ASTM F3097-15(2021)

(Practice)Standard Practice for Installation of an Outside Sewer Service Cleanout through a Minimally Invasive Small Bore Vacuum Excavation

Standard Practice for Installation of an Outside Sewer Service Cleanout through a Minimally Invasive Small Bore Vacuum Excavation

SIGNIFICANCE AND USE

5.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the installation of a sewer service cleanout

SCOPE

1.1 This practice covers installation methods, test methods and required materials for the installation of an outside sewer service clean out, by means of a small vacuum excavated borehole. The utilization of this practice greatly reduces disruption to the general public and requires minimal restoration.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F3097 − 15 (Reapproved 2021)

Standard Practice for

Installation of an Outside Sewer Service Cleanout through a

Minimally Invasive Small Bore Vacuum Excavation

This standard is issued under the fixed designation F3097; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope (PVC) Sewer Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

1.1 This practice covers installation methods, test methods

and required materials for the installation of an outside sewer

3. Terminology

service clean out, by means of a small vacuum excavated

3.1 Unless otherwise indicated, definitions are in accor-

borehole. The utilization of this practice greatly reduces

dance with Terminology F412, and abbreviations are in accor-

disruption to the general public and requires minimal restora-

dance with Terminology D1600.

tion.

3.2 Definitions of Terms Specific to This Standard:

1.2 Units—The values stated in inch-pound units are to be

3.2.1 adhesive/sealant—an elastomeric bonding agent de-

regarded as standard. No other units of measurement are

signed to provide a water activated, leak resistant flexible bond

included in this standard.

between a PVC pipe saddle and a lateral sewer service pipe.

1.3 This standard does not purport to address all of the

3.2.2 borehole —a small diameter vacuum excavated hole.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3.2.3 cleanout—a fitting located on a lateral sewer service

priate safety, health, and environmental practices and deter-

pipe having a vertical riser pipe extending therefrom to the

mine the applicability of regulatory limitations prior to use.

surface providing access to the lateral sewer service pipe.

1.4 This international standard was developed in accor-

3.2.4 cleanout riser pipe—a section of pipe that is con-

dance with internationally recognized principles on standard-

nected to the boss of a saddle and extends from the saddle to

ization established in the Decision on Principles for the

the surface.

Development of International Standards, Guides and Recom-

3.2.5 coring—the process of remotely cutting a hole through

mendations issued by the World Trade Organization Technical

the crown of a sewer service pipe such that the coupon is

Barriers to Trade (TBT) Committee.

retrieved to establish communication from a cleanout riser pipe

and a lateral sewer service pipe.

2. Referenced Documents

3.2.6 coupon—a disc shaped piece of the lateral sewer

2.1 ASTM Standards:

service pipe produced by coring.

C920 Specification for Elastomeric Joint Sealants

D1600 Terminology forAbbreviatedTerms Relating to Plas- 3.2.7 lateral sewer service pipe—a sewer pipe that connects

tics

a building to a municipal, main sewer pipe in a lateral direction

D2855 Practice for the Two-Step (Primer and Solvent Ce- and collects sanitary waste or storm water.

ment) Method of Joining Poly (Vinyl Chloride) (PVC) or

3.2.8 saddle—a PVC saddle that encompasses more than

Chlorinated Poly (Vinyl Chloride) (CPVC) Pipe and

50% of a lateral sewer service pipe where the side walls of the

Piping Components with Tapered Sockets

saddle extend beyond the spring line of the host pipe. The

D3034 Specification for Type PSM Poly(Vinyl Chloride)

saddle includes setoff tabs that allow for uniform distribution

of the adhesive/sealant.

1 3.2.9 setoff tabs—Protruding tabs located on the underside

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on of the saddle one located on each side of the saddle boss for the

Trenchless Plastic Pipeline Technology.

purpose of insuring a specific annulus between the host pipe

Current edition approved July 1, 2021. Published August 2021. Originally

and the saddle and a specific layer thickness of adhesive/

approved in 2015. Last previous edition approved in 2015 as F3097–15. DOI:

sealant.

10.1520/F3097–15R21

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3.2.10 sonde—a device outfitted in a closed circuit video

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

inspection camera that emits a signal in subterranean pipelines

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. that is traceable by use of a locating receiver at surface.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3097 − 15 (2021)

4. Summary of Practice a cutting blade suitable for the specific pipe material on which

the cleanout has been installed.

