ASTM F1284-04(2008)

(Test Method)Standard Test Method for Evaluating Carpet Embedded Dirt Removal Effectiveness of Residential Central Vacuum Cleaning Systems

Standard Test Method for Evaluating Carpet Embedded Dirt Removal Effectiveness of Residential Central Vacuum Cleaning Systems

SIGNIFICANCE AND USE

This test method provides a laboratory test for determining the relative carpet dirt removal effectiveness of residential central vacuum cleaning systems when tested under standard conditions and on representative types of carpets.

This laboratory test method may not give a representation of carpet embedded dirt cleaning effectiveness in the home.

In order to provide a uniform basis for measuring performance as described in 1.1, standardized test carpets and a standardized test dirt are employed in this procedure.

The results reflect a non-loaded cleaning capability and may not be representative of cleaning capabilities under dirt loading conditions.

SCOPE

1.1 This test method is applicable to residential central vacuum cleaning systems intended for cleaning carpets.

1.2 This test method applies only to embedded dirt removal from carpets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

X1.1.1 The purpose of this test is to determine a ratio of a carpet-embedded dirt removal effectiveness and a home-carpet embedded removal effectiveness rating which can be used for comparing one or more vacuum cleaners against a standard vacuum cleaner and determining correlation with laboratory ASTM tests. The results are representative of the geographic area covered by the test homes.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 1284 – 04 (Reapproved 2008)

Standard Test Method for

Evaluating Carpet Embedded Dirt Removal Effectiveness of

Residential Central Vacuum Cleaning Systems

This standard is issued under the fixed designation F 1284; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F 1334 Test Method for Determining A-Weighted Sound

Power Level of Vacuum Cleaners

1.1 This test method is applicable to residential central

F 1409 TestMethodforStraightLineMovementofVacuum

vacuum cleaning systems intended for cleaning carpets.

Cleaners While Cleaning Carpets

1.2 This test method applies only to embedded dirt removal

from carpets.

3. Terminology

1.3 This standard does not purport to address all of the

3.1 Definitions of Terms Specific to This Standard:

safety concerns, if any, associated with its use. It is the

3.1.1 cleaning ability, n—the potential of a vacuum cleaner

responsibility of the user of this standard to establish appro-

to remove dirt from a surface (sometimes referred to in the

priate safety and health practices and determine the applica-

industry as cleanability, dry).

bility of regulatory limitations prior to use.

3.1.2 model, n—the designation of a group of vacuum

2. Referenced Documents cleaners having identical, mechanical and electrical construc-

tion with only cosmetic or nonfunctional differences.

2.1 ASTM Standards:

3.1.3 population, n—the total of all units of a particular

D75 Practice for Sampling Aggregates

model vacuum cleaner being tested.

E11 Specification for Wire Cloth and Sieves for Testing

3.1.4 sample, n—a group of vacuum cleaners taken from a

Purposes

large collection of vacuum cleaners of one particular model,

F 608 Test Method for Evaluation of Carpet Embedded Dirt

whichservestoprovideinformationthatmaybeusedasabasis

Removal Effectiveness of Household/Commercial Vacuum

for making a decision concerning the larger collection.

Cleaners

3.1.5 test run, n—the definitive procedure that produces a

F 655 Specification for Test Carpets and Pads for Vacuum

singular measured result.

Cleaner Testing

3.1.6 test unit, n—a single vacuum cleaner of the model

F 922 Test Method for Motor Life Evaluation of an Electric

being tested.

Motorized Nozzle

F 1038 Test Method for Motor Life Evaluation of a Canis-

4. Significance and Use

ter, Hand-held, Stick, and Utility Type Vacuum Cleaner

4.1 Thistestmethodprovidesalaboratorytestfordetermin-

Without a Driven Agitator

ing the relative carpet dirt removal effectiveness of residential

central vacuum cleaning systems when tested under standard

conditions and on representative types of carpets.

This test method is under the jurisdiction ofASTM Committee F11 onVacuum

4.2 This laboratory test method may not give a representa-

Cleaners and is the direct responsibility of Subcommittee F11.21 on Cleanability.

tion of carpet embedded dirt cleaning effectiveness in the

Current edition approved Oct. 1, 2008. Published February 2009. Originally

approved in 1992. Last previous edition approved in 2004 as F 1284 – 04.

home.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.3 In order to provide a uniform basis for measuring

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

performance as described in 1.1, standardized test carpets and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. a standardized test dirt are employed in this procedure.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1284 – 04 (2008)

