ASTM F1506-10

(Specification)Standard Performance Specification for Flame Resistant Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards

Standard Performance Specification for Flame Resistant Textile Materials for Wearing Apparel for Use by Electrical Workers Exposed to Momentary Electric Arc and Related Thermal Hazards

ABSTRACT

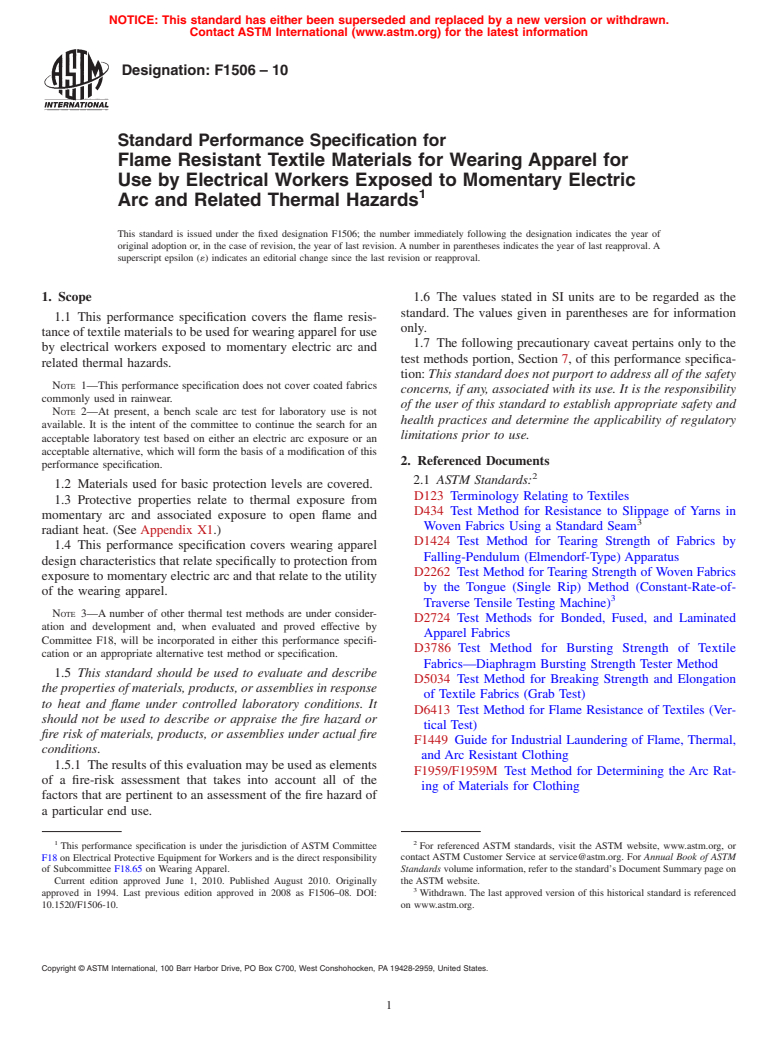

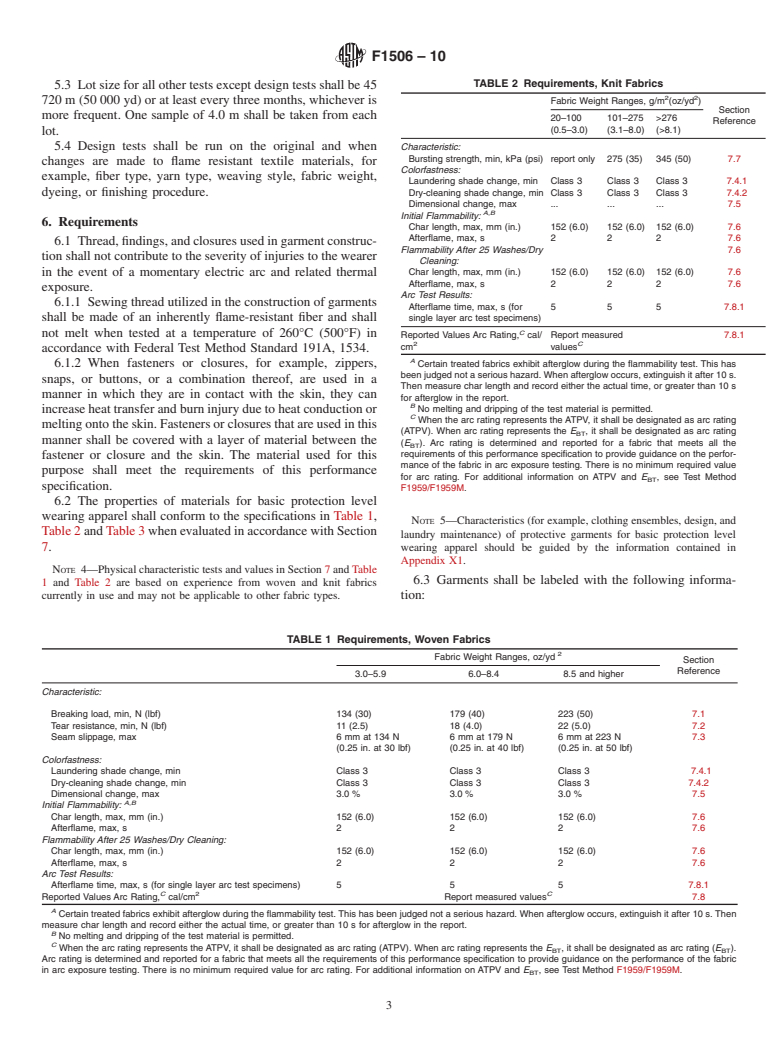

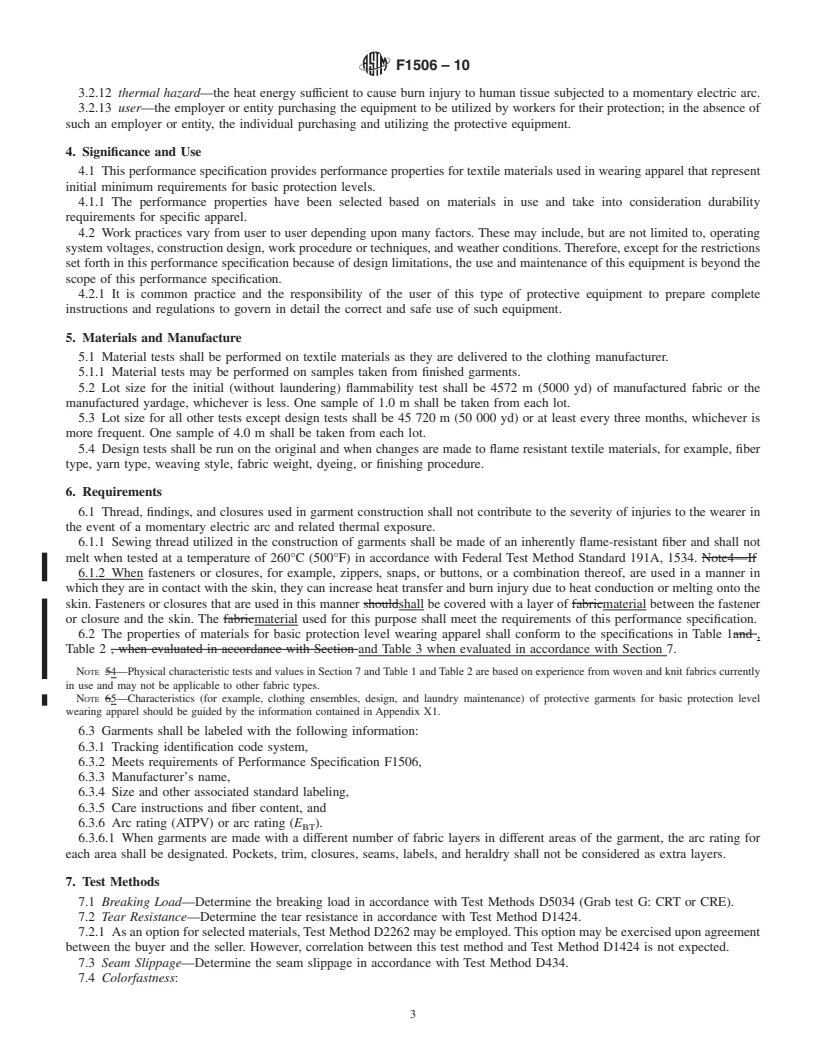

This performance specification covers the design characteristics and associated test methods that relate specifically to the flame resistance of textile materials used in the fabrication of basic protection level occupational apparel worn by electrical workers who are exposed to momentary electric arc and related thermal hazards such as exposure to open flame and radiant heat. When evaluated in accordance with the test procedures enlisted herein, knit fabrics and woven fabrics of different fabric weights shall conform to individually specified values of the following properties: colorfastness such as laundering shade change, dry-cleaning shade change, and dimensional change; initial flammability characteristics and flammability characteristics after 25 washes/dry-cleaning such as char length and afterflame time; and arc test rating. Knit fabrics shall additionally be tested and adhere accordingly to bursting strength characteristics. Conversely, woven fabrics shall also be tested and adhere accordingly to breaking load, tear resistance, and seam slippage characteristics.

