ASTM G99-95a(2000)e1

(Test Method)Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

SCOPE

1.1 This test method describes a laboratory procedure for determining the wear of materials during sliding using a pin-on-disk apparatus. Materials are tested in pairs under nominally non-abrasive conditions. The principal areas of experimental attention in using this type of apparatus to measure wear are described. The coefficient of friction may also be determined.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: G 99 – 95a (Reapproved 2000)

Standard Test Method for

Wear Testing with a Pin-on-Disk Apparatus

This standard is issued under the fixed designation G 99; the number immediately following the designation indicates the year of original

adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A superscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Editorial corrections were made throughout in May 2000.

1. Scope about the disk center. In either case, the sliding path is a circle

on the disk surface. The plane of the disk may be oriented

1.1 This test method describes a laboratory procedure for

either horizontally or vertically.

determining the wear of materials during sliding using a

pin-on-disk apparatus. Materials are tested in pairs under

NOTE 1—Wear results may differ for different orientations.

nominally non-abrasive conditions. The principal areas of

3.1.1 The pin specimen is pressed against the disk at a

experimental attention in using this type of apparatus to

specified load usually by means of an arm or lever and attached

measure wear are described. The coefficient of friction may

weights. Other loading methods have been used, such as,

also be determined.

hydraulic or pneumatic.

1.2 The values stated in SI units are to be regarded as

NOTE 2—Wear results may differ for different loading methods.

standard.

1.3 This standard does not purport to address all of the

3.2 Wear results are reported as volume loss in cubic

safety concerns, if any, associated with its use. It is the

millimetres for the pin and the disk separately. When two

responsibility of the user of this standard to establish appro-

different materials are tested, it is recommended that each

priate safety and health practices and determine the applica-

material be tested in both the pin and disk positions.

bility of regulatory limitations prior to use.

3.3 The amount of wear is determined by measuring appro-

priate linear dimensions of both specimens before and after the

2. Referenced Documents

test, or by weighing both specimens before and after the test. If

2.1 ASTM Standards:

linear measures of wear are used, the length change or shape

E 122 Practice for Choice of Sample Size to Estimate a

change of the pin, and the depth or shape change of the disk

Measure of Quality for a Lot or Process

wear track (in millimetres) are determined by any suitable

E 177 Practice for Use of the Terms Precision and Bias in

metrological technique, such as electronic distance gaging or

ASTM Test Methods

stylus profiling. Linear measures of wear are converted to wear

E 178 Practice for Dealing with Outlying Observations

volume (in cubic millimetres) by using appropriate geometric

G 40 Terminology Relating to Wear and Erosion

relations. Linear measures of wear are used frequently in

2.2 Other Standard:

practice since mass loss is often too small to measure precisely.

DIN-50324 Testing of Friction and Wear

If loss of mass is measured, the mass loss value is converted to

volume loss (in cubic millimetres) using an appropriate value

3. Summary of Test Method

for the specimen density.

3.1 For the pin-on-disk wear test, two specimens are re-

3.4 Wear results are usually obtained by conducting a test

quired. One, a pin with a radiused tip, is positioned perpen-

for a selected sliding distance and for selected values of load

dicular to the other, usually a flat circular disk. A ball, rigidly

and speed. One set of test conditions that was used in an

held, is often used as the pin specimen. The test machine

interlaboratory measurement series is given in Table 1 and

causes either the disk specimen or the pin specimen to revolve

Table 2 as a guide. Other test conditions may be selected

depending on the purpose of the test.

3.5 Wear results may in some cases be reported as plots of

This test method is under the jurisdiction of ASTM Committee G02 on Wear

wear volume versus sliding distance using different specimens

and Erosion and is the direct responsibility of Subcommittee G02.40 on Non-

Abrasive Wear.

for different distances. Such plots may display non-linear

Current edition approved Nov. 10, 1995. Published January 1996. Originally

relationships between wear volume and distance over certain

published as G 99–90. Last previous edition G 99 – 95.

portions of the total sliding distance, and linear relationships

Annual Book of ASTM Standards, Vol 14.02.

over other portions. Causes for such differing relationships

Annual Book of ASTM Standards, Vol 03.02.