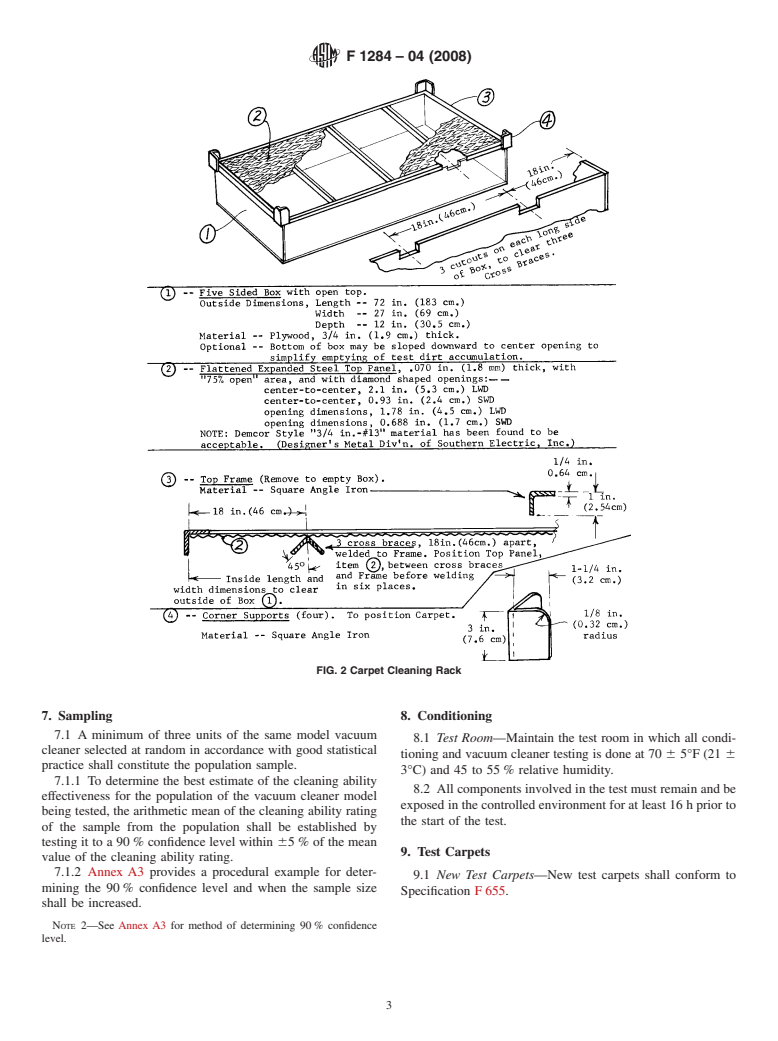

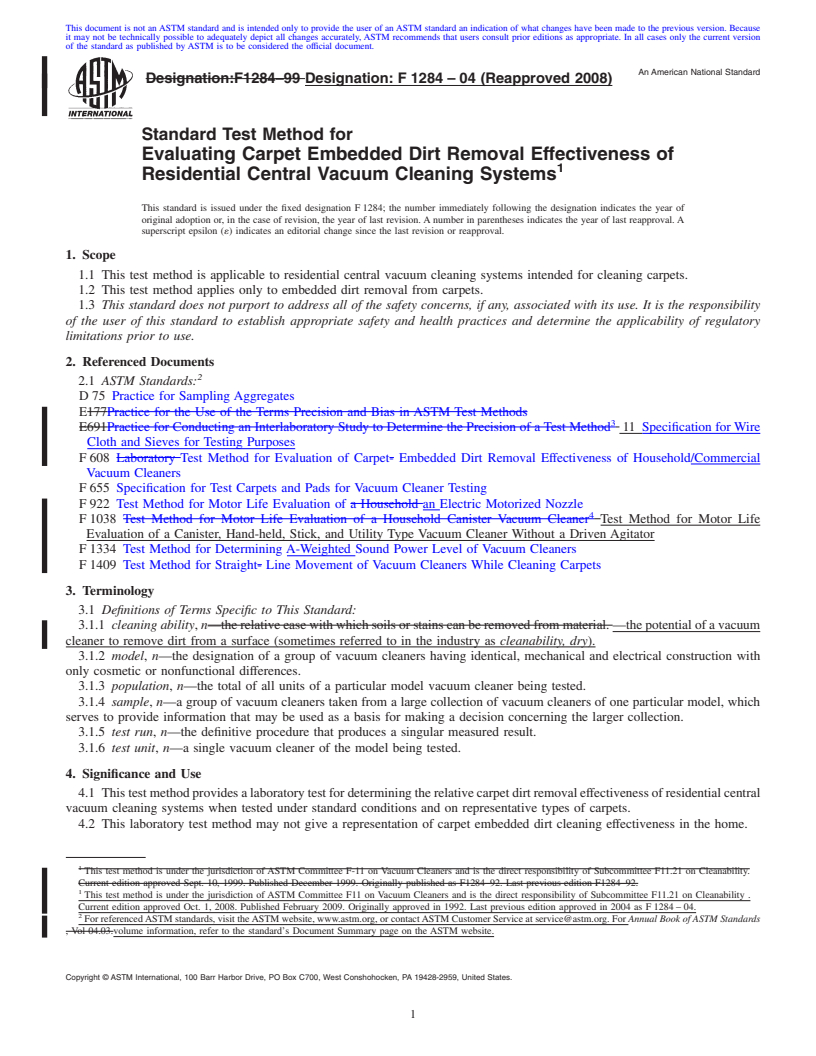

FIG. 1 Dirt Embedment Tool

4.4 The results reflect a non-loaded cleaning capability and 5.8 Carpet Conditioning Equipment, to support the test

may not be representative of cleaning capabilities under dirt carpet during new carpet conditioning and the removal of

loading conditions. residual dirt from the test carpet before each test run (Fig. 2).

5.9 Rotating Agitator Conditioning Vacuum Cleaner/

5. Apparatus

Equipment, for conditioning new test carpets and removing

5.1 Weighing Scale (for weighing carpets; see 9.1.4 and

residual dirt from the test carpet before each test run. This

12.6)—The scale must be accurate to 0.035 oz (1 g) and have

cannot be the unit being tested.

a weighing capacity of at least 15 lb (6.82 kg).

4 NOTE 1—Automatedmethodsforspreadingthetestdirt,embeddingthe

5.2 Weighing Scale (for weighing test dirt and non-

test dirt, and cleaning and reconditioning the test carpets are acceptable if

disposable dirt receptacles; see 10.1.2 and 12.10)—The scale

they do not change the results of this test method.

must be accurate to 0.0035 oz (0.10 g) and have a weighing

5.10 Temperature and Humidity Indicators, to provide tem-

capacity of at least 1.1 lb (500 g).

perature measurements accurate to within 61°F (6 ⁄2 °C) and

5.3 Stopwatch with a second hand, or other type of equip-

humidity measurements accurate to within 62 % relative

ment capable of establishing the specified rate of movement

humidity.

and total cycle time.

5.4 Voltmeter, to measure input volts to the cleaning system 5.11 Supporting Surface—A flat surface consisting of a

to provide measurements accurate to within 61%. piece of ⁄4-in. (19-mm) thick exterior-grade plywood with the

5.5 Voltage Regulator System,tocontroltheinputvoltageto “A” surface upward to support the test carpet and pad.The test

