ASTM F2885-17(2023)

(Specification)Standard Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications

Standard Specification for Metal Injection Molded Titanium-6Aluminum-4Vanadium Components for Surgical Implant Applications

SCOPE

1.1 This specification covers chemical, mechanical, and metallurgical requirements for two types of metal injection molded (MIM) titanium-6aluminum-4vanadium components to be used in the manufacture of surgical implants.

1.2 The Type 1 MIM components covered by this specification may have been densified beyond their as-sintered density by post sinter processing.

1.3 Units—The values in either inch-pound or SI are to be regarded separately as standard. The values stated in each system may not be exact equivalents; therefore, each system shall be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2885 − 17 (Reapproved 2023)

Standard Specification for

Metal Injection Molded Titanium-6Aluminum-4Vanadium

1

Components for Surgical Implant Applications

This standard is issued under the fixed designation F2885; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B923 Test Method for Metal Powder Skeletal Density by

Helium or Nitrogen Pycnometry

1.1 This specification covers chemical, mechanical, and

E3 Guide for Preparation of Metallographic Specimens

metallurgical requirements for two types of metal injection

E8/E8M Test Methods for Tension Testing of Metallic Ma-

molded (MIM) titanium-6aluminum-4vanadium components

terials

to be used in the manufacture of surgical implants.

E29 Practice for Using Significant Digits in Test Data to

1.2 The Type 1 MIM components covered by this specifi-

Determine Conformance with Specifications

cation may have been densified beyond their as-sintered

E165/E165M Practice for Liquid Penetrant Testing for Gen-

density by post sinter processing.

eral Industry

1.3 Units—The values in either inch-pound or SI are to be E407 Practice for Microetching Metals and Alloys

E539 Test Method for Analysis of Titanium Alloys by

regarded separately as standard. The values stated in each

system may not be exact equivalents; therefore, each system Wavelength Dispersive X-Ray Fluorescence Spectrometry

E1409 Test Method for Determination of Oxygen and Nitro-

shall be used independent of the other. Combining values from

the two systems may result in nonconformance with the gen in Titanium and Titanium Alloys by Inert Gas Fusion

E1447 Test Method for Determination of Hydrogen in Re-

specification.

active Metals and Reactive Metal Alloys by Inert Gas

1.4 This standard does not purport to address all of the

Fusion with Detection by Thermal Conductivity or Infra-

safety concerns, if any, associated with its use. It is the

red Spectrometry

responsibility of the user of this standard to establish appro-

E1941 Test Method for Determination of Carbon in Refrac-

priate safety, health, and environmental practices and deter-

tory and Reactive Metals and Their Alloys by Combustion

mine the applicability of regulatory limitations prior to use.

Analysis

1.5 This international standard was developed in accor-

E2371 Test Method for Analysis of Titanium and Titanium

dance with internationally recognized principles on standard-

Alloys by Direct Current Plasma and Inductively Coupled

ization established in the Decision on Principles for the

Plasma Atomic Emission Spectrometry (Performance-

Development of International Standards, Guides and Recom-

Based Test Methodology)

mendations issued by the World Trade Organization Technical

E2626 Guide for Spectrometric Analysis of Reactive and

Barriers to Trade (TBT) Committee.

3

Refractory Metals (Withdrawn 2017)

F601 Practice for Fluorescent Penetrant Inspection of Me-

2. Referenced Documents

tallic Surgical Implants

2

2.1 ASTM Standards:

F629 Practice for Radiography of Cast Metallic Surgical

B243 Terminology of Powder Metallurgy

Implants

B311 Test Method for Density of Powder Metallurgy (PM)

F1108 Specification for Titanium-6Aluminum-4Vanadium

Materials Containing Less Than Two Percent Porosity

Alloy Castings for Surgical Implants (UNS R56406)

F1472 Specification for Wrought Titanium-6Aluminum-

4Vanadium Alloy for Surgical Implant Applications (UNS

1

This specification is under the jurisdiction of ASTM Committee F04 on

R56400)

Medical and Surgical Materials and Devices and is the direct responsibility of

IEEE/ASTM SI 10 American National Standard for Use of

Subcommittee F04.12 on Metallurgical Materials.

the International System of Units (SI): The Modern Metric

Current edition approved Feb. 1, 2023. Published February 2023. Originally

approved in 2011. Last previous edition approved in 2017 as F2885 – 17. DOI: System

10.1520/F2885-17R23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on www.ast-

the ASTM website. m.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2885 − 17 (2023)

4

2.2 ISO Standards: mixing meta

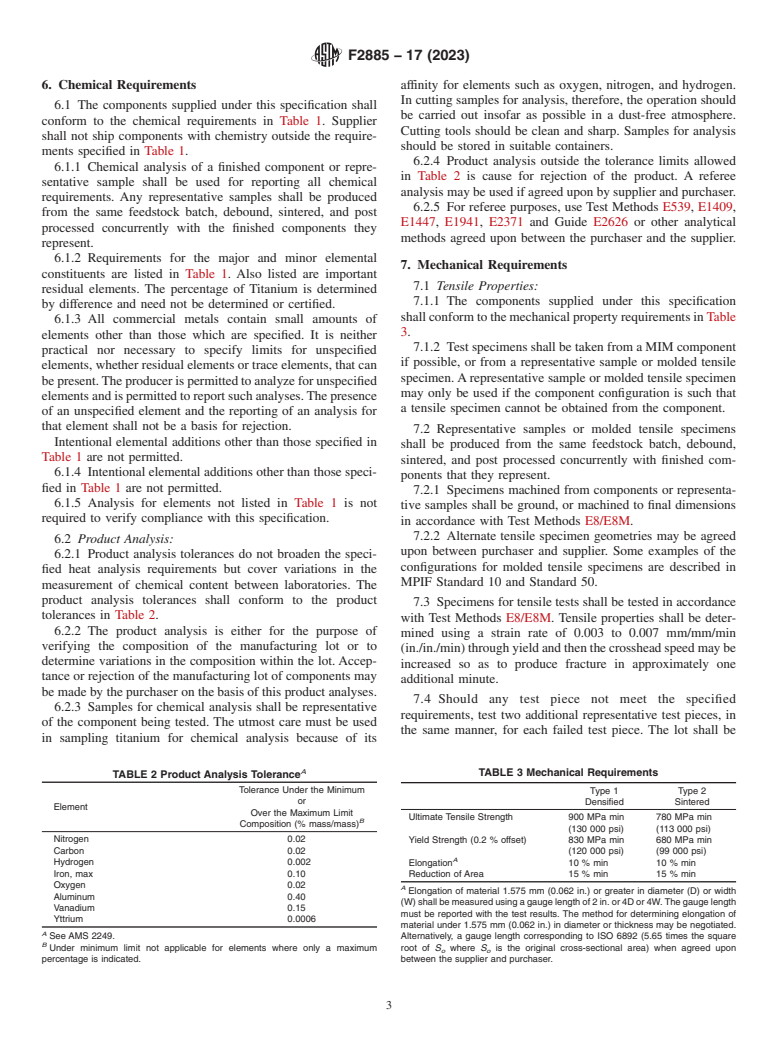

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.