ASTM D6159-97

(Test Method)Standard Test Method for Determination of Hydrocarbon Impurities in Ethylene by Gas Chromatography

Standard Test Method for Determination of Hydrocarbon Impurities in Ethylene by Gas Chromatography

SCOPE

1.1 This test method is used for the determination of methane, ethane, propane, propene, acetylene, iso-butane, propadiene, butane, trans-2-butene, butene-1, isobutene, cis-2-butene, methyl acetylene and 1,3-butadiene in high-purity ethylene. The purity of the ethylene can be calculated by subtracting the total percentage of all impurities from 100.00 %. Since this test method does not determine all possible impurities such as CO, CO2, H2O, alcohols, nitrogen oxides, and carbonyl sulfide, as well as hydrocarbons higher than decane, additional tests may be necessary to fully characterize the ethylene sample.

1.2 Data are reported in this test method as ppmV (parts per million by volume). This test method was evaluated in an interlaboratory cooperative study in the concentration range of 4 to 340 ppmV (2 to 204 mg/kg). The participants in the interlaboratory cooperative study reported the data in non-SI units. Wherever possible, SI units are included.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

Designation: D 6159 – 97

Standard Test Method for

Determination of Hydrocarbon Impurities in Ethylene by Gas

Chromatography

This standard is issued under the fixed designation D 6159; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope graph is provided with a 6–port sampling valve and two wide

bore capillary columns connected in series. These columns are

1.1 This test method is used for the determination of

a dimethyl silicone column and a (porous layer open tubular

methane, ethane, propane, propene, acetylene, iso-butane,

column (PLOT) Al O /KCl column. A flame ionization detec-

2 3

propadiene, butane, trans-2-butene, butene-1, isobutene, cis-2-

tor is used for detection. The integrated detector signal (peak

butene, methyl acetylene and 1,3-butadiene in high-purity

areas) are corrected for detector response. The hydrocarbon

ethylene. The purity of the ethylene can be calculated by

impurities are determined and the total impurities are used to

subtracting the total percentage of all impurities from 100.00

determine the ethylene content.

%. Since this test method does not determine all possible

impurities such as CO, CO ,H O, alcohols, nitrogen oxides,

2 2

4. Significance and Use

and carbonyl sulfide, as well as hydrocarbons higher than

4.1 High-purity ethylene is required as a feedstock for some

decane, additional tests may be necessary to fully characterize

manufacturing processes and the presence of trace amounts of

the ethylene sample.

certain hydrocarbon impurities can have deleterious effects.

1.2 Data are reported in this test method as ppmV (parts per

This test method is suitable for setting specifications, for use as

million by volume). This test method was evaluated in an

an internal quality control tool, and for use in development or

interlaboratory cooperative study in the concentration range of

research work.

4 to 340 ppmV (2 to 204 mg/kg). The participants in the

4.2 This test method does not detect such impurities as H O,

interlaboratory cooperative study reported the data in non-SI

CO, CO , and alcohols that may be present in the sample.

units. Wherever possible, SI units are included.

Hydrocarbons higher than n-decane cannot be analyzed by this

1.3 This standard dose not purport to address all of the

test method, if present in the sample. Test Method D 2504

safety concerns, if any, associated with its use. It is the

addresses the analysis of noncondensable gases and Test

responsibility of the user of this standard to establish appro-

Method D 2505 addresses the analysis of CO . Guide D 5234

priate safety and health practices and determine the applica-

describes all potential impurities present in ethylene. These

bility of regulatory limitations prior to use.

standards should be consulted when determining the total

2. Referenced Documents concentration of impurities in ethylene.

2.1 ASTM Standards:

5. Apparatus

D 2504 Test Method for Noncondensable Gases in C and

2 5.1 Gas Chromatograph (GC), a gas chromatographic in-

Lighter Hydrocarbon Products by Gas Chromatography

strument provided with a temperature programmable column

D 2505 Test Method for Ethylene, Other Hydrocarbons, and

oven and a flame ionization detector (FID). Regulate the carrier

Carbon Dioxide in High-Purity Ethylene by Gas Chroma-

2 gas by pressure control.

tography

3 5.2 Detector—Use a flame ionization detector (FID) having

D 5234 Guide for Analysis of Ethylene Product

a sensitivity of approximately 2.0 ppmV (1.2 mg/kg) or less for

3. Summary of Test Method the compounds listed in 1.1. An FID was exclusively used in

the interlaboratory cooperative study.