SCOPE

1.1 This performance specification covers the flame resistance of textile materials to be used for wearing apparel for use by electrical workers exposed to momentary electric arc and related thermal hazards.

Note 1—This performance specification does not cover coated fabrics commonly used in rainwear.

Note 2—At present, a bench scale arc test for laboratory use is not available. It is the intent of the committee to continue the search for an acceptable laboratory test based on either an electric arc exposure or an acceptable alternative, which will form the basis of a modification of this performance specification.

1.2 Materials used for basic protection levels are covered.

1.3 Protective properties relate to thermal exposure from momentary arc and associated exposure to open flame and radiant heat. (See Appendix X1.)

1.4 This performance specification covers wearing apparel design characteristics that relate specifically to protection from exposure to momentary electric arc and that relate to the utility of the wearing apparel.

Note 3—A number of other thermal test methods are under consideration and development and, when evaluated and proved effective by Committee F18, will be incorporated in either this performance specification or an appropriate alternative test method or specification.

1.5 This standard should be used to evaluate and describe the properties of materials, products, or assemblies in response to heat and flame under controlled laboratory conditions. It should not be used to describe or appraise the fire hazard or fire risk of materials, products, or assemblies under actual fire conditions.

1.5.1 The results of this evaluation may be used as elements of a fire-risk assessment that takes into account all of the factors that are pertinent to an assessment of the fire hazard of a particular end use.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 The following precautionary caveat pertains only to the test methods portion, Section 7, of this performance specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1506 – 10

Standard Performance Specification for

Flame Resistant Textile Materials for Wearing Apparel for

Use by Electrical Workers Exposed to Momentary Electric

1

Arc and Related Thermal Hazards

This standard is issued under the fixed designation F1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 1.6 The values stated in SI units are to be regarded as the

standard. The values given in parentheses are for information

1.1 This performance specification covers the flame resis-

only.

tance of textile materials to be used for wearing apparel for use

1.7 The following precautionary caveat pertains only to the

by electrical workers exposed to momentary electric arc and

test methods portion, Section 7, of this performance specifica-

related thermal hazards.

tion: This standard does not purport to address all of the safety

NOTE 1—This performance specification does not cover coated fabrics

concerns, if any, associated with its use. It is the responsibility

commonly used in rainwear.

of the user of this standard to establish appropriate safety and

NOTE 2—At present, a bench scale arc test for laboratory use is not

health practices and determine the applicability of regulatory

available. It is the intent of the committee to continue the search for an

limitations prior to use.

acceptable laboratory test based on either an electric arc exposure or an

acceptable alternative, which will form the basis of a modification of this

2. Referenced Documents

performance specification.

2

2.1 ASTM Standards:

1.2 Materials used for basic protection levels are covered.

D123 Terminology Relating to Textiles

1.3 Protective properties relate to thermal exposure from

D434 Test Method for Resistance to Slippage of Yarns in

momentary arc and associated exposure to open flame and

3

Woven Fabrics Using a Standard Seam

radiant heat. (See Appendix X1.)

D1424 Test Method for Tearing Strength of Fabrics by

1.4 This performance specification covers wearing apparel

Falling-Pendulum (Elmendorf-Type) Apparatus

design characteristics that relate specifically to protection from

D2262 Test Method for Tearing Strength of Woven Fabrics

exposure to momentary electric arc and that relate to the utility

by the Tongue (Single Rip) Method (Constant-Rate-of-

of the wearing apparel.

3

Traverse Tensile Testing Machine)

NOTE 3—A number of other thermal test methods are under consider-

D2724 Test Methods for Bonded, Fused, and Laminated

ation and development and, when evaluated and proved effective by

Apparel Fabrics

Committee F18, will be incorporated in either this performance specifi-

D3786 Test Method for Bursting Strength of Textile

cation or an appropriate alternative test method or specification.

