ASTM B107/B107M-94

(Specification)Standard Specification for Magnesium-Alloy Extruded Bars, Rods, Profiles, Tubes, and Wire

Standard Specification for Magnesium-Alloy Extruded Bars, Rods, Profiles, Tubes, and Wire

SCOPE

1.1 This specification covers magnesium-alloy extruded bars, rods, profiles, tubes, and wire of the composition given in Table 1.

1.2 The values stated in either inch-pound or SI units are to be regarded separately as standards. The SI units are shown in brackets or in separate tables or columns. The values stated in each system are not exact equivalents; therefore, each system must be used independent of the other. Combining values from the two systems may result in nonconformance with the specification.

1.3 Unless the order specifies the "M" specification designation, the material shall be furnished to the inch-pound units.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 107/B 107M – 94

Standard Specification for

Magnesium-Alloy Extruded Bars, Rods, Shapes, Tubes, and

Wire

This standard is issued under the fixed designation B 107/B 107M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * E 527 Practice for Numbering Metals and Alloys (UNS)

2.3 Federal Standards:

1.1 This specification covers magnesium-alloy extruded

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

bars, rods, shapes, tubes, and wire of the composition given in

Fed. Std. No. 184 Identification Marking of Aluminum,

Table 1.

Magnesium and Titanium

1.2 The values stated in either inch-pound or SI units are to

2.4 Military Standard:

be regarded separately as standards. The SI units are shown in

MIL-STD-129 Marking for Shipment and Storage (Military

brackets or in separate tables or columns. The values stated in

Agencies)

each system are not exact equivalents; therefore, each system

must be used independent of the other. Combining values from

3. Terminology

the two systems may result in nonconformance with the

3.1 Definitions:

specification.

3.1.1 extruded bar—an extruded solid section, long in

1.3 Unless the order specifies the “M” specification desig-

relation to its cross-sectional dimensions, having a symmetrical

nation, the material shall be furnished to the inch-pound units.

cross section that is square or rectangular with sharp or

2. Referenced Documents rounded corners or edges, or is a regular hexagon or octagon,

and whose width or greatest distance between faces is 0.375 in.

2.1 The following documents of the issue in effect on date

[10 mm] or greater.

of order acceptance form a part of this specification to the

3.1.2 extruded rod—a solid extruded product 0.375 in. [10

extent referenced herein.

mm] or greater in diameter that is long in relation to cross

2.2 ASTM Standards:

section.

B 275 Practice For Codification of Certain Nonferrous Met-

3.1.3 extruded shape—a hollow or solid extruded section,

als and Alloys, Cast and Wrought

long in relation to its cross-sectional dimensions, whose cross

B 296 Practice for Temper Designations of Magnesium

section is other than that of wire, rod, bar, or tube.

Alloys, Cast and Wrought

3.1.4 extruded tube—an extruded hollow section, long in

B 557 Test Methods of Tension Testing Wrought and Cast

relation to its cross-sectional dimensions, which is symmetrical

Aluminum- and Magnesium-Alloy Products

and is round, square, rectangular, hexagonal, octagonal or

B 557M Test Methods of Tension Testing Wrought and Cast

elliptical with sharp or rounded corners, and has a uniform wall

Aluminum- and Magnesium-Alloy Products (Metric)

thickness except as affected by corner radii.

B 660 Practices for Packaging/Packing of Aluminum and

2 3.1.5 extruded wire—an extruded solid sectional long in

Magnesium Products

relation to its cross-sectional dimensions, having a symmetrical

E 29 Practice for Using Significant Digits in Test Data to

3 cross section that is square or rectangular with sharp or

Determine Conformance with Specifications

rounded corners or edges, or is round, hexagonal or octagonal,

E 35 Test Methods for Chemical Analysis of Magnesium

4 and whose diameter, width or greatest distance between paral-

and Magnesium Alloys

lel faces is less than 0.375 in. [through 10 mm].

E 55 Practice for Sampling Wrought Nonferrous Metals and

4 3.2 Definitions of Terms Specific to This Standard:

Alloys For Determination of Chemical Composition

3.2.1 producer—the primary manufacturer of the material.

3.2.2 supplier—includes only the category of jobbers and

distributors as distinct from producers.

This specification is under the jurisdiction of ASTM Committee B-7 on Light

4. Ordering Information

Metals and Alloys and is the direct responsibility of Subcommittee B07.04 on

Magnesium Alloy Cast and Wrought Products.

4.1 Orders for material to this specification shall include the

Current edition approved Aug. 15, 1994. Published October 1994. Originally

published as B 107 – 36 T. Last previous edition B 107/B 107M – 92.

Annual Book of ASTM Standards, Vol 02.02.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 14.02.

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Annual Book of ASTM Standards, Vol 03.05.

