ASTM B552-98(2004)

(Specification)Standard Specification for Seamless and Welded Copper--Nickel Tubes For Water Desalting Plants

Standard Specification for Seamless and Welded Copper--Nickel Tubes For Water Desalting Plants

SCOPE

1.1 This specification establishes requirements for seamless and welded copper-nickel tubes from 0.625 to 1.25 in. (15.9 to 31.8 mm) in diameter for use in heat exchangers in water desalting plants. The following alloys are involved: Copper Alloy UNS Nos. C70600, C71500, C71640, and C72200.

1.2 The values stated in inch-pound units are the standard. Values given in parentheses are provided for information only.

The following safety hazard caveat pertains only to the test methods of Section described in this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to its use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 552 – 98 (Reapproved 2004)

Standard Specification for

Seamless and Welded Copper–Nickel Tubes for Water

1

Desalting Plants

This standard is issued under the fixed designation B 552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* E 118 Test Methods for Chemical Analysis of Copper-

Chromium Alloys

1.1 This specification establishes requirements for seamless

E 243 Practice for Electromagnetic (Eddy-Current) Exami-

and welded copper-nickel tubes from 0.625 to 1.25 in. (15.9 to

nation of Copper and Copper-Alloy Tubes

31.8 mm) in diameter for use in heat exchangers in water

E 255 Practice for Sampling Copper and CopperAlloys for

desalting plants. The following alloys are involved: Copper

Determination of Chemical Composition

Alloy UNS Nos. C70600, C71500, C71640, and C72200.

E 478 Test Methods for Chemical Analysis of Copper

1.2 The values stated in inch-pound units are the standard.

Alloys

Values given in parentheses are provided for information only.

1.3 The following safety hazard caveat pertains only to the

3. Terminology

test methods of Section 16 described in this specification: This

3.1 For definitions of terms related to copper and copper

standarddoesnotpurporttoaddressallofthesafetyconcerns,

alloys, refer to Terminology B 846.

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser

of this standard to establish appropriate safety and health

4. Classification

practices and determine the applicability of regulatory limita-

4.1 Tubes furnished to this specification are classified into

tions prior to its use.

two types, as follows:

2. Referenced Documents 4.1.1 Seamless tube and

2 4.1.2 Welded tube.

2.1 ASTM Standards:

B 111 Specification for Copper and Copper-Alloy Seamless

5. Ordering Information

Condenser Tubes and Ferrule Stock

5.1 Ordersforproductsunderthisspecificationshallinclude

B 153 Test Method for Expansion (Pin Test) of Copper and

the following information:

Copper-Alloy Pipe and Tubing

5.1.1 ASTM designation and year of issue,

B 543 Specification for Welded Copper and Copper-Alloy

5.1.2 Copper Alloy UNS number designation,

Heat Exchanger Tube

5.1.3 Whether seamless or welded (Section 4),

B 601 Classification for Temper Designations for Copper

5.1.4 Temper (Section 8),

and Copper Alloys—Wrought and Cast

5.1.5 Dimensions: diameter and wall thickness (whether

B 846 Terminology for Copper and Copper Alloys

minimum or nominal), and length (Section 12),

E 8 Test Methods for Tension Testing of Metallic Materials

5.1.6 Total number of pieces of each size, and

E 62 Test Methods for Chemical Analysis of Copper and

5.1.7 How furnished, whether in straight lengths or coils.

Copper Alloys (Photometric Methods)

5.2 The following options are available and, when required,

E 76 Test Methods for ChemicalAnalysis of Nickel-Copper

3 are to be specified at the time of placing of the order:

Alloys

5.2.1 Whether further finish processing of welded tube is

needed (6.2.2.1),

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper 5.2.2 Hydrostatic test (11.2),

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

5.2.3 Pneumatic test (11.3),

and Tube.

5.2.4 Certification (Section 20), and

Current edition approved May 1, 2004. Published May 2004. Originally

e1

5.2.5 Mill test report (Section 21).

approved in 1971. Last previous edition approved in 1998 as B 552 – 98 .

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 6. Materials and Manufacture

Standards volume information, refer to the standard’s Document Summary page on

6.1 Material:

the ASTM website.

3

Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B 552 – 98 (2004)

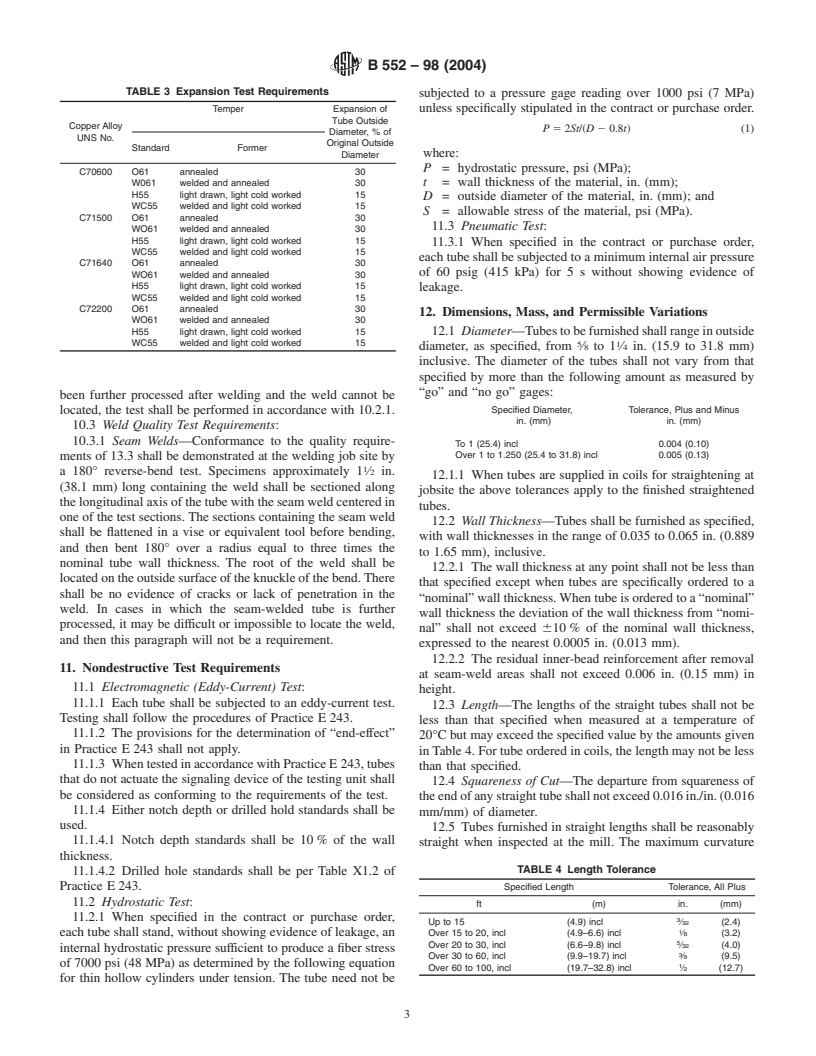

6.1.1 The material of manufacture shall be cast billets of 8.1.1 Seamless Tube—The product shall be furnished in

Copper Alloys UNS Nos. C70600, C71500, C71640, and either the O61 (annealed), or the H55 (light drawn, light

C72200 as specified in the ordering information, and shall be cold-worked) temper, as specified in the ordering information.

of such quality and soundness as to be suitable for processing 8.1.2 WeldedTube—Theproductshallbefurnishedineither

into finished lengths or coils of tube to meet the properties the WO61 (welded and annealed) or the WC55 (welded and

prescribed herein. light cold worked) temper as specified in the ordering info

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.