ASTM D3768-22

(Test Method)Standard Test Method for Microcellular Urethanes—Flexural Recovery

Standard Test Method for Microcellular Urethanes—Flexural Recovery

SIGNIFICANCE AND USE

4.1 This test method is used to indicate the ability of a material to recover after a 180° bend around a 12.7-mm (0.5-in.) diameter mandrel at room temperature.

4.2 Before proceeding with this test method, reference shall be made to any specification for the material being tested. Any test specimen preparation, conditioning, or dimensions, or combination thereof, and testing parameters covered in the materials specification shall take precedence over those mentioned in these test methods. If there are no material specifications, then the default conditions apply.

Note 2: This test method is applicable to solid urethanes.

SCOPE

1.1 This test method covers the procedure and apparatus for measuring the flexural recovery of microcellular urethanes.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D3768 − 22

Standard Test Method for

1

Microcellular Urethanes—Flexural Recovery

This standard is issued under the fixed designation D3768; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 3. Terminology

1.1 Thistestmethodcoverstheprocedureandapparatusfor

3.1 Terms used in this standard are defined in accordance

measuring the flexural recovery of microcellular urethanes.

with Terminology D883, unless otherwise specified. For terms

relating to precision and bias and associated issues, the terms

1.2 The values stated in SI units are to be regarded as

used in this standard are defined in accordance with Terminol-

standard.

ogy E456.

1.3 This standard does not purport to address all of the

3.2 The following definition is from Test Methods D3489:

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.1 microcellular urethane, n—an elastomeric material

priate safety, health, and environmental practices and deter- made by the interaction of a polyol and an organic isocyanate,

mine the applicability of regulatory limitations prior to use.

having cell diameters in the range from 0.0001 to 0.001 mm,

3 3

with a minimum density of 160 kg/m (10 lb/ft ).

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accor-

4. Significance and Use

dance with internationally recognized principles on standard-

4.1 This test method is used to indicate the ability of a

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom- material to recover after a 180° bend around a 12.7-mm

(0.5-in.) diameter mandrel at room temperature.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4.2 Before proceeding with this test method, reference shall

be made to any specification for the material being tested.Any

2. Referenced Documents

test specimen preparation, conditioning, or dimensions, or

2

2.1 ASTM Standards:

combination thereof, and testing parameters covered in the

D883Terminology Relating to Plastics

materials specification shall take precedence over those men-

D3040Practice for Preparing Precision Statements for Stan-

tioned in these test methods. If there are no material

dards Related to Rubber and Rubber Testing (Withdrawn

specifications, then the default conditions apply.

3

1987)

NOTE 2—This test method is applicable to solid urethanes.

