ASTM E518-02

(Test Method)Standard Test Methods for Flexural Bond Strength of Masonry

Standard Test Methods for Flexural Bond Strength of Masonry

SCOPE

1.1 These test methods cover determination of the flexural bond strength of unreinforced masonry assemblages. Two procedures are provided:

1.1.1 Test Method A -Simply supported beam with third-point loading.

1.1.2 Test Method B -Simply supported beam with uniform loading.

1.2 The values stated in SI units are to be regarded as the standard.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 518 – 02

Standard Test Methods for

1

Flexural Bond Strength of Masonry

This standard is issued under the fixed designation E 518; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope * 3. Significance and Use

1.1 These test methods cover determination of the flexural 3.1 These test methods are intended to provide simplified

bond strength of unreinforced masonry assemblages. Two and economical means for gathering comparative research data

procedures are provided: on the flexural bond strength developed with different types of

1.1.1 Test Method A—Simply supported beam with third- masonry units and mortar or for the purpose of checking job

point loading. quality control (materials and workmanship).

1.1.2 Test Method B—Simply supported beam with uniform

NOTE 1—These test methods are not intended for use in establishing

loading.

design stresses. For this purpose, Methods E 72 should be used.

1.2 The values stated in SI units are to be regarded as the

4. Apparatus

standard.

1.3 This standard does not purport to address all of the

4.1 Testing Machine, conforming to the requirements of

safety concerns, if any, associated with its use. It is the

Practices E 4.

responsibility of the user of this standard to establish appro-

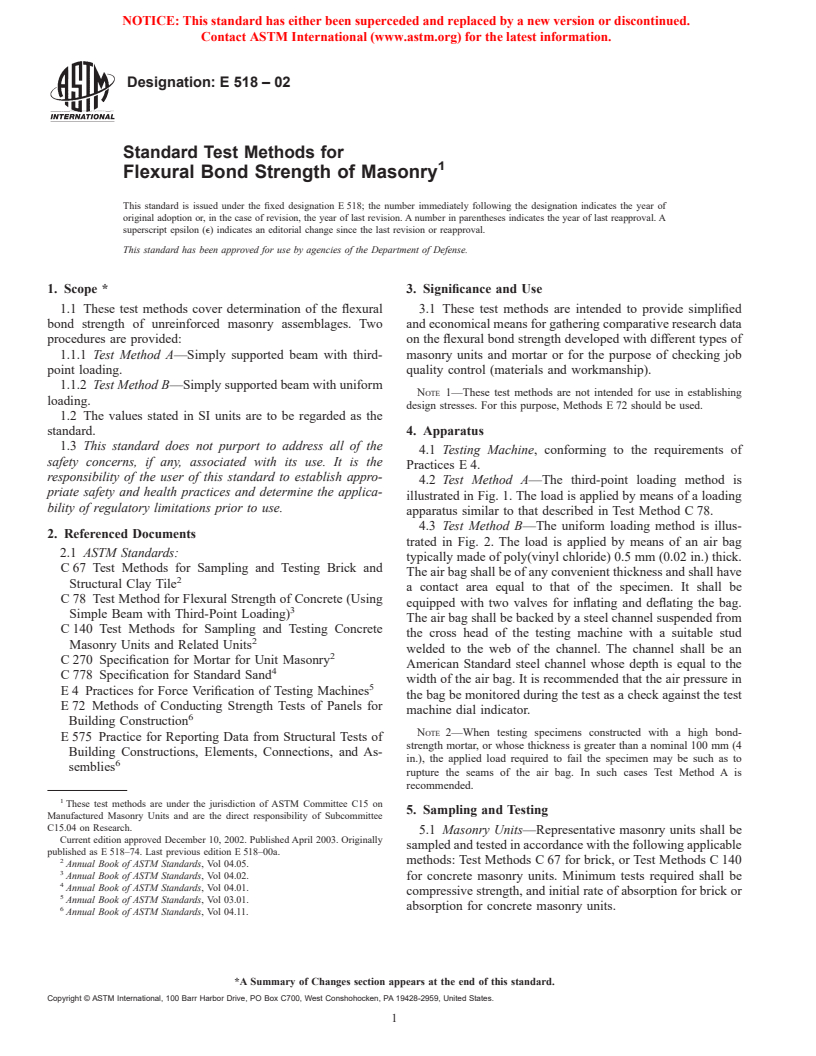

4.2 Test Method A—The third-point loading method is

priate safety and health practices and determine the applica-

illustrated in Fig. 1. The load is applied by means of a loading

bility of regulatory limitations prior to use.

apparatus similar to that described in Test Method C 78.

