ASTM A494/A494M-04

(Specification)Standard Specification for Castings, Nickel and Nickel Alloy

Standard Specification for Castings, Nickel and Nickel Alloy

SCOPE

1.1 This specification covers nickel, nickel-copper, nickel-copper-silicon, nickel-molybdenum, nickel-chromium, and nickel-molybdenum-chromium alloy castings for corrosion-resistant service.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A 494 and SI units for material ordered to Specification A 494M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 494/A 494M – 04

Standard Specification for

1

Castings, Nickel and Nickel Alloy

This standard is issued under the fixed designationA 494/A 494M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* E 38 Methods for Chemical Analysis of Nickel-Chromium

3

and Nickel-Chromium-Iron Alloys

1.1 This specification covers nickel, nickel-copper, nickel-

E 76 Test Methods for ChemicalAnalysis of Nickel-Copper

copper-silicon, nickel-molybdenum, nickel-chromium, and

3

Alloys

nickel-molybdenum-chromium alloy castings for corrosion-

E 354 Test Methods for Chemical Analysis of High-

resistant service.

Temperature, Electrical, Magnetic, and Other Similar Iron,

1.2 The values stated in either inch-pound units or SI units

Nickel, and Cobalt Alloys

are to be regarded separately as standard. Within the text, the

SI units are shown in brackets. The values stated in each

3. Terminology

system are not exact equivalents; therefore, each system must

3.1 Definitions:

be used independently of the other. Combining values from the

3.1.1 master heat—a single furnace charge of refined alloy,

two systems may result in nonconformance with the specifi-

whichmayeitherbepoureddirectlyintocastingsorintoremelt

cation. Inch-pound units are applicable for material ordered to

alloy for individual melts.

Specification A 494 and SI units for material ordered to

3.1.2 melts—a single furnace charge poured into castings.

Specification A 494M.

When master heats are used to prepare melts, a melt analysis

2. Referenced Documents shall be reported.

2

2.1 ASTM Standards:

4. General Conditions for Delivery

A 370 Test Methods and Definitions for MechanicalTesting

4.1 Material furnished to this specification shall conform to

of Steel Products

the requirements of Specification A 781/A 781M, including

A 488/A 488M Practice for Steel Castings, Welding, Quali-

any supplementary requirements that are indicated in the

fications of Procedures and Personnel

purchase order. Failure to comply with the general require-

A 732/A 732M Specification for Castings, Investment, Car-

ments of Specification A 781/A 781M constitutes nonconfor-

bon and Low-Alloy Steel for General Application, and

mance with this specification. In case of conflict between the

Cobalt Alloy for High Strength at Elevated Temperatures

requirements of this specification and Specification A 781/

A 781/A 781M Specification for Castings, Steel and Alloy,

A 781M, this specification shall prevail.

Common Requirements, for General Industrial Use

E 8 Test Methods for Tension Testing of Metallic Materials

5. Ordering Information

E 29 Practice for Using Significant Digits in Test Data to

5.1 Orders for castings to this specification should include

Determine Conformance with Specifications

the following information:

