ASTM B557-15(2023)

(Test Method)Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

Standard Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

SIGNIFICANCE AND USE

4.1 Tension tests provide information on the strength and ductility of materials under uniaxial tensile stresses. This information may be useful in comparisons of materials, alloy development, quality control, and design under certain circumstances.

4.2 The results of tension tests of specimens machined to standardized dimensions from selected portions of a part or material may not totally represent the strength and ductility properties of the entire end product or its in-service behavior in different environments.

4.3 These test methods are considered satisfactory for acceptance testing of commercial shipments and have been used extensively in the trade for this purpose.

SCOPE

1.1 These test methods cover the tension testing of wrought and cast aluminum- and magnesium-alloy products, with the exception of aluminum foil,2 and are derived from Test Methods E8, which cover the tension testing of all metallic materials.

1.2 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: Foil is sheet metal less than 0.0079 in. thick. There is an overlap in the thickness range 0.006 to 0.0079 in. defined for foil and sheet. Sheet products in this thickness range are supplied to sheet product specifications and foil products in this thickness range are supplied to foil product specifications. Exceptions to the provisions of these test methods may need to be made in individual specifications or test methods for a particular material.

Note 2: A complete metric companion to Test Methods B557 has been developed—Test Methods B557M; therefore, no metric equivalents are presented in these test methods.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B557 − 15 (Reapproved 2023)

Standard Test Methods for

Tension Testing Wrought and Cast Aluminum- and

Magnesium-Alloy Products

This standard is issued under the fixed designation B557; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 These test methods cover the tension testing of wrought

B209 Specification for Aluminum and Aluminum-Alloy

and cast aluminum- and magnesium-alloy products, with the

Sheet and Plate (Metric) B0209_B0209M

exception of aluminum foil, and are derived from Test

E4 Practices for Force Calibration and Verification of Test-

Methods E8, which cover the tension testing of all metallic

ing Machines

materials.

E6 Terminology Relating to Methods of Mechanical Testing

1.2 The values stated in inch-pound units are to be regarded

E8 Test Methods for Tension Testing of Metallic Materials

as standard. No other units of measurement are included in this

[Metric] E0008_E0008M

standard.

E29 Practice for Using Significant Digits in Test Data to

1.3 This standard does not purport to address all of the

Determine Conformance with Specifications

safety concerns, if any, associated with its use. It is the

E83 Practice for Verification and Classification of Exten-

responsibility of the user of this standard to establish appro-

someter Systems

priate safety, health, and environmental practices and deter-

E345 Test Methods of Tension Testing of Metallic Foil

mine the applicability of regulatory limitations prior to use.

E691 Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

NOTE 1—Foil is sheet metal less than 0.0079 in. thick. There is an

E1012 Practice for Verification of Testing Frame and Speci-

overlap in the thickness range 0.006 to 0.0079 in. defined for foil and

sheet. Sheet products in this thickness range are supplied to sheet product

men Alignment Under Tensile and Compressive Axial

specifications and foil products in this thickness range are supplied to foil

Force Application

product specifications. Exceptions to the provisions of these test methods

may need to be made in individual specifications or test methods for a

3. Terminology

particular material.

3.1 The definitions of terms relating to tension testing

NOTE 2—A complete metric companion to Test Methods B557 has been

developed—Test Methods B557M; therefore, no metric equivalents are

appearing in Terminology E6 shall be considered as applying

presented in these test methods.

to the terms used in these test methods.

1.4 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.1 Tension tests provide information on the strength and

Development of International Standards, Guides and Recom-

ductility of materials under uniaxial tensile stresses. This

mendations issued by the World Trade Organization Technical information may be useful in comparisons of materials, alloy

Barriers to Trade (TBT) Committee.

development, quality control, and design under certain circum-

stances.

4.2 The results of tension tests of specimens machined to

These test methods are under the jurisdiction of ASTM Committee B07 on standardized dimensions from selected portions of a part or

Light Metals and Alloys and are the direct responsibility of Subcommittee B07.05

on Testing.

Current edition approved April 1, 2023. Published April 2023. Originally For referenced ASTM standards, visit the ASTM website, www.astm.org, or

approved in 1971. Last previous edition approved in 2015 as B557 – 15. DOI: contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

10.1520/B0557-15R23. Standards volume information, refer to the standard’s Document Summary page on

For test methods of tension testing of aluminum foil, see Test Methods E345. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B557 − 15 (2023)

material may not totally represent the strength and ductility the specimens, when under load, shall be as nearly as possible

properties of the entire end product or its in-service behavior in in uniformly distributed pure axial tension (see 5.2.3 – 5.2.5).