the vacuum cleaner. The regulator shall be capable of main- carpet and pad may be retained to the supporting surface, but

taining the vacuum cleaner’s rated voltage 61 % and rated only the four corners, by any acceptable means.

frequency 61 Hz having a wave form that is essentially

5.12 Rotating Agitator Reference Vacuum Cleaner, one, for

sinusoidal with 3 % max harmonic distortion for the duration

calibrating test carpets (see 10.4).

of the test.

5.13 Straight-Air Canister Reference Vacuum Cleaner, one,

5.6 Dirt Embedment Tool,withtherollerlocked(seeFig.1).

for calibrating test carpets (see 10.4).

5.7 Dirt Dispenser—Dispensing system that provides the

5.14 Orifice Adapter Tube—See Fig. 3.

operator with a method to distribute the test dirt uniformly on

the carpet test area.

6. Materials

6.1 Standard Carpets, conforming to Specification F 655.

The OHAUS Models GT-8000, LB30-CO and 1119D, all available from

6.2 Standard Carpet Padding, conforming to Specification

OHAUS, Inc. Florham Park, NJ, or the equivalent, have been found suitable for this

F 655.

purpose. It is recommended that the scale read directly in grams.

The Mettler-Toledo Model PM 2000, available from Mettler-Toledo, Inc., Box

6.3 Test Dirt (see Annex A1).

71, Highstown, NJ, 08520. The OHAUS Model-GT-8000 available from OHAUS,

6.3.1 Silica Sand—(see Annex A1).

Inc., Florham Park, NJ, or equivalent, have been found suitable for this purpose. It

is recommended that the seal read directly in grams. 6.3.2 Talc—see (Annex A1).

F 1284 – 04 (2008)

FIG. 2 Carpet Cleaning Rack

7. Sampling 8. Conditioning

7.1 A minimum of three units of the same model vacuum

8.1 Test Room—Maintain the test room in which all condi-

cleaner selected at random in accordance with good statistical

tioning and vacuum cleaner testing is done at 70 6 5°F (21 6

practice shall constitute the population sample.

3°C) and 45 to 55 % relative humidity.

