ASTM F2562/F2562M-24

(Specification)Specification for Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for Non-Pressure Drainage and Sewerage

Specification for Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for Non-Pressure Drainage and Sewerage

ABSTRACT

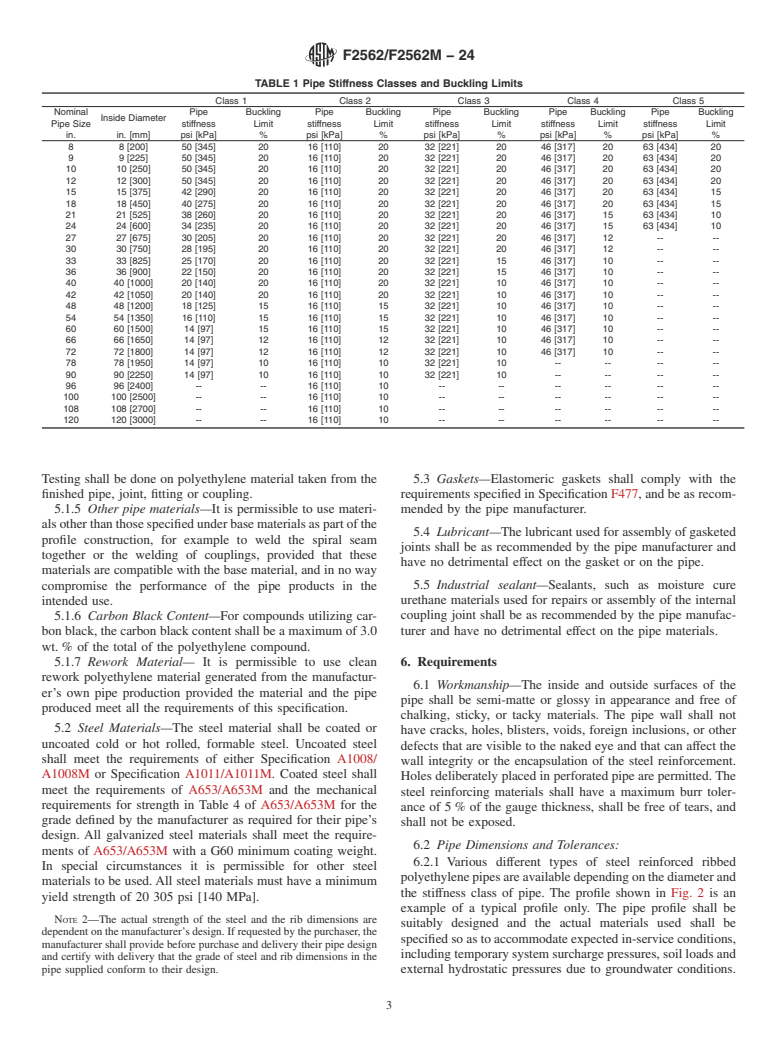

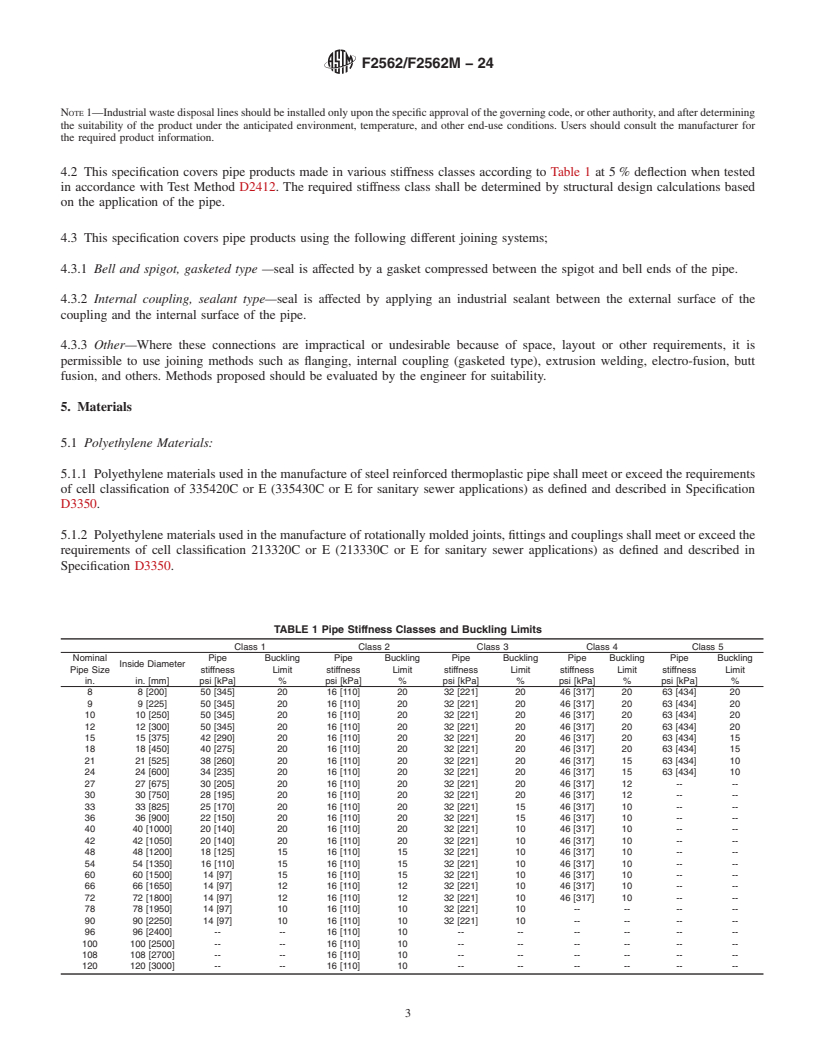

This specification covers requirements and test methods for materials, dimensions, workmanship, impact resistance, pipe stiffness, flattening, buckling, tensile strength of seam, joint systems, perforations, and markings for steel reinforced thermoplastic pipe and fittings. The steel reinforced, spirally formed thermoplastic pipes are intended for use in underground applications where soil provides support for their flexible walls. These pipes will be used for gravity flow and non-pressure applications, such as storm sewers, sanitary sewers, industrial waste applications and drainage pipes. The pipe dimensions, pipe stiffness, flattening, impact resistance, tensile strength of seam, and joint tightness shall be tested to meet the requirements prescribed.

SCOPE

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, impact resistance, pipe stiffness, flattening, buckling, tensile strength of seam, joint systems, perforations, and markings for steel reinforced thermoplastic pipe and fittings of nominal sizes 8 in. [200 mm] through 120 in. [3000 mm]. The steel reinforced, spirally formed thermoplastic pipes governed by this standard are intended for use in underground applications where soil provides support for their flexible walls. These pipes will be used for gravity flow and non-pressure applications, such as storm sewers, sanitary sewers, industrial waste applications and drainage pipes.

1.2 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text the SI units are shown in brackets. The values stated in each system may not be exact equivalents: therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 There is no similar or equivalent ISO standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2562/F2562M − 24

Specification for

Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for