Robbins Ave., Philadelphia, PA 19111-5094. Attn: NPODS.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

B 107/B 107M

A

TABLE 1 Chemical Requirements

NOTE 1—Analysis shall regularly be made only for the elements specifically mentioned in this table. If, however, the presence of other elements is

suspected or indicated in the course of routine analysis to be in amounts greater than the specified limits, further analysis shall be made to determine that

the total of these other elements is not in excess of the limits specified in the last column of the table.

NOTE 2—The following applies to all specified limits in this table: For purposes of acceptance and rejection, an observed value or a calculated value

obtained from analysis should be rounded-off to the nearest unit in the last right-hand place of figures used in expressing the specified limit.

B

Alloy Composition,%

C

Zirco- Other

UNS ASTM Alumi- Man- Sili- Cop- Cal-

Magnesium Zinc nium, Nickel Iron Impuri-

No. No. num ganese con per cium

min ties

M11311 AZ31B remainder 2.5–3.5 0.20–1.0 0.6–1.4 . 0.10 0.05 0.005 0.005 0.04 0.30

D

M11312 AZ31C remainder 2.4–3.6 0.15–1.0 0.50–1.5 . 0.10 0.10 0.03 . . 0.30

M11610 AZ61A remainder 5.8–7.2 0.15–0.5 0.40–1.5 . 0.10 0.05 0.005 0.005 . 0.30

M11800 AZ80A remainder 7.8–9.2 0.12–0.5 0.20–0.8 . 0.10 0.05 0.005 0.005 . 0.30

M15100 M1A remainder . 1.2–2.0 . . 0.10 0.05 0.01 . 0.30 0.30

M16400 ZK40A remainder . . 3.5–4.5 0.45 . . . . . 0.30

M16600 ZK60A remainder . . 4.8–6.2 0.45 . . . . . 0.30

A

Limits are in weight percent maximum unless shown as a range or otherwise stated.

B

These alloy designations were established in accordance with Practice B 275 (see also Practice E 527).

C

Includes listed elements for which no specific limit is shown.

D

Manganese minimum limit need not be met if iron is 0.005 %, or less.

following information: are deemed necessary to assure that material conforms to

4.1.1 This specification number, prescribed requirements.

4.1.2 Quantity in pieces or pounds [kilograms],

6. Chemical Composition

4.1.3 Alloy (Section 6),

4.1.4 Temper (Section 7), 6.1 Limits—The bars, rods, shapes, tubes, or wire shall

4.1.5 Nominal cross-sectional dimensions as follows: conform to the chemical requirements in Table 1.

4.1.5.1 For rod and round wire—diameter, 6.2 Number of Samples—The number of samples taken for

4.1.5.2 For square corner bars and wire—depth and width, determination of chemical composition shall be as follows:

4.1.5.3 For sharp cornered hexagonal or octagonal bars and 6.2.1 When samples are taken at the time the ingots are

wire—distance across flats, poured, at least one sample shall be taken for each group of

4.1.5.4 For round tube—outside or inside diameter and wall ingots poured simultaneously from the same source of molten

thickness, metal.

4.1.5.5 For square or sharp cornered other than round 6.2.2 Unless compliance is established by 6.2.1, sampling of

tube—distance across flats and wall thickness,

the finished product shall be in accordance with Practice E 55.

4.1.5.6 For round cornered bars and wire; shapes; tube other One sample shall be taken for each 4000 lb (2000 kg) or less

than round, square, rectangular, hexagonal or octagonal with

of material comprising the lot, except that not more than one

sharp corners—drawing required, analysis shall be required per piece.

4.1.6 Length,

6.3 Methods of Chemical Analysis—Any suitable method of

4.1.7 Surface finish (see 9.2), chemical analysis may be used. In case of dispute, the analysis

4.1.8 Whether inspection or witness of inspection and tests

shall be made by methods given in Test Methods E 35 or any

by the purchaser’s representative is required prior to material other standard methods of analysis approved by ASTM unless

shipment (Section 10), some other method is agreed upon.