7.1.1 To determine the best estimate of the cleaning ability

8.2 All components involved in the test must remain and be

effectiveness for the population of the vacuum cleaner model

exposed in the controlled environment for at least 16 h prior to

being tested, the arithmetic mean of the cleaning ability rating

the start of the test.

of the sample from the population shall be established by

testing it to a 90 % confidence level within 65 % of the mean

9. Test Carpets

value of the cleaning ability rating.

7.1.2 Annex A3 provides a procedural example for deter-

9.1 New Test Carpets—New test carpets shall conform to

mining the 90 % confidence level and when the sample size

Specification F 655.

shall be increased.

NOTE 2—See Annex A3 for method of determining 90 % confidence

level.

F 1284 – 04 (2008)

FIG. 3 Orifice Adapter Tube

9.1.1 Cut a sample of each test carpet to a size of 27 by 72 9.2.2.2 Place the carpet on the carpet cleaning rack (Fig. 2)

in. (690 by 1830 mm) minimum. If the warp direction or “lay” with pile side down. Run the rotating agitator conditioning

of the carpet fiber can be determined, it shall be in the 72-in. vacuum cleaner over the carpet for 2 min. concentrating on the

direction as indicated in Fig. 4. Carpets shall be bound on all test area; then run the rotating agitator conditioning vacuum

sides. cleaner thoroughly over the entire area at least one time.

9.1.2 Mark the test area on each carpet as indicated in Fig. 9.2.2.3 Then place the carpet (nap up) on the pad, on the

4. plywood supporting surface and clean it with the rotating

agitator conditioning vacuum cleaner for 2 minutes, concen-

9.1.3 Precondition new test carpet samples.

trating on the test area; then run the rotating agitator vacuum

9.1.3.1 Preconditiontheentireareaofthecarpetbycleaning

cleaner thoroughly over the entire area at least one time.

with the rotating agitator conditioning vacuum cleaner. Con-

9.2.2.4 Weigh the carpet.

tinue the operation until less than2gof carpet fiber is picked

up in 5 min.

9.2.2.5 Keep alternating 9.2.2.2 and 9.2.2.3, always ending

with pile side up, until the carpet weight meets the require-

9.1.3.2 Run ten carpet-embedded dirt removal effectiveness

test runs in accordance with Section 12 before conducting test ments of 9.2.1.

calibrations as directed in Section 11.

9.2.2.6 A high-cleaning performance rotating agitator

vacuum cleaner is recommended for reducing the time to

9.1.4 Weigh and record the preconditioned weight of the

carpet. recondition the test carpet.

9.2 Reconditioning Used Test Carpet Samples: 9.2.2.7 Reconditioning equipment, which uses nondispos-

able filters should have the filter or filters cleaned after every

9.2.1 To remove the residual dirt and stabilize the moisture

four carpet reconditioning runs, or more often if desired.

content, clean the carpet with a rotating agitator conditioning

vacuum cleaner until its weight does not exceed its previously 9.2.2.8 Reconditioning equipment, which uses a primary

measured, original preconditioned weight (9.1.4 by more than disposable filter or primary filters should have the filter or

2 g and less than1gis picked up by the conditioning vacuum filters replaced after every four carpet reconditioning runs, or

cleaner after 4 minutes of cleaning. more often, if required.

9.2.2 Procedure: 9.3 Reconditioning Used Carpet Padding:

9.2.2.1 Clean the test carpet with the rotating agitator 9.3.1 Clean carpet padding by shaking after each day’s

conditioning vacuum cleaner at a rate of 1.8 ft/s (0.55 m/s) as testing, or more often if necessary, to remove any collected test

follows: dirt.

F 1284 – 04 (2008)

NOTE 1—Cleaning test area should be positioned as shown. First forward stroke of rotating agitator or carpet is in direction with lay of carpet.

FIG. 4 Test Carpet

9.3.2 Replace carpet padding when it has holes, tears, or 10.4.2 Maintain the performance of the reference vacuum

other signs of wear. cleaners throughout the carpet calibration period.

10. Test Systems and Cleaning Tools

11. Test Carpet Calibration

10.1 New Test Systems and Cleaning Tools:

11.1 The purpose of calibration is to determine when the

10.1.1 Preconditioning a New System—Runthesysteminat

carpet needs to be replaced by establishing a reference rating

rated voltage 61 % and rated frequency 61 Hz with filters in

foreachnewpreconditionedtestcarpetandtocheckthisrating

place for 1 h.

every 50 or fewer test runs.

