ASTM D7568-12

(Specification)Standard Specification for Polyethylene-Based Structural-Grade Plastic Lumber for Outdoor Applications

Standard Specification for Polyethylene-Based Structural-Grade Plastic Lumber for Outdoor Applications

SCOPE

1.1 This specification covers a type of plastic lumber product, defined as polyethylene-based structural-grade plastic lumber (SGPL), for use as main framing members, including joists, stringers, beams, columns; and secondary framing members, including planking, posts and bracing; in outdoor structures such as decks, boardwalks, docks, and platforms.

1.2 This specification is applicable to solid, rectangular SGPL products where polyethylene resin (non cross-linked) is the continuous phase and is at least 50 % of the product (by weight).

1.3 This specification is not applicable to plastic lumber products containing cellulosic materials as additives, fillers or fiber reinforcements.

1.4 SGPL products covered by this specification shall not be used as tensile members.

1.5 SGPL products are produced using several different manufacturing processes. These processes utilize a number of polyethylene resin material systems that include varying proportions of fillers, fiber reinforcements, and other chemical additives.

1.6 Due to thermodynamic effects that result in outer-surface densification during manufacture, SGPL products are typically non-homogeneous in the cross-section. This standard does not address materials that have been modified from their original cross-section.

1.6.1 The cross-section non-homogeneity is addressed in the material property assessments in this document only for applications in which the product cross-section is not modified by cutting, notching, or drilling. For products modified in this manner, additional engineering considerations are required and they are beyond the scope of this document.

1.7 For purposes of this standard, an SGPL product is a specific combination of polyethylene resin, together with fillers, reinforcements, and additives. Each formulation is to be identified as a distinct and different product, to be tested and evaluated separately.

1.8 Diverse and multiple combinations of both virgin and recycled polyethylene material systems are permitted in the manufacture of SGPL products.

1.9 Fiber reinforcements used in SGPL include manufactured materials such as fiberglass (chopped or continuous), carbon, aramid and other polymeric materials.

1.10 A wide variety of chemical additives are typically added to SGPL formulations. Examples include colorants, chemical foaming agents, ultraviolet stabilizers, fire retardants, lubricants, anti-static products, heat stabilizers, and coupling agents.

1.11 Diverse types and combinations of filler systems are permitted in the manufacturing of SGPL products. Fillers that cause the product to fail the requirements of 6.13 are not permitted in the manufacturing of SGPL products.

1.12 In order for a product to be classified as SGPL, it must meet the minimum stress and modulus criteria consistent with the specific product as marked, and additionally the properties specified in Section 6 of this specification.

1.13 This specification pertains to SGPL where any reinforcement is uniformly distributed within the product. When reinforcement is not uniformly distributed, the engineering issues become substantially more complex. For this reason, such products are not covered in this document.

1.14 Products that fail at strains of less than 0.02 (2 %) when tested in flexure in accordance with 6.6 are not compatible with the underlying assumptions of Annex A1 and are beyond the scope of this standard (see Note 1).

Note 1—Calculation of time-dependent properties in Annex A1 is based on the assumption that the product does not fail in a brittle manner. The 2 % strain limit was selected based on the judgment of the task group members that created Annex A1.

1.15 This specification addresses issues relevant to a buyer’s requirements for SGPL products and has therefore been developed in the format of a procurement specification.

