ASTM D1667-22

(Specification)Standard Specification for Flexible Cellular Materials—Poly (Vinyl Chloride) Foam (Closed-Cell)

Standard Specification for Flexible Cellular Materials—Poly (Vinyl Chloride) Foam (Closed-Cell)

ABSTRACT

This specification covers flexible closed-cell or non-interconnecting cellular products, the elastomer content of which is predominantly poly(vinyl chloride) foam or copolymers thereof. Materials shall be produced in sheet, strip, molded, or simple specific shapes. Complete details about apparatuses needed, specimen preparation, and procedures for the testing of compression deflection, compression set under constant deflection, and water absorption are thoroughly itemized.

SCOPE

1.1 This specification covers flexible closed-cell or non-interconnecting cellular products, the elastomer content of which is predominantly poly(vinyl chloride) or copolymers thereof.

1.2 In the case of conflict between the provisions of this specification and those of detailed specifications or methods of test for a particular product, the latter shall take precedence.

1.3 Reference to the methods for testing closed-cell poly(vinyl chloride) contained herein shall specifically state the particular test or tests desired and not refer to these methods of test as a whole.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.5 The following precautionary statement pertains to the test method portions only of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:D1667 −22

Standard Specification for

Flexible Cellular Materials—Poly (Vinyl Chloride) Foam

1

(Closed-Cell)

This standard is issued under the fixed designation D1667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers flexible closed-cell or non- 2.1 ASTM Standards:

interconnecting cellular products, the elastomer content of D883 Terminology Relating to Plastics

which is predominantly poly(vinyl chloride) or copolymers D1056 Specification for Flexible Cellular Materials—

thereof. Sponge or Expanded Rubber

E456 Terminology Relating to Quality and Statistics

1.2 In the case of conflict between the provisions of this

E691 Practice for Conducting an Interlaboratory Study to

specification and those of detailed specifications or methods of

Determine the Precision of a Test Method

test for a particular product, the latter shall take precedence.

1.3 Reference to the methods for testing closed-cell poly- 3. Terminology

(vinyl chloride) contained herein shall specifically state the

3.1 Terms used in this standard are defined in accordance

particular test or tests desired and not refer to these methods of

with Terminology D883, unless otherwise specified. For terms

test as a whole.

relating to precision and bias and associated issues, the terms

1.4 The values stated in SI units are to be regarded as the used in this standard are defined in accordance with Terminol-

standard. The inch-pound units given in parentheses are for ogy E456.

information only.

3.2 Definitions of Terms Specific to This Standard:

1.5 The following precautionary statement pertains to the

3.2.1 flexible cellular material, n—a cellular polymer that

test method portions only of this specification: This standard

will not visibly rupture within a specified time when a

does not purport to address all of the safety concerns, if any,

specimen is bent around a 25.4-mm (1.0-in.) mandrel 180

associated with its use. It is the responsibility of the user of this

degrees within an agreed upon period of time and at a

standard to establish appropriate safety, health, and environ-

predetermined temperature.

mental practices and determine the applicability of regulatory

3.2.2 surface skin, n—the smooth surface on the material

limitations prior to use.

formed during manufacture by contact with the molds, cover

plate, or air.

NOTE 1—There is no known ISO equivalent to this standard.

1.6 This international standard was developed in accor- 3.2.3 V, n—the ASTM symbol designating nonrigid vinyl

dance with internationally recognized principles on standard- cellular plastics.

ization established in the Decision on Principles for the

3.2.4 vinyl or PVC, n—these terms refer to poly(vinyl

Development of International Standards, Guides and Recom-

chloride) or copolymers thereof.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee. 4. Materials and Manufacture

4.1 Closed-cell vinyl is produced in sheet, strip, molded, or

simple specific shapes.

