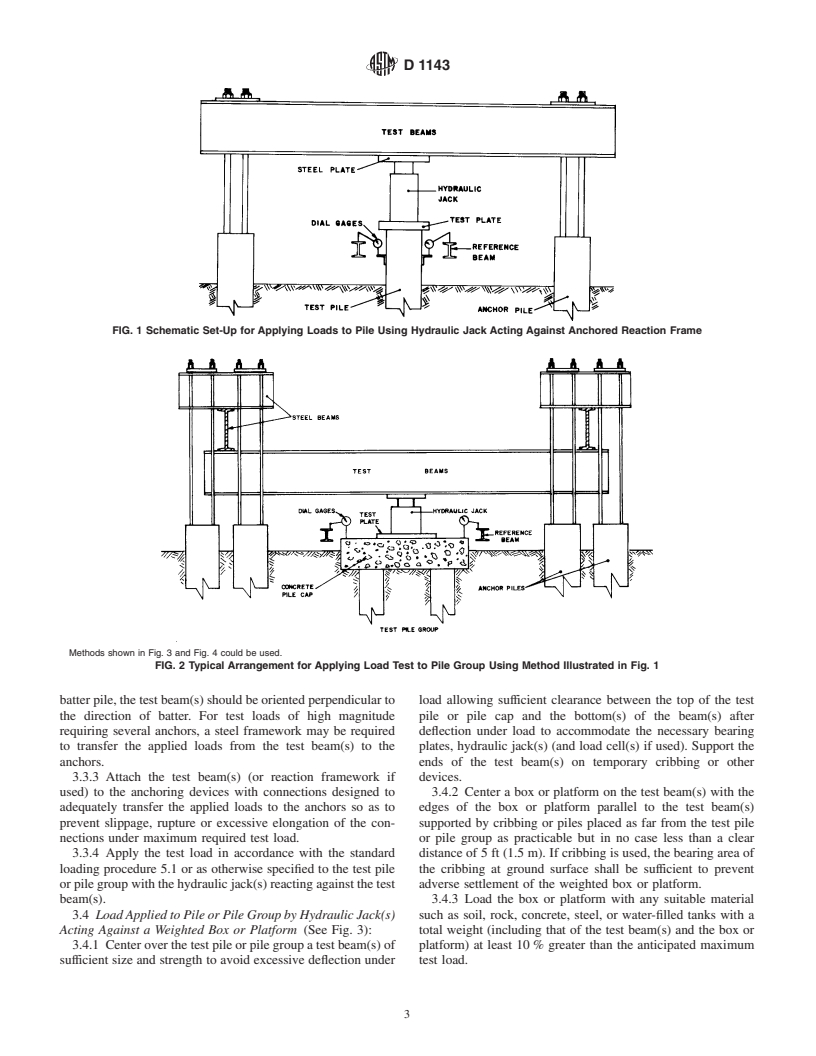

3.3 LoadAppliedtoPileorPileGroupbyHydraulicJack(s)

top of the pile which shall be sawed off to provide full bearing

ActingAgainstAnchored Reaction Frame (See Fig. 1 and Fig.

for the test plate or, alternatively, the test plate may be set in

2):

high-strength quick-setting grout.

3.1.6 In 3.3 and 3.4, the hydraulic jack(s) shall be centered 3.3.1 Install a sufficient number of anchor piles or suitable

anchoring device(s) so as to provide adequate reactive capacity

on the test plate(s) with a steel bearing plate of adequate

thickness between the top(s) of the jack ram(s) and the and a clear distance from the test pile or pile group at least five

times the maximum diameter of the largest anchor or test

bottom(s) of the test beam(s). If a load cell(s) or equivalent

device(s) is to be used, it shall be centered on the bearing plate pile(s) but not less than 7 ft (2 m). When testing individual

batter piles, the anchor piles shall be battered in the same

above the ram(s) with another steel bearing plate of sufficient

thickness between the load cell(s) or equivalent device(s) and direction and angle as the test pile.