3.1 A gaseous ethylene sample is analyzed as received. The

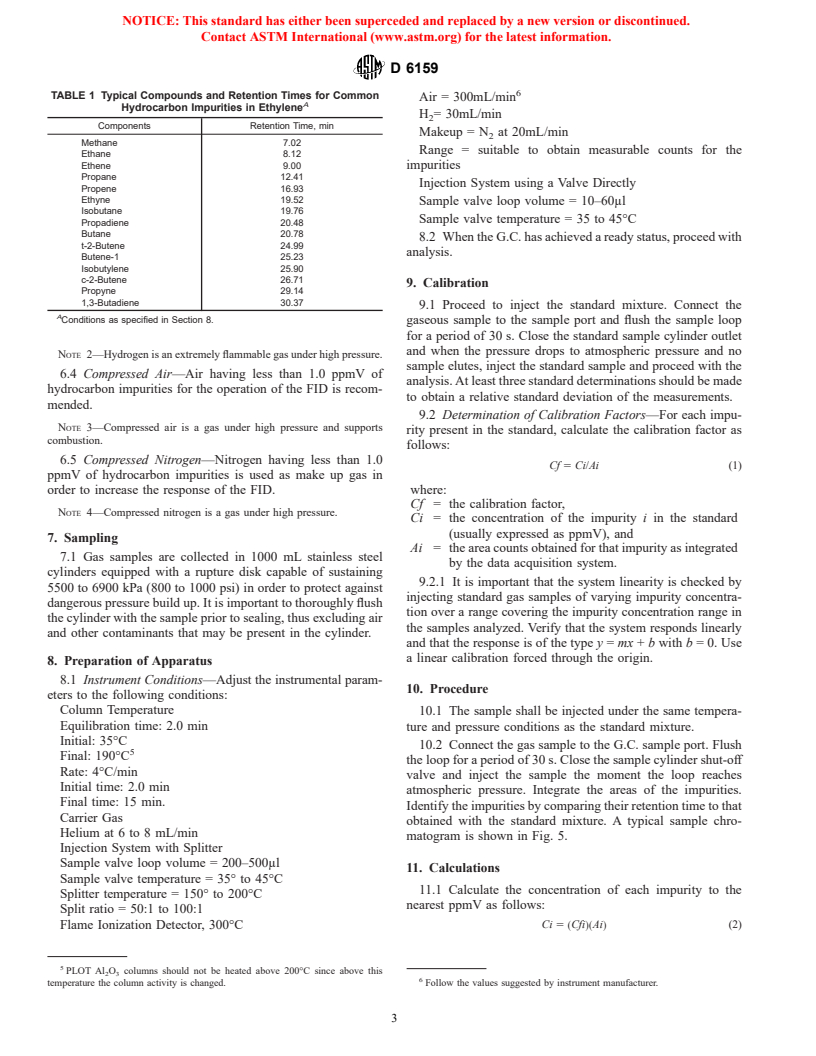

5.3 Column Temperature Programmer—The chromato-

gaseous sample is injected into a capillary gas chromatograph.

graph shall be capable of linear programmed temperature

A split-injector may or may not be used. The gas chromato-

operation over a range sufficient for separation of the compo-

nents of interest. Section 8 lists the recommended operating

This test method is under the jurisdiction of ASTM Committee D02 on

conditions. The programming rate shall be sufficiently repro-

Petroleum Products and Lubricantsand is the direct responsibility of D02.D on

ducible to obtain retention repeatability of 0.05 min (3 s)

Hydrocarbons for Chemical and Special Uses.

Current edition approved July 10, 1997. Published September 1997.

Annual Book of ASTM Standards, Vol 05.01.

3 4

Annual Book of ASTM Standards, Vol 05.03. This column is supplied by major column manufacturers.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6159

throughout the scope of this analysis.

5.4 Columns—Couple the two columns in series with either

a glass press tight connector or a mini-connector equipped with

graphite ferrules.

5.4.1 Column 1, 50 m, 0.53 mm inside diameter (ID) KCl

deactivated Al O PLOT column. Relative retention is depen-

2 3

dent on the deactivation method of the column. Other deacti-

vated Al O plot columns using sulfates as the deactivating

2 3

agent were also used in the interlaboratory comparison.

5.4.2 Column 2, 30 m, 0.53 mm ID, 5μm film thickness

methyl silicone. This column improves the separation of

methyl acetylene, iso-pentane, and n-pentane.

5.5 Sample Inlet System—Two injection modes were used

FIG. 2 Valve On – Injection

for the interlaboratory cooperative study.

5.5.1 A gas sampling valve placed in an unheated zone of

the gas chromatograph injecting the sample directly into the

column.

5.5.2 A gas sampling valve placed in an unheated zone of

the gas chromatograph in conjunction with a splitter injector

heated with a variable temperature control.

5.6 Gas Sampling Valve and Injection System—Use a 6-port

valve provided with ⁄16 in. fittings as the sample injection

system. A typical valve arrangement is shown in Fig. 1 and Fig.