10.1.1.1 If a rotating agitator type cleaning tool is included

11.2 The reference ratings are determined for each test

with the system, operate it for 1 h with agitator bristles not

carpet by the percent pickup using the reference rotating

engaged on any surface.

agitatorvacuumcleanerorsystemandthereferencestraightair

10.1.2 For systems with nondisposable filters, weigh and

vacuum cleaner or system.

recordthefilter’soriginalweighttothenearest0.0035oz(0.10

11.3 This percent pickup is determined by performing a

g). This may not be possible with some systems in which the

cleaning effectiveness test (see Section 12).

nondisposable filter cannot be removed.

11.4 Repeat the test carpet calibration procedure on the

10.2 Used Test Systems and Cleaning Tools:

carpets every 50 or fewer test runs.

10.2.1 Recondition a used test system prior to each test run

11.5 When the pickup for either reference vacuum cleaner

as follows:

or system varies by 4 g from the original reference rating for

10.2.1.1 Thoroughly remove excess dirt from the test sys-

the carpet, replace the carpet.

tem.Without using tools for disassembly, clean the entire outer

surface, brushes, nozzle chamber, ductwork, inside of the

12. Carpet-Embedded Dirt Removal Effectiveness Test

chamber surrounding the primary filter, and inside hose and

wands.

12.1 Set up the system as shown in Fig. 5. On the intake

10.2.1.2 Clean the entire inner surface of the wands. side, use an orifice tube adapter terminating with a wall inlet

10.2.1.3 For systems using disposable filters, use a new

valve. Insert into the wall valve a flexible cleaning hose as

primary filter for each test. Thoroughly clean the inside of the provided with the system. The hose, wands, and nozzle should

chamber surrounding the primary filter each time the filter is

be those normally offered with the particular unit being tested.

replaced. If more than one hose, wand, or nozzle type is offered with the

10.2.1.4 For systems using cloth filter bags or other types of

unit, the manufacturer’s part, catalog or model number of the

nondisposable dirt receptacles, empty according to manufac- ductwork, fittings, hose, wands, and nozzle used in the test

turer’s instructions after each test run, and clean the cloth filter

must be recorded and presented as part of the cleaning

bag or nondisposable dirt receptacle until its weight is within effectiveness rating.

0.07 oz (2 g) of its original weight (see 10.1.2). Thoroughly

12.1.1 Thehoseshouldbelaidoutstraightalongthefloorof

clean the inside of the chamber surrounding the primary filter

the test area, except for the excess required to co

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

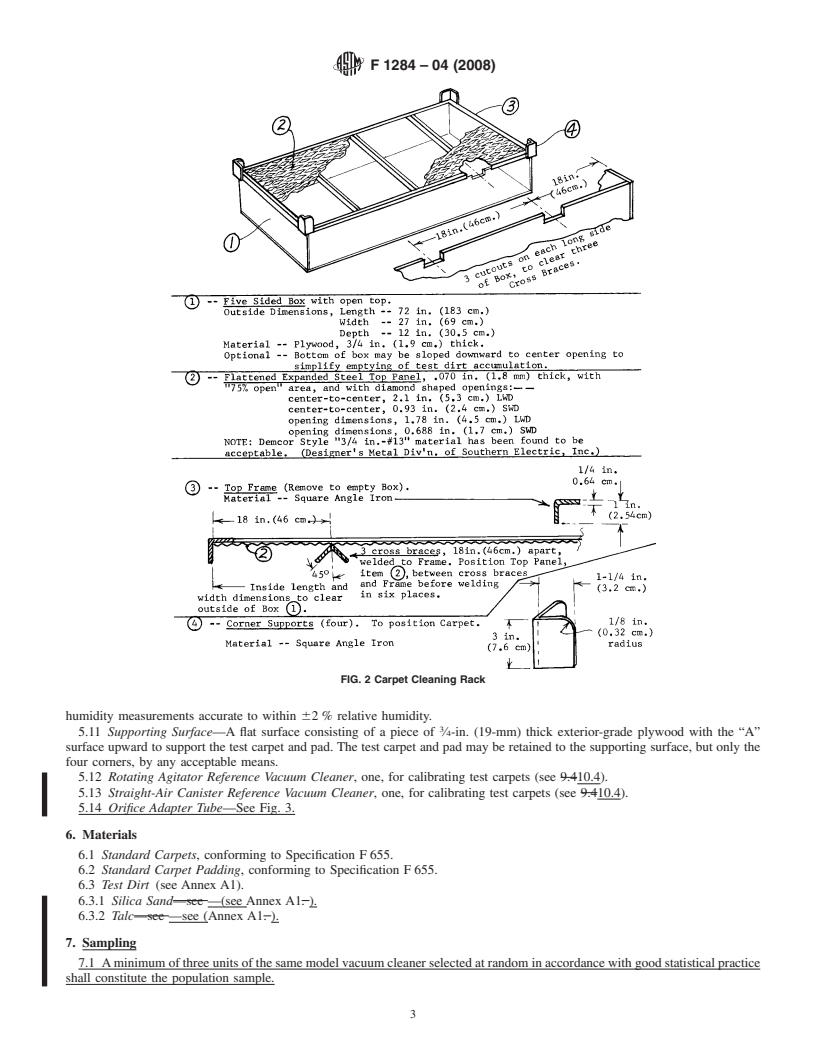

An American National Standard

Designation:F1284–99 Designation: F 1284 – 04 (Reapproved 2008)