D3489Test Methods for Microcellular Urethane Materials

E456Terminology Relating to Quality and Statistics

5. Apparatus

E691Practice for Conducting an Interlaboratory Study to

Determine the Precision of a Test Method

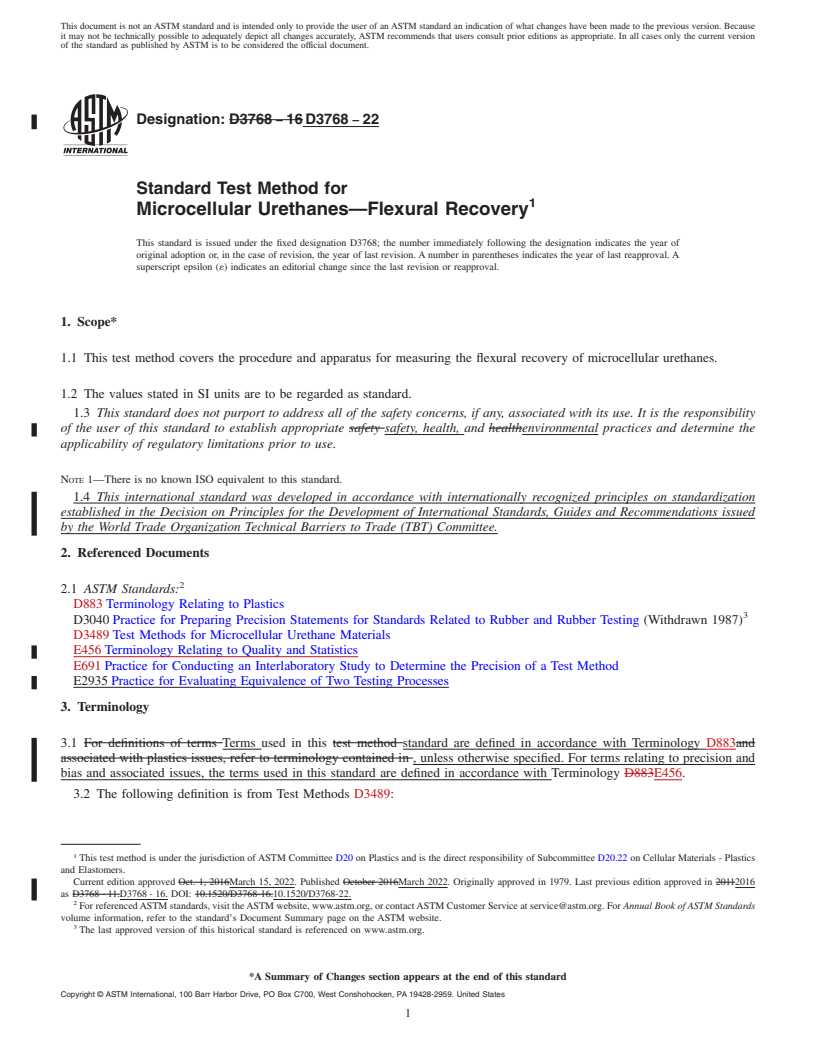

5.1 Flexural Recovery Test Fixture—The test fixture shall

E2935Practice for Evaluating Equivalence of Two Testing

consist of a 12.7-mm diameter mandrel mounted to a base

Processes

equipped with a protractor. A drawing of a typical test fixture

is shown in Fig. 1.

5.2 Timer, capable of indicating seconds.

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

and is the direct responsibility of Subcommittee D20.22 on Cellular Materials -

5.3 Thickness Indicator, accurate to 0.03 mm.

Plastics and Elastomers.

Current edition approved March 15, 2022. Published March 2022. Originally

6. Test Specimens

approved in 1979. Last previous edition approved in 2016 as D3768-16. DOI:

10.1520/D3768-22.

2

6.1 The test specimens shall be cut from molded plaques or

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

parts. The recommended standard test specimen is 4 mm in

Standards volume information, refer to the standard’s Document Summary page on

thickness, and the minimum specimen thickness shall not be

the ASTM website.

3

less than 3 mm.The specimen shall be 25 mm in width by 150

The last approved version of this historical standard is referenced on

www.astm.org. mm in length (1 by 6 in.).