the bottom(s) of the test beam(s). Bearing plates shall be of 3.3.2 Center over the test pile or pile group a test beam(s) of

sufficient size to accommodate the jack ram(s) and the load sufficient size and strength to avoid excessive deflection under

cell(s) or equivalent device(s) and properly bear against the load with sufficient clearance between the bottom flange(s) of

bottom(s) of the test beam(s). the test beam(s) and the top of the test pile or pile group to

3.1.7 In 3.5 for tests on pile groups a test plate may be used provide for the necessary bearing plates, hydraulic jack(s) (and

in accordance with the appropriate provisions of 3.1 or, loadcell(s)ifused).Whenapplyingaxialloadstoanindividual

D1143

FIG. 1 Schematic Set-Up for Applying Loads to Pile Using Hydraulic Jack Acting Against Anchored Reaction Frame

Methods shown in Fig. 3 and Fig. 4 could be used.

FIG. 2 Typical Arrangement for Applying Load Test to Pile Group Using Method Illustrated in Fig. 1

batter pile, the test beam(s) should be oriented perpendicular to load allowing sufficient clearance between the top of the test

the direction of batter. For test loads of high magnitude pile or pile cap and the bottom(s) of the beam(s) after

requiring several anchors, a steel framework may be required deflection under load to accommodate the necessary bearing

to transfer the applied loads from the test beam(s) to the plates, hydraulic jack(s) (and load cell(s) if used). Support the

anchors. ends of the test beam(s) on temporary cribbing or other

3.3.3 Attach the test beam(s) (or reaction framework if devices.

used) to the anchoring devices with connections designed to 3.4.2 Center a box or platform on the test beam(s) with the

adequately transfer the applied loads to the anchors so as to edges of the box or platform parallel to the test beam(s)

prevent slippage, rupture or excessive elongation of the con- supported by cribbing or piles placed as far from the test pile

nections under maximum required test load. or pile group as practicable but in no case less than a clear

3.3.4 Apply the test load in accordance with the standard distance of 5 ft (1.5 m). If cribbing is used, the bearing area of

loading procedure 5.1 or as otherwise specified to the test pile the cribbing at ground surface shall be sufficient to prevent

or pile group with the hydraulic jack(s) reacting against the test adverse settlement of the weighted box or platform.

beam(s). 3.4.3 Load the box or platform with any suitable material

3.4 LoadAppliedtoPileorPileGroupbyHydraulicJack(s) such as soil, rock, concrete, steel, or water-filled tanks with a

Acting Against a Weighted Box or Platform (See Fig. 3): total weight (including that of the test beam(s) and the box or

3.4.1 Center over the test pile or pile group a test beam(s) of platform) at least 10 % greater than the anticipated maximum

sufficient size and strength to avoid excessive deflection under test load.

D1143

FIG. 3 Schematic Set-Up for Applying Loads to Pile Using Hydraulic Jack Acting Against Weighted Box or Platform

3.4.4 Apply the test loads to the pile or pile group in 3.5.3 Place sufficient pairs of timber wedges between the

accordance with the standard procedure in 5.1 or as otherwise top of the cribbing or timber cap beams and the bottom edges

specified with the hydraulic jack(s) reacting against the test of the platform so that the platform can be stabilized during

beam(s). loading or unloading.

3.5 Load Applied Directly to the Pile or Pile Group with

3.5.4 When ready to load the platform, remove any tempo-

Known Weights (See Fig. 4, Fig. 5, and Fig. 6):

rary supports at the ends of the test beam(s) and tighten the

3.5.1 Center on the test plate or pile cap a test beam(s) of

wedges along the bottom edges of the platform so that the

known weight and of sufficient size and strength to avoid

platform is stable. Load the platform in accordance with the

excessive deflection under load with the ends supported on

standard loa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.