ASTM D6372-05(2010)

(Practice)Standard Practice for Design, Testing, and Construction of Micro-Surfacing

Standard Practice for Design, Testing, and Construction of Micro-Surfacing

SIGNIFICANCE AND USE

This micro-surfacing practice is written as a guide and should not be construed as a specification. End use specifications should be adapted to conform to job and user requirements.

SCOPE

1.1 This practice covers the design, testing, and construction of mixtures of polymer modified asphalt emulsion, mineral aggregate, mineral filler, water, and other additives, properly proportioned, mixed and spread on a paved surface. It is written as a guide and should be used as such. End use specifications should be adapted to conform to job and user requirements.

Note 1—This practice references test methods outside the jurisdiction of ASTM that may or may not have a precision statement.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6372 −05(Reapproved 2010)

Standard Practice for

1

Design, Testing, and Construction of Micro-Surfacing

This standard is issued under the fixed designation D6372; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ISSA Documents:

ISSATechnicalBulletinNo.100,TestMethodforWetTrack

1.1 Thispracticecoversthedesign,testing,andconstruction

3

Abrasion of Slurry Surfaces

of mixtures of polymer modified asphalt emulsion, mineral

ISSATechnical Bulletin No. 109,Test Method for Measure-

aggregate, mineral filler, water, and other additives, properly

mentofExcessAsphaltinBituminousMixturesbyUseof

proportioned, mixed and spread on a paved surface. It is

a Loaded Wheel Tester and Sand Adhesion

written as a guide and should be used as such. End use

ISSATechnical Bulletin No. 139, Test Method to Classify

specifications should be adapted to conform to job and user

EmulsifiedAsphalt/Aggregate Mixture Systems by Modi-

requirements.

fied Cohesion Tester, Measurement of Set and Cure

NOTE 1—This practice references test methods outside the jurisdiction 3

Characteristics

of ASTM that may or may not have a precision statement.

ISSAA143 Revised May 2003 Recommended Performance

3

1.2 The values stated in SI units are to be regarded as the

Guidelines For Micro-Surfacing

standard.

ISSATechnical Bulletin No. 144, Test Method for Classifi-

cation of Aggregate Filler—Bitumen Compatability by

1.3 This standard does not purport to address all of the

Schultze-Breuer and Ruck Procedures

safety concerns, if any, associated with its use. It is the

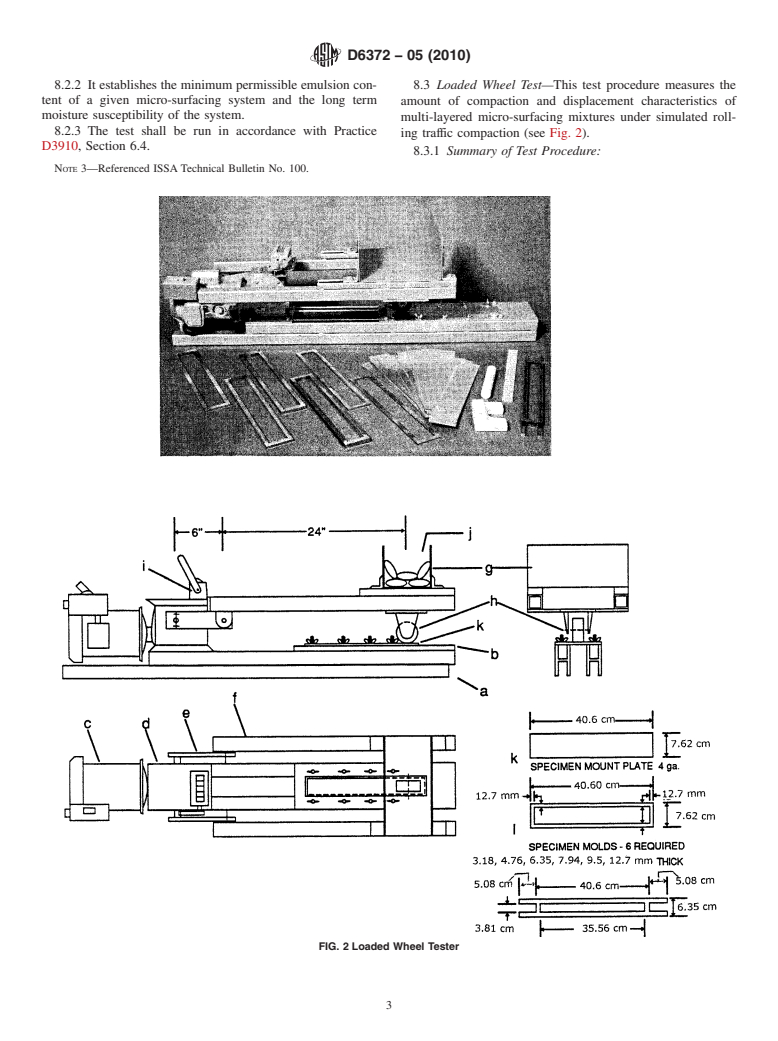

ISSATechnical Bulletin No. 147, Test Methods for Mea-

responsibility of the user of this standard to establish appro-

surements of Stability and Resistance to Compaction,

priate safety and health practices and determine the applica-

Vertical and Lateral Displacement of Multilayered Fine

bility of regulatory limitations prior to use.

3

Aggregate Cold Mixes

2. Referenced Documents

3. Terminology

2

2.1 ASTM Standards:

3.1 Definitions of Terms Specific to This Standard:

C88Test Method for Soundness of Aggregates by Use of

3.1.1 polymer modified emulsified asphalt micro-surfacing

Sodium Sulfate or Magnesium Sulfate

mixtures—asrelatedtothispractice,mixturesoffineaggregate

C131Test Method for Resistance to Degradation of Small-

with mineral filler, mixing water, and field control additive,

Size CoarseAggregate byAbrasion and Impact in the Los

uniformly mixed with polymer modified emulsified asphalt.

Angeles Machine

4. Summary of Practice

D2397Specification for Cationic Emulsified Asphalt

D2419Test Method for Sand Equivalent Value of Soils and

4.1 This practice outlines the basic properties for materials,

Fine Aggregate

mix design procedures, and application techniques for the

D3910Practices for Design, Testing, and Construction of

design and application of micro-surfacing. The mix developed

Slurry Seal

through this practice should be capable of being spread in

E145Specification for Gravity-Convection and Forced-

variable thick cross sections, which after curing and initial

Ventilation Ovens

traffic consolidation, resist compaction through the entire

design tolerance range of bitumen content and variable thick-

nesstobeencountered.Theendproductshouldmaintainahigh

1

friction surface and variable thick sections throughout its

This practice is under the jurisdiction ofASTM Committee D04 on Road and

Paving Materials and is the direct responsibility of Subcommittee D04.24 on

surface life. The mix should be a quick traffic system and

Bituminous Surface Treatments.

should be able to accept rolling traffic on a 12.7 mm thick

Current edition approved Dec. 1, 2010. Published December 2010. Originally

surface within 1 h after placement in 24°C temperature and

approved in 1999. Last previous edition approved in 1999 as D6372–05. DOI:

50% or less humidity.

10.1520/D6372-05R10.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available from International Slurry Surfacing Association, 3 Church Circle,

the ASTM website. PMB 250, Annapolis, MD 21401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D6372−05 (2010)

5. Significance and Use trafficona12.7mmthicksurfacewithin1hafterplacementat

24°Ctemperatureand50%orlesshumidity.Themixtureshall

5.1 This micro-surfacing practice is written as a guide and

conformtooneoft

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.