ASTM F1781-21

(Specification)Standard Specification for Elastomeric Flexible Hinge Finger Total Joint Implants

Standard Specification for Elastomeric Flexible Hinge Finger Total Joint Implants

ABSTRACT

This specification covers the biocompatibility and other performance requirements, and associated test methods for elastomeric flexible hinge finger total joint implants, used with and without metal grommets in the reconstruction of the metacarpophalangeal (MCP) and proximal interphalangeal (PIP) joints. This specification excludes those implants that do not have an across-the-joint elastomeric linkage, and is limited to implants made from one material in a single one-step molding procedure.

SCOPE

1.1 This specification covers elastomeric flexible hinge finger total joint implants, used with and without metal grommets, in the reconstruction of the metacarpophalangeal (MCP) and proximal interphalangeal (PIP) joints.

1.2 This specification excludes those implants that do not have an across-the-joint elastomeric linkage. This specification is limited to implants made from one material in a single, one-step molding procedure.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F1781 −21

Standard Specification for

1

Elastomeric Flexible Hinge Finger Total Joint Implants

This standard is issued under the fixed designation F1781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F86 Practice for Surface Preparation and Marking of Metal-

lic Surgical Implants

1.1 This specification covers elastomeric flexible hinge

F601 Practice for Fluorescent Penetrant Inspection of Me-

finger total joint implants, used with and without metal

tallic Surgical Implants

grommets, in the reconstruction of the metacarpophalangeal

F748 PracticeforSelectingGenericBiologicalTestMethods

(MCP) and proximal interphalangeal (PIP) joints.

for Materials and Devices

1.2 This specification excludes those implants that do not

F981 Practice for Assessment of Compatibility of Biomate-

have an across-the-joint elastomeric linkage.This specification

rials for Surgical Implants with Respect to Effect of

is limited to implants made from one material in a single,

Materials on Muscle and Insertion into Bone

one-step molding procedure.

F983 Practice for Permanent Marking of Orthopaedic Im-

1.3 The values stated in SI units are to be regarded as plant Components

F2038 GuideforSiliconeElastomers,Gels,andFoamsUsed

standard. No other units of measurement are included in this

standard. in Medical Applications Part I—Formulations and Un-

cured Materials

1.4 This international standard was developed in accor-

F2042 GuideforSiliconeElastomers,Gels,andFoamsUsed

dance with internationally recognized principles on standard-

in Medical Applications Part II—Crosslinking and Fabri-

ization established in the Decision on Principles for the

cation

Development of International Standards, Guides and Recom-

F2503 Practice for Marking Medical Devices and Other

mendations issued by the World Trade Organization Technical

Items for Safety in the Magnetic Resonance Environment

Barriers to Trade (TBT) Committee.

F2943 Guide for Presentation of End User Labeling Infor-

mation for Musculoskeletal Implants

2. Referenced Documents

3

2.2 Government Standards:

2

2.1 ASTM Standards:

21 CFR 820 Quality System Regulation

D412 Test Methods forVulcanized Rubber andThermoplas-

21 CFR 888.6 Degree of Constraint

tic Elastomers—Tension

MIL STD 177A Rubber Products, Terms for Visible De-

D624 Test Method for Tear Strength of Conventional Vul-

3

fects

canized Rubber and Thermoplastic Elastomers

4

2.3 ISO Standard:

D813 TestMethodforRubberDeterioration—CrackGrowth

ISO 10993-1 Biological Evaluation of Medical Devices—

D1052 Test Method for Measuring Rubber Deterioration—

Part 1: Evaluation and testing within a risk management

Cut Growth Using Ross Flexing Apparatus

process

D2240 Test Method for Rubber Property—Durometer Hard-

ness

3. Significance and Use

F67 Specification for Unalloyed Titanium, for Surgical Im-

3.1 The prostheses described in this specification are in-

plant Applications (UNS R50250, UNS R50400, UNS

tended for use in the proximal interphalangeal (PIP) and

R50550, UNS R50700)

metacarpophalangeal (MCP) joints.

4. Classification

1

This specification is under the jurisdiction of ASTM Committee F04 on

4.1 Constrained—A constrained joint prosthesis is used for

Medical and Surgical Materials and Devices and is the direct responsibility of

Subcommittee F04.22 on Arthroplasty.

joint replacement and prevents dislocation of the prosthesis in

Current edition approved Sept. 1, 2021. Published September 2021. Originally

approved in 1997. Last previous edition approved in 2015 as F1781 – 15. DOI:

3

10.1520/F1781-21. AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401, http://

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.access.gpo.gov.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