4.1 The process of installing a cleanout through a minimally

invasiveexcavationbegins with locating the 4 in. or 6in. sewer 7.3 Power head—power device that rotates the coring saw.

service lateral. This is accomplished by use of a CCTV

7.4 Extension rods—extension shafts that connect the power

outfitted with a locatable sonde and vacuum excavating a small

head to the coring saw. Available in various lengths according

borehole, providing access to the exterior surface of a lateral

to the depth of the service lateral pipe that the cleanout is being

sewer service pipe. Once the lateral sewer service pipe has

attached to.

been exposed, a self-clamping saddle is prepared by applying

7.5 Video camera—CCTV camera that’s outfitted with a

a specified amount of adhesive/sealant to the underside of the

sonde locating device and a compatible receiver. The camera is

saddle and a riser pipe is attached to the boss of the saddle.The

suitable sewer pipe conditions.

prepared saddle is lowered into the small diameter bore hole

until it contacts the lateral sewer service pipe; a downward 7.6 Water—The amount of water required to perform the

force is applied to the riser pipe causing the side walls of the

exfiltration test is outlined in Table 1.

saddle to spread and encompass more than 50-percent of the

8. Procedure

host pipe. Surface restoration is minimal and in most cases is

accomplished the same day the cleanout is installed.

8.1 The first step in installing a trenchless sewer service

cleanout begins with locating the non-lined lateral sewer

5. Significance and Use

service pipe. A method utilized and associated with this

5.1 This practice is for use by designers and specifiers, installationprocessconsistsofinsertingavideocamerawithan

regulatory agencies, owners, and inspection organizations who

internal sonde into the lateral service line remotely from the

are involved in the installation of a sewer service cleanout ma

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F3097 − 15 F3097 − 15 (Reapproved 2021)

Standard Practice for

Installation of an Outside Sewer Service Cleanout through a

Minimally Invasive Small Bore Vacuum Excavation

This standard is issued under the fixed designation F3097; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers installation methods, test methods and required materials for the installation of an outside sewer service

clean out, by means of a small vacuum excavated borehole. The utilization of this practice greatly reduces disruption to the general

public and requires minimal restoration.

1.2 Units—The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in

this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

C920 Specification for Elastomeric Joint Sealants

D1600 Terminology for Abbreviated Terms Relating to Plastics

D2855 Practice for the Two-Step (Primer and Solvent Cement) Method of Joining Poly (Vinyl Chloride) (PVC) or Chlorinated

Poly (Vinyl Chloride) (CPVC) Pipe and Piping Components with Tapered Sockets

D3034 Specification for Type PSM Poly(Vinyl Chloride) (PVC) Sewer Pipe and Fittings

F412 Terminology Relating to Plastic Piping Systems

3. Terminology

3.1 Unless otherwise indicated, definitions are in accordance with Terminology F412, and abbreviations are in accordance with

Terminology D1600.

This practice is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.67 on Trenchless Plastic

Pipeline Technology.

Current edition approved May 15, 2015July 1, 2021. Published June 2015August 2021. Originally approved in 2015. Last previous edition approved in 2015 as F3097–15.

DOI: 10.1520/F3097–1510.1520/F3097–15R21

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F3097 − 15 (2021)

3.2 Definitions of Terms Specific to This Standard:

3.2.1 adhesive/sealant—an elastomeric bonding agent designed to provide a water activated, leak resistant flexible bond between

a PVC pipe saddle and a lateral sewer service pipe.

3.2.2 borehole —a small diameter vacuum excavated hole.

3.2.3 cleanout—a fitting located on a lateral sewer service pipe having a vertical riser pipe extending therefrom to the surface

providing access to the lateral sewer service pipe.

3.2.4 cleanout riser pipe—a section of pipe that is connected to the boss of a saddle and extends from the saddle to the surface.

3.2.5 coring—the process of remotely cutting a hole through the crown of a sewer service pipe such that the coupon is retrieved

to establish communication from a cleanout riser pipe and a lateral sewer service pipe.

3.2.6 coupon—a disc shaped piece of the lateral sewer service pipe produced by coring.

3.2.7 lateral sewer service pipe—a sewer pipe that connects a building to a municipal, main sewer pipe in a lateral direction and

collects sanitary waste or storm water.

3.2.8 saddle—a PVC saddle that encompasses more than 50% of a lateral sewer service pipe where the side walls of the saddle

extend beyond the spring line of the host pipe. The saddle includes setoff tabs that allow for uniform distribution of the

adhesive/sealant.

3.2.9 setoff tabs—Protruding tabs located on the underside of the saddle one located on each side of the saddle boss for the purpose

of insuring a specific annulus between the host pipe and the saddle and a specific layer thickness of adhesive/sealant.

3.2.10 sonde—a device outfitted in a closed circuit video inspection camera that emits a signal in subterranean pipelines that is

traceable by use of a locating receiver at surface.