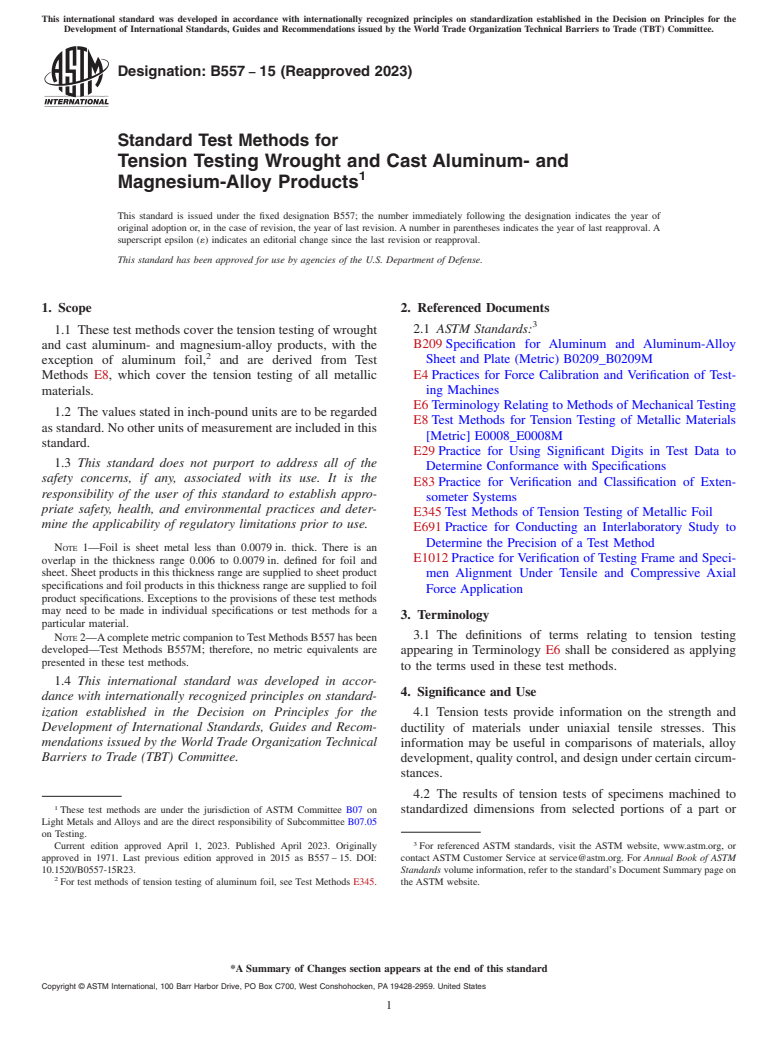

different environments. 5.2.3 Grips for Threaded and Shouldered Specimens—A

schematic diagram of a gripping device for threaded-end

4.3 These test methods are considered satisfactory for ac-

specimens is shown in Fig. 2, while Fig. 3 shows a device for

ceptance testing of commercial shipments and have been used

gripping specimens with shouldered ends. Both of these

extensively in the trade for this purpose.

gripping devices should be attached to the heads of the testing

machine through properly lubricated spherical-seated bearings.

5. Apparatus

The distance between spherical bearings should be as great as

5.1 Testing Machines—Machines used for tension testing

feasible.

shall conform to the requirements of Practices E4. The forces

5.2.4 Grips for Sheet Materials—The self-adjusting grips

used in determining tensile strength and yield strength shall be

shown in Fig. 4 have proved satisfactory for testing sheet

within the verified force application range of the testing

materials that cannot be tested satisfactorily in the usual type of

machine as defined in Practices E4.

wedge grips.