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3768 − 22

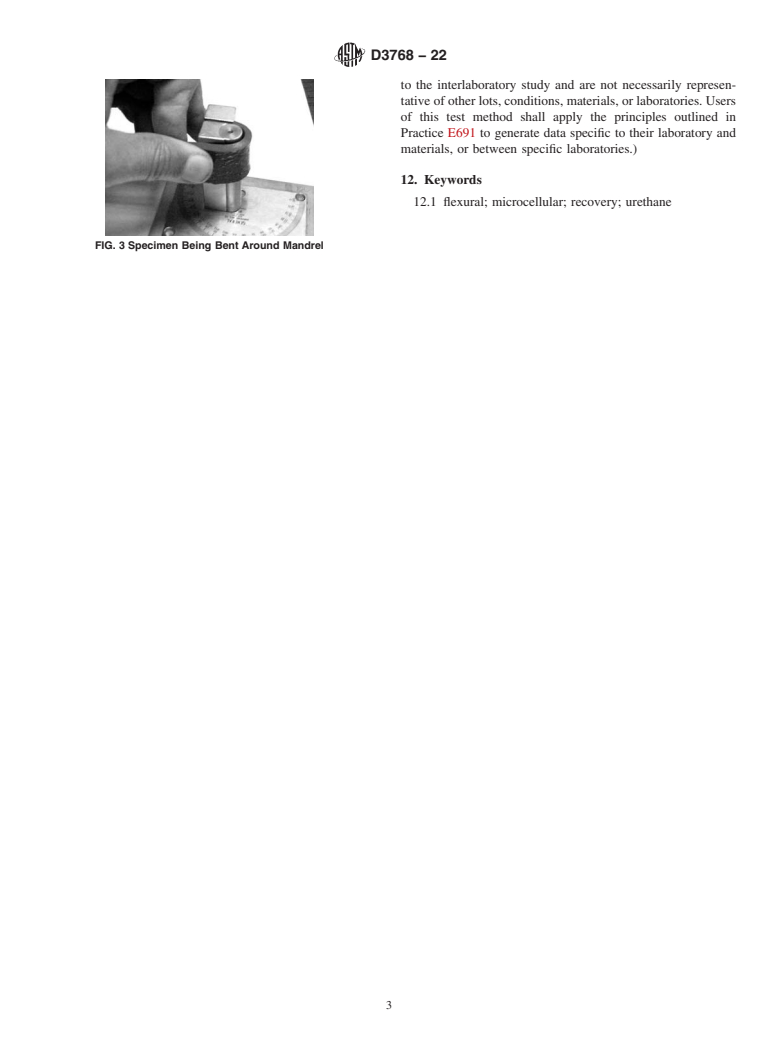

FIG. 2 Specimen Mounted in Fixture

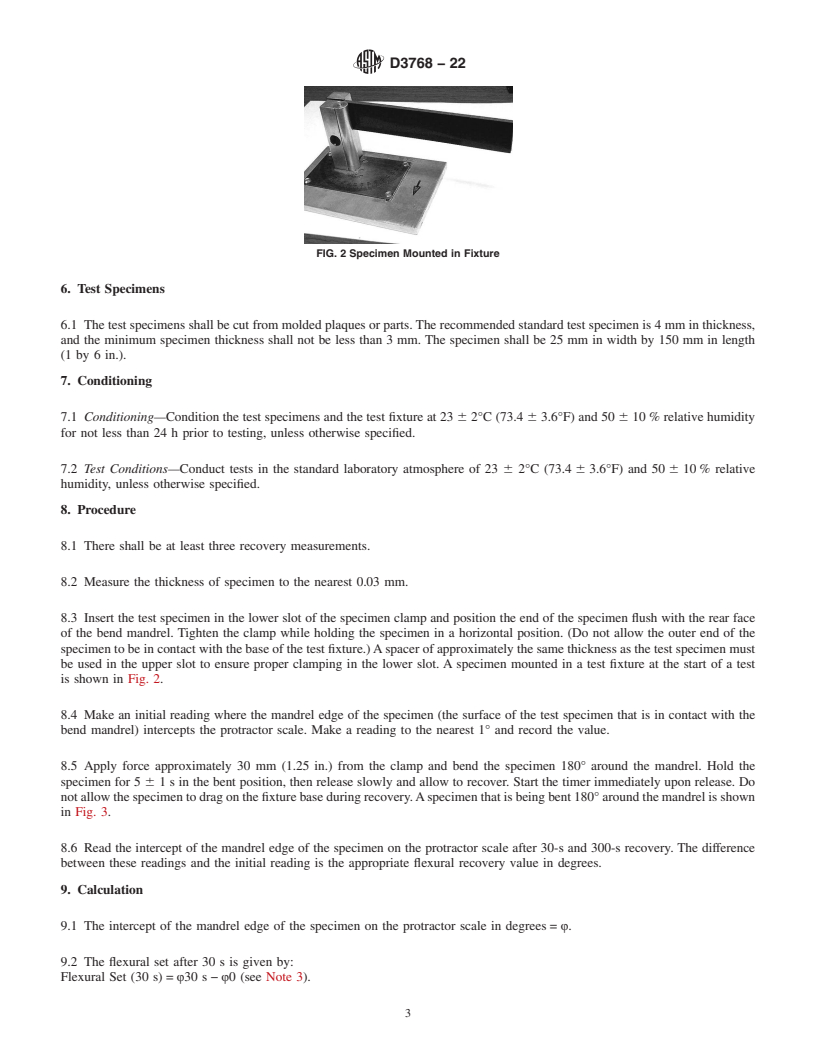

8.5 Apply force approximately 30 mm (1.25 in.) from the

clamp and bend the specimen 180° around the mandrel. Hold

the specimen for 5 6 1

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D3768 − 16 D3768 − 22

Standard Test Method for

1

Microcellular Urethanes—Flexural Recovery

This standard is issued under the fixed designation D3768; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This test method covers the procedure and apparatus for measuring the flexural recovery of microcellular urethanes.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D883 Terminology Relating to Plastics

3

D3040 Practice for Preparing Precision Statements for Standards Related to Rubber and Rubber Testing (Withdrawn 1987)

D3489 Test Methods for Microcellular Urethane Materials

E456 Terminology Relating to Quality and Statistics

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

E2935 Practice for Evaluating Equivalence of Two Testing Processes

3. Terminology

3.1 For definitions of terms Terms used in this test method standard are defined in accordance with Terminology D883and

associated with plastics issues, refer to terminology contained in , unless otherwise specified. For terms relating to precision and

bias and associated issues, the terms used in this standard are defined in accordance with Terminology D883E456.

3.2 The following definition is from Test Methods D3489:

1

This test method is under the jurisdiction of ASTM Committee D20 on Plastics and is the direct responsibility of Subcommittee D20.22 on Cellular Materials - Plastics

and Elastomers.

Current edition approved Oct. 1, 2016March 15, 2022. Published October 2016March 2022. Originally approved in 1979. Last previous edition approved in 20112016

as D3768 - 11.D3768 - 16. DOI: 10.1520/D3768-16.10.1520/D3768-22.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D3768 − 22

FIG. 1 Example Fixture for Flexural Recovery Test

3.2.1 microcellular urethane, n—an elastomeric material made by the interaction of a polyol and an organic isocyanate, having

3 3

cell diameters in the range from 0.0001 to 0.001 mm, with a minimum density of 160 kg/m (10 lb/ft ).

4. Significance and Use

4.1 This test method is used to indicate the ability of a material to recover after a 180° bend around a 12.7-mm (0.5-in.) diameter

mandrel at room temperature.

4.2 Before proceeding with this test method, reference shall be made to any specification for the material being tested. Any test

specimen preparation, conditioning, or dimensions, or combination thereof, and testing parameters covered in the materials

specification shall take precedence over those mentioned in these test methods. If there are no material specifications, then the

default conditions apply.

NOTE 2—This test method is applicable to solid urethanes.

5. Apparatus

5.1 Flexural Recovery Test Fixture—The test fixture shall consist of a 12.7-mm diameter mandrel mounted to a base equipped with

a protractor. A drawing of a typical test fixture is shown in Fig. 1.

5.2 Timer, capable of indicating seconds.

5.3 Thickness Indicator, accurate to 0.03 mm.

2

---------------------- Page: 2 ----------------------

D3768 − 22

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.