1.16 Criteria for design are included as part of this specification for SGPL products.

1.17 Use of...

General Information

Relations

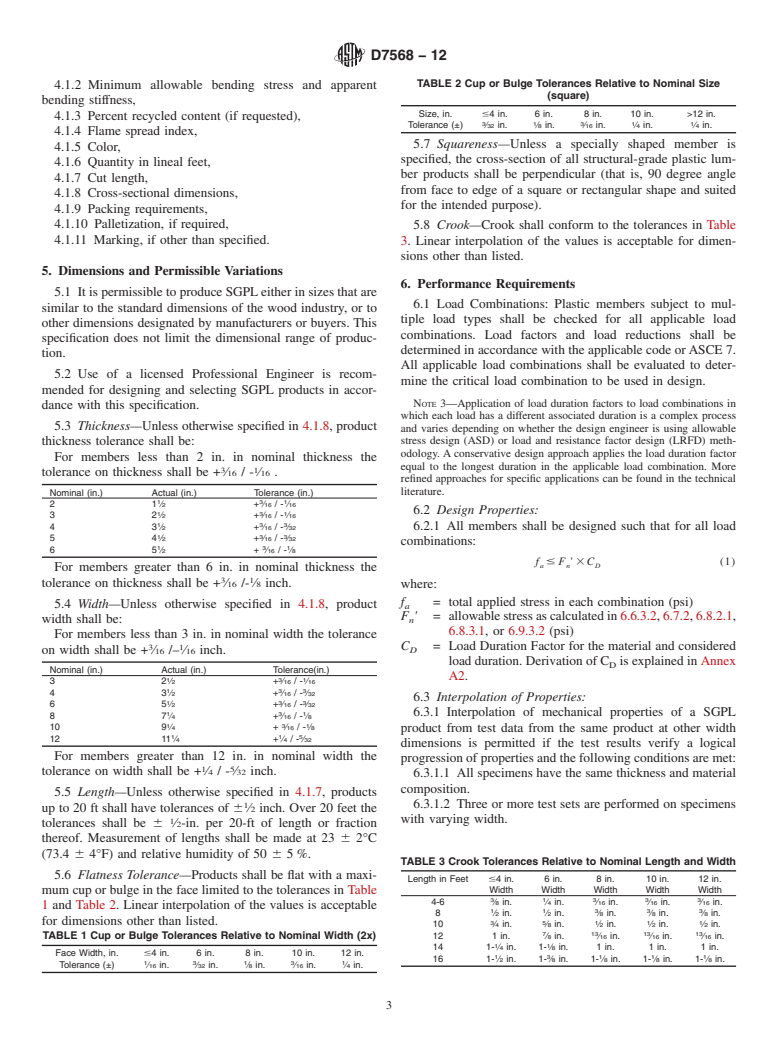

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7568 −12

StandardSpecification for

Polyethylene-Based Structural-Grade Plastic Lumber for

1

Outdoor Applications

This standard is issued under the fixed designation D7568; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope fillers,reinforcements,andadditives.Eachformulationistobe

identified as a distinct and different product, to be tested and

1.1 This specification covers a type of plastic lumber

evaluated separately.

product, defined as polyethylene-based structural-grade plastic

1.8 Diverse and multiple combinations of both virgin and

lumber (SGPL), for use as main framing members, including

recycled polyethylene material systems are permitted in the

joists, stringers, beams, columns; and secondary framing

manufacture of SGPL products.

members, including planking, posts and bracing; in outdoor

structures such as decks, boardwalks, docks, and platforms.

1.9 Fiber reinforcements used in SGPL include manufac-

tured materials such as fiberglass (chopped or continuous),

1.2 This specification is applicable to solid, rectangular

carbon, aramid and other polymeric materials.

SGPL products where polyethylene resin (non cross-linked) is

the continuous phase and is at least 50% of the product (by

1.10 A wide variety of chemical additives are typically

weight).

added to SGPL formulations. Examples include colorants,

chemicalfoamingagents,ultravioletstabilizers,fireretardants,

1.3 This specification is not applicable to plastic lumber

lubricants, anti-static products, heat stabilizers, and coupling

products containing cellulosic materials as additives, fillers or

agents.

fiber reinforcements.

1.11 Diverse types and combinations of filler systems are

1.4 SGPLproductscoveredbythisspecificationshallnotbe

permitted in the manufacturing of SGPL products. Fillers that

used as tensile members.

cause the product to fail the requirements of 6.13 are not

1.5 SGPL products are produced using several different

permitted in the manufacturing of SGPL products.

manufacturing processes. These processes utilize a number of

1.12 In order for a product to be classified as SGPL, it must

polyethylene resin material systems that include varying pro-

meet the minimum stress and modulus criteria consistent with

portions of fillers, fiber reinforcements, and other chemical

the specific product as marked, and additionally the properties

additives.

specified in Section 6 of this specification.

1.6 Due to thermodynamic effects that result in outer-

1.13 This specification pertains to SGPL where any rein-

surface densification during manufacture, SGPL products are

forcement is uniformly distributed within the product. When

typically non-homogeneous in the cross-section. This standard

reinforcement is not uniformly distributed, the engineering

does not address materials that have been modified from their

issues become substantially more complex. For this reason,

original cross-section.

such products are not covered in this document.

1.6.1 The cross-section non-homogeneity is addressed in

1.14 Products that fail at strains of less than 0.02 (2%)

the material property assessments in this document only for

when tested in flexure in accordance with 6.6 are not compat-

applications in which the product cross-section is not modified

ible with the underlying assumptions of Annex A1 and are

by cutting, notching, or drilling. For products modified in this

beyond the scope of this standard (see Note 1).

manner,additionalengineeringconsiderationsarerequiredand

they are beyond the scope of this document.

NOTE 1—Calculation of time-dependent properties in Annex A1 is

based on the assumption that the product does not fail in a brittle manner.

1.7 For purposes of this standard, an SGPL product is a

The2%strainlimitwasselectedbasedonthejudgmentofthetaskgroup

specific combination of polyethylene resin, together with

members that created Annex A1.

1.15 This specification addresses issues relevant to a buy-

er’s requirements for SGPL products and has therefore been

1

This is under the jurisdiction of ASTM Committee D20 on Plastics and is the developed in the format of a procurement specification.

direct responsibility of Subcommittee D20.20 on Plastic Lumber.

1.16 Criteria for design are included as part of this specifi-

Current edition approved June 1, 2012. Published September 2012.

DOI:10.1520/D7568–12. cation for SGPL products.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7568−12

1.17 Use of SGPL members in application will typically

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.