5.2 Gripping Devices: 5.2.5 Grips for Wire—Grips of either the wedge or snubbing

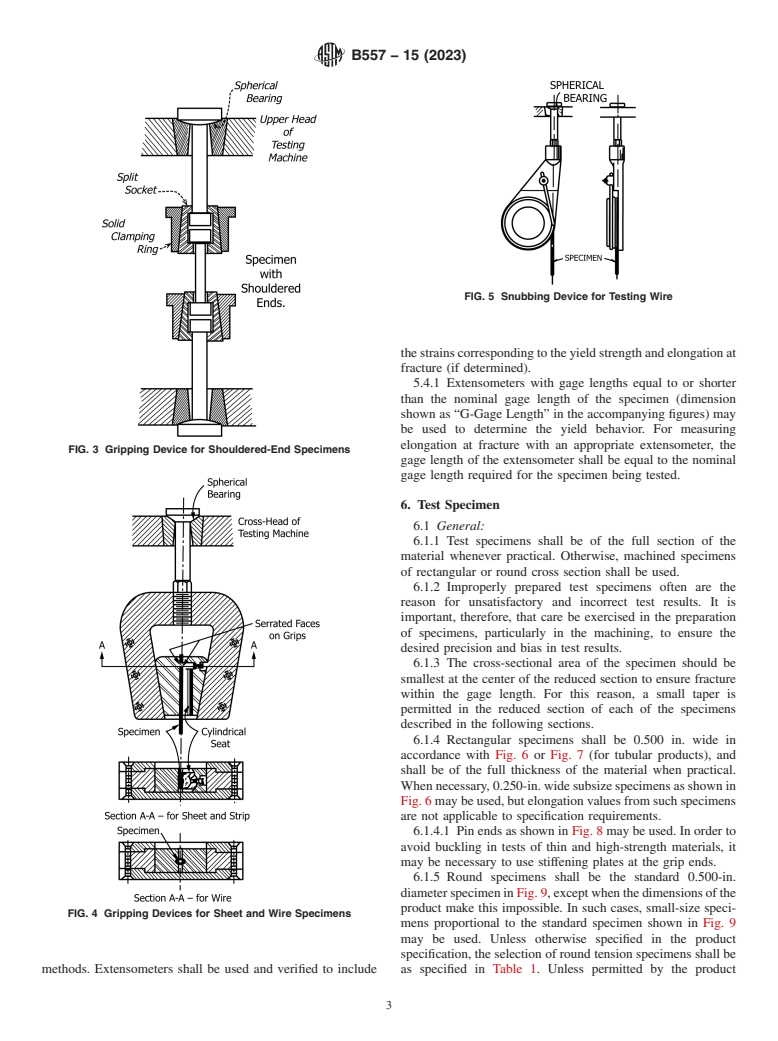

types as shown in Figs. 4 and 5 or flat wedge grips may be

5.2.1 General—Various types of gripping devices may be

used to transmit the measured load applied by the testing used.

machine to the test specimens. To ensure axial tensile stress

5.3 Dimension-Measuring Devices—Micrometers and other

within the gage length, the axis of the test specimen must

devices used for measuring linear dimensions shall be accurate

coincide with the centerline of the heads of the testing

and precise to at least one half the smallest unit to which the

machine. Any departure from this requirement may introduce

individual dimension is required to be measured.

bending stresses that are not included in the usual stress

5.4 Extensometers—Extensometers used in tensile testing

computation (load divided by cross-sectional area).

shall conform to the requirements of Practice E83 for the

NOTE 3—The effect of this eccentric loading may be illustrated by

classifications specified by the procedure section of these test

calculating the bending moment and stress thus added. For a standard

0.500-in. diameter specimen, the stress increase is 1.5 percentage points

for each 0.001 in. of eccentricity. This error increases to 2.24 percentage

points/0.001 in. for a 0.350-in. diameter specimen and to 3.17 percentage

points/0.001 in. for a 0.250-in. diameter specimen.

NOTE 4—Alignment methods are given in Practice E1012.

5.2.2 Wedge Grips—Testing machines usually are equipped

with wedge grips. These wedge grips generally furnish a

satisfactory means of gripping long specimens of ductile metal.

If, however, for any reason, one grip of a pair advances farther

than the other as the grips tighten, an undesirable bending

stress may be introduced. When liners are used behind the

wedges, they must be of the same thickness and their faces

must be flat and parallel. For best results, the wedges should be

supported over their entire length by the heads of the testing

machine. This requires that liners of several thicknesses be

available to cover the range of specimen thickness. For proper

gripping, it is desirable that the entire length of the serrated

face of each wedge be in contact with the specimen. Proper

alignment of wedge grips and liners is illustrated in Fig. 1. For

short specimens it is generally necessary to use machined test

specimens and to use a special means of gripping to ensure that

FIG. 1 Wedge Grips with Liners for Flat Specimens FIG. 2 Gripping Device for Threaded-End Specimens

B557 − 15 (2023)

FIG. 5 Snubbing Device for Testing Wire

the strains corresponding to the yield strength and elongation at

fracture (if determined).

5.4.1 Extensometers with gage lengths equal to or shorter

than the nominal gage length of the specimen (dimension

shown as “G-Gage Length” in the accompanying figures) may

be used to determine the yield behavior. For measuring

elongation at fracture with an appropriate extensometer, the

FIG. 3 Gripping Device for Shouldered-End Specimens

gage length of the extensometer shall be equal to the nominal

gage length required for the specimen being tested.

6. Test Specimen

6.1 General:

6.1.1 Test specimens shall be of the full section of the

material whenever practical. Otherwise, machined specimens

of rectangular or round cross section shall be used.

6.1.2 Improperly prepared test specimens often are the

reason for unsatisfactory and incorrect test results. It is

important, therefore, that care be exercised in the preparation

of specimens, particularly in the machining, to ensure the

desired precision and bias in test results.

6.1.3 The cross-sectional area of the specimen should be

smallest at the center of the reduced section to ensure fracture

within the gage length. For this reason, a small taper is

permitted in the reduced section of each of the specimens

described in the following sections.