1

Non-Pressure Drainage and Sewerage

This standard is issued under the fixed designation F2562/F2562M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

2

1.1 This specification covers requirements and test methods 2.1 ASTM Standards:

for materials, dimensions, workmanship, impact resistance, A1008/A1008M Specification for Steel, Sheet, Cold-Rolled,

pipe stiffness, flattening, buckling, tensile strength of seam, Carbon, Structural, High-Strength Low-Alloy, High-

joint systems, perforations, and markings for steel reinforced Strength Low-Alloy with Improved Formability, Required

thermoplastic pipe and fittings of nominal sizes 8 in. [200 mm] Hardness, Solution Hardened, and Bake Hardenable

through 120 in. [3000 mm]. The steel reinforced, spirally A1011/A1011M Specification for Steel, Sheet and Strip,

formed thermoplastic pipes governed by this standard are Hot-Rolled, Carbon, Structural, High-Strength Low-

intended for use in underground applications where soil pro- Alloy, High-Strength Low-Alloy with Improved

vides support for their flexible walls. These pipes will be used Formability, and Ultra-High Strength

for gravity flow and non-pressure applications, such as storm D618 Practice for Conditioning Plastics for Testing

sewers, sanitary sewers, industrial waste applications and D638 Test Method for Tensile Properties of Plastics

drainage pipes. A653/A653M Specification for Steel Sheet, Zinc-Coated

(Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed)

1.2 Units—The values stated in either inch-pound units or

by the Hot-Dip Process

SI units are to be regarded separately as standard. Within the

D2122 Test Method for Determining Dimensions of Ther-

text the SI units are shown in brackets. The values stated in

moplastic Pipe and Fittings

each system may not be exact equivalents: therefore, each

D2321 Practice for Underground Installation of Thermoplas-

system shall be used independently of the other. Combining

tic Pipe for Sewers and Other Gravity-Flow Applications

values from the two systems may result in non-conformance

D2412 Test Method for Determination of External Loading

with the standard.