Standard Test Method for

Evaluating Carpet Embedded Dirt Removal Effectiveness of

Residential Central Vacuum Cleaning Systems

This standard is issued under the fixed designation F 1284; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method is applicable to residential central vacuum cleaning systems intended for cleaning carpets.

1.2 This test method applies only to embedded dirt removal from carpets.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D75 Practice for Sampling Aggregates

E177Practice for the Use of the Terms Precision and Bias in ASTM Test Methods

E691Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method 11 Specification for Wire

Cloth and Sieves for Testing Purposes

F 608 Laboratory Test Method for Evaluation of Carpet- Embedded Dirt Removal Effectiveness of Household/Commercial

Vacuum Cleaners

F 655 Specification for Test Carpets and Pads for Vacuum Cleaner Testing

F 922 Test Method for Motor Life Evaluation of a Household an Electric Motorized Nozzle

F 1038 Test Method for Motor Life Evaluation of a Household Canister Vacuum Cleaner Test Method for Motor Life

Evaluation of a Canister, Hand-held, Stick, and Utility Type Vacuum Cleaner Without a Driven Agitator

F 1334 Test Method for Determining A-Weighted Sound Power Level of Vacuum Cleaners

F 1409 Test Method for Straight- Line Movement of Vacuum Cleaners While Cleaning Carpets

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 cleaning ability, n—therelativeeasewithwhichsoilsorstainscanberemovedfrommaterial.—thepotentialofavacuum

cleaner to remove dirt from a surface (sometimes referred to in the industry as cleanability, dry).

3.1.2 model, n—the designation of a group of vacuum cleaners having identical, mechanical and electrical construction with

only cosmetic or nonfunctional differences.

3.1.3 population, n—the total of all units of a particular model vacuum cleaner being tested.

3.1.4 sample, n—a group of vacuum cleaners taken from a large collection of vacuum cleaners of one particular model, which

serves to provide information that may be used as a basis for making a decision concerning the larger collection.

3.1.5 test run, n—the definitive procedure that produces a singular measured result.

3.1.6 test unit, n—a single vacuum cleaner of the model being tested.

4. Significance and Use

4.1 Thistestmethodprovidesalaboratorytestfordeterminingtherelativecarpetdirtremovaleffectivenessofresidentialcentral

vacuum cleaning systems when tested under standard conditions and on representative types of carpets.

4.2 This laboratory test method may not give a representation of carpet embedded dirt cleaning effectiveness in the home.

This test method is under the jurisdiction of ASTM Committee F-11 on Vacuum Cleaners and is the direct responsibility of Subcommittee F11.21 on Cleanability.

Current edition approved Sept. 10, 1999. Published December 1999. Originally published as F1284–92. Last previous edition F1284–92.

This test method is under the jurisdiction of ASTM Committee F11 on Vacuum Cleaners and is the direct responsibility of Subcommittee F11.21 on Cleanability .

Current edition approved Oct. 1, 2008. Published February 2009. Originally approved in 1992. Last previous edition approved in 2004 as F 1284 – 04.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 04.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 1284 – 04 (2008)

4.3 In order to provide a uniform basis for measuring performance as described in 1.1, standardized test carpets and a

standardized test dirt are employed in this procedure.

4.4 The results reflect a non-loaded cleaning capability and may not be representative of cleaning capabilities under dirt loading

conditions.

5. Apparatus

5.1 Weighing Scale (for weighing carpets; see 8.1.4 9.1.4 and 11.612.6)—The scale must be accurate to 0.035 oz (1 g) and

have a weighing capacity of at least 15 lb (6.82 kg).

5.2 Weighing Scale (for weighing test dirt and non-disposable dirt receptacles; see 9.1.2 10.1.2 and 11.1012.10)—The scale

must be accurate to 0.0035 oz (0.10 g) and have a weighing capacity of at least 1.1 lb (500 g).

5.3 Stopwatchwith a second hand, or other type of equipment capable of establishing the specified rate of movement and total

time of the dirt embedment tool, cleaning tool, and power unit. with a second hand, or other type of equipment capable of

establishing the specified rate of movement and total cycle time.

