ASTM D6112-23

(Test Method)Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

Standard Test Methods for Compressive and Flexural Creep and Creep-Rupture of Plastic Lumber and Shapes

SIGNIFICANCE AND USE

5.1 Data from creep and creep-rupture tests are necessary to predict the creep modulus and strength of materials under long-term loads and to predict dimensional changes that have the potential to occur as a result of such loads.

5.2 Data from these test methods can be used to characterize plastic lumber: for comparison purposes, for the design of fabricated parts, to determine long-term performance under constant load, and under certain conditions, for specification purposes.

5.3 For many products, it is possible that there will be a specification that requires the use of this test method, but with some procedural modifications that take precedence when adhering to the specification. Therefore, it is advisable to refer to that product specification before using this test method. Table 1 in Classification D4000 lists the ASTM materials standards that currently exist.

SCOPE

1.1 These test methods cover the determination of the creep and creep-rupture properties of plastic lumber and shapes, when loaded in compression or flexure under specified environmental conditions. Test specimens in the “as-manufactured” form are employed. As such, these are test methods for evaluating the properties of plastic lumber or shapes as a product and not material property test methods.

1.2 Plastic lumber and plastic shapes are currently made predominantly with recycled plastics. However, this test method would also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the cross-section.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

Note 1: There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6112 − 23

Standard Test Methods for

Compressive and Flexural Creep and Creep-Rupture of

1

Plastic Lumber and Shapes

This standard is issued under the fixed designation D6112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

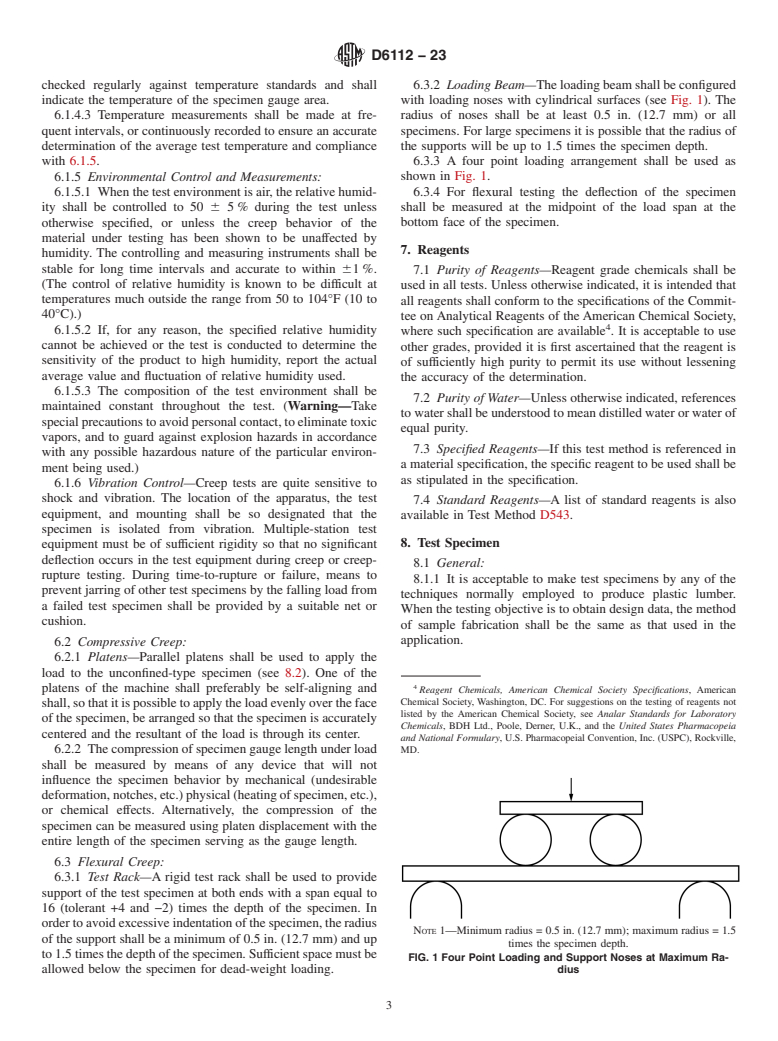

1. Scope* D543 Practices for Evaluating the Resistance of Plastics to

Chemical Reagents

1.1 These test methods cover the determination of the creep

D883 Terminology Relating to Plastics

and creep-rupture properties of plastic lumber and shapes,

D2990 Test Methods for Tensile, Compressive, and Flexural

when loaded in compression or flexure under specified envi-

Creep and Creep-Rupture of Plastics

ronmental conditions. Test specimens in the “as-manufactured”

D4000 Classification System for Specifying Plastic Materi-

form are employed. As such, these are test methods for

als

evaluating the properties of plastic lumber or shapes as a

D5033 Guide for Development of ASTM Standards Relating

product and not material property test methods.

to Recycling and Use of Recycled Plastics (Withdrawn

3

1.2 Plastic lumber and plastic shapes are currently made

2007)

predominantly with recycled plastics. However, this test

D5947 Test Methods for Physical Dimensions of Solid

method would also be applicable to similar manufactured

Plastics Specimens

plastic products made from virgin resins where the product is

E4 Practices for Force Calibration and Verification of Test-

non-homogenous in the cross-section.

ing Machines

1.3 The values stated in inch-pound units are to be regarded E176 Terminology of Fire Standards

E456 Terminology Relating to Quality and Statistics

as standard. The values given in parentheses are for informa-

tion only.