Available from Beuth Verlag GmbH, Burggrafenstrasse 6, 1000 Berlin 30,

Germany.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G99

TABLE 1 Characteristics of the Interlaboratory Wear Test Specimens

NOTE 1—See Note 4 in 10.4 for information.

A

Roughness

Composition (weight% ) Microstructure Hardness (HV 10)

R (mean) (μm) R (mean) (μm)

z a

B

Steel ball (100 Cr6) (AISI 52 100) 1.35 to 1.65 Cr martensitic with minor carbides 838 6 21 0.100 0.010

Diameter 10 mm ← 0.95 to 1.10 C and austenite

0.15 to 0.35 Si

0.25 to 0.45 Mn

C

Steel disc (100 Cr6) (AISI 52 100) ← <0.030 P martensitic with minor carbides 852 6 14 0.952 0.113

Diameter 40 mm <0.030 S and austenite

D

Alumina ball, diameter 5 10 mm ← 95%Al O (with addi- equi-granular alpha alumina 1610 6 101 (HV 0.2) 1.369 0.123

2 3

tives of TiO , with very minor secondary

D

Alumina disc, diameter 5 40.6 mm ← MgO and ZnO) phases 1599 6 144 (HV 0.2) 0.968 0.041

A

Measured by stylus profilometry. R is maximum peak-to-valley roughness. R is arithmetic average roughness.

z a

B

Standard ball-bearing balls (SKF).

C

Standard spacers for thrust bearings (INA).

D

Manufactured by Compagnie Industrielle des Ceramiques Electroniques, France.

A

TABLE 2 Results of the Interlaboratory Tests

NOTE 1— See Note 4 in 10.4.

NOTE 2—Numbers in parentheses refer to all data received in the tests. In accordance with Practice E 178, outlier data values were identified in some

cases and discarded, resulting in the numbers without parentheses. The differences are seen to be small.

NOTE 3—Values preceded by 6 are one standard deviation.

NOTE 4—Between eleven and twenty laboratories provided these data.

NOTE 5—Calculated quantities (for example, wear volume) are given as mean values only.

NOTE 6—Values labeled “NM” were found to be smaller than the reproducible limit of measurement.

NOTE 7—A similar compilation of test data is given in DIN–50324.

Specimen Pairs

Results (ball) (disk)

Steel-steel Alumina-steel Steel-alumina Alumina-alumina

Ball wear scar diameter 2.11 6 0.27 NM 2.08 6 0.35 0.36 0.06

(mm) (2.11 6 0.27) (2.03 6 0.41) (0.3 6 0.06)

−3

Ball wear volume (10 198 . 186 0.08

mm ) (198) (169) (0.08)

Number of values 102 . 60 56

(102) (64) (59)

Disk wear scar width (mm) NM 0.64 6 0.12 NM NM

(0.64 6 0.12)

−3

Disk wear volume (10 . 480 . .

mm ) (480)

Number of values . 60 . .

(60)

Friction coefficient 0.60 6 0.11 0.76 6 0.14 0.60 6 0.12 0.41 6 0.08

Number of values 109 75 64 76

A −1

Test conditions: F 5 10 N; v 5 0.1 ms , T 5 23°C; relative humidity range 12 to 78 %; laboratory air; sliding distance 1000 m; wear track (nominal) diameter 5 32

mm; materials: steel 5 AISI 52 100; and alumina5a-Al O .

2 3

include initial “break-in” processes, transitions between re- load, machine characteristics, sliding speed, sliding distance,

gions of different dominant wear mechanisms, etc. The extent the environment, and the material properties. The value of any

of such non-linear periods depends on the details of the test

wear test method lies in predicting the relative ranking of

system, materials, and test conditions.

material combinations. Since the pin-on-disk test method does

3.6 It is not recommended that continuous wear depth data

not attempt to duplicate all the conditions that may be

obtained from position-sensing gages be used because of the

experienced in service (for example; lubrication, load, pres-

complicated effects of wear debris and transfer films present in

sure, contact geometry, removal of wear debris, and presence

the contact gap, and interferences from thermal expansion or

of corrosive environment), there is no ensurance that the test

contraction.

will predict the wear rate of a given material under conditions

differing from those in the test.