Fabrics—Diaphragm Bursting Strength Tester Method

1.5 This standard should be used to evaluate and describe

D5034 Test Method for Breaking Strength and Elongation

the properties of materials, products, or assemblies in response

of Textile Fabrics (Grab Test)

to heat and flame under controlled laboratory conditions. It

D6413 Test Method for Flame Resistance of Textiles (Ver-

should not be used to describe or appraise the fire hazard or

tical Test)

fire risk of materials, products, or assemblies under actual fire

F1449 Guide for Industrial Laundering of Flame, Thermal,

conditions.

and Arc Resistant Clothing

1.5.1 The results of this evaluation may be used as elements

F1959/F1959M Test Method for Determining the Arc Rat-

of a fire-risk assessment that takes into account all of the

ing of Materials for Clothing

factors that are pertinent to an assessment of the fire hazard of

a particular end use.

1 2

This performance specification is under the jurisdiction of ASTM Committee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F18 on Electrical Protective Equipment for Workers and is the direct responsibility contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

of Subcommittee F18.65 on Wearing Apparel. Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

Current edition approved June 1, 2010. Published August 2010. Originally

3

approved in 1994. Last previous edition approved in 2008 as F1506–08. DOI: Withdrawn. The last approved version of this historical standard is referenced

10.1520/F1506-10. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1506 – 10

2 2

4

2.2 AATCC Test Methods: 3.2.7.1 Discussion—This is the value in

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:F1506–08 Designation: F1506 – 10

Standard Performance Specification for

Flame Resistant Textile Materials for Wearing Apparel for

Use by Electrical Workers Exposed to Momentary Electric

1

Arc and Related Thermal Hazards

This standard is issued under the fixed designation F1506; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This performance specification covers the flame resistance of textile materials to be used for wearing apparel for use by

electrical workers exposed to momentary electric arc and related thermal hazards.

NOTE 1—This performance specification does not cover coated fabrics commonly used in rainwear.

NOTE 2—At present, a bench scale arc test for laboratory use is not available. It is the intent of the committee to continue the search for an acceptable

laboratory test based on either an electric arc exposure or an acceptable alternative, which will form the basis of a modification of this performance

specification.

1.2 Materials used for basic protection levels are covered.

1.3 Protectivepropertiesrelatetothermalexposurefrommomentaryarcandassociatedexposuretoopenflameandradiantheat.

(See Appendix X1.)

1.4 This performance specification covers wearing apparel design characteristics that relate specifically to protection from

exposure to momentary electric arc and that relate to the utility of the wearing apparel.

NOTE 3—A number of other thermal test methods are under consideration and development and, when evaluated and proved effective by Committee

F18, will be incorporated in either this performance specification or an appropriate alternative test method or specification.

1.5 This standard should be used to evaluate and describe the properties of materials, products, or assemblies in response to

heat and flame under controlled laboratory conditions. It should not be used to describe or appraise the fire hazard or fire risk

of materials, products, or assemblies under actual fire conditions.

1.5.1 The results of this evaluation may be used as elements of a fire-risk assessment that takes into account all of the factors

that are pertinent to an assessment of the fire hazard of a particular end use.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 The following precautionary caveat pertains only to the test methods portion, Section 7, of this performance specification:

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the

user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations

prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D434 Test Method for Resistance to Slippage of Yarns in Woven Fabrics Using a Standard Seam

D1424 Test Method for Tearing Strength of Fabrics by Falling-Pendulum (Elmendorf-Type) Apparatus

D2262 Test Method for Tearing Strength of Woven Fabrics by the Tongue (Single Rip) Method (Constant-Rate-of-Traverse

3

Tensile Testing Machine)

D2724 Test Methods for Bonded, Fused, and Laminated Apparel Fabrics

D3786 Test Method for Bursting Strength of Textile FabricsDiaphragm Bursting Strength Tester Method

1

This performance specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.65 on Wearing Apparel.

´1

Current edition approved May 1, 2008. Published June 2008. Originally approved in 1994. Last previous edition approved in 2002 as F1506–02a . DOI:

10.1520/F1506-08.

Current edition approved June 1, 2010. Published August 2010. Originally approved in 1994. Last previous edition approved in 2008 as F1506–08. DOI:

10.1520/F1506-10.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F1506 – 10

D5034 Test Method for Breaking Strength and Elongation o

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.