5.4 Voltmeter, to measure input volts to the cleaning system to provide measurements accurate to within 61%.

5.5 Voltage Regulator System, to control the input voltage to the vacuum cleaner. The regulator shall be capable of maintaining

the vacuum cleaner’s rated voltage 61 % and rated frequency 61 Hz having a wave form that is essentially sinusoidal with 3 %

max harmonic distortion for the duration of the test.

5.6 Dirt Embedment Tool, with the roller locked (see Fig. 1).

5.7 Dirt Dispenser—Any convenient dispensing — Dispensing system that provides the operator with a method to distribute

the test dirt uniformly on the carpet test area.

5.8 Carpet Conditioning Equipment , to support the test carpet during new carpet conditioning and the removal of residual dirt

from the test carpet before each test run (Fig. 2).

5.9 Rotating Agitator Conditioning Vacuum Cleaner/Equipment, for conditioning new test carpets and removing residual dirt

from the test carpet before each test run. This cannot be the unit being tested.

NOTE 1—Automated methods for spreading the test dirt, embedding the test dirt, and cleaning and reconditioning the test carpets are acceptable if they

do not change the results of this test method.

5.10 Temperature and Humidity Indicators , to provide temperature measurements accurate to within 61°F (6 ⁄2 °C) and

Annual Book of ASTM Standards, Vol 14.02.

The OHAUS Models GT-8000, LB30-CO and 1119D, all available from OHAUS, Inc. Florham Park, NJ, or the equivalent, have been found suitable for this purpose.

It is recommended that the scale read directly in grams.

Annual Book of ASTM Standards, Vol 15.08.

The Mettler-Toledo Model PM 2000, available from Mettler-Toledo, Inc., Box 71, Highstown, NJ, 08520. The OHAUS Model-GT-8000 available from OHAUS, Inc.,

Florham Park, NJ, or equivalent, have been found suitable for this purpose. It is recommended that the seal read directly in grams.

FIG. 1 Dirt Embedment Tool

F 1284 – 04 (2008)

FIG. 2 Carpet Cleaning Rack

humidity measurements accurate to within 62 % relative humidity.

5.11 Supporting Surface—A flat surface consisting of a piece of ⁄4-in. (19-mm) thick exterior-grade plywood with the “A”

surface upward to support the test carpet and pad. The test carpet and pad may be retained to the supporting surface, but only the

four corners, by any acceptable means.

5.12 Rotating Agitator Reference Vacuum Cleaner, one, for calibrating test carpets (see 9.410.4).

5.13 Straight-Air Canister Reference Vacuum Cleaner, one, for calibrating test carpets (see 9.410.4).

5.14 Orifice Adapter Tube—See Fig. 3.

6. Materials

6.1 Standard Carpets, conforming to Specification F 655.

6.2 Standard Carpet Padding, conforming to Specification F 655.

6.3 Test Dirt (see Annex A1).

6.3.1 Silica Sand—see —(see Annex A1. ).

6.3.2 Talc—see —see (Annex A1. ).

7. Sampling

7.1 Aminimumofthreeunitsofthesamemodelvacuumcleanerselectedatrandominaccordancewithgoodstatisticalpractice

shall constitute the population sample.

F 1284 – 04 (2008)

FIG. 3 Orifice Adapter Tube

7.1.1 To determine the best estimate of the cleaning ability effectiveness for the population of the vacuum cleaner model being

tested, the arithmetic mean of the cleaning ability rating of the sample from the population shall be established by testing it to a

90 % confidence level within 65 % of the mean value of the cleaning ability rating.

7.1.2 Annex A3 provides a procedural example for determining the 90 % confidence level and when the sample size shall be

increased.

NOTE 2—See Annex A3 for method of determining 90 % confidence level.

8. Conditioning

7.1

8.1 Test Room—Maintain the test room in which all conditioning and vacuum cleaner testing is done at 70 6 5°F (21 6 3°C)

and 45 to 55 % relative humidity.

7.2All8.2 All components involved in the test must remain and be exposed in the controlled environment for at least 16 h prior

to the start of the test.

8.9. Test Carpets

8.1

9.1 New Test Carpets— New test carpets shall conform to Specification F 655.

8.1.1Cut9.1.1 Cut a sample of each test carpet to a size of 27 by 72 in. (690 by 1830 mm) minimum. If the warp direction or

“lay” of the carpet fiber can be determined, it shall be in the 72-in. direction as indicated in Fig. 34. Carpets shall be bound on

all sides.

89.1.2 Mark the test area on each carpet as indicated in Fig. 34.

89.1.3 Precondition new test carpet samples.

89.1.3.1 Precondition the entire area of the carpet by cleaning with the rotating agitator conditioning vacuum cleaner. Continue

the operation until less than2gof carpet fiber is picked up in 5 min.