4. Significance and Use

4.1 The amount of wear in any system will, in general,

depend upon the number of system factors such as the applied

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G99

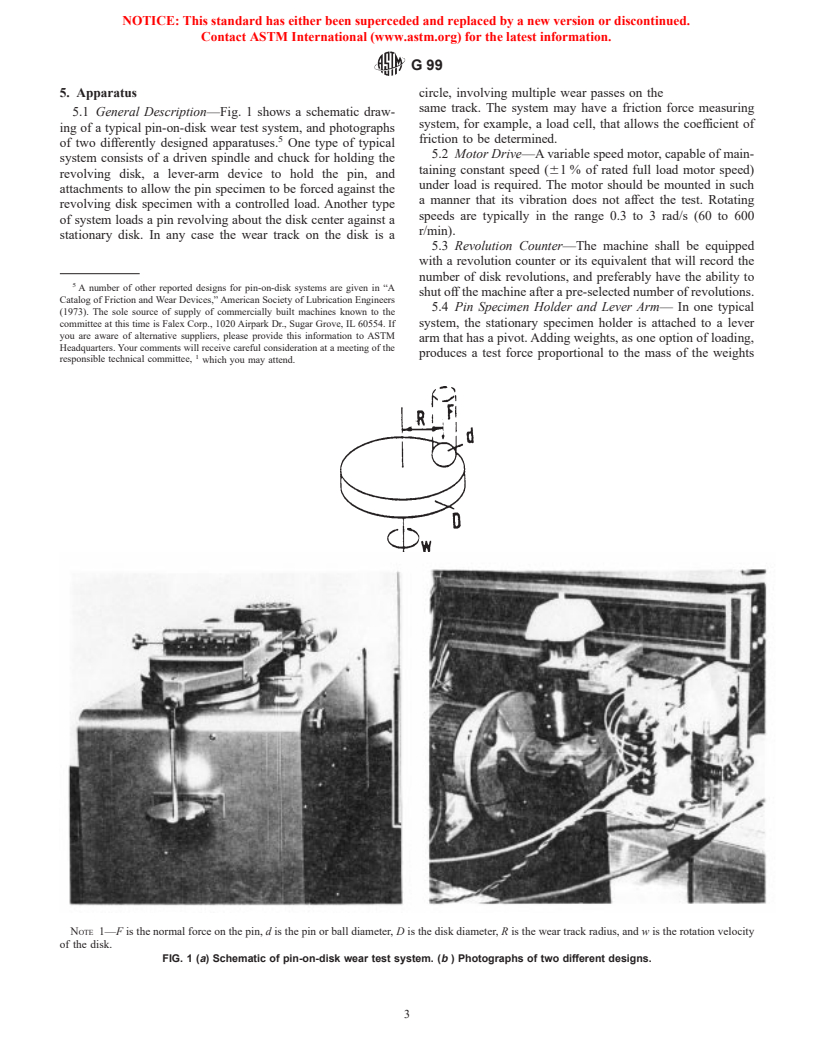

5. Apparatus circle, involving multiple wear passes on the

same track. The system may have a friction force measuring

5.1 General Description—Fig. 1 shows a schematic draw-

system, for example, a load cell, that allows the coefficient of

ing of a typical pin-on-disk wear test system, and photographs

friction to be determined.

of two differently designed apparatuses. One type of typical

5.2 Motor Drive—A variable speed motor, capable of main-

system consists of a driven spindle and chuck for holding the

taining constant speed (61 % of rated full load motor speed)

revolving disk, a lever-arm device to hold the pin, and

under load is required. The motor should be mounted in such

attachments to allow the pin specimen to be forced against the

a manner that its vibration does not affect the test. Rotating

revolving disk specimen with a controlled load. Another type

speeds are typically in the range 0.3 to 3 rad/s (60 to 600

of system loads a pin revolving about the disk center against a

r/min).

stationary disk. In any case the wear track on the disk is a

5.3 Revolution Counter—The machine shall be equipped

with a revolution counter or its equivalent that will record the

number of disk revolutions, and preferably have the ability to

A number of other reported designs for pin-on-disk systems are given in “A

shut off the machine after a pre-selected number of revolutions.