E 30 Test Methods for Chemical Analysis of Steel, Cast

3 5.1.1 Quantity, in pieces, and

Iron, Open-Hearth Iron, and Wrought Iron

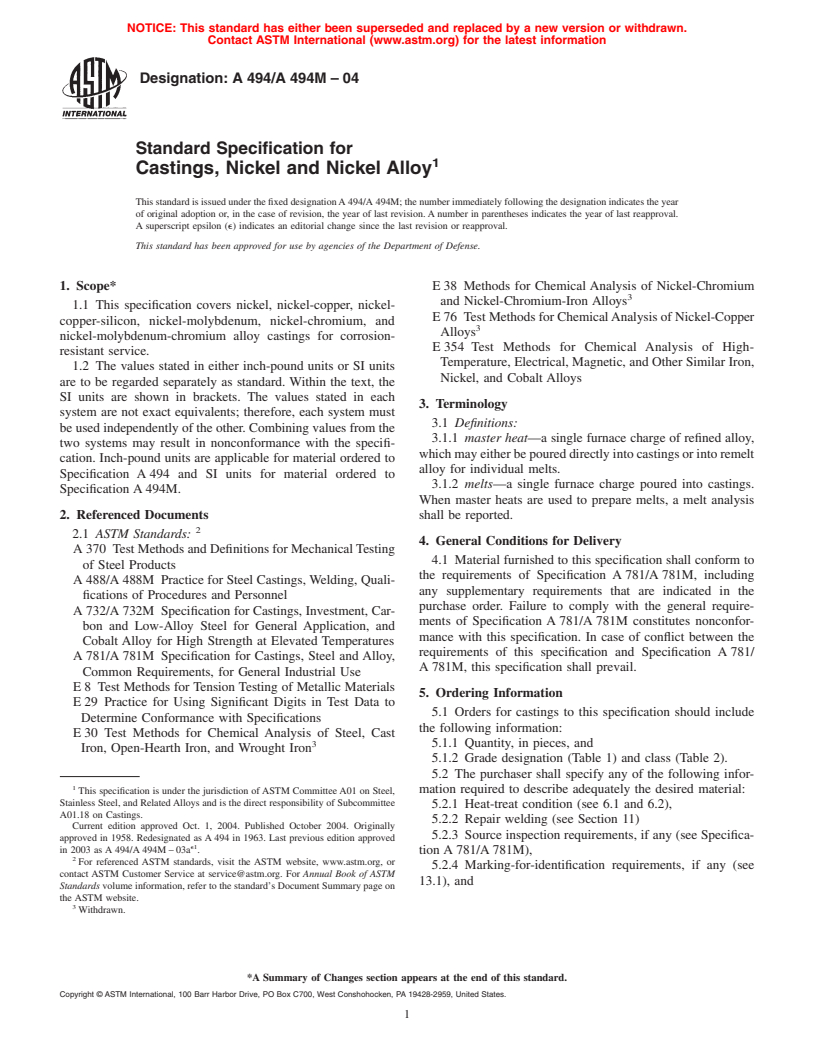

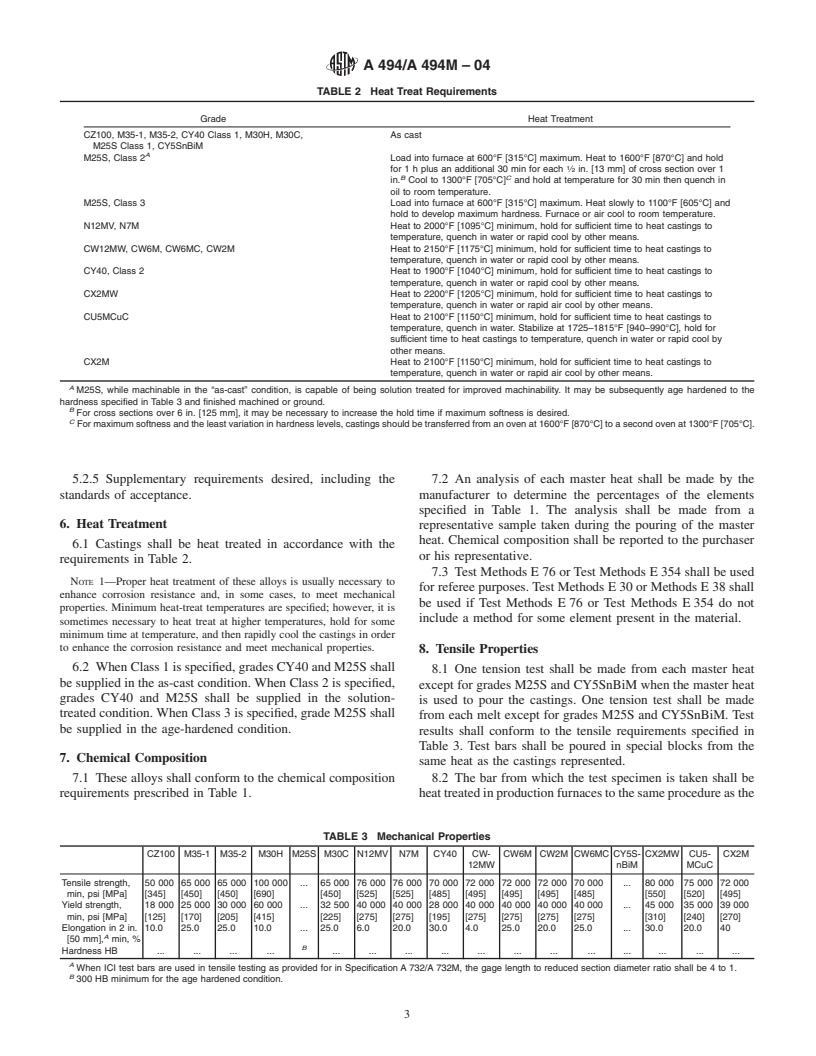

5.1.2 Grade designation (Table 1) and class (Table 2).

5.2 The purchaser shall specify any of the following infor-

1

mation required to describe adequately the desired material:

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel, and RelatedAlloys and is the direct responsibility of Subcommittee

5.2.1 Heat-treat condition (see 6.1 and 6.2),

A01.18 on Castings.

5.2.2 Repair welding (see Section 11)

Current edition approved Oct. 1, 2004. Published October 2004. Originally

5.2.3 Source inspection requirements, if any (see Specifica-

approved in 1958. Redesignated as A 494 in 1963. Last previous edition approved

e1

in 2003 as A 494/A 494M – 03a . tion A 781/A 781M),

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.2.4 Marking-for-identification requirements, if any (see

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

13.1), and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3

Withdrawn.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A 494/A 494M – 04

2

TABLE 1 Chemical Requirements

NOTE—Values are maximum unless otherwise indicated.

A A

Grade CZ100 M35-1 M35-2 M30H M25S M30C N12MV N7M CY40 CW12MW CW6M CW2M CW6MC CY5SnBiM CX2MW CU5MCuC CX2M

UNS N02100 N24135 N04020 N24030 N24025 N24130 N30012 N30007 N06040 N30002 N30107 N26455 N26625 N26055 N26022 N08826 N26059

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.