3. Terminology

1.4 This standard does not purport to address all of the

3.1 Definitions of Terms—For definitions of terms used in

safety concerns, if any, associated with its use. It is the

these test methods and associated with plastics issues refer to

responsibility of the user of this standard to establish appro-

the terminology contained in Terminology D883 or in Guide

priate safety, health, and environmental practices and deter-

D5033. For definitions of terms used in this specification and

mine the applicability of regulatory limitations prior to use.

associated with fire issues refer to the terminology contained in

NOTE 1—There is no known ISO equivalent to this standard.

Terminology E176. For terms relating to precision and bias and

1.5 This international standard was developed in accor-

associated issues, the terms used in this standard are defined in

dance with internationally recognized principles on standard-

accordance with Terminology E456.

ization established in the Decision on Principles for the

3.1.1 plastic lumber, n—a manufactured product made pri-

Development of International Standards, Guides and Recom-

marily from plastic materials (filled or unfilled), typically used

mendations issued by the World Trade Organization Technical

as a building material for purposes similar to those of tradi-

Barriers to Trade (TBT) Committee.

tional lumber, which is usually rectangular in cross-section.

3.1.1.1 Discussion—Plastic lumber is typically supplied in

2. Referenced Documents

sizes similar to those of traditional lumber board, timber and

2

2.1 ASTM Standards:

dimension lumber; however the tolerances for plastic lumber

and for traditional lumber are not necessarily the same. D883

3.1.2 resin, n—a solid or pseudo-solid organic material

1

These test methods are under the jurisdiction of ASTM Committee D20 on

often of high molecular weight, that exhibits a tendency to flow

Plastics and are the direct responsibility of Subcommittee D20.20 on Plastic

Lumber. when subjected to stress, usually has a softening or melting

Current edition approved Nov. 1, 2023. Published November 2023. Originally

range, and usually fractures conchoidally.

approved in 1997. Last previous edition approved in 2018 as D6112 - 18. DOI:

3.1.2.1 Discussion—In a broad sense, the term is used to

10.1520/D6112-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The last approved version of this historical standard is referenced on

the ASTM website. www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 B

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6112 − 18 D6112 − 23

Standard Test Methods for

Compressive and Flexural Creep and Creep-Rupture of

1

Plastic Lumber and Shapes

This standard is issued under the fixed designation D6112; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 These test methods cover the determination of the creep and creep-rupture properties of plastic lumber and shapes, when

loaded in compression or flexure under specified environmental conditions. Test specimens in the “as-manufactured” form are

employed. As such, these are test methods for evaluating the properties of plastic lumber or shapes as a product and not material

property test methods.

1.2 Plastic lumber and plastic shapes are currently made predominantly with recycled plastics. However, this test method would

also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogenous in the

cross-section.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

NOTE 1—There is no known ISO equivalent to this standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D543 Practices for Evaluating the Resistance of Plastics to Chemical Reagents

D883 Terminology Relating to Plastics

D2990 Test Methods for Tensile, Compressive, and Flexural Creep and Creep-Rupture of Plastics

D4000 Classification System for Specifying Plastic Materials

3

D5033 Guide for Development of ASTM Standards Relating to Recycling and Use of Recycled Plastics (Withdrawn 2007)

D5947 Test Methods for Physical Dimensions of Solid Plastics Specimens

1

These test methods are under the jurisdiction of ASTM Committee D20 on Plastics and are the direct responsibility of Subcommittee D20.20 on Plastic Lumber (Section

D20.20.01).

Current edition approved June 1, 2018Nov. 1, 2023. Published June 2018November 2023. Originally approved in 1997. Last previous edition approved in 20132018 as

D6112 - 13.D6112 - 18. DOI: 10.1520/D6112-18.10.1520/D6112-23.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6112 − 23

E4 Practices for Force Calibration and Verification of Testing Machines

E176 Terminology of Fire Standards

E456 Terminology Relating to Quality and Statistics

3. Terminology

3.1 Definitions of Terms—For definitions of terms used in these test methods and associated with plastics issues refer to the

terminology contained in Terminology D883 or in Guide D5033. For definitions of terms used in this specification and associated

with fire issues refer to the terminology contained in Terminology E176. For terms relating to precision and bias and associated

issues, the terms used in this standard are defined in accordance with Terminology E456.

3.1.1 plastic lumber, n—a manufactured product made primarily from plastic materials (filled or unfilled), typically used as a

building material for purposes similar to those of traditional lumber, which is usually rectangular in cross-section.

3.1.1.1 Discussion—

Plastic lumber is typically supplied in sizes similar to those of traditional lumber board, timber and dimension lumber; however

the tolerances for plastic lumber and for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.