1

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular

2

Materials - Plastics and Elastomers. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved May 1, 2022. Published May 2022. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1959. Last previous edition approved in 2017 as D1667 - 17. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D1667-22. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1667−22

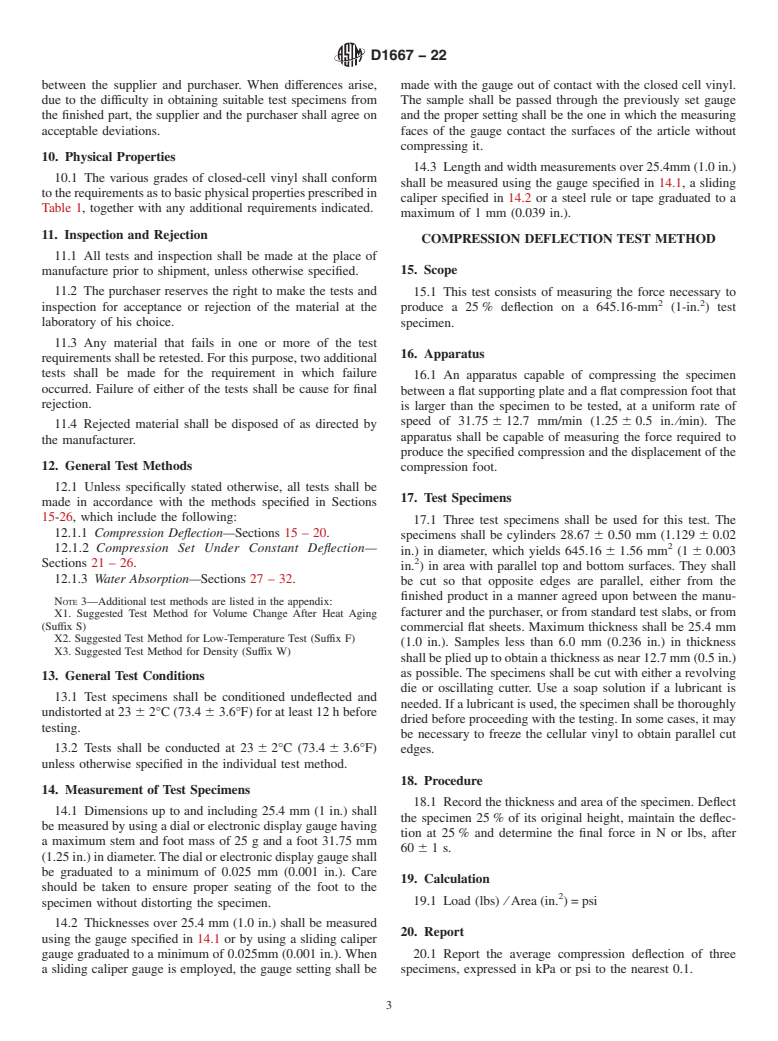

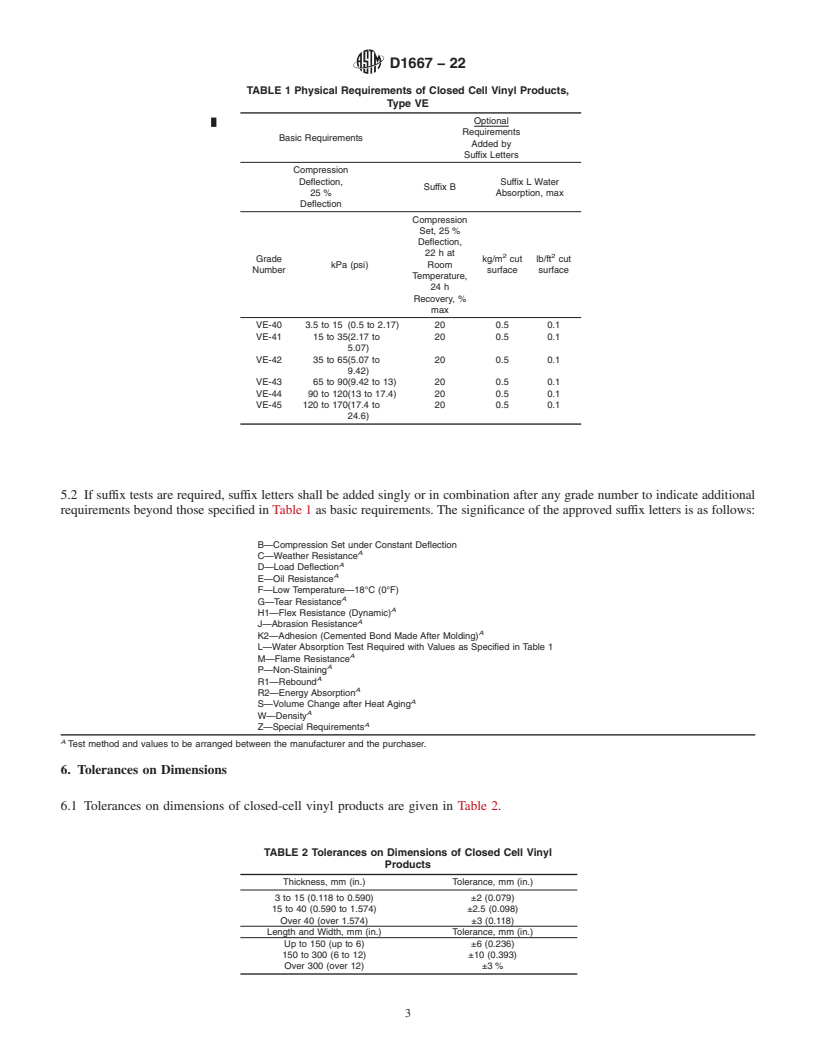

TABLE 2 Tolerances on Dimensions of Closed Cell Vinyl

5. Grades of Closed-Cell Vinyl or PVC-Symbol VE

Products

5.1 Closed-cell vinyl shall be designated by two symbol

Thickness, mm (in.) Tolerance, mm (in.)

letters VE, indicating V for vinyl and E for closed cell. The

3 to 15 (0.118 to 0.590) ±2 (0.079)

grade shall be designated by two digits, the first of which

15 to 40 (0.590 to 1.574) ±2.5 (0.098)

designates closed cell, and the second of which indicates the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1667 − 17 D1667 − 22

Standard Specification for

Flexible Cellular Materials—Poly (Vinyl Chloride) Foam

1

(Closed-Cell)

This standard is issued under the fixed designation D1667; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

1.1 This specification covers flexible closed-cell or non-interconnecting cellular products, the elastomer content of which is

predominantly poly(vinyl chloride) or copolymers thereof.

1.2 In the case of conflict between the provisions of this specification and those of detailed specifications or methods of test for

a particular product, the latter shall take precedence.

1.3 Reference to the methods for testing closed-cell poly(vinyl chloride) contained herein shall specifically state the particular test

or tests desired and not refer to these methods of test as a whole.

1.4 The values stated in SI units are to be regarded as the standard. The inch-pound units given in parentheses are for information

only.

1.5 The following precautionary statement pertains to the test method portions only of this specification:This standard does not

purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to

establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D395D883 Test Methods for Rubber Property—Compression SetTerminology Relating to Plastics

D573 Test Method for Rubber—Deterioration in an Air Oven

D1056 Specification for Flexible Cellular Materials—Sponge or Expanded Rubber

1

This specification is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials - Plastics

and Elastomers.

Current edition approved March 1, 2017May 1, 2022. Published March 2017May 2022. Originally approved in 1959. Last previous edition approved in 20112017 as

D1667 - 05D1667 - 17.(2011). DOI: 10.1520/D1667-17.10.1520/D1667-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1667 − 22

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

3. Terminology

3.1 Terms used in this standard are defined in accordance with Terminology D883, unless otherwise specified. For terms relating

to precision and bias and associated issues, the terms used in this standard are defined in accordance with Terminology E456.

3.2 Definitions of Terms Specific to This Standard:

3.1.1 closed cell—an expanded structure consisting of a multitude of individual, non-connecting, gas-tight cells.

3.2.1 flexible cellular material—material, n—a cellular organic polymeric material which polymer that will not visibly rupture

when a specimen 200 by 25 by 25 mm (8 by 1 by 1 in.) within a specified time when a specimen is bent around at 25-mm (1-in.)

diameter mandrel at a uniform rate of one lap in 5 s at a temperature between 18 and 29°C (65 and 85°F).a 25.4-mm (1.0-in.)

mandrel 180 degrees within an agreed upon period of time and at a predetermined temperature.

3.2.2 surface skin—skin, n—the smooth surface on the material formed during manufacture by contact with the molds, cover plate,

or air.

3.2.3 V—V, n—the ASTM symbol designating nonrigid vinyl cellular plastics.

3.2.4 vinyl or PVC—PVC,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.