4. Summary of Practice

4.1 The process of installing a cleanout through a minimally invasive excavation begins with locating the 4 in. or 6 in. sewer

service lateral. This is accomplished by use of a CCTV outfitted with a locatable sonde and vacuum excavating a small borehole,

providing access to the exterior surface of a lateral sewer service pipe. Once the lateral sewer service pipe has been exposed, a

self-clamping saddle is prepared by applying a specified amount of adhesive/sealant to the underside of the saddle and a riser pipe

is attached to the boss of the saddle. The prepared saddle is lowered into the small diameter bore hole until it contacts the lateral

sewer service pipe; a downward force is applied to the riser pipe causing the side walls of the saddle to spread and encompass more

than 50-percent of the host pipe. Surface restoration is minimal and in most cases is accomplished the same day the cleanout is

installed.

5. Significance and Use

5.1 This practice is for use by designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved

in the installation of a sewer service cleanout

6. Components

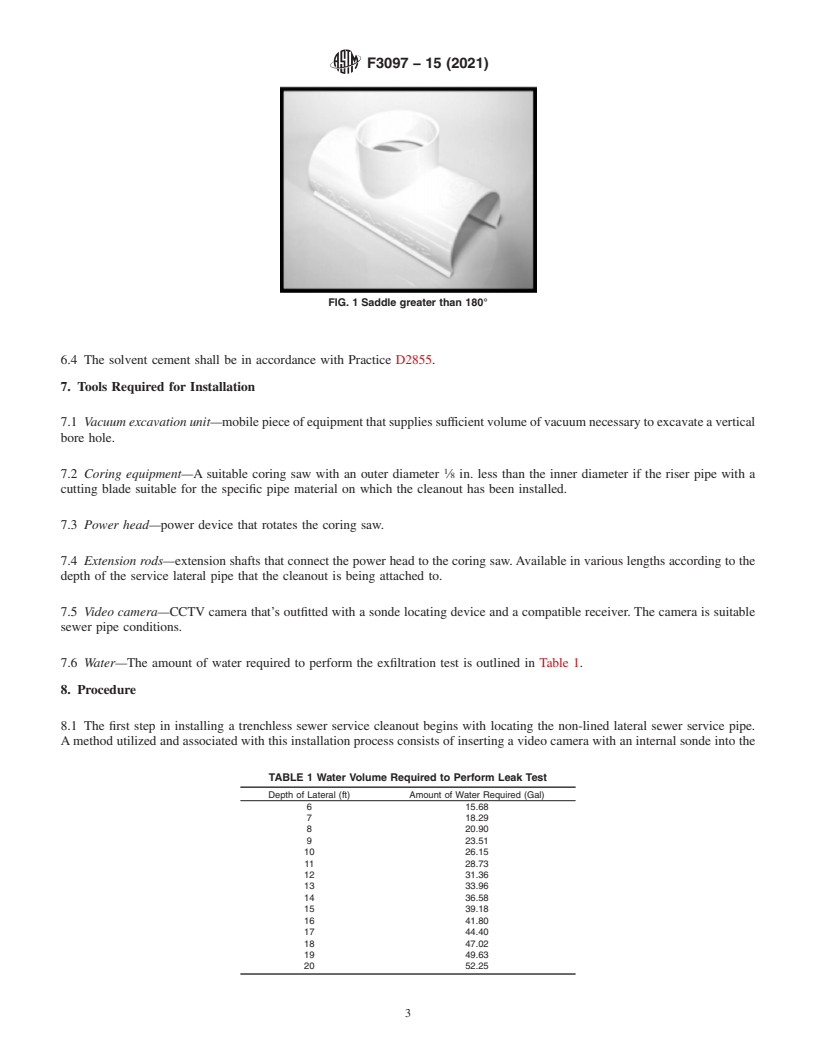

6.1 The saddle shall be formed as a semi-circle and shall encompass more than 180-degrees of the pipe circumference. The saddle

shall have an inner diameter equal to the outer diameter of the host pipe (see Fig. 1).

6.2 The riser pipe shall be PVC pipe in accordance with Specification D3034.

6.3 Adhesive/Sealant shall be in accordance with Specification C920.

F3097 − 15 (2021)

FIG. 1 Saddle greater than 180°

6.4 The solvent cement shall be in accordance with Practice D2855.

7. Tools Required for Installation

7.1 Vacuum excavation unit—mobile piece of equipment that supplies sufficient volume of vacuum necessary to excavate a vertical

bore hole.

7.2 Coring equipment—A suitable coring saw with an outer diameter ⁄8 in. less tha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.