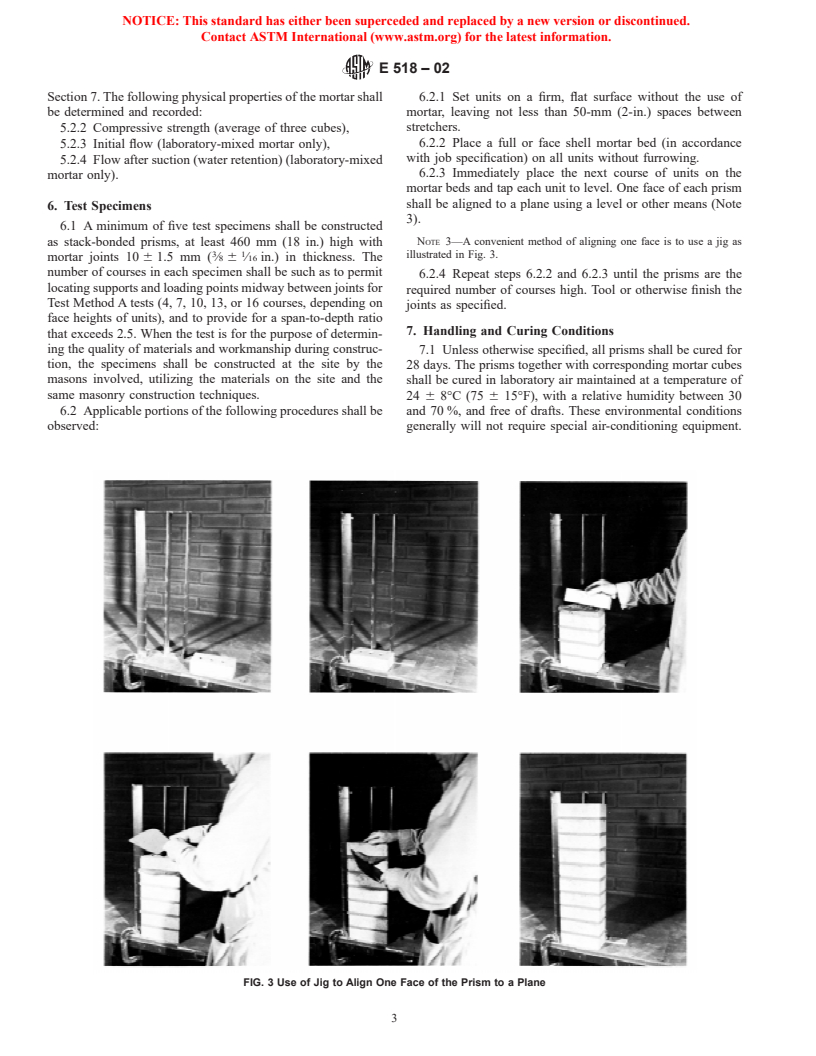

4.3 Test Method B—The uniform loading method is illus-

2. Referenced Documents

trated in Fig. 2. The load is applied by means of an air bag

2.1 ASTM Standards:

typically made of poly(vinyl chloride) 0.5 mm (0.02 in.) thick.

C 67 Test Methods for Sampling and Testing Brick and

The air bag shall be of any convenient thickness and shall have

2

Structural Clay Tile

a contact area equal to that of the specimen. It shall be

C 78 Test Method for Flexural Strength of Concrete (Using

equipped with two valves for inflating and deflating the bag.

3

Simple Beam with Third-Point Loading)

The air bag shall be backed by a steel channel suspended from

C 140 Test Methods for Sampling and Testing Concrete

the cross head of the testing machine with a suitable stud

2

Masonry Units and Related Units

welded to the web of the channel. The channel shall be an

2

C 270 Specification for Mortar for Unit Masonry

American Standard steel channel whose depth is equal to the

4

C 778 Specification for Standard Sand

width of the air bag. It is recommended that the air pressure in

5

E 4 Practices for Force Verification of Testing Machines

the bag be monitored during the test as a check against the test

E 72 Methods of Conducting Strength Tests of Panels for

machine dial indicator.

6

Building Construction

NOTE 2—When testing specimens constructed with a high bond-

E 575 Practice for Reporting Data from Structural Tests of

strength mortar, or whose thickness is greater than a nominal 100 mm (4

Building Constructions, Elements, Connections, and As-

in.), the applied load required to fail the specimen may be such as to

6

semblies

rupture the seams of the air bag. In such cases Test Method A is

recommended.

1

These test methods are under the jurisdiction of ASTM Committee C15 on

5. Sampling and Testing

Manufactured Masonry Units and are the direct responsibility of Subcommittee

C15.04 on Research.

5.1 Masonry Units—Representative masonry units shall be

Current edition approved December 10, 2002. Published April 2003. Originally

sampled and tested in accordance with the following applicable

published as E 518–74. Last previous edition E 518–00a.

2

methods: Test Methods C 67 for brick, or Test Methods C 140

Annual Book of ASTM Standards, Vol 04.05.

3

Annual Book of ASTM Standards, Vol 04.02. for concrete masonry units. Minimum tests required shall be

4

Annual Book of ASTM Standards, Vol 04.01.

compressive strength, and initial rate of absorption for brick or

5

Annual Book of ASTM Standards, Vol 03.01.

absorption for concrete masonry units.

6

Annual Book of ASTM Standards, Vol 04.11.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.or

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.