2. Use a 10–60μL loop as shown in Fig. 1. Use good valve

maintenance techniques to avoid such problems as dead

volumes, cold spots, long connections, and non-uniform heated

zones. The preferred carrier gas arrangement for sample

introduction is pressure regulation. Use a 6-port valve in

conjunction with a splitter injector. A typical arrangement is FIG. 3 Valve Off – Sample Loading

shown in Fig. 3 and Fig. 4. Use split ratios of 50:1 to 100:1 at

temperatures of 150°C to 200°C. Loop sizes of 200–500μL

were used in the interlaboratory study. When using a splitter it

is important to check linearity of the splitter. Inject the standard

blend at 50:1, 75:1, and 100:1 split ratios. Check the response

factors as determined in 9.1, and the factors shall not vary more

than 3 %.

5.7 Data Acquisition System—Use any integrator or com-

puterized data acquisition system for peak area integration, as

well as for recording the chromatographic trace.

6. Reagent Materials

6.1 Standard Mixture—Use a gravimetrically blended gas

standard containing levels of 2 to 204 mg/kg (4 to 340 ppmV)

FIG. 4 Valve On – Injection

of each of the trace components listed in Table 1 to calibrate

the detector’s response. The standard gas mixture shall be

prepared gravimetrically from known raw materials, and cross

contaminants shall be taken into account. The mixtures should

be certified analytically such that the gravimetric and analyti-

cally derived values agree to an acceptable tolerance; that is 6

1or 6 2 %. The concentration of the minor components in the

calibration standard shall be within 20 to 50 % above the

concentration of the process stream or samples.

6.2 Compressed Helium, gas having purity of 99.999 %, or

better, with a total hydrocarbon level of < 1ppmV.

NOTE 1—Compressed helium is a gas under high pressure.

6.3 Compressed Hydrogen, gas used as fuel in the FID

FIG. 1 Valve Off – Sample Loading detector (less than 1.0 ppmV hydrocarbon impurities).

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

D 6159

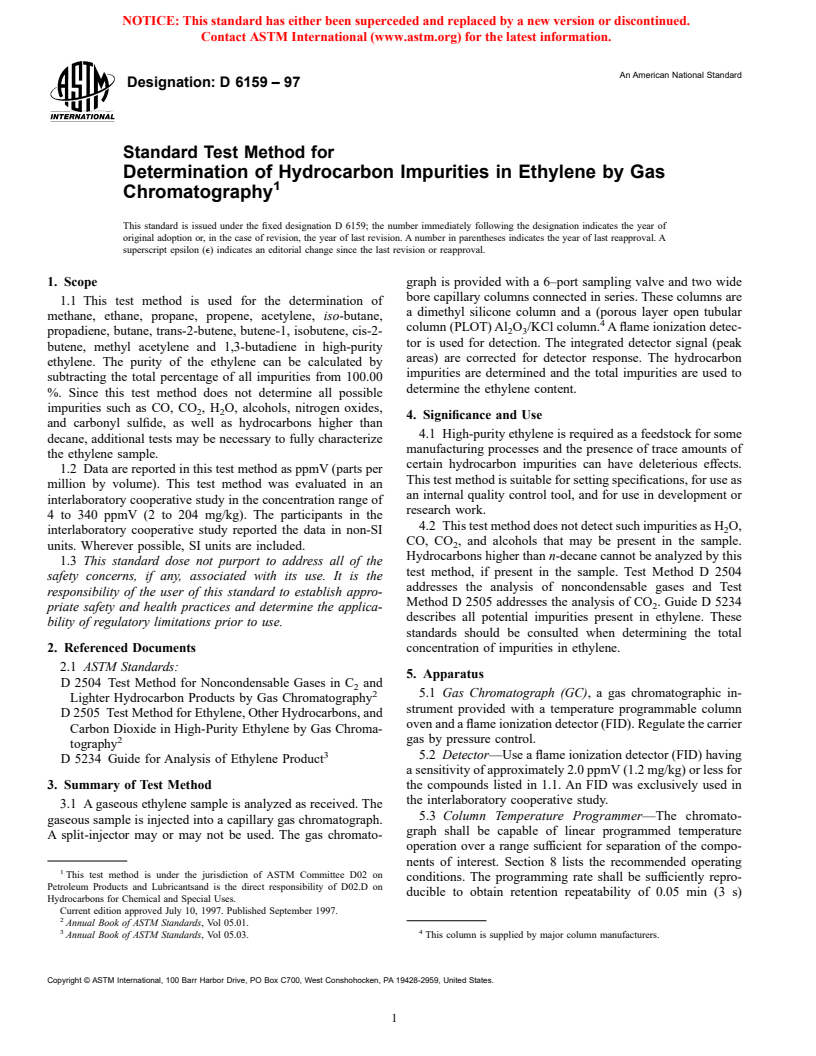

TAB

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.