ASTM G99-03

(Test Method)Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus

SCOPE

1.1 This test method describes a laboratory procedure for determining the wear of materials during sliding using a pin-on-disk apparatus. Materials are tested in pairs under nominally non-abrasive conditions. The principal areas of experimental attention in using this type of apparatus to measure wear are described. The coefficient of friction may also be determined.

1.2 The values stated in SI units are to be regarded as standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation:G99–03

Standard Test Method for

1

Wear Testing with a Pin-on-Disk Apparatus

ThisstandardisissuedunderthefixeddesignationG99;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (e) indicates an editorial change since the last revision or reapproval.

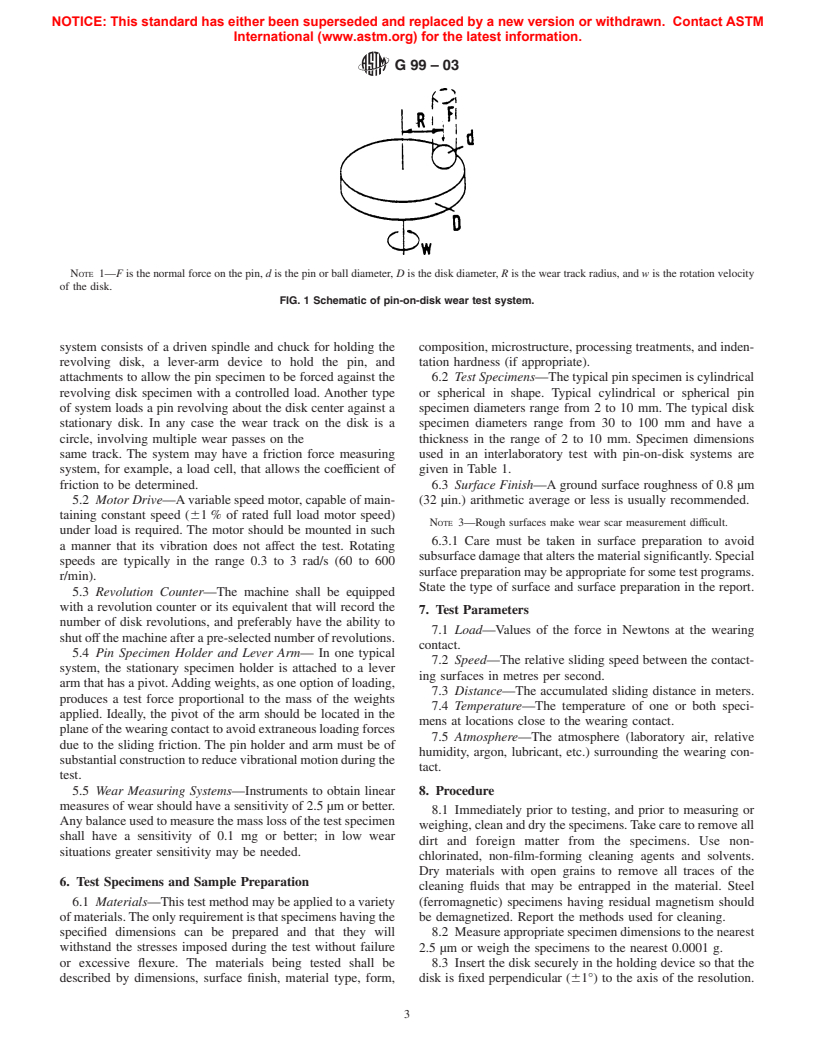

1. Scope about the disk center. In either case, the sliding path is a circle

on the disk surface. The plane of the disk may be oriented

1.1 This test method describes a laboratory procedure for

either horizontally or vertically.

determining the wear of materials during sliding using a

pin-on-disk apparatus. Materials are tested in pairs under

NOTE 1—Wear results may differ for different orientations.

nominally non-abrasive conditions. The principal areas of

3.1.1 The pin specimen is pressed against the disk at a

experimental attention in using this type of apparatus to

specifiedloadusuallybymeansofanarmorleverandattached

measure wear are described. The coefficient of friction may

weights. Other loading methods have been used, such as,

also be determined.

hydraulic or pneumatic.

1.2 The values stated in SI units are to be regarded as

NOTE 2—Wear results may differ for different loading methods.

standard.

1.3 This standard does not purport to address all of the

3.2 Wear results are reported as volume loss in cubic

safety concerns, if any, associated with its use. It is the

millimetres for the pin and the disk separately. When two

responsibility of the user of this standard to establish appro-

different materials are tested, it is recommended that each

priate safety and health practices and determine the applica-

material be tested in both the pin and disk positions.

bility of regulatory limitations prior to use.

3.3 The amount of wear is determined by measuring appro-

priatelineardimensionsofbothspecimensbeforeandafterthe

2. Referenced Documents

test,orbyweighingbothspecimensbeforeandafterthetest.If

2.1 ASTM Standards:

linear measures of wear are used, the length change or shape

E122 Practice for Choice of Sample Size to Estimate a

change of the pin, and the depth or shape change of the disk

2

Measure of Quality for a Lot or Process

wear track (in millimetres) are determined by any suitable

E177 Practice for Use of the Terms Precision and Bias in

metrological technique, such as electronic distance gaging or

2

ASTM Test Methods

stylusprofiling.Linearmeasuresofwearareconvertedtowear

2

E178 Practice for Dealing with Outlying Observations

volume (in cubic millimetres) by using appropriate geometric

3

G40 Terminology Relating to Wear and Erosion

relations. Linear measures of wear are used frequently in

4

2.2 Other Standard:

practicesincemasslossisoftentoosmalltomeasureprecisely.

DIN-50324 Testing of Friction and Wear

Iflossofmassismeasured,themasslossvalueisconvertedto

volume loss (in cubic millimetres) using an appropriate value

3. Summary of Test Method

for the specimen density.

3.1 For the pin-on-disk wear test, two specimens are re-

3.4 Wear results are usually obtained by conducting a test

quired. One, a pin with a radiused tip, is positioned perpen-

for a selected sliding distance and for selected values of load

dicular to the other, usually a flat circular disk. A ball, rigidly

and speed. One set of test conditions that was used in an

held, is often used as the pin specimen. The test machine

interlaboratory measurement series is given in Table 1 and

causes either the disk specimen or the pin specimen to revolve

Table 2 as a guide. Other test conditions may be selected

depending on the purpose of the test.

3.5 Wear results may in some cases be reported as plots of

1

This test method is under the jurisdiction of ASTM Committee G02 on Wear

wear volume versus sliding distance using different specimens

and Erosion and is the direct responsibility of Subcommittee G02.40 on Non-

for different distances. Such plots may display non-linear

Abrasive Wear.

relationships between wear volume and distance over certain

Current edition approved May 10, 2003. Published June 2003. Originally

e1

approved in 1990. Last previous edition approved in 2000 as G99–95a(2000) .

portions of the total sliding distance, and linear relationships

2

Annual Book of ASTM Standards, Vol 14.02.

over other portions. Causes for such differing relationships

3

Annual Book of ASTM Standards, Vol 03.02.

4 include initial “break-in” processes, transitions between re-

Available from Beuth Verlag GmbH, Burggrafenstrasse 6, 1000 Berlin 30,

Germany. gions of different dominant wear mechanisms, etc. The extent

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This sta

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.