Catalog of Friction and Wear Devices,” American Society of Lubrication Engineers

5.4 Pin Specimen Holder and Lever Arm— In one typical

(1973). The sole source of supply of commercially built machines known to the

committee at this time is Falex Corp., 1020 Airpark Dr., Sugar Grove, IL 60554. If system, the stationary specimen holder is attached to a lever

you are aware of alternative suppliers, please provide this information to ASTM

arm that has a pivot. Adding weights, as one option of loading,

Headquarters. Your comments will receive careful consideration at a meeting of the

produces a test force proportional to the mass of the weights

responsible technical committee, which you may attend.

NOTE 1—F is the normal force on the pin, d is the pin or ball diameter, D is the disk diameter, R is the wear track radius, and w is the rotation velocity

of the disk.

FIG. 1 (a) Schematic of pin-on-disk wear test system. (b ) Photographs of two different designs.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

G99

applied. Ideally, the pivot of the arm should be located in the 8.3 Insert the disk securely in the holding device so that the

plane of the wearing contact to avoid extraneous loading forces disk is fixed perpendicular (61°) to the axis of the resolution.

due to the sliding friction. The pin holder and arm must be of 8.4 Insert the pin specimen securely in its holder and, if

substantial construction to reduce vibrational motion during the necessary, adjust so that the specimen is perpendicular (61°) to

test. the disk surface when in contact, in order to maintain the

5.5 Wear Measuring Systems—Instruments to obtain linear necessary contact conditions.

measures of wear should have a sensitivity of 2.5 μm or better. 8.5 Add the proper mass to the system lever or bale to

Any balance used to measure the mass loss of the test specimen develop the selected force pressing the pin against the disk.

shall have a sensitivity of 0.1 mg or better; in low wear 8.6 Start the motor and adjust the speed to the desired value

situations greater sensitivity may be needed. while holding the pin specimen out of contact with the disk.

Stop the motor.

6. Test Specimens and Sample Preparation

8.7 Set the revolution counter (or equivalent) to the desired

6.1 Materials—This test method may be applied to a variety number of revolutions.

of materials. The only requirement is that specimens having the 8.8 Begin the test with the specimens in contact under load.

specified dimensions can be prepared and that they will The test is stopped when the desired number of revolutions is

achieved. Tests should not be interrupted or restarted.

withstand the stresses imposed during the test without failure

or excessive flexure. The materials being tested shall be 8.9 Remove the specimens and clean off any loose wear

debris. Note the existence of features on or near the wear scar

described by dimensions, surface finish, material type, form,

composition, microstructure, processing treatments, and inden- such as: protrusions, displaced metal, discoloration, microc-

racking, or spotting.

tation hardness (if appropriate).

6.2 Test Specimens—The typical pin specimen is cylindrical 8.10 Remeasure the specimen dimensions to the nearest 2.5

μm or reweigh the specimens to the nearest 0.0001 g, as

or spherical in shape. Typical cylindrical or spherical pin

specimen diameters range from 2 to 10 mm. The typical disk appropriate.

8.11 Repeat the test with additional specimens to obtain

specimen diameters range from 30 to 100 mm and have a

thickness in the range of 2 to 10 mm. Specimen dimensions sufficient data for statistically significant results.

used in an interlaboratory test with pin-on-disk systems are

9. Calculation and Reporting

given in Table 1.

9.1 The wear measurements should be reported as the

6.3 Surface Finish—A ground surface roughness of 0.8 μm

volume loss in cubic millimetres for the pin and disk, sepa-

(32 μin.) arithmetic average or less is usually recommended.

rately.

NOTE 3—Rough surfaces make wear scar measurement difficult.

9.1.1 Use the following equations for calculating volume

6.3.1 Care must be taken in surface preparation to avoid losses when the pin has initially a spherical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.