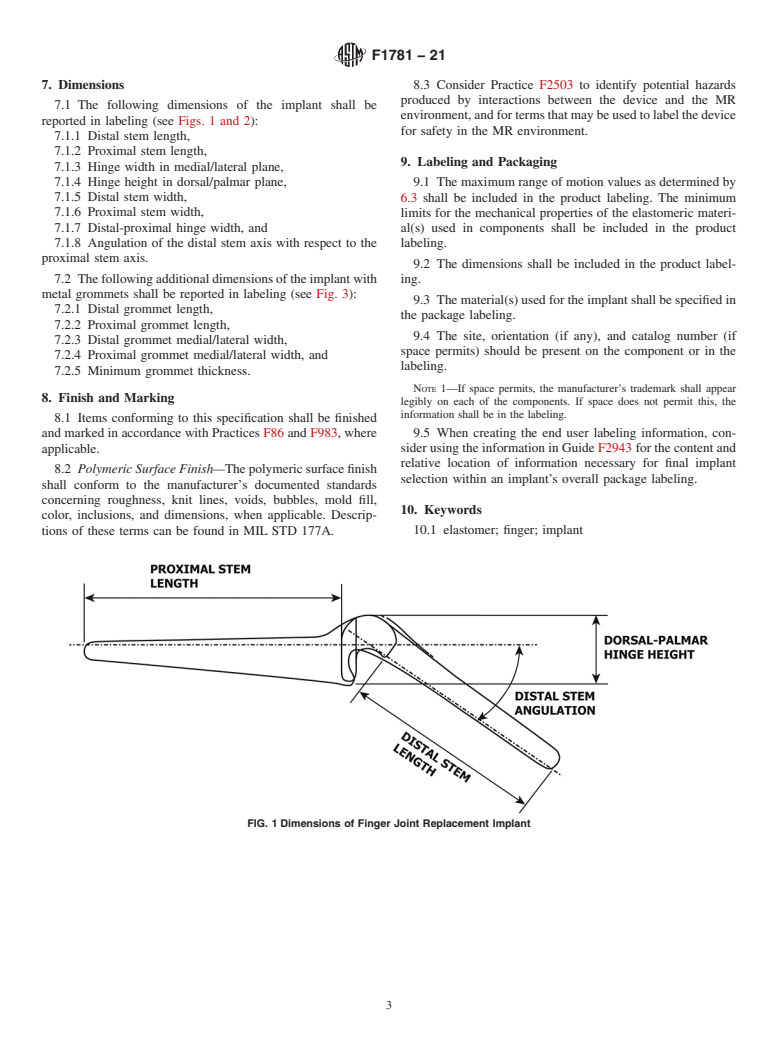

F1781 − 21

5

more than one anatomic plane and consists of either a single, hinge have been reported (1-3). The fatigue characteristics of

flexible, across-the-joint component or more t

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F1781 − 15 F1781 − 21

Standard Specification for

1

Elastomeric Flexible Hinge Finger Total Joint Implants

This standard is issued under the fixed designation F1781; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers elastomeric flexible hinge finger total joint implants, used with and without metal grommets, in the

reconstruction of the metacarpophalangeal (MCP) and proximal interphalangeal (PIP) joints.

1.2 This specification excludes those implants that do not have an across-the-joint elastomeric linkage. TheThis specification is

limited to implants made from one material in a single, one-step molding procedure.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D813 Test Method for Rubber Deterioration—Crack Growth

D1052 Test Method for Measuring Rubber Deterioration—Cut Growth Using Ross Flexing Apparatus

D2240 Test Method for Rubber Property—Durometer Hardness

F67 Specification for Unalloyed Titanium, for Surgical Implant Applications (UNS R50250, UNS R50400, UNS R50550, UNS

R50700)

F86 Practice for Surface Preparation and Marking of Metallic Surgical Implants

F601 Practice for Fluorescent Penetrant Inspection of Metallic Surgical Implants

F748 Practice for Selecting Generic Biological Test Methods for Materials and Devices

F981 Practice for Assessment of Compatibility of Biomaterials for Surgical Implants with Respect to Effect of Materials on

Muscle and Insertion into Bone

F983 Practice for Permanent Marking of Orthopaedic Implant Components

F2038 Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part I—Formulations and Uncured

Materials

F2042 Guide for Silicone Elastomers, Gels, and Foams Used in Medical Applications Part II—Crosslinking and Fabrication

F2503 Practice for Marking Medical Devices and Other Items for Safety in the Magnetic Resonance Environment

1

This specification is under the jurisdiction of ASTM Committee F04 on Medical and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.22 on Arthroplasty.

Current edition approved Oct. 1, 2015Sept. 1, 2021. Published December 2015September 2021. Originally approved in 1997. Last previous edition approved in 20092015

as F1781 – 03 (2009).F1781 – 15. DOI: 10.1520/F1781-15.10.1520/F1781-21.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1781 − 21

F2943 Guide for Presentation of End User Labeling Information for Musculoskeletal Implants

3

2.2 Government Standards:

21 CFR 820 Good Manufacturing Practices for Medical DevicesQuality System Regulation

21 CFR 888.6 Degree of Constraint

3

MIL STD 177A Rubber Products, Terms for Visible Defects

4

2.3 ISO Standard:

ISO 10993-1 Biological EvaluationsEvaluation of Medical Devices — Part Devices—Part 1: Evaluation and testing within a risk

management process

3. Significance and Use

3.1 The prostheses described in this specification are intended for use in the proximal interphalangeal (PIP) and metacarpopha-

langeal (MCP) joints.

4. Classification

4.1 Constrained—A constrained joint prosthesis is used for joint replacement and prevents dislocation of the prosthesis in more

than one anatomicalanatomic plane and consists of either a single, flexible, across-the-joint component,component or more than

one component linked together or affined.affined (21 CFR 888

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.