6.1.4 Rectangular specimens shall be 0.500 in. wide in

accordance with Fig. 6 or Fig. 7 (for tubular products), and

shall be of the full thickness of the material when practical.

When necessary, 0.250-in. wide subsize specimens as shown in

Fig. 6 may be used, but elongation values from such specimens

are not applicable to specification requirements.

6.1.4.1 Pin ends as shown in Fig. 8 may be used. In order to

avoid buckling in tests of thin and high-strength materials, it

may be necessary to use stiffening plates at the grip ends.

6.1.5 Round specimens shall be the standard 0.500-in.

diameter specimen in Fig. 9, except when the dimensions of the

product make this impossible. In such cases, small-size speci-

FIG. 4 Gripping Devices for Sheet and Wire Specimens

mens proportional to the standard specimen shown in Fig. 9

may be used. Unless otherwise specified in the product

specification, the selection of round tension specimens shall be

methods. Extensometers shall be used and verified to include as specified in Table 1. Unless permitted by the product

B557 − 15 (2023)

Dimensions, in.

Standard Specimen Sheet- Subsize Specimen

1 1

Type, ⁄2-in. Wide ⁄4-in. Wide

G—Gage length 2.000 ± 0.005 1.000 ± 0.003

W—Width (Note 1 and Note 2) 0.500 ± 0.010 0.250 ± 0.002

T—Thickness (Note 3) thickness of material thickness of material

1 1

R—Radius of fillet, min ⁄2 ⁄4

L—Overall length, min (Note 4) 8 4

1 1

A—Length of reduced section, min 2 ⁄4 1 ⁄4

B—Length of grip section, min (Note 5) 2 1 ⁄4

3 3

C—Width of grip section, approximate ⁄4 ⁄8

(Note 2 and Note 6)

NOTE 1—The ends of the reduced section shall not differ in width by more than 0.002 in. for the 2.00-in. gage length specimen or 0.001 in. for the

1.00-in. gage length specimen. There may be a gradual taper in width from the ends of the reduced section to the center, but the width at each end shall

not be more than 1 % greater than the width at the center.

NOTE 2—For each of the specimens, narrower widths (W and C) may be used when necessary. In such cases the width of the reduced section should

be as large as the width of the material being tested permits; however, unless stated specifically, the requirements for elongation in a product specification

shall not apply when these narrower specimens are used. If the width of the material is less than W, the sides may be parallel throughout the length of

the specimen.

NOTE 3—The dimension T is the thickness of the test specimen as stated in the applicable material specifications. Maximum nominal thicknesses of

1 1 1 1

⁄2-in. and ⁄4-in. wide specimens shall be ⁄2 in. and ⁄4 in., respectively.

NOTE 4—To aid in obtaining axial loading during testing of ⁄4-in. wide specimens, the overall length should be as large as the material will permit,

up to 8 in.

NOTE 5—It is desirable, if possible, to make the length of the grip section large enough to allow the specimen to extend into the grips a distance equal

1 3

to two thirds or more of the length of the grips. If the thickness of ⁄2-in. wide specimens is over ⁄8 in., longer grips and correspondingly longer grip

sections of the specimen may be necessary to prevent failure in the grip section.

1 1

NOTE 6—The grip-end centerline of the ⁄2 –in. wide and ⁄4 –in. wide specimens shall coincide with the centerline of the reduced section within 0.01

and 0.005 in., respectively.

FIG. 6 Rectangular Tension Test Specimens

Dimensions, in.

G—Gage length 2.000 ± 0.005

W—Width (Note 1) 0.500 ± 0.010

T—Measured thickness of specimen Note 2

R—Radius of fillet, min ⁄2

A—Length of reduced section, min 2 ⁄4

B—Length of grip section, min (Note 3) 3

C—Width of grip section, approximate (Note 4) ⁄16

NOTE 1—The ends of the reduced section shall not differ in width by more than 0.002 in. There may be a gradual taper in width from the ends of the

reduced section to the center, but the width at each end shall not be more than 1 % greater than the width at the center.

NOTE 2—The dimension T is the thickness of the tubular section as provided for in the applicable material specifications.

NOTE 3—It is desirable, if possible, to make the length of the grip section great enough to allow the specimen to extend into the grips a distance equal

to two thirds or more of the length of the grips.

NOTE 4—The grip-end centerline of the specimen shall coincide with the centerline of the reduced section within 0.05 in.

NOTE 5—For circular segment, the cross-sectional area shall be calculated using the formula shown in 7.2.3.

NOTE 6—The radii of all fillets shall be equal to each other within a tolerance of 0.05 in., and the centers of curvature of the two fillets at a particular

end shall be located across from each other (on a line perpendicular to the centerline) within a tolerance of 0.10 in.

FIG. 7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.