Characteristics of Plastic Pipe by Parallel-Plate Loading

1.3 This standard does not purport to address all of the

D2444 Practice for Determination of the Impact Resistance

safety concerns, if any, associated with its use. It is the

of Thermoplastic Pipe and Fittings by Means of a Tup

responsibility of the user of this standard to establish appro-

(Falling Weight)

priate safety, health, and environmental practices and deter-

D3212 Specification for Joints for Drain and Sewer Plastic

mine the applicability of regulatory limitations prior to use.

Pipes Using Flexible Elastomeric Seals

1.4 There is no similar or equivalent ISO standard.

D3350 Specification for Polyethylene Plastics Pipe and Fit-

1.5 This international standard was developed in accor-

tings Materials

dance with internationally recognized principles on standard-

F412 Terminology Relating to Plastic Piping Systems

ization established in the Decision on Principles for the

F477 Specification for Elastomeric Seals (Gaskets) for Join-

Development of International Standards, Guides and Recom-

ing Plastic Pipe

mendations issued by the World Trade Organization Technical

F2136 Test Method for Notched, Constant Ligament-Stress

Barriers to Trade (TBT) Committee.

(NCLS) Test to Determine Slow-Crack-Growth Resis-

tance of HDPE Resins or HDPE Corrugated Pipe

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

2

Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 15, 2024. Published March 2024. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2007. Last previous edition approved in 2019 as F2562/F2562M- Standards volume information, refer to the standard’s Document Summary page on

15(2019). DOI: 10.1520/F2562_F2562M-24. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2562

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2562/F2562M − 15 (Reapproved 2019) F2562/F2562M − 24

Specification for

Steel Reinforced Thermoplastic Ribbed Pipe and Fittings for

1

Non-Pressure Drainage and Sewerage

This standard is issued under the fixed designation F2562/F2562M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, impact resistance, pipe

stiffness, flattening, buckling, tensile strength of seam, joint systems, perforations, and markings for steel reinforced thermoplastic

pipe and fittings of nominal sizes 8 in. [200 mm] through 120 in. [3000 mm]. The steel reinforced, spirally formed thermoplastic

pipes governed by this standard are intended for use in underground applications where soil provides support for their flexible

walls. These pipes will be used for gravity flow and non-pressure applications, such as storm sewers, sanitary sewers, industrial

waste applications and drainage pipes.

1.2 Units—The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text the

SI units are shown in brackets. The values stated in each system may not be exact equivalents: therefore, each system shall be used

independently of the other. Combining values from the two systems may result in non-conformance with the standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 There is no similar or equivalent ISO standard.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A1008/A1008M Specification for Steel, Sheet, Cold-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-Strength

Low-Alloy with Improved Formability, Required Hardness, Solution Hardened, and Bake Hardenable

A1011/A1011M Specification for Steel, Sheet and Strip, Hot-Rolled, Carbon, Structural, High-Strength Low-Alloy, High-

Strength Low-Alloy with Improved Formability, and Ultra-High Strength

D618 Practice for Conditioning Plastics for Testing

D638 Test Method for Tensile Properties of Plastics

A653/A653M Specification for Steel Sheet, Zinc-Coated (Galvanized) or Zinc-Iron Alloy-Coated (Galvannealed) by the

Hot-Dip Process

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.62 on Sewer.

Current edition approved Nov. 15, 2019Feb. 15, 2024. Published November 2019March 2024. Originally approved in 2007. Last previous edition approved in 20152019

as F2562/F2562MF2562/F2562M-15(2019).-15. DOI: 10.1520/F2562_F2562M-15R19.10.1520/F2562_F2562M-24.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2562/F2562M − 24

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2321 Practice for Underground Installation of Thermoplastic Pipe for Sewers and Other Gravity-Flow Applications

D2412 Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel-Plate Loading

D2444 Practice for Determination of the Impact Resistance of Thermoplastic Pipe and Fittings by Means of a Tup (Falling

Weight)

D3212 Specification for Joints for Drain and Sewer Plastic Pipes Using Flexible Elastomeric Seals

D3350 Specification for Polyethylene Plastics Pipe and Fittings Materials

F412 Terminology Relating to Plastic Piping System

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.