4.1.9 Whether certification is required (Section 12),

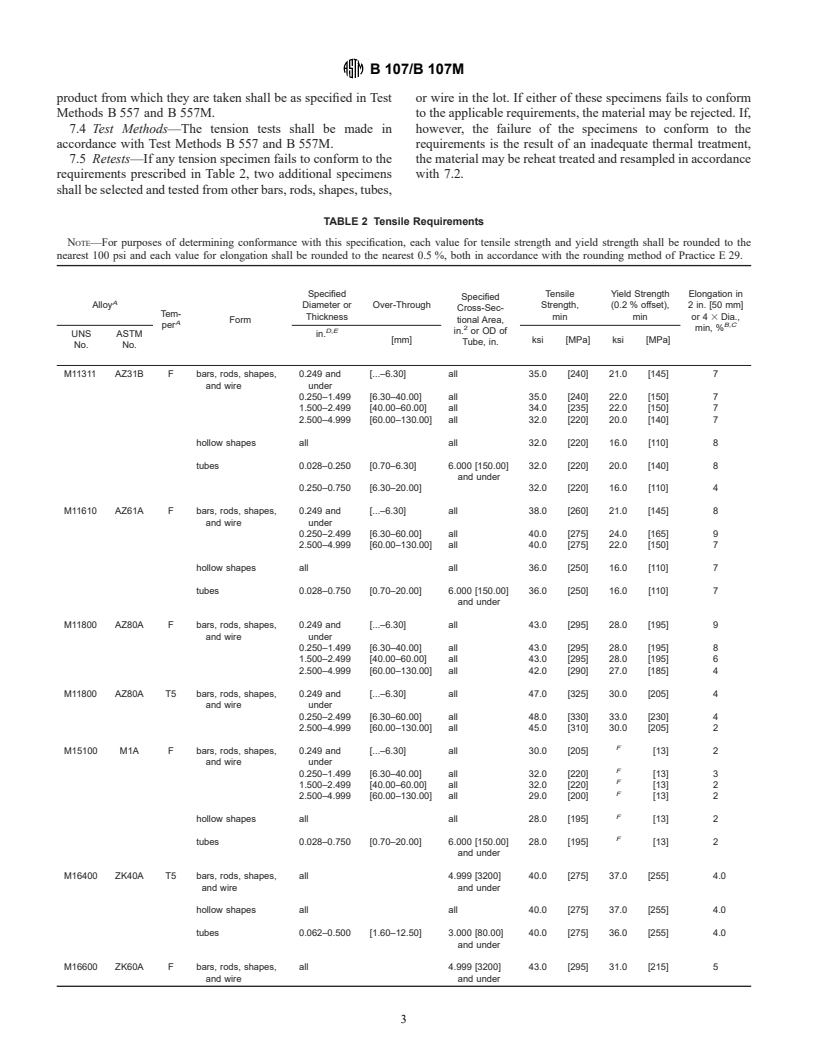

7. Tensile Requirements

4.1.10 Whether marking for identification is required (Sec-

tion 13 and Practices B 660), and 7.1 Limits—The bars, rods, shapes, tubes, and wire shall

4.1.11 Whether special packaging is required for shipment

conform to the tensile properties requirements in Table 2 unless

(Section 14). other agreement is made between producer or supplier and

purchaser. Properties for sizes and tempers not shown in Table

5. Quality Assurance

2 shall be as agreed by producer or supplier and purchaser.

5.1 Responsibility for Inspection— Unless otherwise speci- 7.2 Number of Specimens—From material having nominal

fied in the contract or purchase order, the producer or supplier weight of less than 1 lb/linear ft [through 1.7 kg/linear m], one

is responsible for the performance of all inspection and test tension test sample shall be taken for each 1000 lb [500 kg] or

requirements specified herein. Except as otherwise specified in fraction thereof in the shipment. For material having a nominal

the contract or order, the producer or supplier may use his own weight of 1 lb/linear ft [over 1.7 kg/linear m] or more, one

or any other suitable facilities for the performance of the tension test shall be taken for each 1000 ft [300 m] or fraction

inspection and test requirements specified herein, unless dis- thereof in the shipment. Other procedures for selecting samples

approved by the purchaser at the time the order is placed. The may be employed if agreed upon by the seller and the

purchaser shall have the right to perform any of the inspections purchaser.

and tests set forth in this specification where such inspections 7.3 Geometry of test specimens and the location in the

B 107/B 107M

product from which they are taken shall be as specified in Test or wire in the lot. If either of these specimens fails to conform

Methods B 557 and B 557M. to the applicable requirements, the material may be rejected. If,

7.4 Test Methods—The tension tests shall be made in however, the failure of the specimens to conform to the

accordance with Test Methods B 557 and B 557M. requirements is the result of an inadequate thermal treatment,

7.5 Retests—If any tension specimen fails to conform to the the material may be reheat treated and resampled in accordance

requirements prescribed in Table 2, two additional specimens with 7.2.

shall be selected and tested from other bars, rods, shapes, tubes,

TABLE 2 Tensile Requirements

NOTE—For purposes of determining conformance with this specification, each value for tensile strength and yield strength shall be rounded to the

nearest 100 psi and each value for elongation shall be rounded to the nearest 0.5 %, both in accordance with the rounding method of Practice E 29.

Specified Tensile Yield Strength Elongation in

Specified

A

Alloy Diameter or Over-Through Strength, (0.2 % offset), 2 in. [50 mm]

Cross-Sec-

Tem-

Thickness min min or 4 3 Dia.,

Form tional Area,

A

B,C

per

min, %

D,E in. or OD of

UNS ASTM in.

[mm] ksi [MPa] ksi [MPa]

Tube, in.