89.1.3.2 Run ten carpet-embedded dirt removal effectiveness test runs in accordance with Section 1112 before conducting test

calibrations as directed in Section 1011.

8.1.4

9.1.4 Weigh and record the preconditioned weight of the carpet.

8.2

F 1284 – 04 (2008)

NOTE 1—Cleaning test area should be positioned as shown. First forward stroke of rotating agitator or carpet is in direction with lay of carpet.

FIG.34TestCarpet

9.2 Reconditioning Used Test Carpet Samples:

8.2.1

9.2.1 To remove the residual dirt and stabilize the moisture content, clean the carpet with a rotating agitator conditioning

vacuum cleaner until its weight does not exceed its previously measured, original preconditioned weight (8.1.4 9.1.4 by more than

2 g and less than1gis picked up by the conditioning vacuum cleaner after 4 minutes of cleaning.

8.2.2

9.2.2 Procedure:

89.2.2.1 Clean the test carpet with the rotating agitator conditioning vacuum cleaner at a rate of 1.8 ft/s (0.55 m/s) as follows:

8.2.2.29.2.2.2 Place the carpet on the carpet cleaning rack (Fig. 2) with pile side down. Run the rotating agitator conditioning

vacuumcleaneroverthecarpetfor2min.concentratingonthetestarea;thenruntherotatingagitatorconditioningvacuumcleaner

thoroughly over the entire area at least one time.

89.2.2.3 Then place the carpet (nap up) on the pad, on the plywood supporting surface and clean it with the rotating agitator

conditioningvacuumcleanerfor2minutes,concentratingonthetestarea;thenruntherotatingagitatorvacuumcleanerthoroughly

over the entire area at least one time.

89.2.2.4 Weigh the carpet.

89.2.2.5 Keep alternating 8.2.2.29.2.2.2 and 8.2.2.39.2.2.3, always ending with pile side up, until the carpet weight meets the

requirements of 8.2.19.2.1.

8.2.2.6A9.2.2.6 A high-cleaning performance rotating agitator vacuum cleaner is recommended for reducing the time to

recondition the test carpet.

89.2.2.7 Reconditioning equipment, which uses nondisposable filters should have the filter or filters cleaned after every four

carpet reconditioning runs, or more often if desired.

89.2.2.8 Reconditioning equipment, which uses a primary disposable filter or primary filters should have the filter or filters

replaced after every four carpet reconditioning runs, or more often, if required.

8.39.3 Reconditioning Used Carpet Padding:

89.3.1 Clean carpet padding by shaking after each day’s testing, or more often if necessary, to remove any collected test dirt.

89.3.2 Replace carpet padding when it has holes, tears, or other signs of wear.

9.10. Test Systems and Cleaning Tools

9.1

10.1 New Test Systems and Cleaning Tools:

9.1.1

10.1.1 Preconditioning a New System —Run the system in at rated voltage 61 % and rated frequency 61 Hz with filters in

place for 1 h.

910.1.1.1 Ifarotatingagitatortypecleaningtoolisincludedwiththesystem,operateitfor1hwithagitatorbristlesnotengaged

on any surface.

9.1.210.1.2 For systems with nondisposable filters, weigh and record the filter’s original weight to the nearest 0.0035 oz (0.10

g). This may not be possible with some systems in which the nondisposable filter cannot be removed.

9.2

10.2 Used Test Systems and Cleaning Tools:

9.2.1Recondition a

10.2.1 Recondition a used test system prior to each test run as follows:

910.2.1.1 Thoroughly remove excess dirt from the test system. Without using tools for disassembly, clean the entire outer

surface, brushes, nozzle chamber, ductwork, inside of the chamber surrounding the primary filter, and inside hose and wands.

910.2.1.2 Clean the entire inner surface of the wands.

910.2.1.3 Forsystemsusingdisposablefilters,useanewprimaryfilterforeachtest.Thoroughlycleantheinsideofthechamber

surrounding the primary filter each time the filter is replaced.

F 1284 – 04 (2008)

910.2.1.4 Forsystemsusingclothfilterbagsorothertypesofnondisposabledirtreceptacles,emptyaccordingtomanufacturer’s

instructions after each test run, and clean the cloth filter bag or nondisposable dirt receptacle until its weight is within 0.07 oz (2

g) of its original weight (see 9.1.210.1.2). Thoroughly clean the inside of the chamber surrounding the primary filter and reinstall

the filter.

9.3

10.3 Test System and Tool Settings :

9.3.1

10.3.1 Test System Settings—If various settings are provided, set the motor speed setting, suction regulator, nozzle hei

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.