No. No.

M11311 AZ31B F bars, rods, shapes, 0.249 and [.–6.30] all 35.0 [240] 21.0 [145] 7

and wire under

0.250–1.499 [6.30–40.00] all 35.0 [240] 22.0 [150] 7

1.500–2.499 [40.00–60.00] all 34.0 [235] 22.0 [150] 7

2.500–4.999 [60.00–130.00] all 32.0 [220] 20.0 [140] 7

hollow shapes all all 32.0 [220] 16.0 [110] 8

tubes 0.028–0.250 [0.70–6.30] 6.000 [150.00] 32.0 [220] 20.0 [140] 8

and under

0.250–0.750 [6.30–20.00] 32.0 [220] 16.0 [110] 4

M11610 AZ61A F bars, rods, shapes, 0.249 and [.–6.30] all 38.0 [260] 21.0 [145] 8

and wire under

0.250–2.499 [6.30–60.00] all 40.0 [275] 24.0 [165] 9

2.500–4.999 [60.00–130.00] all 40.0 [275] 22.0 [150] 7

hollow shapes all all 36.0 [250] 16.0 [110] 7

tubes 0.028–0.750 [0.70–20.00] 6.000 [150.00] 36.0 [250] 16.0 [110] 7

and under

M11800 AZ80A F bars, rods, shapes, 0.249 and [.–6.30] all 43.0 [295] 28.0 [195] 9

and wire under

0.250–1.499 [6.30–40.00] all 43.0 [295] 28.0 [195] 8

1.500–2.499 [40.00–60.00] all 43.0 [295] 28.0 [195] 6

2.500–4.999 [60.00–130.00] all 42.0 [290] 27.0 [185] 4

M11800 AZ80A T5 bars, rods, shapes, 0.249 and [.–6.30] all 47.0 [325] 30.0 [205] 4

and wire under

0.250–2.499 [6.30–60.00] all 48.0 [330] 33.0 [230] 4

2.500–4.999 [60.00–130.00] all 45.0 [310] 30.0 [205] 2

F

M15100 M1A F bars, rods, shapes, 0.249 and [.–6.30] all 30.0 [205] [13] 2

and wire under

F

0.250–1.499 [6.30–40.00] all 32.0 [220] [13] 3

F

1.500–2.499 [40.00–60.00] all 32.0 [220] [13] 2

F

2.500–4.999 [60.00–130.00] all 29.0 [200] [13] 2

F

hollow shapes all all 28.0 [195] [13] 2

F

tubes 0.028–0.750 [0.70–20.00] 6.000 [150.00] 28.0 [195] [13] 2

and under

M16400 ZK40A T5 bars, rods, shapes, all 4.999 [3200] 40.0 [275] 37.0 [255] 4.0

and wire and under

hollow shapes all all 40.0 [275] 37.0 [255] 4.0

tubes 0.062–0.500 [1.60–12.50] 3.000 [80.00] 40.0 [275] 36.0 [255] 4.0

and under

M16600 ZK60A F bars, rods, shapes, all 4.999 [3200] 43.0 [295] 31.0 [215] 5

and wire and under

B 107/B 107M

TABLE 2 Continued

Specified Tensile Yield Strength Elongation in

Specified

A

Alloy Diameter or Over-Through Strength, (0.2 % offset), 2 in. [50 mm]

Cross-Sec-

Tem-

Thickness min min or 4 3 Dia.,

Form tional Area,

A

B,C

per

min, %

D,E

in. or OD of

UNS ASTM in.

[mm] ksi [MPa] ksi [MPa]

Tube, in.

No. No.

5.000–39.999 43.0 [295] 31.0 [215] 4

[3201–26 000]

hollow shapes all all 40.0 [275] 28.0 [195] 5

tubes 0.028–0.750 [0.70–20.00] 3.000 [80.00] 40.0 [275] 28.0 [195] 5

and under

M16600 ZK60A T5 bars, rods, shapes, all 4.999 [3200] 45.0 [310] 36.0 [250] 4

and wire and under [310] 34.0 [235] 6

5.000–24.999 45.0 [295] 31.0 [215] 6

[3201–16 000] 43.0

25.000–39.999

[16 001–26 000]

hollow shapes all all 46.0 [315] 38.0 [260] 4

tubes 0.028–0.250 [0.70–6.30] 3.000 [80.00] 46.0 [315] 38.0 [260] 4

and under

0.094–1.188 [2.50–30.00] 3.001 [80.00]– 44.0 [305] 33.0 [230] 4

8.500 [215]

A

See Practice B 296.

B

Elongation of full-section and machined sheet-type specimens is measured in 2 in. [50 mm] of machined round specimens, in 4 3 specimen dia. [5 3 dia. in metric].

C

For material of such dimensions that a standard test specimen cannot be obtained, for wire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.